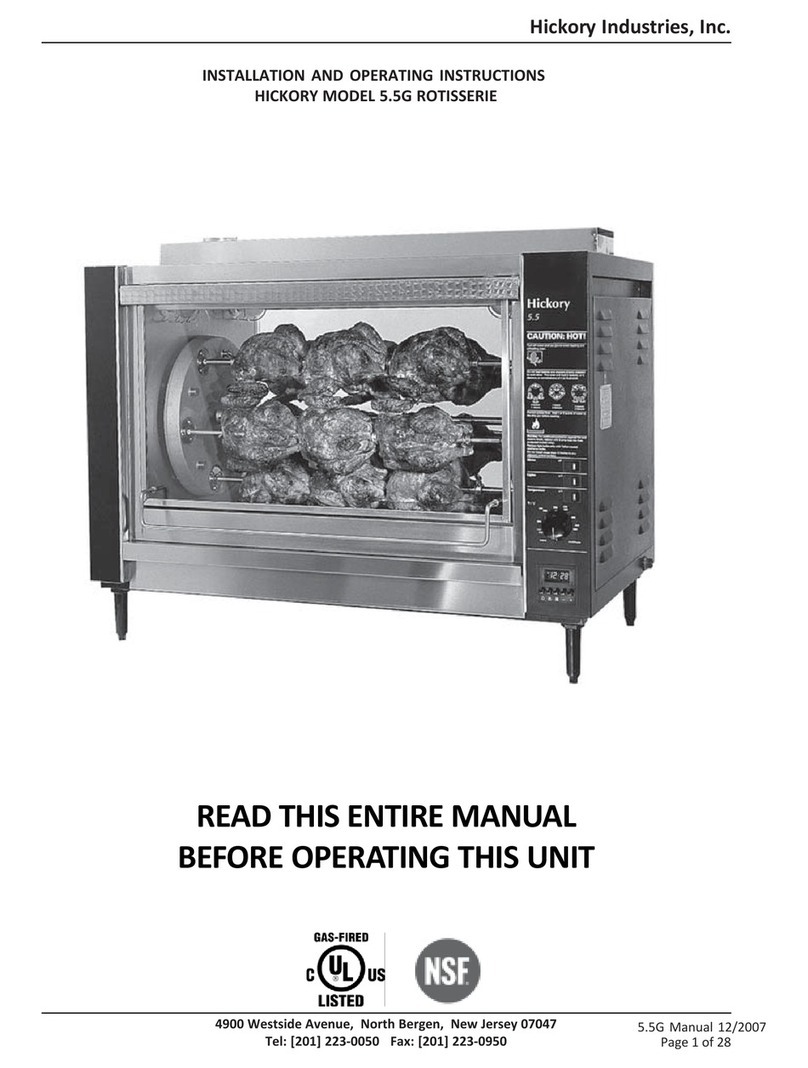

Hickory N/5.5 G User manual

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 1 of 18

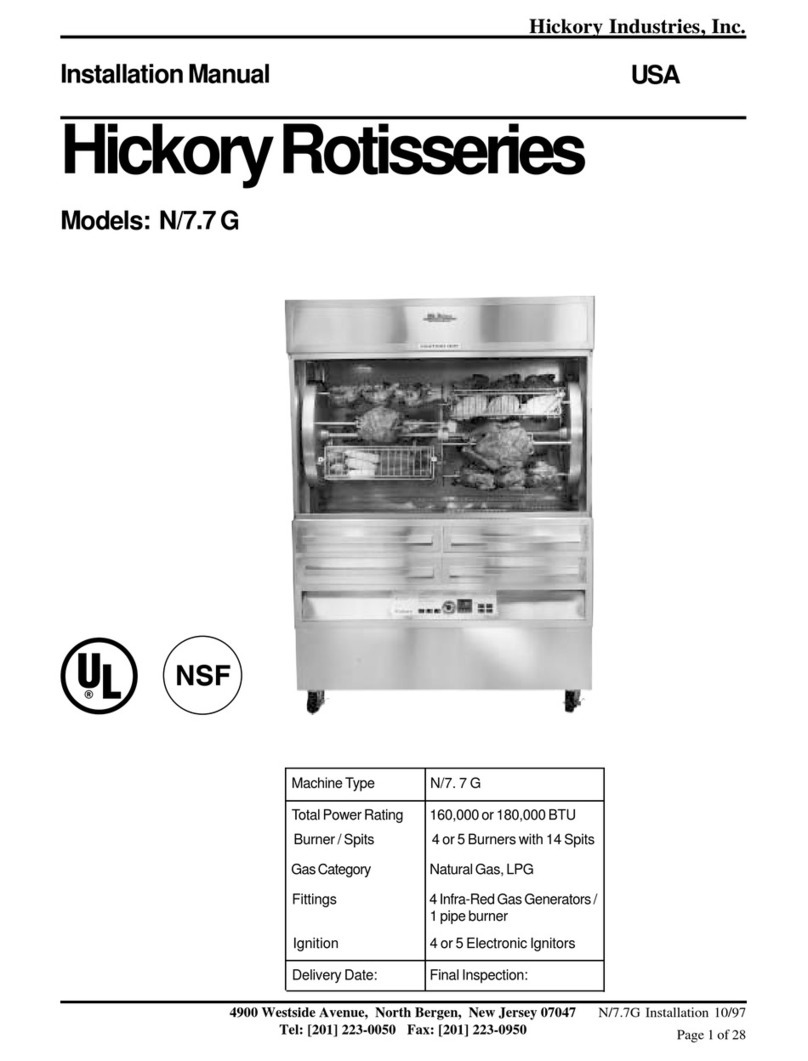

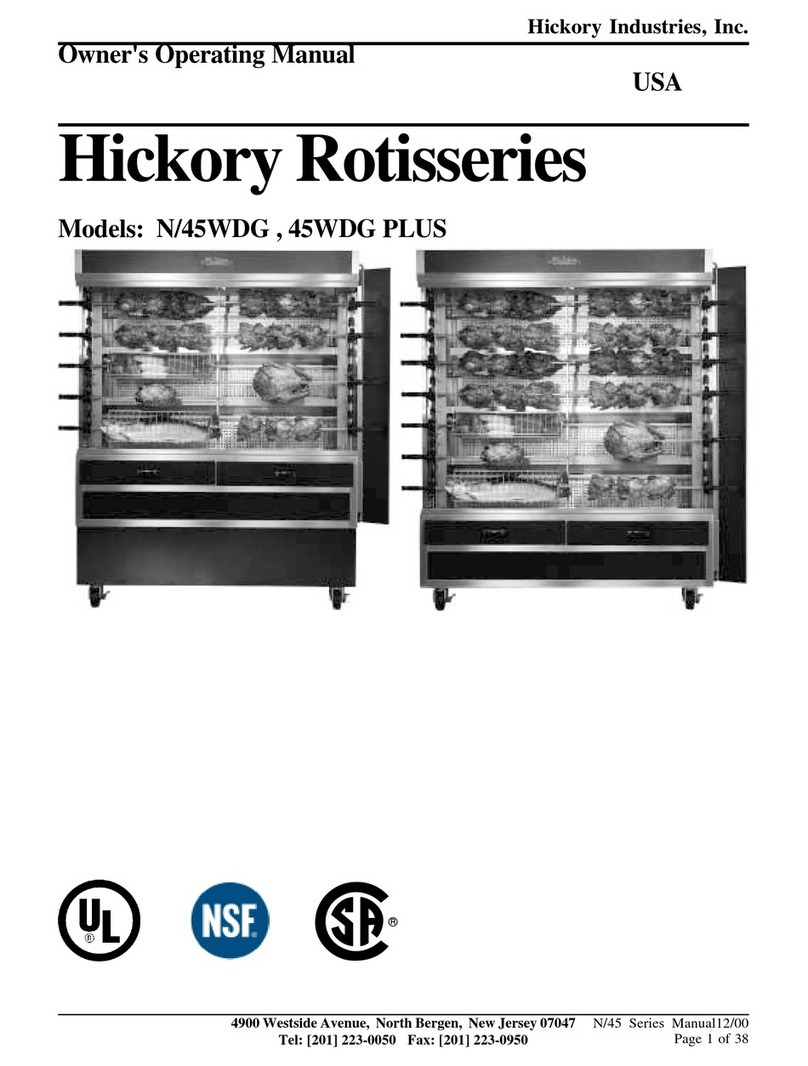

HickoryRotisseries USA

InstallationManual

Models: N/5.5G

TotalPowerRating

Burner / Spits

GasCategory

Fittings

Ignition

DeliveryDate:

MachineType N / 5. 5 G

20,000Btu

1 Burners with 5Spits

NaturalGas,LPG

1Infra-RedGasGenerators

1 Electronic Ignitor

FinalInspection:

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 2 of 18

1.0InstallationInstructions 3

1.1 GeneralInformation 4

1.2 DescriptionoftheDataPlate 4

1.3 MachineDrawingsandDimensions 5

1.4 ConversionandAdjustmentInstructions 6

1.5 AdjustmentsandVerificationforusewithNaturalGas 6

1.6 NaturalGasFlowTable(Consumption) 7

1.6.1 VolumetricMethodtoVerifytheFlameSetting,Mathematical 7

1.7 OrificeDiameters,ElectronicIgnitionSettings 8

1.8 ChangingGasOrifices 8

1.8.1 ChangingtheGasOrifice-GasGenerators 8

1.8.2 ChangingtheGasOrifice-PipeBurner 8

1.9 IgnitionCycle 8

1.10.1 AdjustingtheIgnitionElectrode 8

1.10 CheckingtheConnectedGasPressure(NominalPressure) 9

1.10.1 AdjustingtheIgnitionElectrode 9

1.11 Maintenance,ResponsetoTechnicalProblems 10

1.12 SpitDriveMechanism 11

1.12.1 Reasonsforproblemsandsolutions 12

1.13 SpitDriveMechanism 13

1.14 TestingandCheckingforSafety 14

1.15 DescriptionoftheElectricalConnection 14

1.16 ElectricalDiagram 15

1.17 5.5GPartsList 16

1.18 ExplodedViewDiagrams 18

TableofContents

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 3 of 18

a. Wheninstallingtheseunits,itisimportanttocomplywiththemostrecently

establishedrulesandregulationsasdeemedpertinentbythelocalandnational

electrical,gas,ventilation,sanitation,andfirecodes. Theseunitsareclassified

byUnderwritersLaboratories,Inc.asGas-FiredFoodServiceEquipmentin

accordancewithAmericanNationalStandardsInstituteANSIZ83.11b-1991,Gas

FoodServiceEquipment-RangesandUnitBoilers.

b. Gasunitsmustnotbedirectlyconnectedtoagasflueorexhaust. However,both

electricandgasunitsmayrequireoperationinconjuctionwithacanopytypeexhaust

hoodifdeemednecessarybylocalauthorities.

c. Theunitsmustbeinstalledinsuchawaythatproperventilationandheatexchangeis

assured. Theroommustbeventilatedinaccordancetothevalidcodesand

regulations.

d. Theunitsaretobeinstalledsecurelyandhorizontally. Theunitsmaybeinstalledon

combustiblefloors. Theunitsmustbeinstalledwithadjustablelegsifplacedona

combustiblesurface.

e. Theminimumclearancetotherearorsidewallsmustbe13inches. Itisalso

importanttoinsurethatthebottomoftheunitsiskeptclearsothat properventilation

orairexchangecanoccur.

f. Normally,theunitswillbesenttotheoperatoralreadysetupfortheparticular

typeofgasorelectricalserviceavailableattheirlocation. However,unlessotherwise

specified,thegasunitswillbesetupfornaturalgasuse(includinganelectricalcord

for120V,1Phase,60Hzoperation)andtheelectricunitsfor208V,3Phase,60Hz

electricaluse. Beforeinstallingandusingtheunitsforthefirsttime,itisimportantto

makesurethatthegastypeand/orelectricalpowerindicatedonthedataplate

matchesthetypeofgasandelectricalpoweravailableinthelocation. Shouldthisnot

bethecase,itisimperativetochangeorconverttheunitstotheneededtypes.

g. Thegasunitsmustbefittedwiththemanualshut-offgascock(valve)andpressure

regulatorsuppliedwiththemachine. Thismanualvalveisneededtoshutoffthegas

tothemachineduringmaintenancework,repairs,andiftheunitneedstobe

disconnectedforanyreason. Thepressureregulatorisneededtoadjustthegas

pressureenteringtheunittoensuretheproperoperationoftheunit.

Electricunitsmustbehard-wiredorfittedwithapowercordbyalicensedelectrician.

i. Dependingonlocalcodesorifdeemednecessary,agasfiltermayalsoberequired

forgasunits.

1.0 InstallationInstructions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 4 of 18

1.1 GeneralInformation

TheOperatingInstructionsaretobegiventotheoperatoroftherotisserie. Allunit

operatorsaretobefamiliarwiththefunctionsoftherotisserie.

TheOperatingInstructionsshouldbekeptinalocationclosetotherotisserie. Itshouldbe

easilyrecognizeableandeasilyaccessible.

ThegasrotisseriescanbeusedwithbothnaturalandLPGgases. Therotisseriescanbe

convertedoradjustedtoanytypeofthelocallydistributednaturalandLPGgases.

Electricunitscanbeorderedtomeetmostelectricalspecifications.

Itisrecommendedthatarepairandmaintenancecontractbesignedwiththe

manufacturer'sagent,distributor,orserviceagency.

1.2 DescriptionoftheDataPlate

WARNING!

Thisunitmustbeinstalledandconnectedinaccordancetothelatestregulations

andcanonlybeoperatedinconjunctionwithforcedventilationorexhausthood.

Thisunithasbeendesignedforprofessionaluseonly

andmayonlybeinstalledorrepairedbylicensedserviceagencies!

Beforeinstallingorusingthisequipment,readtheseinstructions!

Model: 5.5 G Serial No.

HickoryIndustries,Inc.

CommercialCookingAppliances

NorthBergen,NJ 07047

Motor: 110 - 115 VAC, 50/60 HZ, 3 RPM

Gas: NAT

Burners: 1

BTU/H

ManifoldPressure: 5"Naturalor10-11"Propane

20,000

Phase: 1

LISTED

69D6

MinimumInstallation Clearance

Sides: 13" Back: 13"

Maximum Lamp Wattage: 40 Watts

HickoryIndustries,Inc.

CommercialCookingAppliances

NorthBergen,NJ 07047

Model: 5.5 G Serial No.

Motor: 110 - 115 VAC, 50/60 HZ, 3 RPM

Gas: LPG

Burners: 1

BTU/H

ManifoldPressure: 5"Naturalor10-11"Propane

17,000

Phase: 1

LISTED

69D6

MinimumInstallation Clearance

Sides: 13" Back: 13"

Maximum Lamp Wattage: 40 Watts

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 5 of 18

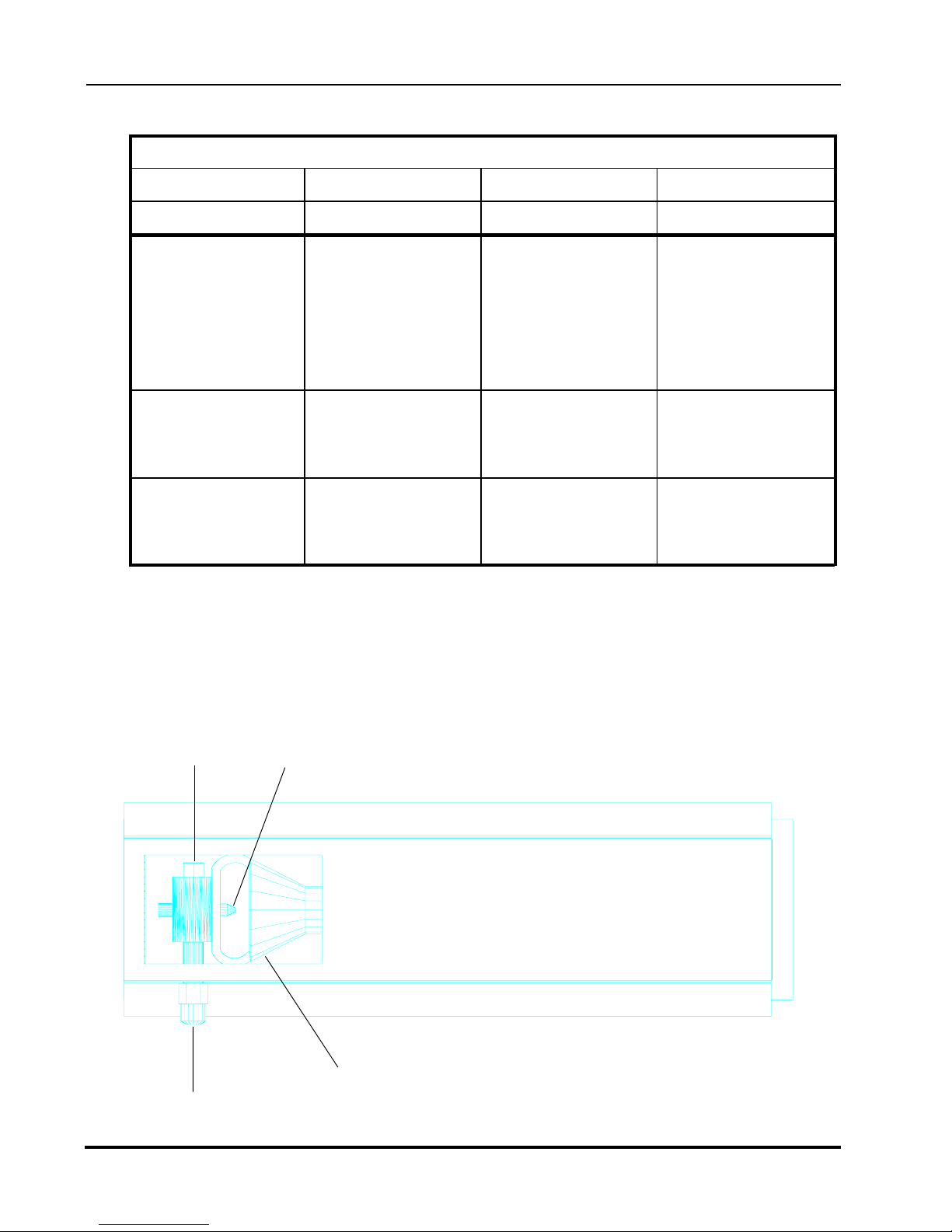

Front View Right Side View

1.3 MachineDrawingsandDimensions

ThefollowingdrawingoftheFrontView,SideView,andTopViewindicatewherethe

dimensionsaretakenandshouldbeusedtoplantheinstallationoftheunits.

N/ 5.5 G

Top View

Height 31.5" 800

Width 39.25" 997

Depth 22" 560

N/5.5 G inches mm

* Includes Gas Connection Attachments

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 6 of 18

1.4 GasConversionandAdjustmentInstructions

Beforeconvertingoradjustingthemachinetoanothertypeofgas,itisimperativethatthe

manualgascockbeturnedtothe"off"position. Theelectricalpowertothemachinesshould

alsobeturnedoff. Whenconvertingthegasgeneratorsforusefromonetypeofgasuseto

another,thegasorifice(orinjector)mustbechangedaccordingtothetableonpage8. In

addition,thespringinthepressureregulatorsuppliedwiththeunitmustbechangedsothatit

canoperateatothergaspressures. SpringsfortheregulatorcanbeorderedfromHickory

Industries.

1.5 VerificationforusewithNaturalGas

Theflamesettingforthegasgeneratorcanbeconfirmedbyusing

thevolumetricmethodinconjunctionwiththemaingasmeter. Theburnerhasan

independentsolenoidgasvalve. ThevalveiscontrolledbyanindependentGaslite

sparkignitionmodule. Theamountofgasflowingthroughthevalvecannotbeadjusted

manually;thereisonlyan"on"or"off"position.

Tocarryoutthisverificationprocedure,itisnecessarytoobtaintheheatingvalue(BTU/ft3)

ofthelocalgasfromthelocalgascompany.

Avariationintheheatingvalueof thelocalgasfromthatonthetable(1.6)willresultin

avariationofthepoweroutputof theunit!

Ifthemeasuredgasvolumedoesnotcorrespondtothevaluesinthefollowingtable(1.6),the

itemswhichshouldbecheckedare:

A. Theincoming(connected)gaspressurewhiletheburnersandallotherappliances

inthelocationareoperational.

B. Ifthegaspressureiscorrect,itmustbeverifiedthatthepropersizegasorificesarein

place(seepage8).

Solenoid Valve

ConnectiontoIgnition

Module(Electrical)

GasInput

GasOutput

(connectiontoburner)

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 7 of 18

1.7.1 VolumetricMethodtoVerify theFlameSetting,Mathematical

WARNING! Noothergasequipmentcanbeinoperationduringthisprocedure.

Calculationofflow rateV inft3/hour

V = FP

Hi

V= Flow ratein ft3/minute

FP= HighFlamePowersettinginBTU/hr

Hi= HeatingvalueinBTU/ft3

Thus,fornaturalgas:

V=20,000 BTU/hr = 19.23ft3/hr = 0.32ft3/min.

1040 BTU/ft3

V= 0.32 ft3/min.

Thisisthenaturalgasneededin1hourbyaN/5.5G(1burner)atfullpower.

Thetimeandtheflowmeasurementsshouldbetakenatthegas(flow)meterwitha

chronometer(stopwatch).

Torunthetest,openthemanualgascockvalve,startuptheunitaccordingtothestart-up

instructions.

Allowtheunittopre-heat(burn)for10to15minutes. Verifythattheflowrateiscalibrated

totheappropriateflowrateindicatedinthetable.

Gas Flow - in ft3/hr

20,000 BTU - Natural

BTU/ft³

Heating Value in

Gas

HighFlameSetting

Natural

Propane

Butane 2480 6.85

1040 19.23

1.7 NaturalGasFlowTable

3215

17,000 BTU - LPG

5.28

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 8 of 18

TypeN/5.5 G

1.8 OrificeDiameters,ElectrodeGapSettings,andAirIntakeSettings

Gas/Pressure OrificeSize

Øindrill size

Natural/5.5"

inchesW.C.

Butane/11"

#46

#55

ElectronicIgnition

ElectrodeGap

1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

Propane/11" #55 1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

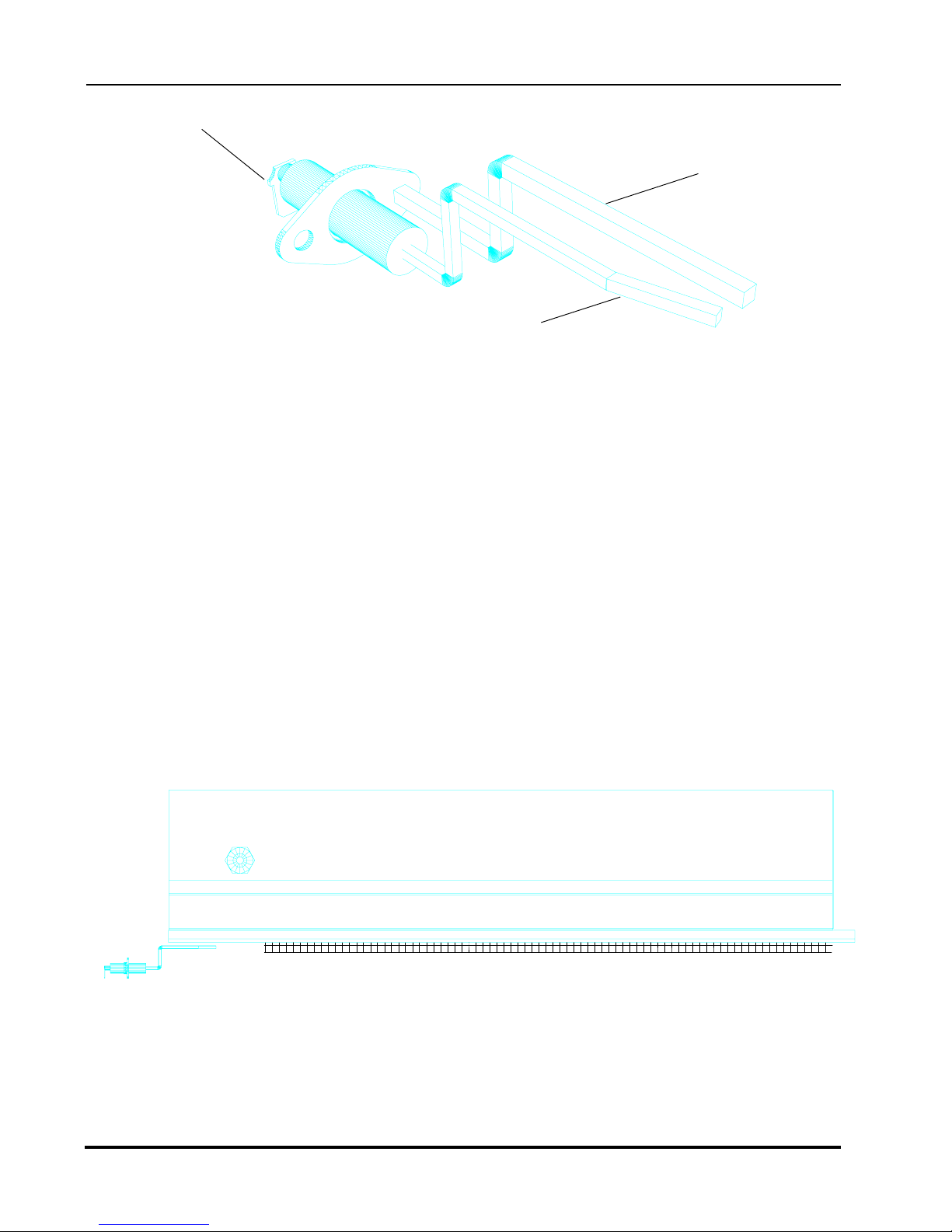

1.9 ChangingGasOrificesontheGasGenerators

TheN/5.5Gasunithasoneinfra-redgasgenerators. Thesegeneratorsuse ceramicradiating

plates.

The burner orifice can be removed and replaced using a 7/16" wrench. The orifice must be

sealed and tightly in place.

Gas Inlet Pipe

Alternate Opening for

Inlet Pipe Burner

Orifice

Venturi

Top View Gas Generator

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 9 of 18

1.10 IgnitionCycle

Inordertostartthecookingcycle,theburnersmustbeignited. Theignitioncyclewillstart

onlywhenthefollowingprocedureisfollowed:

a. The"HEAT"switchisturned to"on".

b. Acookingtemperaturemustbesetonthethermostat(i.e.450°F).

c. Thecookingtimermustbeactivated(seeOperatingInstructions).

Oncethesestepsarecompleted,theunitwillcallforheatandtheignitioncyclewillbe

activated. Theignitionsystemwillcausesparkingontheignitionelectrode. Oncethe

burnerislitbythespark,theflameoftheburnerwillheatthesensingprongontheignition

electrodesendingasignalbacktotheignitionmodule. Thissignalindicatesthatasparkis

nolongerneededandthatthesolenoidgasvalvemuststayopen. Whenthecooking

temperatureisreached,assensedbythethermocoupleattachedtothethermostat,the

electricalpowertotheignitionmoduleswillbecutoff,shuttingdowntheignitionmodule

andtheburners. Whenthetemperaturedropsbelowthesetpoint,electricalpowerissentto

theignitionsystemonceagain,thusstartingtheignitioncycleallover. Thesystemwill

cycleonandoffasneededtomaintainthesetcookingpoint.

Theignitionmoduleswillattempttoignitetheburnerthreetimes. Iftheburnersfailtolight

afterthreetries,themodulewilllock-out,shuttingdownallgasflowandfurthersparking.

Inordertostarttheignitioncycleafteralock-out,theheatswitchesandindividualburner

switchesmustbeturned"off"and"on"again. Thismayhavetobedoneseveraltimeswhen

startinguptheunitforthefirsttimeduetoairinthegaslines.

1.10.1 AdjustingtheIgnitionElectrode

Theignitionelectrodesareadjustedforanoptimumignitioncyclebeforetheunitleavesthe

factory. Ifforsomereasontheelectrodesneedadjusting(i.e.ifonetakesahitwithaspit),it

canbedoneasfollows.

1. Toreachtheignitionelectrode,openthefrontglassdoorsandremoveallspits.

2. Theelectrodeisattachedtothemainbodyofthemachinewithan8/32"screwand

nut. Itisimportantthatthisscrewmakesolidmetaltometalcontactbetweenthe

electrodecasingandthebodyoftherotisserie. Thismetaltometalcontactiswhat

actsasagroundingconductorforthegroundingprongontheignitionelectrode.

3. Duringtheignitionprocess,asolidbluesparkshouldtravelbetweenthetipofthetwo

electrodeprongs.

4. Makesurethatthedistancesbetweentheprongsandthesurfaceoftheburnerare

about1/8".

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 10 of 18

IgnitionElectrode

Grounding Prong

Ignition / Sensing Prong

Ignition Wire Connection

5. Ifthedistancesbetweentheprongsand/ortheburnersurfacearetoogreat,theunit

maysparkbutnotignitetheburner.

6. Whenadjustingtheprongs,makesuretosupportthebaseoftheprongwithonepair

ofpliersandadjustthetipoftheprongwithanotherpair. Thiswillpreventbreakage

oftheceramic casingoftheignition/sensingprong. Iftheceramiccasingdoesbreak,

theelectrodewillhavetobereplaced.

IgnitionElectrodePosition

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 11 of 18

1.11 CheckingtheConnectedGasPressure(NominalPressure)

Closethegascockwherethegaslineisconnectedtothemachineandattachamanometer

tothetap(allenscrew)onthegascock. Withthemanometerconnected,openthegas

cockandignitetheburner. Alongwithallothergasappliancesatthelocationin

operation,measurethegaspressure.

Thisidealoperatingpressureshouldbe5.5"W.C.fornaturalgasand11"W.C.forLPG.

Ifthepressureistoohighandcannotbeadjusteddownward,checktoseeiftheproper

adjustingspringisintheregulator. Ifthisiscorrect,theregulatormembranemayhavebeen

rupturedbyexcessivegaspressureandmayhavetobereplaced. Donotoperatetherotisserie

ifthegaspressureexceedstheidealvalues.

Iftheoperatingpressureisbelow5.5"W.C.fornaturalgasorbelow11"W.C.forLPG,the

unitshouldnotbeoperated. Thepressureshouldbeadjustedtotheidealsettingusingthe

pressureregulatingscrewonthepressureregulator.

Ifthepressureistoolowandcannotbeadjustedupward,alsochecktheregulator. Ifthisis

operatingproperly,verifythepressurecomingoutofthemaingasmeter. Anothertypical

sourceofthispressureproblemisthatthegasline(pipe)diameterleadinguptotheunitis

toosmall. Ifthegaslineisunder-sized,theappropriatepressuremaynotbereached. Donot

operatetheunitifthepressurefallsbelowtheidealvalues.

Ifthemeasuredpressureisstillbelowtheidealrangeanditisnotpossibletoresolvethe

problem,thelocalgascompanyorgassuppliershouldbecontactedsothattheycanresolve

theproblem.

Afterthepressurehasbeenset,closethegascockonceagain,removethemanometer,seal

thegastap,andthenre-openthegascock.

WARNING: Afteraninstallation,repairs,ormaintenance,makesurethatthereare

nogasleaksanywhereinthegaslinesorsystem.

1.12 Maintenance,responsetotechnicalproblems.

Shouldatechnicalproblemariseforanyreason,shutoffthemachineandcallfortechnical

service.

Aroutinemaintenanceshouldbecarriedoutatleastonceayear. Contactyourlocal,

certifiedservicecompanyformaintenance.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 12 of 18

Solution

a. MakesurethattheHEATswitchison.

Thermostatmustbeset(i.e.550°F)and

thecookingtimermustbeoperational

(cookcycle).

b. Makesurethatthethreepronged

plugsuppliedwiththeunitisbeing

used. Makesurethattherotisserieis

properlygrounded.

c. Adjustelectrodetipsto1/8"apart.

d. Ifthemachineisused,fatmayhave

carbonizedontheelectrodetipsorrust

mayhaveappeared. Thisprevents

propersparking. Sandandclean

metalrods.

e. Makesurethatelectrodeisproperly

fastenedandmakessolidcontactwith

therotisseriebody.

f. Makesurethattheignitionwireis

properlyfastenedtotheignition

moduleandtotheelectrode.

g. Checktheignitionwireforbreaches

whichmaycausesparkingtooccur

betweenthecableandthebodyof

rotisserie. Insulatecableatbreach.

h. Checkelectricalinputtomodule.

Modulemayneedtobereplaced.

a. Turnallmanualgasvalvesto"on".

Makesurethesolenoidvalveopens.

b. Makesurethatthehot,neutral,and

groundleadsareproperlymatchedup.

Ifneutralandhotareswitched,the

"flameon"signalwillnotreach

ignitionmodule,lockingoutgas.

c. Checktheoperatinggaspressure. If

thisiscorrect,checkgaslineand

orificefordirtorobstructions.

a. Adjustthetipsoftheelectroderods

sothattheyareabout1/8"fromthe

burnersurface.

b. Switchexhausthoodtoonbefore

ignitingtheunit. Openfrontdoor

oftheunittoallowairflow.

b. Re-adjustignitionprongs.

Problem

Electrode

doesnotspark.

Electrodesparks,

flamedoesnotlight.

Burnerignitesfor5

to10secondand

thengoesoff,espe-

ciallyinthemorning

whencold.

Cause

a. Rotisserienot"on".

b. Electricalsystemnot

groundedproperly.

c. Electrodetipstoofarapart.

d. Electrodetipsaredirty.

e. Electrodenotgrounded.

f. Ingnitionwireloose.

g. Ignitionwirenotproperly

insulated.

h. Ignitionmodulefaulty.

a. Checkallgasflow.

b. Checkpolarityonthe

electricalconnections.

c. Flameistooweak.Not

enoughgasflow.

a. Electrodetipsaretoofar

fromburner.

b. Highhumidityevironment,

suchascausedbyleaving

waterindrippan

overnight.

c. Unitnotproperlyadjusted

tonewconditions.

1.12.1 Reasonsforproblemsandsolutions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 13 of 18

1.13 Spit Drive Mechanism

This unit is equipped with a planetary motion spit drive system. This means that each spit is

turning upon its axis at the same time that they turn about the center shaft. When the motor

switch is turned to on, the disks and the spits will begin to turn. Insure that the mechanism

turns smoothly when testing the unit.

Center Shaft

Spit

Before cooking, it is imperative that the center shaft be covered and protected with aluminum foil.

This will prevent fats from carbonizing on the shaft, making the removal of the aluminum disks

much easier in the future. If the shaft is not protected, it may eventually be impossible to remove the

disks should there be a problem in the spit drive mechanism.

The driven and the stationary drive gears are located behind the aluminum drive disk. These can be

viewed by taking out the removable aluminum disks (there are two removable panels). The driven

gears and the stationary gear should be viewed once a week to check for fat or carbonization build-

up. Any fat or dirt should be cleaned off since a build-up will eventually damage the drive system.

AluminumDrive

Disk

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 14 of 18

NOTE: If fat or carbon have built up on the center shaft, it may not be possible to move

the alumium disks!

With the disks away from the sides, all components of the drive mechanism should be

thoroughly cleaned. This will guarantee that the drive mechanism works smoothly.

Even though the aluminum disks protect the gears, fat will eventually manage to

build up on the gears. If this fat is not cleaned, it will eventually carbonize. When the

carbon build-up is serious enough, the drive mechanism will jam and it will need

to be replaced.

When replacing the disks, a slight dab of FDA (food safe) approved gease should be added

to all gears.

Finally, when inserting spits, make sure to stop the motor! This unit is supplied with a motor

switch which will stop the drive mechanism, allowing the operator to insert the spits easily.

If spits are inserted without stopping the motor, there is a chance that the drive system will be

jammed and cause severe damage.

1.14 Testingorcheckingforsafety

Afteraconversion,anewinstallation,orafterarepair,itisimportantthattheunitbe

testedtoinsurethatitoperatesproperly. Thisshouldincludethefollowing:

Testthegassystemforgasleaks.

Checkthattheunithasenoughclearancebehindandtothesides.

Checkthatenoughprimaryandsecondaryairisavailable(brightorangegasgenerator).

Checkforpotentiallyflammableobjectsorpotentialflammabilityproblems.

Checkforproperventilationandexhaust.

Checkforproperroomventilation.

1.15 DescriptionoftheElectricalConnection

Theelectricalconnectionsaretobemadeinaccordancetolocalandnationalcodes.

Allgasmachinesoperatewith120Volt,singlephase,60Hz. ANEMA5-15Pplug

issuppliedwiththeunits.

Allpertinentelectricalinformationcanbetakenfromtheelectricaldiagram.

NOTE: Properpolarityintheelectricalsystemisneededforproper

operationofthegassystem!

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 15 of 18

1.16 ElectricalDiagram

Rev:Jan/97

120V40Watt

Timer

LampSwitch

Ground

Gear

Motor

Motor Switch

GasliteIgnitionModule

Infra-redGasBurner

SparkIgnitor/Sensor

SolenoidGasValve

Thermostat

1

Temperature

N

HickoryIndustries,Inc.

4900WestsideAvenue

NorthBergen,NJ07047

ElectricalDiagram

ModelN/5.5G (WithTimer Adapter)

Input:120Volt

LocatedonTheLeftControlPanel

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 16 of 18

1.17 Parts List for 5.5 G

Item Qty. Description Material Length Size Manufacturer

553 1 Shaft5/8(RemovableDrums-Center) SS 5/8" Hickory

554 1 ShaftLockingSlide SS Hickory

519 1 DriveBearingHolder(Left- withbrassbearing) Steel(Chromed) Hickory

520 1 DriveBearingHolder(Right- withteflonbearing) Steel(Chromed) Hickory

1 BrassShaftBearing Brass Hickory

566 1 TeflonShaftBearing Teflon Hickory

501 1 AluminumDiskDrive(Bare) CastAluminum Hickory

502 1 AluminumDiskSlave(Bare) CastAluminum Hickory

503 1 Alum.DiskDrv.(Completew/SpitDrivenGears) Hickory

504 1 Alum.DiskSlave(Completew/SpitSupports) Hickory

514 1 DiskRetaining Pin Steel 1-1/2" 5/32" Hickory

564 5 TeflonSpacers-1/4"round Hickory

505 Aluminum Disk TeflonCoating Hickory

561 5 SpitDrivenGearAssembly Steel(Chromed) Hickory

555 5 SnapRing(Gears) Steel Hickory

559 5 SpitDrivenGearBearingHolder Steel(Chromed) Hickory

560 5 SpitDrivenGear Steel(Chromed) Hickory

565 5 TeflonSpitDrivenGearBearing 1/4" Hickory

563 1 StationaryGear Steel Hickory

562 5 SpitSupport Steel(Chromed) Hickory

510 1 Chain(Roller-5.5) Steel Hickory

511 1 ChainLink (Roller-5.5) Steel Hickory

521 1 DriveSprocket-RollerChain Steel Hickory

522 1 DrivenSprocket -RollerChain Steel Hickory

512 1 ChainTensioner Steel Hickory

509 1 BussFuse0.5Amp Buss

527 1 FuseHolder0.5Amp

536 1 IgnitorElectronicIgnition Channel

1 IgnitionWire

537 1 IgnitorModule(Gaslite) Channel

538 4 LampCover Steel(Chromed) Hickory

541 3 MicroSwitch & Toggle Marquardt

567 1 Thermostat200-550

568 1 ThermostatKnob

569 1 Timer(withoutAdapter) Eaton

569 1 Adapter(forTimer) Eaton

542 1 MotorGear-120V Bodine

539 1 Lamp,120V Hickory

540 4 LampSocket Ceramic Leviton

120 1 DripPan(5.5) SS Hickory

121 1 DripPanPlug Brass Hickory

122 1 DripPanReceptacle Brass Hickory

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 17 of 18

1.17 Parts List for 5.5 G (Contd.)

Item Qty. Description Material Length Size Manufacturer

546 1 PressureRegulator(Connection)RV53 Alum. 1/2" Maxitrol

1 SpringforPressureRegulator Maxitrol

528 1 GasCock Steel 1/2" Jomar

1 Nipple Steel 1/2" Hickory

1 Elbow(90°) Steel 1/2" Hickory

1 Pipe Steel 6" 1/2" Hickory

529 1 Basotrol SolenoidGasValve 1/2" Basotrol

1 Pipe Steel 13.5" 1/2" Hickory

1 Elbow(90°)St. Steel 1/2" Hickory

530a 1 GasBurnerwithCeramics Ceramic Hickory

543 1 Orifice (Blank) Brass Hickory

513 2 GlassHinge SS Hickory

515 2 DoorBearingBrass Brass Hickory

516 1 DoorHandle(Metal) Steel Hickory

518 1 DoorSpring(Mechanical) Steel Hickory

545 1 PneumaticSpring

532 1 GlassTemperedLarge(Door) Glass 28.94"x16.5" Hickory

533 1 GlassTempered(Rear) Glass 28.94"x12" Hickory

534 1 GlassTempered(Rear-Small) Glass 28.94"x4.5" Hickory

526 4 FeetAdjustablePlastic Plastic Hickory

556 5 SpitComplete SS Hickory

185 5/Spit SkewerDouble SS Hickory

186 5/Spit SkewerSingle SS Hickory

219 1/Skw.ThumbScrew Steel Hickory

439a Angle(V)Spits Steel(Chromed) Hickory

508 BasketSpits Steel(Chromed) Hickory

557 1 SpitTurkeyCenteronly SS Hickory

225 2 TurkeySkewersSingle SS Hickory

506 5 BasketHanging Steel(Chromed) Hickory

507 5 BasketBearingBrass Brass Hickory

123 1 ElectricalGroundingCap Hickory

ElectricalWire JanorWire

1 ConnectionCable TIPProducts

104 1 ContactSection 242(terminal) Buchanan

105 1 ContactSection 250(end-piece) Buchanan

*All components are inventories and sold through Hickory Industries and their distributors and

dealers.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5 Installation 8/5/97

Page 18 of 18

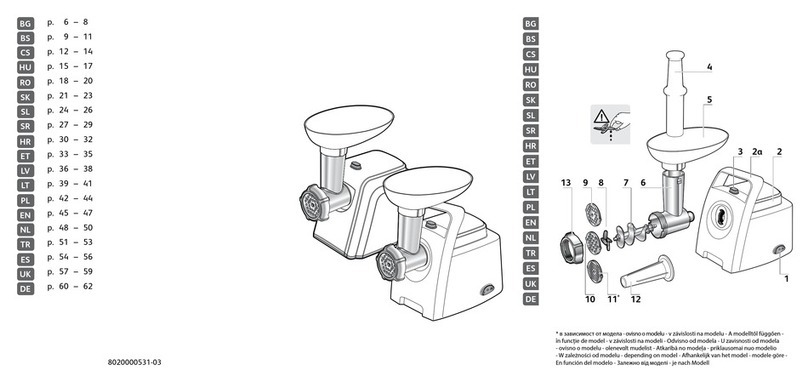

1.18 Exploded View Diagrams

Table of contents

Other Hickory Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Henny Penny

Henny Penny HHC-902 Technical manual

Bravetti

Bravetti EP493 Use and care instructions

Aroma

Aroma ABT-3276 instruction manual

Scarlett

Scarlett SC-JE50S09 instruction manual

Trisa electronics

Trisa electronics 7738.7010 Instructions for use

Cuisinart

Cuisinart Griddler GR-6S INSTRUCTION AND RECIPE BOOKLET