Hickory N/7.7 G User manual

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 1 of 28

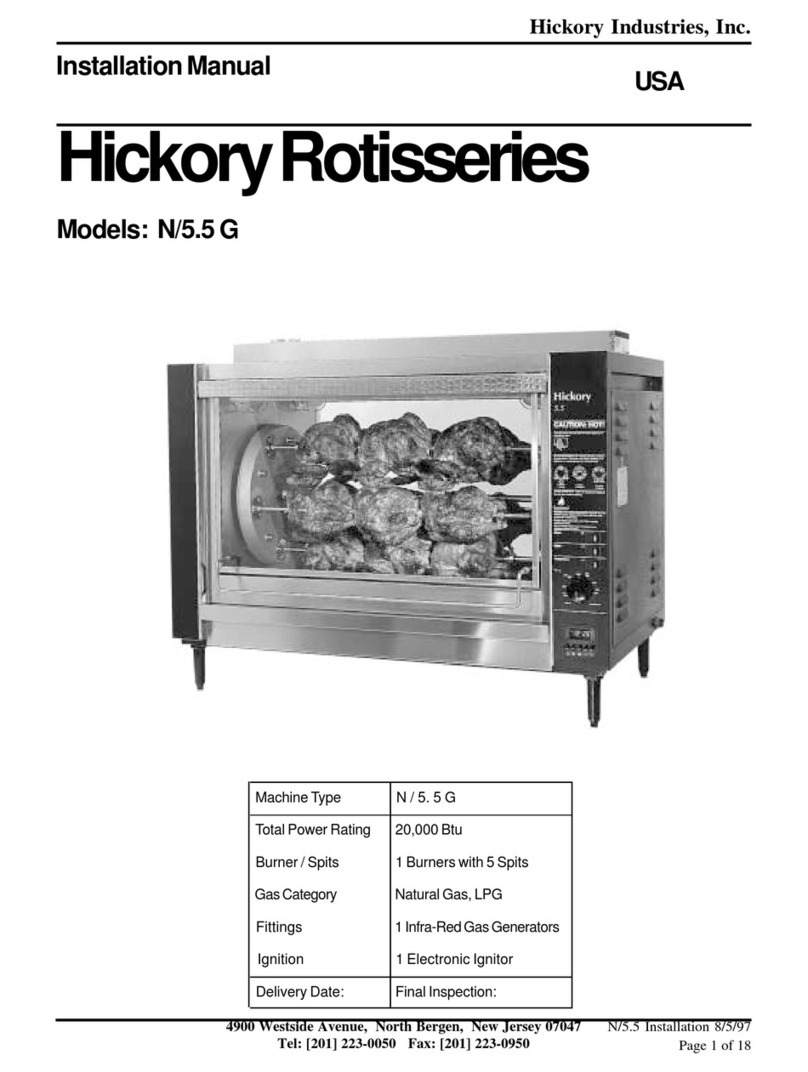

HickoryRotisseries USA

InstallationManual

Models: N/7.7G

TotalPowerRating

Burner/Spits

GasCategory

Fittings

Ignition

Delivery Date:

MachineType N/7.7 G

160,000or180,000BTU

4 or5Burnerswith 14Spits

NaturalGas,LPG

4Infra-RedGasGenerators/

1pipeburner

4 or5Electronic Ignitors

FinalInspection:

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 2 of 28

1.0Installation 3

1.1 GeneralInformation 4

1.2 DescriptionoftheDataPlate 4

1.3 MachineDimensionsininchesandmm 5

1.4 GasConversionandAdjustmentInstructions 8

1.5.1 GasConversionandAdjustmentInstructionforShowBurner(SB) 8

andWoodburningModule (WB)

1.5 VerificationforusewithNaturalGas 8

1.6 GasFlowTable(Consumption) 9

1.7.1 VolumetricMethodtoVerifytheFlameSetting,Mathematical 9

1.7 OrificeDiameters,ElectrodeGapSettings,andAirIntakeSettings 10

1.8 ChangingGasOrifices 11

1.8.1 ChangingtheGasOrifice-GasGenerators 11

1.8.2 ChangingtheGasOrifice-PipeBurnerforSBandWB 12

1.9 IgnitionCycle 13

1.9.1 AdjustingtheIgnitionElectrode 13

1.10 CheckingtheConnectedGasPressure(NominalPressure) 15

1.11 Maintenance,ResponsetoTechnicalProblems 15

1.11.1 Reasonsforproblemsandsolutions 16

1.12 SpitDriveMechanism 17

1.13 TestingorCheckingforSafety 18

1.14 DescriptionoftheElectricalConnection 18

1.15 ElectricalDiagram 19

1.16 PartsListforN/7.7G 23

1.17 ListofAdditionalPartsforN/7.7GwithShowBurner(SB) 25

1.18 ListofAdditionalPartsforN/7.7G withWoodburningModule(WB) 25

1.19 PartsListforWoodburningModule(WB) 25

TableofContents

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 3 of 28

a. Wheninstallingtheseunits,itisimportanttocomplywiththemostrecently

establishedrulesandregulationsasdeemedpertinentbythelocalandnational

electrical,gas,ventilation,sanitation,andfirecodes. Theseunitsareclassified

byUnderwritersLaboratories,Inc.asGas-FiredFoodServiceEquipmentin

accordancewithAmericanNationalStandardsInstituteANSIZ83.11b-1991,Gas

FoodServiceEquipment-RangesandUnitBoilers.

b. Thesegasunitsmustnotbedirectlyconnectedtoagasflueorexhaust. However,the

unitsmayonlybeoperatedinconjuctionwithacanopytypeexhausthood.

c. Theroomwheretheunitsarebeinginstalledmustbeventilatedinaccordanceto

thevalidcodesandregulations.

d. Theunitsaretobeinstalledsecurelyandhorizontally. Theunitsmaybe

installedoncombustiblefloors. Theunitsmaybeinstalledonadjustablelegsoron

casters(wheels).

e. Theminimumclearancetotherearorsidewallsmustbe3inches. Itisalso

importanttoinsurethatthebottomoftheunitsiskeptclearsothat properventilation

orairexchangecanoccur.

f. Normally,theunitswillbesenttotheoperatoralreadysetupfortheparticular

typeofgasavailableattheirlocation. However,unlessotherwisespecified,the

unitswillbesetupfornaturalgasuse. Beforeinstallingandusingtheunitsforthe

firsttime,itisimportanttomakesurethatthegastypeandpressureindicatedonthe

dataplatematchesthetypeofgasavailableinthelocation. Shouldthisnotbethe

case,itisimperativetochangeorconverttheunitstotheneededgastype.

g. Theunitsmustbefittedwiththemanualshut-offgascock(valve)suppliedwiththe

machine. Thismanualvalveisneededtoshutoffthegastothemachineduring

maintenancework,repairs,andiftheunitneedstobedisconnectedforanyreason.

h. Agasregulatorisalsosuppliedwiththemachine. Thiscomponentisneededsothat

theappropriategaspressurecanbesetandinsureanoptimumoperationoftheunit.

i. Dependingonlocalcodesorifdeemednecessary,agasfiltermayalsoberequired.

1.0 InstallationInstructions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 4 of 28

1.1 GeneralInformation

TheOperatingInstructionsaretobegiventotheoperatoroftherotisserie. Allunit

operatorsaretobefamiliarwiththefunctionsoftherotisserie.

TheOperatingInstructionsshouldbekeptinalocationclosetotherotisserie. Itshouldbe

easilyrecognizeableandeasilyaccessible.

Theserotisseriescanbeusedwithboth naturalandLPGgases. Therotisseriescanbe

convertedoradjustedtoanytypeofthelocallydistributednaturalandLPGgases.

Itisrecommendedthatarepairandmaintenancecontractbesignedwiththe

manufacturer'sagent,distributor,orserviceagency.

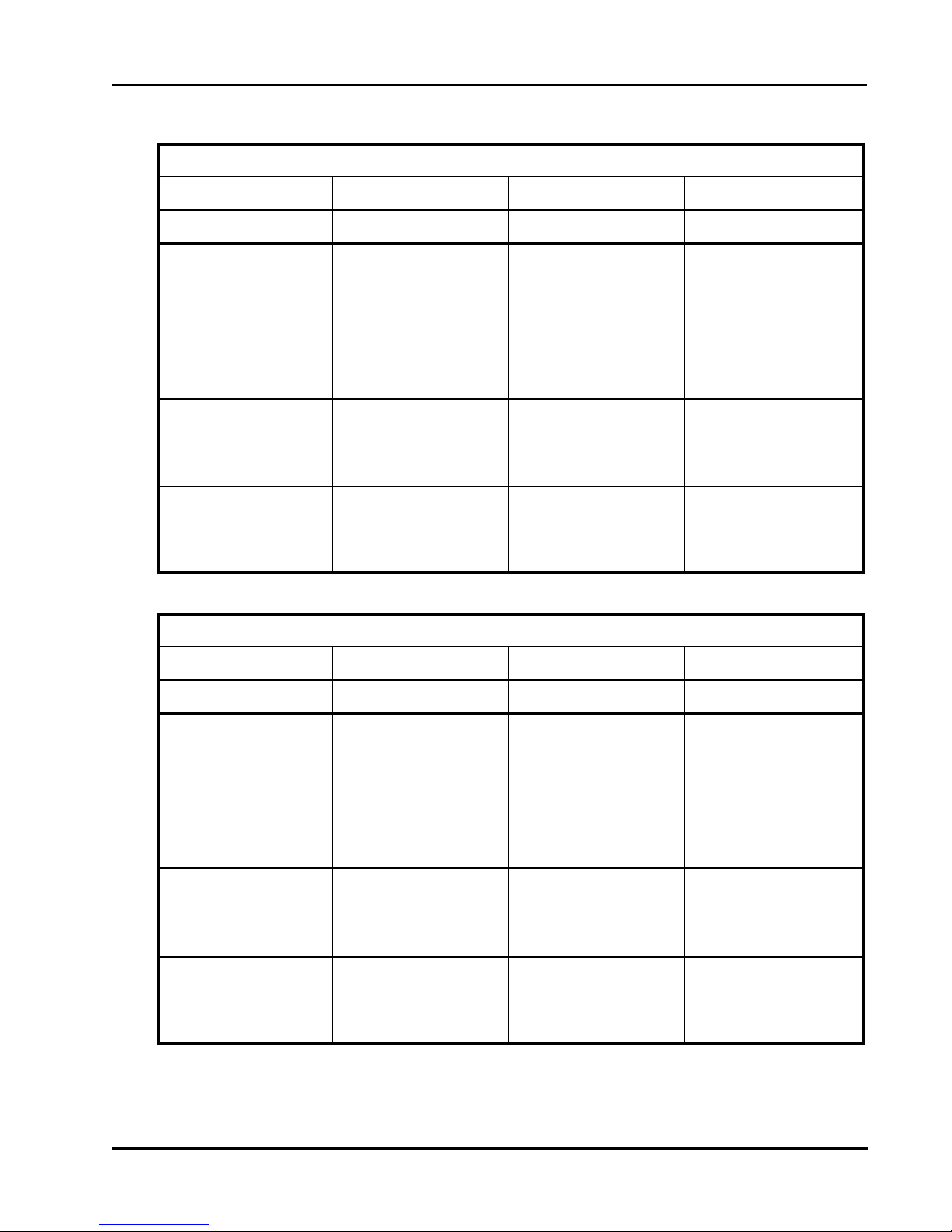

1.2 DescriptionoftheDataPlate

WARNING!

Thisunitmustbeinstalledandconnectedinaccordancetothelatestregulations

andcanonlybeoperatedinconjunctionwithforcedventilationorexhausthood.

Thisunithasbeendesignedforprofessionaluseonly

andmayonlybeinstalledorrepairedbylicensedserviceagencies!

Beforeinstallingorusingthisequipment,readtheseinstructions!

HICKORY INDUSTRIES, INC.

COMMERCIAL COOKING APPLIANCES

NORTH BERGEN, NJ 07047

MODEL N/7.7 G SERIAL NO.

MOTOR: 110 - 115 VOLTS 60 CYCLE AC CURRENT

1/2 HP SINGLE PHASE 5.7 RPM

BURNERS 4 / 1

GASINPUTPERBURNER BTU/H

MANIFOLDPRESSURE

TYPEOF GAS

MFG.DATE

40,000/20,000

5.5"

NAT

MINIMUM INSTALLATION CLEARANCE

SIDE: 6INCHES

BACK: 6 INCHES

MAXIMUM LAMP WATTAGE: 150 WATTS

FOR INSTALLATION ON A COMBUSTIBLE FLOOR

Gas-firedFood ServiceEquipmentClassified by

UnderwritersLaboratories Inc. In accordancewithAmerican

NationalStandards InstituteANSIZ 83.11b-1991,GasFood

ServiceEquipment-Ranges andUnitBoilers

LISTED

69D6

HICKORY INDUSTRIES, INC.

COMMERCIAL COOKING APPLIANCES

NORTH BERGEN, NJ 07047

MODEL N/7.7 G SERIAL NO.

MOTOR: 110 - 115 VOLTS 60 CYCLE AC CURRENT

1/2 HP SINGLE PHASE 5.7 RPM

BURNERS 4 / 1

GASINPUTPERBURNER BTU/H

MANIFOLDPRESSURE

TYPEOF GAS

MFG.DATE

11"

LPG

MINIMUM INSTALLATION CLEARANCE

SIDE: 6INCHES

BACK: 6 INCHES

MAXIMUM LAMP WATTAGE: 150 WATTS

FOR INSTALLATION ON A COMBUSTIBLE FLOOR

Gas-firedFood ServiceEquipmentClassified by

UnderwritersLaboratories Inc. In accordancewithAmerican

NationalStandards InstituteANSIZ 83.11b-1991,GasFood

ServiceEquipment-Ranges andUnitBoilers

LISTED

69D6

40,000/20,000

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 5 of 28

1.3 MachineDrawingsandDimensions

ThefollowingdrawingoftheFrontView,SideView,andTopViewindicatewherethe

dimensionsaretakenandshouldbeusedtoplantheinstallationoftheunits.

N/7.7 G inches[mm]

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 6 of 28

7.7GwithShow Burner inches[mm]

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 7 of 28

N/7.7Gwithseparatehearthburner inches[mm]

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 8 of 28

1.4 GasConversionandAdjustmentInstructions

Beforeconvertingoradjustingthemachinetoanothertypeofgas,itisimperativethatthe

manualgascockbeturnedtothe"off"position. Theelectricalpowertothemachinesshould

alsobeturnedoff. Whenconvertingthegasgeneratorsforusefromonetypeofgasuseto

another,thegasorifice(orinjector)mustbechangedaccordingtothetableonpage9. In

addition,thespringinthepressureregulatorsuppliedwiththeunitmustbechangedsothatit

canoperateatothergaspressures. SpringsfortheregulatorcanbeorderedfromHickory

Industries.

1.4.1 GasConversionandAdjustmentInstructionsforShowBurner(SB) and

WoodburningModule(WB)

Beforeconvertingoradjustingthemachine,itisimperativethatthemanualgascockbe

turnedtothe"off"position. Theelectricalpowertothemachinesshouldalsobeturnedoff.

Whenconvertingfromonetypeofgastoanother,thegasorifice(orinjector)andthe

primaryairadjustmentmustbechangedaccordingtothetableonpage9. Inaddition,the

springinthepressureregulatormustbechangedaspreviouslyexplained.

1.5 VerificationforusewithNaturalGas

Theflamesettingforeachgasgeneratorandforthepipeburnercanbeconfirmedbyusing

thevolumetricmethodinconjunctionwiththemaingasmeter. Eachburnerhasan

independentsolenoidgasvalve. Eachvalveiscontrolledbyitsown,independentGaslite

sparkignitionmodule. Theamountofgasflowingthroughthevalvescannotbeadjusted

manually;thereisonlyan"on"or"off"position.

Tocarryoutthisverificationprocedure,itisnecessarytoobtaintheheatingvalue(BTU/ft3)

ofthelocalgasfromthelocalgascompany. Avariationintheheatingvalueofthelocal

gasfromthat onthetable(1.6)willresultinavariationofthepoweroutputoftheunit!

Ifthemeasuredgasvolumedoesnotcorrespondtothevaluesinthefollowingtable(1.6),the

itemswhichshouldbecheckedare:

A. Theincoming(connected)gaspressurewhileallburnersandallotherappliances

inthelocationareoperational.

B. Ifthegaspressureiscorrect,itmustbeverifiedthatthepropersizegasorificesarein

place(seepage9).

Solenoid Valve

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 9 of 28

1.6.1 VolumetricMethodtoVerifytheFlameSetting,Mathematical

WARNING! Noothergasequipmentcanbeinoperationduringthisprocedure.

CalculationofflowrateEinft3/hour

Q= E

Hi

Q= Flow rateinft3/time

E= HighFlamePowersettinginBTU/hr

Hi= HeatingvalueinBTU/ft3

Thus,fornaturalgas:

Q=40,000 BTU/hr = 38.50ft3/hr = 0.64ft3/min.

1040 BTU/ft3

Q= 0.64ft3/min.

Calculationofthenaturalgasneededin1hourbya7.7G(4burners)atfullpower:

Q=38.50 *4 = 154ft3/hr = 2.56ft3/min.

Thetimeandtheflowmeasurementsshouldbetakenatthegas(flow)meterwitha

chronometer(stopwatch).

Torunthetest,openthemanualgascockvalve,startuptheunitaccordingtothestart-up

instructions.

Allowtheunittopre-heat(burn)for10to15minutes. Verifythattheflowrateiscalibrated

totheappropriateflowrateindicatedinthetable.

NOTE: Thismathematicalcalculationwasdoneassuminga#38orificesizeandaconnected

gaspressureof5.5"withaninfra-redgenerator. Theactualflowratewillvary

dependingontheHeatingValueofthelocalgasandonthesetgaspressure!

1.6 GasFlowTable(Consumption)

in ft3/hr

Gas Flow

per Burner (40,000 BTU)

BTU/ft³

Heating Value in

Gas

HighFlameSetting

Natural

Propane

Butane

1040 38.50

2500

2500 16.00

16.00

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 10 of 28

Gas/Pressure OrificeSize PrimaryAirIntake

TypeN/7.7Gwith ShowBurnerorWoodburningModule

TypeN/7.7 G

1.7 OrificeDiameters,ElectrodeGapSettings,andAirIntakeSettings

Gas/Pressure OrificeSize

Øindrill size

Natural/5.5"

inchesW.C.

Butane/11"

#38

#51

inchesW.C. Øindrill size ininches

Natural/5.5" #40

ElectronicIgnition

ElectrodeGap

ElectronicIgnition

1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

1/8"Betweenrod

andPipeBurner 1/8"

Propane/11" #51 1/8"Betweenrods

1/8"Betweenrods

andBurnersurface

Propane/11" #55

Propane/11" #55

1/8"

1/8"

1/8"Betweenrod

andPipeBurner

1/8"Betweenrod

andPipeBurner

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 11 of 28

1.8 ChangingGasOrifices

1.8.1 ChangingtheGasOrifice-GasGenerators

The7.7Gasunithasfourinfra-redgasgenerators. Inoldermodels,thesegeneratorsused

ceramicradiatingplates. Allnew7.7unitsuseInconel(Metalalloy)radiatingplates. All

fourburnersareinterchangeablewithaminorburnerinletpipepositionmodification.

1. Whenlookingfromtheverytopoftherotisseriedownward,youwillseethe

following:

Gas Inlet Pipe

Alternate Opening for

Inlet Pipe (plugged) Burner

Orifice

Venturi

Top View Gas Generator

2. The burner orifice can be removed and replaced using a 7/16" wrench. The orifice

must be sealed and tightly in place.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 12 of 28

AirIntakeAdjustment

LockNut

MainOrifice

VenturiTube

VenturiAssembly

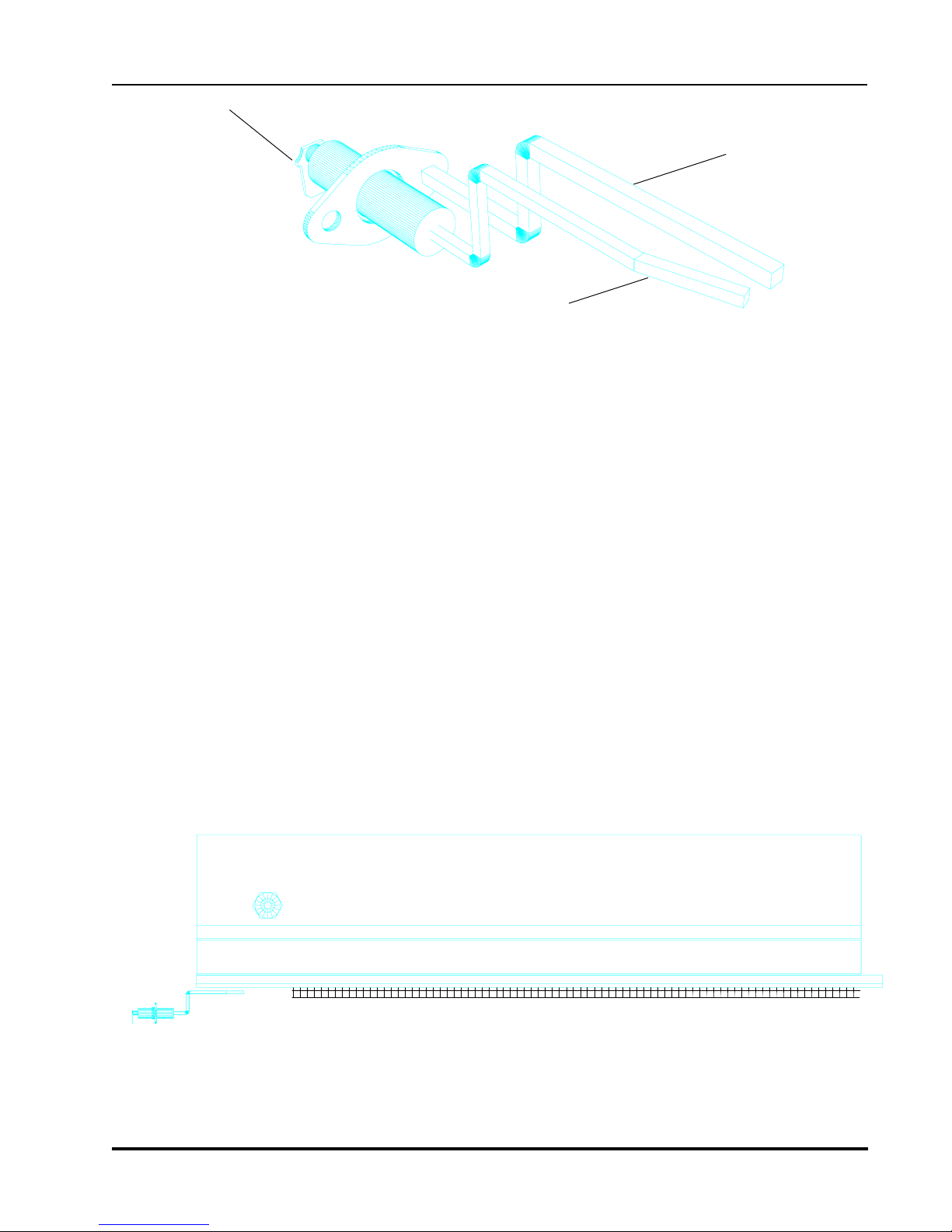

1.8.2 ChangingtheGas Orifice-PipeBurnerforSBandWB

1. Removethelefthanddrippanandloadingtray.

2. Unscrewandremovethemetalcovertoexposetheventuri.

3. Theventuritubeisontheinletsidetothepipeburner.

4. Ontheventuri,loosenthelocknuts(7/8"wrench)andthenmovethenut

andtheairintakecapallthewaytothetopofthenipple.

5. Witha3/4"wrench,loosenthenipplesothatitcanberemovedfromthe

venturi.

6. Withthenipple/orificeassemblyoff,separatethemainorificefromthe

nipplewithapipewrenchorapairofpliers.

AirIntakeCap

Nipple

Re-assembleallofthecomponentswiththeneworifice. Makesurethattheproperairintake

adjustmentismadeforthenewtypeofgas(accordingtothetableonpage9). Theflamesshouldbe

blueincolor,mustbestable,andmustnot"liftoff"theburner.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 13 of 28

1.9 IgnitionCycle

Inordertostartthecookingcycle,theburnersmustbeignited. Theignitioncyclewillstart

onlywhenthefollowingprocedureisfollowed:

a. The"HEAT"switchisturnedto"on".

b. Theindividualburnerswitchesareturnedto"on".

NOTE: TheSBandWBpipeorrearburnerscanbeshutoffusingan

unmarkedtoggleswitchlocatedontheuppersideofthe

controlpanel. Makesurethatthisisinthedesiredposition.

c. Acookingtemperaturemustbesetonthethermostat(i.e.450°F).

d. Thecookingtimermustbeactivated(seeOperatingInstructions).

Oncethesestepsarecompleted,theunitwillcallforheatandtheignitioncyclewillbe

activated. Theignitionsystemwillcausesparkingontheignitionelectrode. Oncethe

burnerislitbythespark,theflameoftheburnerwillheatthesensingprongontheignition

electrodesendingasignalbacktotheignitionmodule. Thissignalindicatesthatasparkis

nolongerneededandthatthesolenoidgasvalvemuststayopen. Whenthecooking

temperatureisreached,assensedbythethermocoupleattachedtothethermostat,the

electricalpowertotheignitionmoduleswillbecutoff,shuttingdowntheignitionmodule

andtheburners. Whenthetemperaturedropsbelowthesetpoint,electricalpowerissentto

theignitionsystemonceagain,thusstartingtheignitioncycleallover. Thesystemwill

cycleonandoffasneededtomaintainthesetcookingpoint.

Theignitionmoduleswillattempttoignitetheircorrespondingburnersthreetimes. Ifthe

burnersfailtolightafterthreetries,themodulewilllock-out,shuttingdownallgasflowand

furthersparking.

Inordertostarttheignitioncycleafteralock-out,theheatswitchesandindividualburner

switchesmustbeturned"off"and"on"again. Thismayhavetobedoneseveraltimeswhen

startinguptheunitforthefirsttimeduetoairinthegaslines.

1.9.1 AdjustingtheIgnitionElectrode

Theignitionelectrodesareadjustedforanoptimumignitioncyclebeforetheunitleavesthe

factory. Ifforsomereasontheelectrodesneedadjusting(i.e.ifonetakesahitwithaspit),it

canbedoneasfollows.

1. Toreachtheignitionelectrode,opentheslidingglassdoorsandremoveallspits.

2. Eachelectrodeisattachedtothemainbodyofthemachinewithan8/32"screwand

nut. Itisimportantthatthisscrewmakesolidmetaltometalcontactbetweenthe

electrodecasingandthebodyoftherotisserie. Thismetaltometalcontactiswhat

actsasagroundingconductorforthegroundingprongontheignitionelectrode.

3. Duringtheignitionprocess,asolidblue/yellowsparkshouldtravelbetweenthetipof

thetwoelectrodeprongs.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 14 of 28

IgnitionElectrode

Grounding Prong

Ignition / Sensing Prong

Ignition Wire Connection

4. Makesurethatthedistancesbetweentheprongsandthesurfaceoftheburnerare

about1/8".

5. Ifthedistancesbetweentheprongsand/ortheburnersurfacearetoogreat,theunit

maysparkbutnotignitetheburner.

6. Ifthedistancebetweentheprongsandtheburnersurfacearetooclose,contactmay

occurcausingashort-circuitandpreventinganyignition. NotethattheINCOLOY

(metal)surfaceoftheburnerswillwarpdownwardoncetheburnerheatsup. Ifthis

happensandthesurfacedoes makecontactwiththeelectrodeprongs,theburnerwill

shutoff.

7. Whenadjustingtheprongs,makesuretosupportthebaseoftheprongwithonepair

ofpliersandadjustthetipoftheprongwithanotherpair. Thiswillpreventbreakage

oftheceramic casingofthesensingprong. Iftheceramiccasingdoesbreak,itwill

causeerraticignitionproblemsandtheelectrodewillhavetobereplaced.

IgnitionElectrodePosition

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 15 of 28

1.10 CheckingtheConnectedGasPressure(NominalPressure)

Closethegascockwherethegaslineisconnectedtothemachineandattachamanometer

tothetap(allenscrew)onthegascock. Withthemanometerconnected,openthegas

cockandigniteallburners. Alongwithallothergasappliancesatthelocationin

operation,measurethegaspressure.

Thisidealoperatingpressureshouldbe5.5"W.C.fornaturalgasand11"W.C.forLPG.

Ifthepressureistoohighandcannotbeadjusteddownward,checktoseeiftheproper

adjustingspringisintheregulator. Ifthisiscorrect,theregulatormembranemayhavebeen

rupturedbyexcessivegaspressureandmayhavetobereplaced. Donotoperatetherotisserie

ifthegaspressureexceedstheidealvalues.

Iftheoperatingpressureisbelow5.5"W.C.fornaturalgasorbelow11"W.C.forLPG,the

unitshouldnotbeoperated. Thepressureshouldbeadjustedtotheidealsettingusingthe

pressureregulatingscrewonthepressureregulator.

Ifthepressureistoolowandcannotbeadjustedupward,alsochecktheregulator. Ifthisis

operatingproperly,verifythepressurecomingoutofthemaingasmeter. Anothertypical

sourceofthispressureproblemisthatthegasline(pipe)diameterleadinguptotheunitis

toosmall. Ifthegaslineisunder-sized,theappropriatepressuremaynotbereached. Donot

operatetheunitifthepressurefallsbelowtheidealvalues.

Ifthemeasuredpressureisstillbelowtheidealrangeanditisnotpossibletoresolvethe

problem,thelocalgascompanyorgassuppliershouldbecontactedsothattheycanresolve

theproblem.

Afterthepressurehasbeenset,closethegascockonceagain,removethemanometer,seal

thegastap,andthenre-openthegascock.

WARNING: Afteraninstallation,repairs,ormaintenance,makesurethatthereare

nogasleaksanywhereinthegaslinesorsystem.

1.11 Maintenance,ResponsetoTechnicalProblems.

Shouldatechnicalproblemariseforanyreason,shutoffthemachineandcallfortechnical

service.

Aroutinemaintenanceshouldbecarriedoutatleastonceayear. Contactyourlocal,

certifiedservicecompanyformaintenance.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 16 of 28

Solution

a. MakesurethattheTEMPERATURE

switch,theindividualburnerswitches

areon. Thermostatmustbeset(i.e.

550°F)andtimermustbeoperational

(cookcycle).

b. Makesurethatthethreepronged

plugsuppliedwiththeunitisbeing

used,thatthepolarityiscorrect,and

therotisserieisproperlygrounded.

a. Adjustelectrodetipsto1/8"apart.

b. Ifthemachineisused,fatmayhave

carbonizedontheelectrodetipsorrust

mayhaveappeared. Thisprevents

propersparking. Sandandclean

metalrods.

c. Makesurethatelectrodeisproperly

fastenedandmakessolidcontactwith

therotisseriebody.

d. Makesurethattheignitionwireis

properlyfastenedtotheignition

moduleandtotheelectrode.

e. Checktheignitionwireforbreaches

whichmaycausesparkingtooccur

betweenthecableandthebodyof

rotisserie. Repaircableatbreach.

f. Checkelectricalinputtomodule.

Modulemayneedtobereplaced.

a. Turnallmanualgasvalvesto"on".

Makesureallsolenoidvalvesopen.

b. Makesurethatthehot,neutral,and

groundleadsareproperlymatchedup.

Ifneutralandhotareswitched,the

"flameon"signalwillnotreach

ignitionmodule,lockingoutgas.

c. Checktheoperatinggaspressure.

a. Adjustthetipsoftheelectroderods

sothattheyareabout1/8"fromthe

burnersurface. Makesurenocontact

occursbetweentherodsandburner.

a. Switchexhausthoodtoonbefore

ignitingtheunit. Alsoopenoneofthe

slidingglassdoors.

b. Re-adjustignitionprongs.

Problem

Allelectrodes

donotspark.

Oneelectrode

doesnotspark.

Allelectrodesspark,

noburnerlights.

Anelectrodesparks,

flamedoesnotlight.

Burnerignitesfor5

to10secondand

thengoesoff,espe-

ciallyinthemorning

whencold

Cause

a. Burnersnot"on".

b. Electricalsystemnot

groundedproperly.

a. Electrodetipstoofarapart.

b. Electrodetipsaredirtyor

carbonized.

c. Electrodenotgrounded.

d. Ingnitionwireloose.

e. Ignitionwirenotproperly

insulated.

f. Ignitionmodulefaulty.

a. Checkallgasflow.

b. Checkpolarityonthe

electricalconnections.

c. Flameistooweak.Not

enoughgasflow.

a. Electrodetipsaretoofar

fromburner.

a. Highhumidityevironment.

suchascausedbyleaving

waterindrippan

overnight.

b. Unitnotproperlyadjusted

tonewconditions.

1.11.1 Reasonsforproblemsandsolutions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 17 of 28

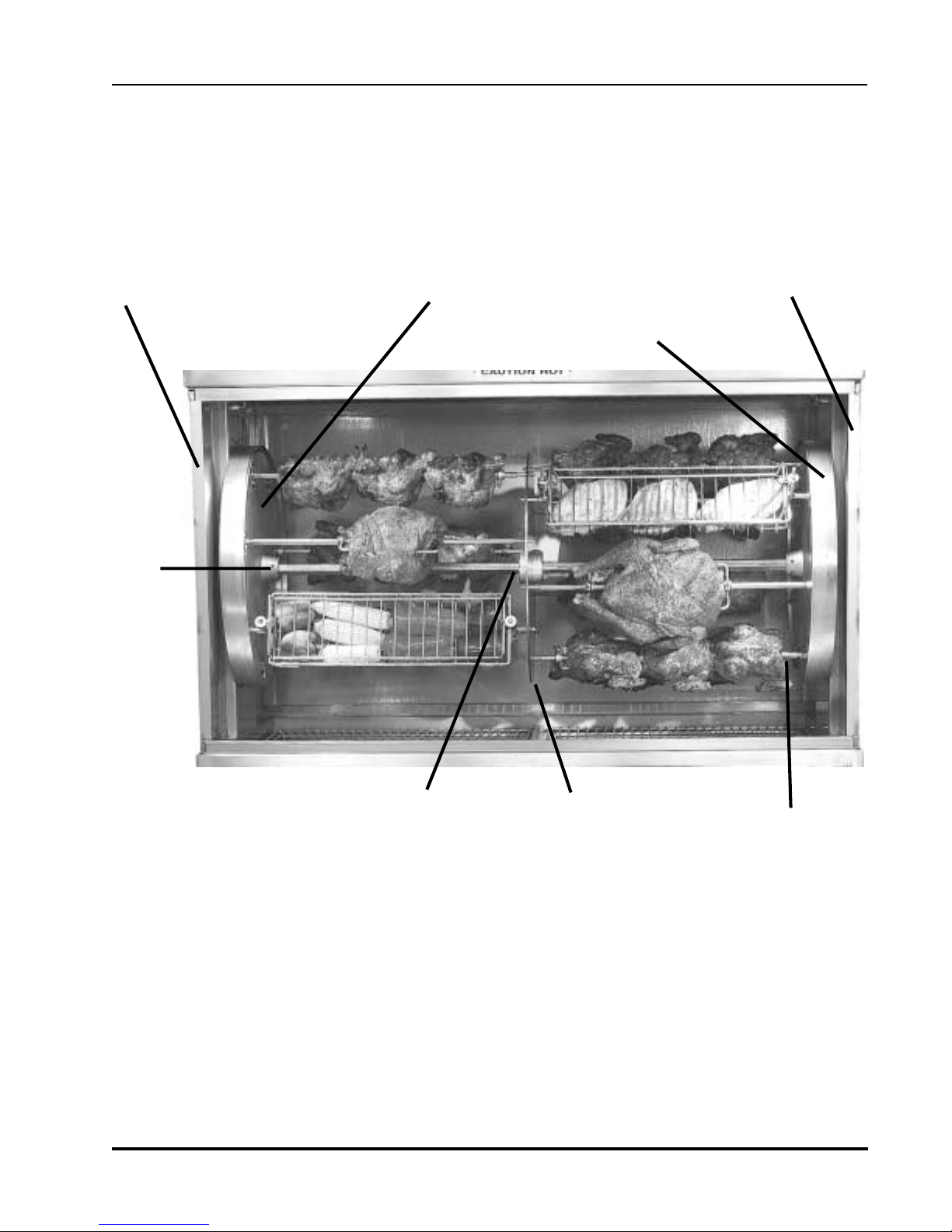

1.12 Spit Drive Mechanism

This unit is equipped with a planetary motion spit drive system. This means that each spit is

turning upon its axis at the same time that they turn about the center shaft. When the motor

switch is turned to on, the disks and the spits will begin to turn. Insure that the mechanism

turns smoothly when testing the unit.

Center Shaft Spit

Set

Screws

Removable Side Panels Removable Side Panels

Before cooking, it is imperative that the center shaft and the set screws be covered and protected

with aluminum foil. This will prevent fats from carbonizing on the shaft, making the removal of the

aluminum disks much easier in the future. If the screws and shaft are not protected, eventually it

may be impossible remove them should there be a problem in the spit drive mechanism.

The driven and the stationary drive gears are located behind the aluminum disks. These can be

viewed by taking out the removable side panels (there are four removable panels). The driven gears

and the stationary gear should be viewed once a week to check for fat or carbonization build-up.

Any fat or dirt should be cleaned off since a build-up will eventually damage the drive system.

In order to access the entire drive system, loosen the set screws fastening the aluminum disks to the

center shaft. Once loose, the disks can be slid along the center shaft toward the steel slave disk in

the center.

Center Disk Slave

Aluminum Disk

Aluminum Disk Cover

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 18 of 28

NOTE: If fat or carbon have built up on the set screws or on the center shaft, it may not

be possible to move the alumium disks!

With the disks away from the sides, all components of the drive mechanism should be

thoroughly cleaned. This will guarantee that the drive mechanism works smoothly.

Even though the aluminum disks are protected with stainless steel covers, fat will eventually

build up on the gears. If this fat is not cleaned, it will eventually carbonize. When the

carbon build-up is serious enough, the drive mechanism will jam and it will need

to be replaced.

When replacing the disks, a slight dab of FDA (food safe) approved gease should be added

to all gears.

Finally, when inserting spits, make sure to stop the motor! This unit is supplied with a

foot switch which will stop the drive mechanism, allowing the operator to insert the

spits easily! If spits are inserted without stopping the motor, there is a chance that the drive

system will be jammed and cause severe damage.

1.13 TestingorCheckingforSafety

Afteraconversion,anewinstallation,orafterarepair,itisimportantthattheunitbe

testedtoinsurethatitoperatesproperly. Thisshouldincludethefollowing:

Testthegassystemforgasleaks.

Checkthattheunithasenoughclearancebehindandtothesides.

Checkthatenoughprimaryandsecondaryairisavailable(strongblueflameonthepipe

burner,brightorangegasgenerators).

Checkforpotentiallyflammableobjectsorpotentialflammabilityproblems.

Checkforproperventilationandexhaust.

Checkforproperroomventilation.

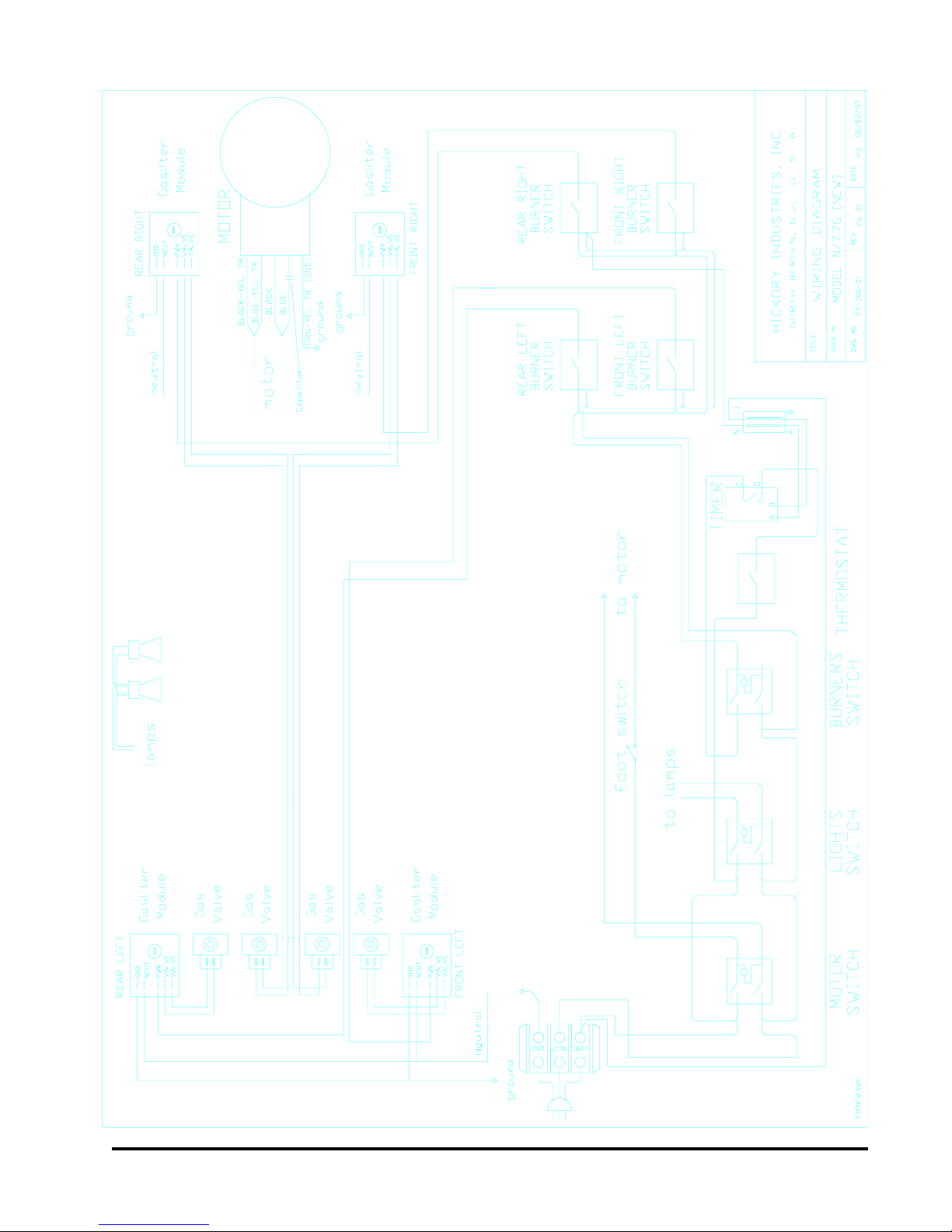

1.14 DescriptionoftheElectricalConnection

Theelectricalconnectionsaretobemadeinaccordancetolocalandnationalcodes.

Allgasmachinesoperatewith120Volt,singlephase,60Hz. ANEMA5-15Pplug

issuppliedwiththeunits.

Allpertinentelectricalinformationcanbetakenfromtheelectricaldiagram.

NOTE: Properpolarityintheelectricalsystemisneededforproper

operationofthegassystem!

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 19 of 28

1.15 ElectricalDiagram

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/7.7G Installation 10/97

Page 20 of 28

Table of contents

Other Hickory Kitchen Appliance manuals