ITMBT Low temperature dehumidifiers

MTITMBTGB REV.112008

9

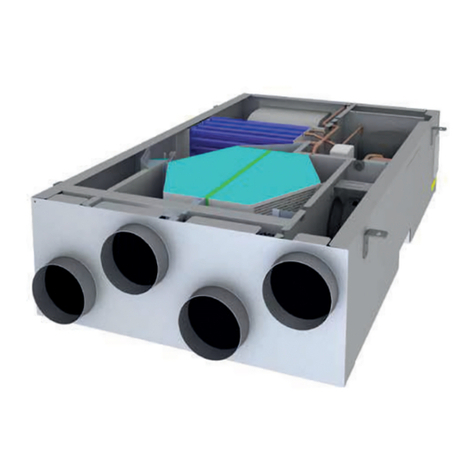

UNIT DESCRIPTION

ITMBT low temp erature dehumidifiers series are high performances units especially designed for cold room applications where th e

humidity level should be controlled during pr oduct storage treatment. All units are s upplied with hot gas defrost system and

antifreeze heater on condensate drip tray.

Frame

All ITMBT units are made from hot-galvanised thick sheet meta l, painted with po lyurethane powder enamel at 180°C to ensure the

best resistan ce against the atm ospheric agents. The frame is self-supporting with removable panels. The drip tray is present

standard in all ITMBT units and it’s in stainless steel. The colour of the units is RAL 7035

Refrigerant circuit

The refrigerant gas used in the se units is R407C. The ref rigerant circuit is mad e by using international primary brands compone nts

and according to ISO 97/23 concerning welding procedures. The refrigerant circuit includes:

sight glass,

filter drier,

thermal expansion valve with external equalizer,

Schrader valves form maintenance and control,

pressure safety device (according to PED regulation),

Solenoid valve for hot gas defrost injection,

Antifreeze electric heater mounted in the condensate drip tray.

Compressors

The compressor is scroll type with crankcase heater and thermal overload protection by a klixon embedded in the motor winding. It’s

mounted on rub ber vibration dampers and, by request, it can b e supplied with some jackets to reduce the noise (accessory). The

crankcase heate r, when present, is always powered when the c ompressor is in stand-by. The in spection is possible through the

frontal panel of the unit.

Condensers and evaporators

The condensers and evaporators are made of copper pipes and aluminiu m fins. The diameter o f the copper pipes is 3/8” and t he

thickness of the aluminium fins is 0 ,1 mm. The tubes are me chanically expa nded into the aluminium fin s to improve the h eat

exchange factor. The geometry of these conden sers guarantees a lo w air side pressure drop and then the use of low rotation (and

low noise emission) fans. All the units have a stainless steel drip tray. Besides t his, each evaporator is supplied of a temper ature

probe used as automatic antifreeze probe.

Fans

The fan is centrifugal type. It’s st atically and dynamically balanced and supp lied complete of the safety fan guard according t o EN

294. It’s mounted on the unit fra me by interposition of rubbe r vibration dampers. The electric motor is at 4 poles (about 1500 rpm).

Connected to the fan by belts and pulleys and it’s equipped of an integrated thermal overload protection. The protection class of the

motors is IP 54.

Air Filter

It’s supplied standard with the unit. It’s made of filtering materi al in synthetic fibre without electrostatic charge. It can b e removed for

differential disposal, class G3, according to EN 779:2002

Electric box

The electric switch board is mad e according to e lectromagnetic compatibility norms CEE 73/23 a nd 89/336. The accessibi lity to the

board is possible after removing the front panel of the unit and t he OFF positioning of the ma in switch. The moisture protection

degree is IP55. In all ITMBT units are installe d, standard, t he compressors sequence relay who disables th e operation of the

compressor in case the power supply phase sequence is not the correct one (scroll compressor s in fact, can be damaged if the y

rotate reverse wise). The following components are also standard installed: main switch, magnetic-thermal switches (as a protection

of pumps and f ans), compressors fuses, contr ol circuit automatic breakers, compressor contactors. The terminal board is also

supplied with voltage free contacts for remote ON-OFF.

Microprocessors

All ITMBT units are supplied standard with microprocessor controls. The microprocessor controls the following functions: compressor

timing, automatic defrost cycles, alarms. An appropriate LCD display shows the operation mode of the unit, set point and alarms.