HIdRos iCHiLL 100CX User manual

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 1 di 20

iCHiLL 100CX

Service Manual

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 2 di 20

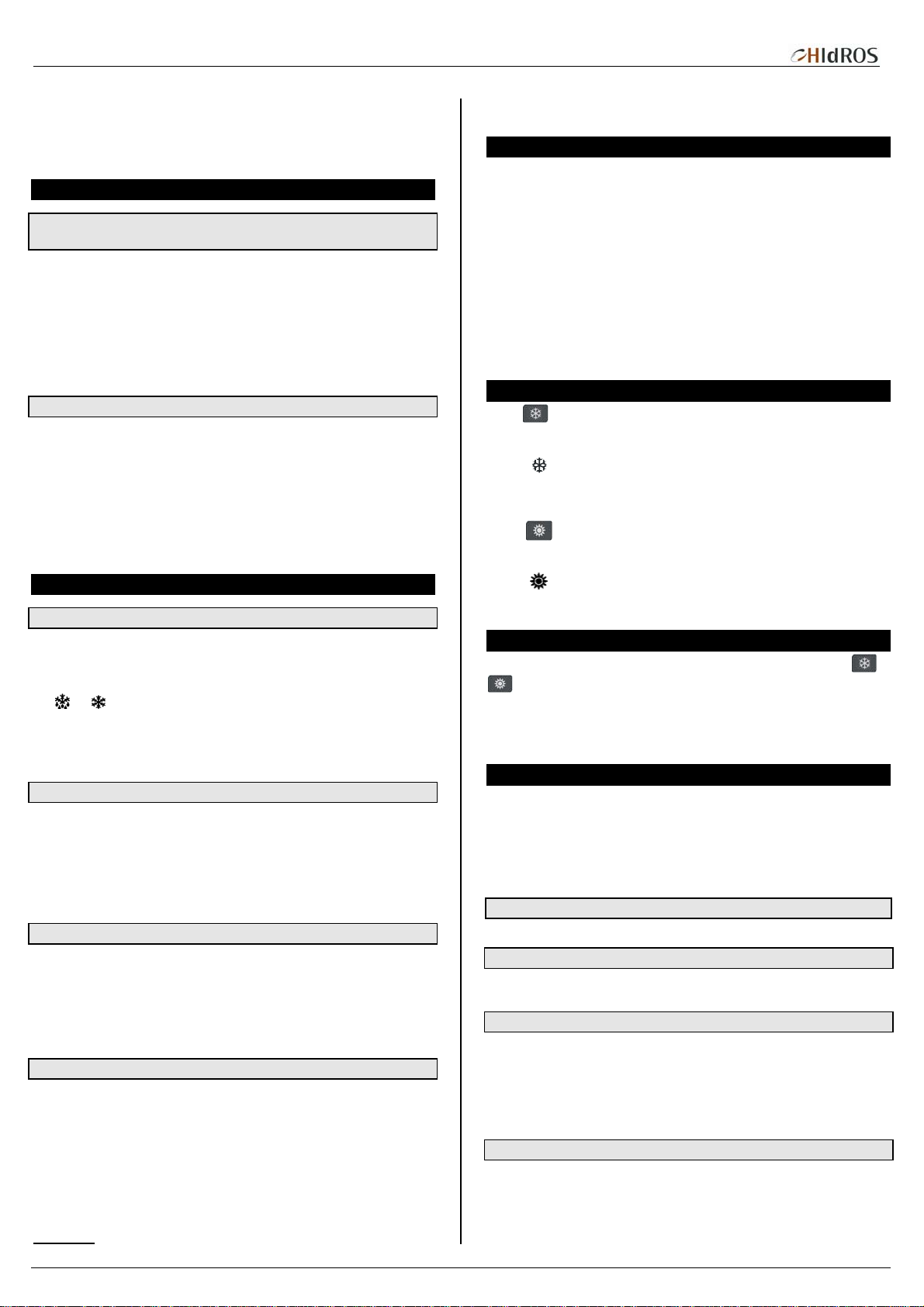

USER INTERFACE

Display

Upper digits (red color): configurable, see parameter CF36 (PB1, PB2, PB4, Set-point

(parameter value)*, working set-point (real set-point modified from dinamic set-point,

Energy saving or function for units without water storage tank), Hysteresis, Machine

status **))

Lower digits (yellow color): configurable, see parameter CF43 (PB1, PB2, PB3, PB4,

Set-point (parameter value)*, working set-point (real set-point modified from dinamic set-

point, Energy saving or function for units without water storage tank), Hysteresis, RTC,

Machine status **)).

*the display visualizes chiller set point when the unit is on and in chiller mode, heating

set point when the unit is on and in heat pump mode, and OFF when the unit is in

standby.

**the display visualizes OnC when the unit is on and in chiller mode, OnH when the unit

is on and in heat pump mode, and OFF when the unit is in standby.

Icons of the Display

Icon Meaning

°C -°F

bar-PSI ON when the display visualizes a temperature or a pressure

On when the display visualizes the RTC, working hours, etc.

On flashing in case of alarm

On if the Energy Saving, dynamic set-point or function for units without

water storage tank are active.

OFF if a function above is enabled but not active.

On during menù visualization

On if heaters are activated (antifreeze heaters or/and boiler)

On flashing during defrost delay time.

On during defrost

On flashing if water flow switch is activated.

When the pump is OFF, the led is on flashing to indicate the correct

status of the digital input

On if at least one water pump is on

On if evaporator fans are activated

On if a compressor is on.

On flashing during the delay time for compressor activation.

On if open collector output is active

On if the controller is on in Heat or Cool mode

On in case of Low pressure alarm or High pressure alarm

Keys

1. Push to enter in the Menu

2. Push and hold (about 3 seconds) to set the clock

1. Push

to visualize the set point.

2. Push and release 2 times: 1st time is visualized the setpoint

(the value of the parameter), 2nd time is visualized the real

setpoint (when Energy saving, Dynamic setpoint or function

for units without water storage tank are enebled)

3. Push and hold to modify the setpoint

4. Push during parameter programming:

- to enter in parameter modification

- to confirm the changes of the parameter

5. Menù AlrM: push to reset

the alarms

1. Push and release to visualize all the probes configured

2. In programming mode it scrolls the parameter list

3. In programming mode increases the value of the

parameters.

1. Push and release to visualize all the probes configured

2. In programming mode it scrolls the parameter list

3. In programming mode decreases the value of the

parameters

1. Push and hold to switch on/off the machine (chiller or heat

pump depending from CF31 parameter)

1. Push and old to switch on/off the machine (chiller or heat

pump depending from CF31 parameter)

Key Combination

+ Push and hold to enter on the parameters programming

+1. Push to exit to the programming parameters

2. Push and hold to activate manual defrost

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 3 di 20

REMOTE KEYBOARD VICX610

The Ichill has to be configured to manage the remote keyboard.

Upper digits (red color): configurable by parameter CF44 (PB1, PB2, PB4, Set-point

(parameter value)*, working set-point (real set-point modified from dinamic set-point,

Energy saving or function for units without water storage tank), Hysteresis, Machine

status **))

Lower digits (yellow color): configurable by parameter CF45 (PB1, PB2, PB3, PB4,

Set-point (parameter value)*, working set-point (real set-point modified from dinamic set-

point, Energy saving or function for units without water storage tank), Hysteresis, RTC,

Machine status **)).

*the display visualizes chiller set point when the unit is on and in chiller mode, heating

set point when the unit is on and in heat pump mode, and OFF when the unit is in

standby.

**the display visualizes OnC when the unit is on and in chiller mode, OnH when the unit

is on and in heat pump mode, and OFF when the unit is in standby.

Note:

the Ichill 100CX is not compatible with VI610 remote keyboard.

Key Function

Concerning the meaning of the keys, refer to paragraph 2.3.

Air/Air unit: using the remote keyboard with NTC sensor on board (VICX610S model

and parameter CF35 = 2), the read-out and the regulation are controlled by the NTC

sensor mounted on the remote keyboard.

When there is not communication between the keyboard and the instrument the display

visualizes ”noL” (no link message).

DISPLAY VISUALIZATION

Upper digits (red color): configurable by parameter CF36 (PB1, PB2, PB4, Set-point

(parameter value)*, working set-point (real set-point modified from dinamic set-point,

Energy saving or function for units without water storage tank), Hysteresis, Machine

status **)

Lower digits (yellow color): configurable by parameter CF43 (PB1, PB2, PB3, PB4,

Set-point (parameter value)*, working set-point (real set-point modified from dinamic set-

point, Energy saving or function for units without water storage tank), Hysteresis, RTC,

Machine status **).

*the display visualizes chiller set point when the unit is on and in chiller mode, heating

set point when the unit is on and in heat pump mode, and OFF when the unit is in

standby.

**the display visualizes OnC when the unit is on and in chiller mode, OnH when the unit

is on and in heat pump mode, and OFF when the unit is in standby.

Alarm visualization

When the instrument detects an alarm, the lower display shows the alarm code

alternated to probe value. The alarm icon ( ) is on flashing.

In case of HIGH PRESSURE alarm (HP), LOW PRESSURE alarm (LP) or WATER

FLOW SWITCH (Flow!), dedicated icons are on.

STD-BY visualization

It is possible to choose what visualize when the Ichill is in STD-BY.

CF 46 = 0: the display visualizes the same informations configured in CF36 e CF43

CF 46 = 1: the display visualizes the label “OFF”

CF 46 = 2: the display visualizes the label “StbY”

SILENCING THE BUZZER

Automatically:just after the alarm condition is recovered.

Manually:push and release one of the keys; the buzzer is stopped even if the alarm is

still active.

FIRST INSTALLING

After giving power supply to the instrument, the lower display can show “rtC” alternated

to the probe value: it is necessary to set the clock time.

If the probes are not connected, or they are faulty, the display shows the corresponding

alarm code.

In any case it is possible to proceed with clock setting.

HOW TO SET THE CLOCK RTC

1. Push “menu” key for some seconds and wait until “Hour” label appears.

2. Push “SET”: the hour value starts flashing.

3. Push nor o to change the value. Confirm by pushing “SET”; after some seconds

the controller will show “Min”.

4. Repeat points 2 and 3 to set other parameters:

Min: minutes (0÷60)

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 4 di 20

UdAy: day of the week (Sun = Sunday, Mon = Monday, tuE = Tuesday, UEd =

Wednesday, tHu = Thursday, Fri = Friday, SAt = Saturday).

dAy: day of the month(0÷31)

MntH: Month (1÷12)

yEAr: Year (00÷99)

“HOT KEY”PROGRAMMING

Download from the Hot Key (previously programmed) to the Instrument

Memory

The controller has to be not connected to the power supply

Insert the Hot Key into dedicated connector

Connect the controller to the power supply

The download starts and lasts some seconds.

During this phase the whole regulation is locked and the “dOL” message is flashing.

“End “ message will appear if the programming result is good, after 15 sec. the

regulation automatically restarts

If “Err” message appears the operation has given bad result. Turn the controller off and

then on again to repeat the operation or restart the normal regulation.

Upload the Parameter from the Controller to the Hot Key

The instrument has to be connected to the power supply:

1. Insert the Hot Key

2. Push “menu”

3. Select “UPL” function with the arrow keys

4. Push “SET” key.The Upload starts immediately.

During this phase the whole regulation is locked and the “UPL” message is flashing.

“End “ message will appear if the programming result is good, after 15s the regulation

automatically restarts.

If “Err” message appears the operation has given bad result. Repeat the points 1-4 for a

new Upload.

PARAMETERS PROGRAMMING

“Pr1” Programming Level (User Level)

How to access the “Pr1” User Level:

1) Push “SET” + nkey for some seconds;the upper display shows “ALL” (first family

of parameters).

and icons are flashing.

2) Using oand narrows scroll the other family labels.

3) Push “SET” to enter and see all the parameter belonging to that family. The display

shows the first parameter label and its value.

Scroll the parameter list with oand narrows or modify the value as described in 9.4.

“Pr2” Programming Level (Factory Level)

“Pr2” parameters level is accessible through password:

1. Enter the “Pr1” level as described in 9.1.

2. Search parameter “Pr2”; “PAS” label appears on the upper side.

3. Push “SET”: the lower display shows “Pas” and the upper display shows “0”

flashing.

4. Set the password using o and n keys.

5. Push SET key to confirm the value.

How to Move a Parameter from “Pr2” Level to “Pr1” Level

Enter the “Pr2” level and select the parameter to move; keeping pressed “SET” key,

push and immediately release the nkey.

The led in lower display will light to indicate the presence of the parameter in “Pr1”.

Then release also SET key.

To move the parameter in “Pr2” again: keep pressed SET key and immediately release

the nkey. The led turns off so as the parameter is not more visible in “Pr1” but just in

“Pr2”.

Changing a Parameter Value

1. Access to programming mode Pr1 or Pr2

2. Select the parameter to modify

3. Push “SET”

4. Modify the value with o and nkeys

5. Push SET key again to confirm the new value;after some seconds next parameter

will be displayed

6. Exit the programming mode: push “SET” and owhen a parameter label is

displayed, or wait 15s (time-out) without pushing any keys.

NOTE: The new parameter value is also confirmed if, after changing it, no SET key is

pressed for the time-out to exit.

ATTENTION:

CF parameters (Configuration parameters) can be modified

only if the controller is in OFF (digital input) or STD-BY.

HOW TO CHANGE THE PASSWORD

To change the password you must know the previous value. This operation is possible

only starting from Pr2 level.

1) Enter the Pr1 level

2) Select a family of parameters (ST, or CF, or SD,…) and push “SET” key

3) Using o and n keys select the parameter “Pr2”, then push “SET” key. The lower

display shows “PAS” and the upper display shows 0flashing

4) Use nand okeys to input the active PASSWORD; push “SET” to confirm the

value and enter to Pr2 level

5) Search “Pr2” parameter with nand o keys

6) Push “SET” key to enter the new value (flashing)

7) Insert the new password with oand n keys.

8) Push “SET” key to confirm it.

9) The upper display will flash for few seconds then, next parameter will be showed.

10) Exit the programming by pushing “SET” and o together or wait the time-out.

START /STOP CHILLER OR HEAT PUMP

Press key for 3 seconds:

the unit starts or stops the Chiller cycle if the parameter CF31 =0

the unit starts or stops the Heat Pump cycle if the parameter CF31 =1

The icon flashes for 3 seconds when the controller is waiting to turn on/off.

To move from Chiller mode to Heat Pump mode or vice versa, it is necessary to stop the

current cycle and then restart the new (Chiller STD-BY Heat Pump) .

Press key for 3 seconds:

the unit starts or stops the Heat Pump cycle if parameter CF31 =0

the unit starts or stops the Chiller cycle if parameter CF31 =1

The icon flashes for 3 seconds when the controller is waiting to turn on/off.

To move from Chiller mode to Heat Pump mode or vice versa, it is necessary to stop the

current cycle and then restart the new (Chiller STD-BY Heat Pump) .

STAND-BY FUNCTION

When the controller is working, it is possible to switch it in std-by modepushing or

key.

In stand-by is possible:

Display probes value using arrow keys.

Display and modify the set-point.

Enter the “menu” function

“MENU”FUNCTION

Access the “menù” to perform the following operations:

1. Display and reset the active alarms.

2. Display and reset working hours of compressors and water pumps

3. Display delay time between two defrost cycles

4. Upload the parameters map from the controller to the Hot Key (see 8.2).

5. Display/reset the alarm log.

During the Menu operations the “menu” icon is on.

Access to the “menu”

Push and release the “menu” key. The ” menu” icon is on.

Exit from the “menu”

Push and release the “menu”key or wait the time out.

The “menu” icon disappears.

How to Display the Alarm Events

Enter the “menu”:

1. Use oor n keys to find “ALrM” label.

2. Push and release the “SET” key.

3. Use oor n keys to scroll the alarm list.

To exit the function “menu” push and release the “menu” key or wait the time-out. The

“menu” icon disappears.

How to Reset an Alarm Event

1) Enter the function “menu”.

2) Use oor nkeys to find the “ALrM” label.

3) Push and release the “SET” key the lower display shows the alarm code.

4) Lower display shows the alarm code.

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 5 di 20

Upper display shows “rSt” label if the alarm can be reset, “NO” label if it is not

possible.

Use oor nkeys to scroll the alarm list.

5) Push “SET” key when “rSt” is lighted to reset the alarm; after a while the read-out

move to next alarm.

6) To exit the function menu push and release the “menu” key or wait the time-out.

The “menu” icon disappears.

Compressors And Pumps Working hours

Enter the function “menu”.

Use oor nkeys to find on the lower display:

C1Hr (Compressor n°1 working hours),

C2Hr (Compressor n°2 working hours),

PFHr (Evaporator Water pump or supply fan working hours),

PCHr (Condenser water pump working hours).

The clock icon is lighted.

Reset Working Hours

1. Enter the function “menu”.

2. Use o or nkeys to find on the lower display the C1Hr, C2Hr, PFHr or PCHr.

3. Push “SET” key for 3 seconds: the upper display shows “0” indicating the reset.

4. To exit the function menu push and release the “menu” key or wait the time-out.

The “menu” icon disappears.

How to Display the Delay Time Between Two Defrost

1. Enter the function “menu”.

2. Use o or n keys to find on the upper display the “dEF” label; the lower display

shows delay time between two defrost (minutes and seconds).

3. The icon is flashing.

4. To exit the function “menu” push and release the “menu” key or wait the time-out.

The “menu” icon disappears.

How to See the Alarm Log

1. Enter the function “menu”.

2. Use o or n keys to find “ALOG” label.

3. Push “SET” key: the lower display showsthe alarm code, the upper display shows

“n°” followed by the progressive number.

4. With oor n scroll the alarm list.

5. To exit from ALOG function push “menu” key or wait the time-out delay is

expired.

Memory capacity is 50 alarm structured in a FIFO list (first in first out). Each new alarm

will take the place of the oldest alarm contained in the list ( the read-out is ordered from

the oldest to the newest).

How to Reset the Alarm Log

1) Enter the function “menu”.

2) Use o or n keys to find “ALOG” label.

3) Push “SET” key.

4) Use oor n keys to find “ArSt” (Alarm reset) label on the lower display; the upper

display shows “PAS”.

5) Push “SET” key and then enter the password value using oor n keys; confirm the

value pushing “SET” key.

6) The ArSt label starts flashing for 5s, to confirm the alarm logging data is reset.

KEYBOARD FUNCTIONS

How to See the Set Point Value

Push and release the “SET” key.

Lower display shows: “SetC” set point chiller;

“SetH” set point heat pump.

The upper display shows the value.

Note:

SetH is available only if configured for Heat Pump.

How to Change the Set Point Value

1) Push and hold “SET” key (for about 3 seconds).

2) The setpoint value is flashing.

3) Use o and nto increase or decrease the new value.

4) Push and release “SET” key or wait the time-out to exit the programming.

How to See the real Set Point

When Energy Saving, Dynamic Set Point or Function For Units Without Water Storage

Tank are enabled is possible to see the real set point.

When the machine is running:

push “SET” key once: lower display shows “SetC” (setpoint chiller) or “SetH”

(setpoint heat pump) and upper display shows the value.

push “SET” key again:

- when “Energy Saving” is enabled the lower display shows “SEtS” (Energy

saving setpoint) and upper display shows the value.

- when “Dynamic Set” is enabled,the lower display shows “SEtd” (dynamic

set point) and upper display shows the value.

- when the function for units without water storage tank is enabled the lower

display shows “Setr” (real set point) and upper display showsits value.

- when two function above are both enabled, the lower display shows “Setr”

(real set point) and upper display shows its value.

REMOTE ON/OFF

If a digital input is configured as remote on/off, it is possible to switch on or switch off the

unit.

The remote ON/OFF:

It has priority over the keyboard

The unit can be switched on and off by keyboard only if the digital input set

the unit switched on

When the digital input is disabled the instrument returns to its condition prior

to activation

It is possible to navigate the functions menu

The upper display visualizes “OFF” and the decimal LED will be flashing.

HOW TO DISABLE A COMPRESSOR

A compressor can be disabled for maintenance; the unit continues to work normally but

only with one compressor.

How to disable a compressor:

1. Access to the programming parameters mode.

2. Set the parameter CO12 = 1 or CO13=1 (compressor 1 or 2 = OFF).

To enable the compressor set C011=0 or CO12= 0.

DYNAMIC SET POINT

This function is useful to save energy or to use the unit during particular external air

temperature condition.

The setpoint is changed according to the external temperature or 4..20mA trasducer.

The Dynamic Set point function is enabled:

- if Sd01 = 1 and CF06 = 3 (Pb3 probe is configured as 4..20mA signal for dynamic set

point), or;

- if Sd01 = 1 and CF07 = 3 (Pb4 probe is configured as outside air temperature).

ENERGY SAVING

It’s possible to change the setpointfor the Energy saving periods.

The activation can be:

weekly/daily; in this case is required a controller with RTC on board

by digital input configured as “Energy saving”

The setpoint during an Energy Saving period is:

Chiller: setpoint =SET+ES10 differential=ES11

Heat pump: setpoint =SET+ES12 differential=ES13

Daily Programming

It is necessary to set parameters ES03 ES09 to activate the Energy saving (one

parameter for each day of the week).

The value “1” enable the function for that day.

Eg: ES03 = 1 means that every Monday the Energy Saving is activated for all day.

Programmable timer (RTC is required)

It’s possible to activate the Energy Saving for a period of the day by setting the start time

end the end time.

ES01 Energy Saving start hour

ES02 Energy Saving stop hour

Eg: ES01 = 8.0 and ES02 = 10.0: Energy Saving is active from 8 to 10.0for all the days

of the week.

Eg: ES01 = 23.0 and ES02 = 8.0: Energy Saving is active from 23.0 to 8.0 of the next

morning for all the days of the week.

Energy Saving is disabled if the parameters ES01 / ES02 are both “0”.

Energy Saving by Digital Input

The function is enabled when a digital input, configured as Energy Saving, is activated

by remote contact.

DEFROST FUNCTION

The defrost cycle is enabled only if the following conditions are satisfied:

1. the unit is working in heat pump mode (heat pump enabled by parameter CF28)

2. the unit is air/air or air/water (CF01=0 or CF01=1)

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 6 di 20

3. dF01=1 defrost cycle enabled

4. one relay configured as reversing valve

5. Pb3 or Pb4 must be configured as condensing probe (without active faulty probe

alarms).

If only one of these conditions is not satisfied the defrost does not operate.

When the condensing temperature/pressure falls below dF03, starts the counting of time

dF10. When the counting ends, if the temperature/pressure is lower than dF03 the

defrost starts.

The compressor is switched off for dF08 and, after dF08/2, the the 4-ways reversing

valve is activated. When the counting of dF08 ends the compressor is switched on

(CO01 and CO02 are disabled during the defrost).

The defrost ends when the temperature/pressure is >dF04 or for maximun time dF07.

At the end of the defrost, the compressor is switched off for dF09 and, after dF09/2, the

the 4-ways reversing valve is deactivated.

When the counting of dF09 ends, the compressor is switched on.

Forced Defrost

This function is enabled if dF05 0 and allows to activate a defrost even if the interval

time between defrosts is running and the temperature/pressure value is lower than the

parameter dF19 for the dF05 time.

If during the time delay dF05 thetemperature/pressure becomes higher than dF19+dF20

value, the whole procedure is stopped and the time delay dF05 will be reloaded.

Combined Defrost

This function is enabled if CF07 = 5 and Pb4 is configured as NTC probe for combined

defrost (placed typically on the evaporator coil). The detected temperature allows to

calculate a better defrost cycle giving the start and the end commands for the cycle

itself.

Functioning:

when the temperature detected by Pb3 probe is lower than dF03, the time delay dF10

starts.

When the time dF10 is elapsed the controller check Pb4 value: if it is lower than dF11

the defrost procedure starts, otherwise the unit still works in Heat Pump.

When Pb4 value is higher than dF12 the combined defrost ends.

Manual Defrost

This function is enabled if:

at least one compressor is running

the condenser temperature/pressure is lower than dF03

if the “combined defrost” is enabled, Pb4 value must be lower than dF11

If the conditions above are satisfied, by pushing o + SET (before o, then SET) for more

than 5 sec. the defrost cycle immediately starts.

FUNCTION FOR UNITS WITHOUT WATER STORAGE TANK

This function manages the compressor(s) to optimize the production of refrigerated

water in units with low thermal loads.

The function analyses the compressor operating time (from regulation start-up to

shutdown request) and compares it with the time configured with parameter CO01

(minimum ON time); when the regulation temperature reach the set point and the

operation time is lower than CO01, the controller modifies the set point and the

differential to increase the compressor operating time.

If the compressor operates for longer than the minimum time (CO01), when ST15 time is

elapsed (this time starts when the CO01 is elapsed) the function progressively restores

the set point and hysteresis to the initial values (ST01 or ST03); in this case:

Heat pump: whenever the time ST15 expires, the function subtracts the ST13 value to

the setpoint and ST14 value to the hysteresis

Chiller: whenever the time ST15 expires, the function adds the ST13 value to the set

point and subtracs the ST14 value to the hysteresis.

When the unit is switched OFF (by digital input or by keyboard), the set point and

differential are restored to the initial values (ST01…ST04).

Below the formulas for calculating the new set point and hysteresis.

Heat pump:

Set point = set point heat pump + Par ST13 + (CO01 – compressor working time*) x

ST16 / 10

Differential = differential heat pump + Par.ST14 + (CO01 - actual time*) x Par ST16 / 10

Chiller:

Set point = set point cool – [Par ST13+ (CO01 - compressor working time *) x Par ST16/

10]

Differential = differential chiller + Par.ST14 + (CO01 - compressor working time *) x Par

ST16 /10

*Compressor working time is in sec x 10.

The function for units without water storage tank is compatible with Energy Saving

function or with the Dynamic set point.

Visualization of the set point on the display:

Chiller with energy saving or dynamic set point enabled:

push “SET” button once = SetC (set point value from parameter)

push “SET” button twice = Sets or Setd (real operating set point value)

Chiller with energy saving or dynamic set point and function for machine without water

storage tank enabled:

push “SET” button once = SetC (set point value from parameter)

push “SET” button twice = Setr (real operating set point value)

Heat pump with energy saving or dynamic set point enabled:

push “SET” button once = SetH (set point value from parameter)

push “SET” button twice = Sets or Setd (real operating set point value)

Heat Pump with energy saving or dynamic set point and function for machine without

water storage tank enabled:

push “SET” button once = SetH (set point value from parameter)

push “SET” button twice = Setr (real operating set point value)

When the function for units without water storage tank is enabled, the protection for high

temperature o low temperature is active; the compressor/s will be switched off if:

Chiller: outlet evaporator temperature < ST11

Heat pump: outlet evaporator temperature > ST12

GEOTHERMAL CHILLER FUNCTION

This function, to work, requires the Ichill remote keyboad with internal probe to detect the

room temperature; the function is enabled if the parameter CF03=2.

The unit works according to Pb2 probe and the set point ST01 and ST03.

During the regulation, the compressor/s status (only compresor/s status) depend on the

room temperature and the user set point configured with parameters ST18 and ST22.

When the room temperature reach the user set point, the compressor/s are switched off;

in this case the other loads status (pump, fan, etc.) doesn’t depend from compressor

status (they work normally).

Manufacturer set point

The unit works on the manufacturer set point:

set point chiller ST01, differential chiller ST02;

set point Heat pump ST03, differential Heat pump ST04.

User set point

To visualize the room set point press the “SET” button on the remote keyboard or on the

controller.

To change the room set point press and hold the “SET” button: the set point value is

displayed flashing on upper display. To change its value press oor n keys and confirm

with “SET”.

Dynamic set point

The dynamic set point function, if enabled (Sd01=1), works normally (probe PB4) and

modify ST01 / ST03 set point. SEtd dynamic set point is displayed in the functions menu.

Energy saving

The Energy saving function,if enabled by clock or digital input, modify the room set point

(ST18 / ST22).

UNLOADING FUNCTION

High temperature inlet evaporator

The function allows the machine to operate in case of high evaporator inlet temperature

(to avoid possible high pressure intervention).

When the evaporator inlet temperature is greater than CO17 set point for a time of

CO19, a compressor (if two compressors are working) or the capacity control (in case of

one compressor with capacity step) is switched off.

When only one compressor is working or only the capacity step is active, the function

has not effect on the regulation.

When the function is activated the lower display shows “AEUn” label alternated to

default visualization.

The function is disabled if the evaporator inlet temperature is lower than CO17 set point

– CO18 differential.

Note

When the unloading function is active, to avoid a prolonged working time in this

condition, if the evaporator inlet temperature is lower than CO17 set point and higher

than CO17 – CO18 for a time of CO20, the function is disabled.

CO20 delay time starts when the evaporator inlet temperature is lower than CO17 set

point.

High pressure in chiller mode

The function allows the machine to operate incase of high outside temperature (start-up

in summer with hot external temperature), to avoid possible high pressure alarm.

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 7 di 20

Pb3 probe has to be configured to use a pressure transducer.

When the evaporator condenser pressure is greater than CO21 set point, a compressor

(if two compressors are working) or the capacity control (in case of one compressor with

capacity step) is switched off.

When only one compressor is working or only the capacity step is active, the function

has not effect on the regulation.

The lower display shows “ACUn” alternated to default visualization.

When the evaporator condenser pressure falls below CO21 – CO22, the function is

disabled and, if required for the regulation, the previously shut down

compressor/capacity step can be re-inserted.

Note

When the unloading function is active, to avoid a prolonged working time in this

condition, if the evaporator condenser pressure is lower than CO21 set point and higher

than CO21 – CO22 for a time of CO25, the function is disabled.

CO25 delay time starts when the evaporator condenser pressure is lower than CO21 set

point.

Low pressure in heat pump mode

The function allows the machine to operate in case of low outside temperature (start-up

in winter with ice-covered batteries), to avoid possible low pressure alarm.

Pb3 probe has to be configured to use a pressure transducer.

When the evaporator condenser pressure is lower than CO23 set point, a compressor

(if two compressors are working) or the capacity control (in case of one compressor with

capacity step) is switched off.

When only one compressor is working or only a capacity step is active, the function has

not effect on the regulation.

The lower display shows “ACUn” alternated to default visualization.

When the evaporator condenser pressure is greater than CO23 + CO24, the function is

disabled and, if required for the regulation, the previously shut down

compressor/capacity step can be re-inserted.

Note

When the unloading function is active, to avoid a prolonged working time in this

condition, if the evaporator pressure is higher than CO23 set point and lower than CO23

+ CO24 for a time of CO25, the function is disabled.

CO25 delay time starts when the evaporator pressure is higher than CO23 set point.

BOILER FUNCTION

The boiler function can be used for heating (Ar20=1) or for support the heating function

(Ar20=0).

To enable the function is necessary:

unit configured in Heat Pump mode

Pb4 configured as external air probe (CF07=3)

Heating Integration Control Ar20=0

Anti-freeze/support heater 1:

Heather ON if:

outside air temperature < Ar21 for more than Ar23 time

regulation probe < Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

Ar23 delay time starts when outside temperature falls below Ar21 set point.

If outside temperature exceeds the Ar21 + Ar22 when the counting of Ar23 is running,

the boiler function is not enabled and the Ar23 time is re-loaded.

Heather OFF if:

outside air temperature > Ar21 + Ar22

regulation probe > Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

If outside air temperature falls below the Ar25 set point the compressors are switched

off; when outside air temperature is higher than Ar25 set point + the Ar26 differential the

compressors are switched on.

Anti-freeze/support heater 2:

Heather ON if:

outside air temperature < Ar21 for more than Ar23 + Ar24 time

regulation probe < Heating set point– (ST04 / 2) or real Heating set point – (ST04/ 2)

(if Energy saving or Dynamic set point or function for units without water storage tank

are enabled)

Ar23 delay time starts when outside temperature falls below Ar21 set point.

Ar24 delay time starts when Ar23 is elapsed.

If the outside temperature exceeds Ar21 + Ar22 when the counting of Ar23 is running,

the boiler function is not enabled and the Ar23 time is re-loaded.

Heather OFF if:

outside air temperature > Ar21 + Ar22

regulation probe > Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

If the outside air temperature falls below the Ar25 set point the compressors are

switched off; when outside air temperature is higher than Ar25 set point + the Ar26

differential, the compressors are switched on.

Heating Control Ar20=1

Anti-freeze/support heater 1:

Heather ON if:

outside air temperature < Ar21 for more than Ar23 time

regulation probe < Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

Ar23 delay time starts when outside temperature falls below Ar21 set point.

When the heather is switched on, the compressor and condenser fans are switched off.

If the outside temperature exceeds Ar21 + Ar22 when the counting of Ar23 is running,

the boiler function is not enabled and the Ar23 time is re-loaded

Heather OFF if:

outside air temperature > Ar21 + Ar22

regulation probe > Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

If the outside air temperature exceeds the Ar21 + Ar22 the heater is switched off and the

compressor and fans are switched on (if the heat regulator calls for it).

Anti-freeze/support heater 2:

Heather ON if:

outside air temperature < Ar21 for more than Ar23 + Ar24 time

regulation probe < Heating set point– (ST04 / 2) or real Heating set poinf – (ST04/ 2)

(if Energy saving or Dynamic set point or function for units without water storage tank

are enabled)

Ar23 delay time starts when outside temperature falls below Ar21 set point.

Ar24 delay time starts when Ar23 is elapsed.

If the outside temperature exceeds Ar21 + Ar22 when the counting of Ar23 is running,

the boiler function is not enabled and the Ar23 time is re-loaded.

Heather OFF if:

outside air temperature > Ar21 + Ar22

regulation probe > Heating set point or real Heating set poinf (if Energy saving or

Dynamic set point or function for units without water storage tank are enabled)

MAINTENANCE FUNCTION

The maintenance warning is activated if the compressor 1, compressor 2, evaporator

water pump / supply fan (air/air unit), condenser water pump have worked for a time set

by parameter (CO14, CO15, CO16 and CO28).

The maintenance alarm code are:

A13=comp.1, A14=comp.2, A15=water pump or supply fan, A20=condenser pump.

The maintenance warning is only a visual signaling and does not influence the

regulation.

To reset the warning is necessary to set the operating hours at zero value in the menù

function.

BLACK OUT

After a black-out:

1. the controller restarts from the pervious status.

2. The defrost cycle is stopped.

3. All the working time delay will be reloaded.

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 8 di 20

ALARM CODE AND EVENTS

Cod Meaning

P1 Pb1 probe alarm

P2 Pb2 probe alarm

P3 Pb3 probe alarm

P4 Pb4 probe alarm

A01 High pressure switch alarm

A02 Low pressure switch alarm

A03 Low temperature alarm of the supplied temperature

A04 Low temperature alarm of the outlet air from evaporator.

A05 High temperature High pressure

A06 Low temperature Low pressure

A07 Anti freeze alarm

A07 Anti freeze alarm motocondensing unit

A08 Evaporator water flow alarm (air/water or water/water units)

A09 Compressor 1 thermal protection alarm

A10 Compressor 2 thermal protection alarm

A11 Condenser fan thermal protection alarm

A12 Defrost error alarm

A13 Compressor 1 maintenance warning

A14 Compressor 2 maintenance warning

A15 Water pump or supply air fan (air/air) maintenance warning

A16 High temperature evaporator inlet water

A17 Thermal protection alarm for evaporator water pump / supply fan

A18 Thermal protection alarm for condenser water pump

A19 Condenser water flow alarm

A20 Condenser water pump maintenance alarm

rtC Clock alarm

rtF Clock alarm

EE EEPROM error alarm

ACF1 Configuration alarm

ACF2 Configuration alarm

ACF3 Configuration alarm

ACF4 Configuration alarm

ACF5 Configuration alarm

FErr Functioning alarm

AFr Frequency alarm

ALOC

General alarm for machine block

bLOC General alarm, signal only

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 9 di 20

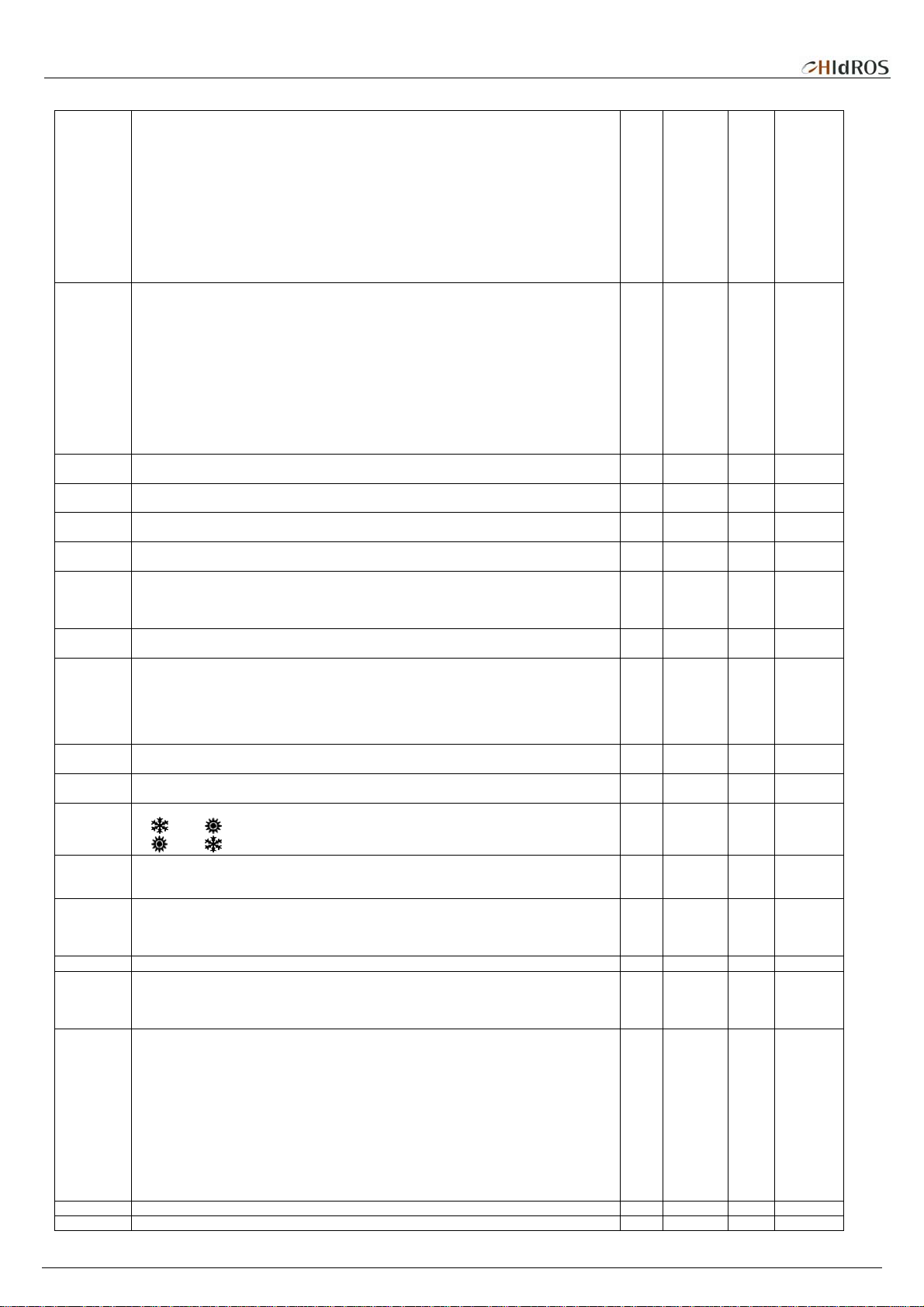

PARAMETER TABLE

SUB MENU SELECTIONS

LABEL Meaning

ALL Shows the whole set of parameters

ST It contains only the regulation parameters

CF It contains only the configuration parameters

SD It contains only the dynamic Set point parameters

ES It contains only the Energy Saving parameters

CO It contains only the compressor parameters

FA It contains only the fan regulation parameters

Ar It contains only the anti freeze parameters

DF It contains only the defrost parameters

AL It contains only the alarm parameters

Regulation Parameters

Paramete

r

Description Min

Max Meas. Resolution

ST01 Summer Set point ST05 ST06 °C/°F Decimal

integer

ST02 Summer differential 0.0

0 25.0

45 °C

°F Decimal

integer

ST03 Winter Set point ST07 ST08 °C/°F Decimal

integer

ST04 Winter differential 0.0

0 25.0

45 °C

°F Decimal

integer

ST05 Minimum set point limit for ST01 (summer) -50.0

-58 ST01 °C

°F Decimal

integer

ST06 Maximum set point limit for ST01 (summer) ST01 110

230 °C

°F Decimal

integer

ST07 Minimum set point limit for ST03 (winter) -50.0

-58 ST03 °C

°F Decimal

integer

ST08 Maximum set point limit for ST03 (winter) ST03 110

230 °C

°F Decimal

integer

ST09 Regulation band 0.0

0 25.0

45 °C

°F Decimal

integer

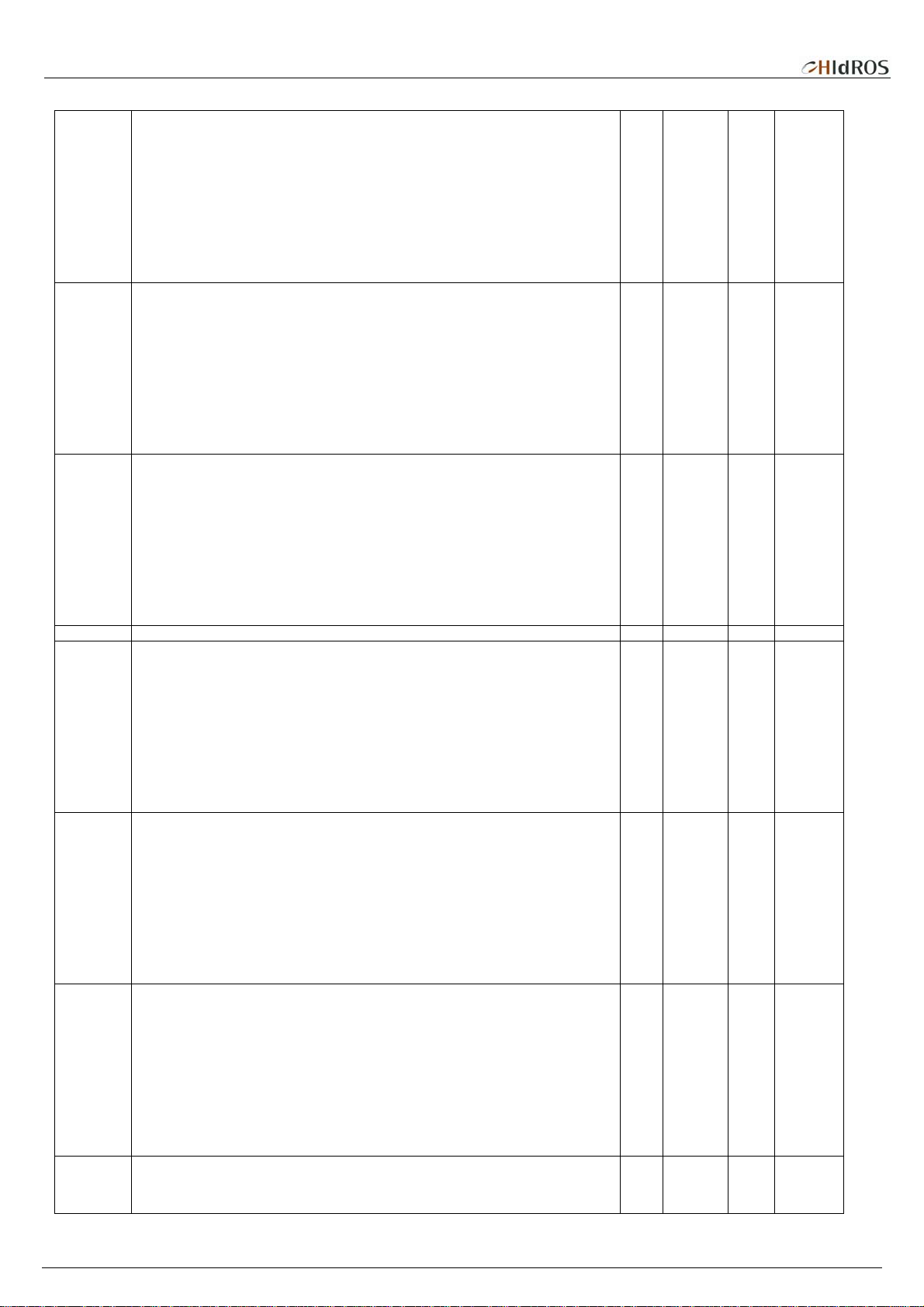

Function for units without water storage tank

Paramete

r

Description Min

Max Meas. Resolution

ST10 Chiller unit without water storage tank

0= function disabled

1= function activated

0

1

ST11 Minimum temperature Set point for outlet water in chiller mode (unit without water storage

tank) -50.0

-58 110

230 °C

°F Dec

int

ST12 Maximum temperature Set point for outlet water in HP function (unit without water storage

tank) -50.0

-58 110

230 °C

°F Dec

int

ST13 Differential set point for chiller / heat pump function

0.0

0 25.0

45 °C

°F Dec

int

ST14 Offset of the differential for chiller / HP function

0.0

0 25.0

45 °C

°F Dec

int

ST15 Compressor operation time above which the delta set point and delta differential for chiller /

HP function is decreased 0

250 Sec 10 sec

ST16 Constant for calculationg the set point value and differential for chiller/HP function

0

250

ST17 Delay for changing the operating set point 1

250 Sec 10 sec

Geothermal chiller function

Paramete

r

Description Min

Max Meas. Resolution

ST18 Room set point in chiller function ST20

ST21 °C/°F dec/int

ST19 Room differential in chiller function 0.0

0 25.0

45 °C

°F Dec

int

ST20 Minimum value of the room set point in chiller function

-50.0

-58 ST18 °C

°F Dec

int

ST21 Maximum value of the room set point in chiller function

ST18 110

230 °C

°F Dec

int

ST22 Room set point in heat pump function ST24

ST25 °C/°F dec/int

ST23 Room differential in heat pump function 0.0

0 25.0

45 °C

°F Dec

int

ST24 Minimum value of the room set point in heat pump function

-50.0

-58 ST22 °C

°F Dec

int

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 10 di 20

ST25 Maximum value of the room set point in heat pump function

ST22 110

230 °C

°F Dec

int

Pr2 Password 0 999

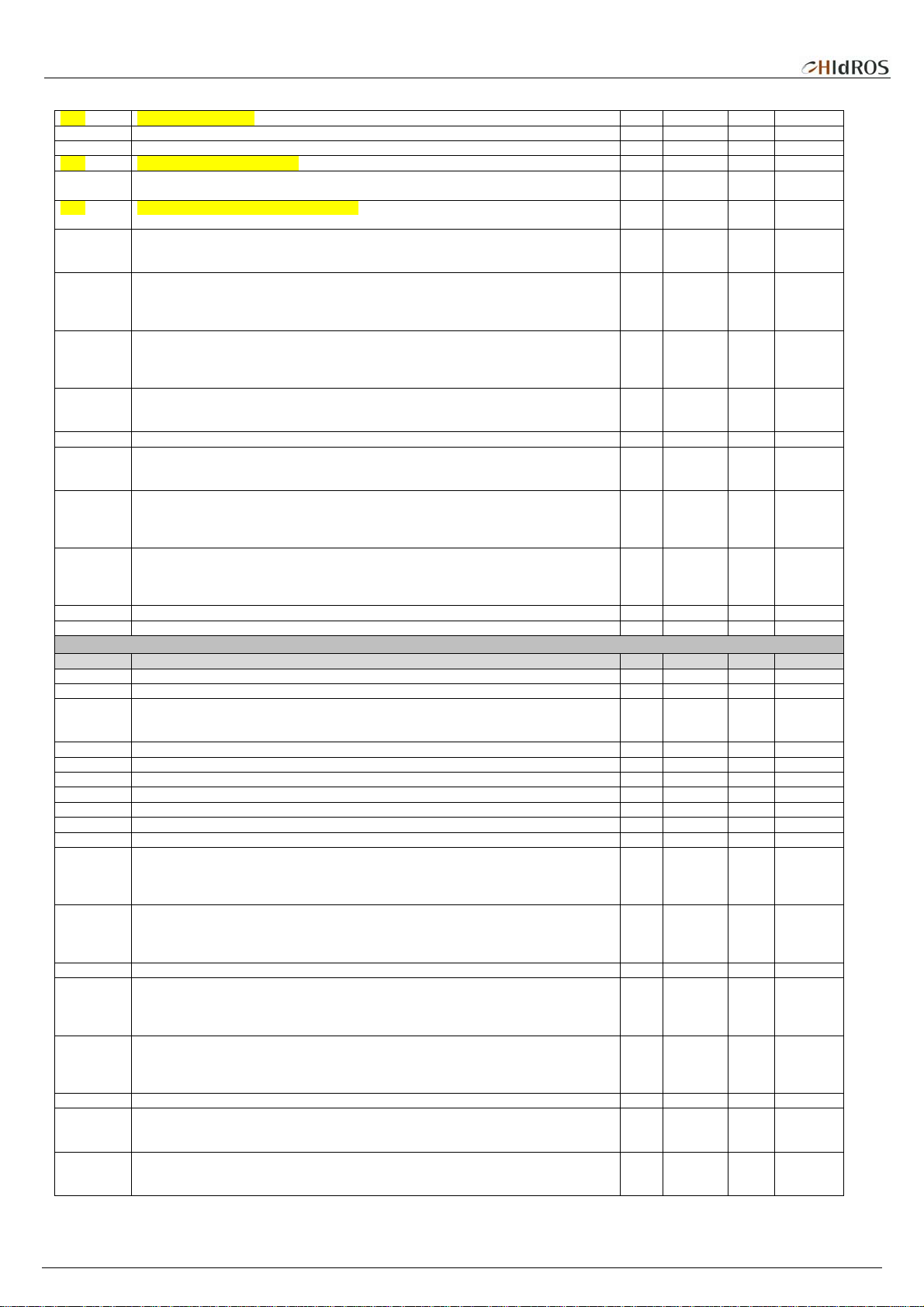

Configuration Parameters

Paramete

r

Description Min

Max Meas. Resolution

CF01 Unit model:

0= Chiller air / air

1= Chiller air / water

2= Chiller water / water

3= Chiller water / water with reversal on water circuit

0

3

CF02 Motocondensing unit

0= No

1= Yes

0

1

CF03 Regulation probe

0= Pb1 regulation

1= Pb2 regulation

2= PB2 regulation and compressors activation with user set on PB1 probe

0

2

CF04 Pb1 configuration

0= Probe not enabled

1= NTC temperature of evaporator inlet

2= Digital input for temperature regulation demand

3= Digital input cooling demand

0

3

CF05 Pb2 configuration

0= Probe not enabled

1= NTC temperature of evaporator outlet

2= Digital Input for antifreeze alarm

3= Digital input for heating demand

4= External air temperature

0

4

CF06 Pb3 configuration

0= Probe not enabled

1= NTC temperature condensing control

2= 4..20mA for condensing pressure

3= 4..20ma for Dynamic Set point

4= NTC temperature for anti freeze alarm (water/water)

5= NTC high temperature probe of system inlet water

6= 0..5V for condensing pressure

0

6

CF07 Pb4 configuration

0= Probe not enabled

1= NTC condensing control

2= Multifunction digital input

3= External air temperature

4= NTC temperature for anti freeze alarm (water/water)

5= NTC temperature for combined defrost

6= NTC temperature for logging

6= NTC condenser outlet temperature (water/water units whith reversal on water circuit)

7= NTC high temperature probe of system inletwater

0

7

CF08 ID1 configuration

0= 1st compressor thermal protection

1= Condenser fan thermal protection

2= Evaporator flow switch alarm

3= Remote On/off

4= Remote Cooling/Heating

5= 2nd compressor thermal protection

6= 2nd compressor or step request (Motocondensing unit)

7= End defrost

8= Energy Saving

9= Anti Freeze alarm

10= 1st and 2nd compressor thermal protection

11= General alarm (unit shutdown)

12= Evaporator water pump thermal protection alarm/ supply fan thermal protection alarm

13= Condenser water pump thermal protection alarm

14= Condenser flow switch alarm

15= not used

0

15

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 11 di 20

CF09 ID2 configuration

0= 1st compressor thermal protection

1= Condenser fan thermal protection

2= Evaporator flow switch alarm

3= Remote On/off

4= Cooling/Heating

5= 2nd compressor thermal protection

6= 2nd compressor or step request (Motocondensing unit)

7= End defrost

8= Energy Saving

9= Anti Freeze alarm

10= 1st and 2nd compressor thermal protection

11= General alarm for total unit shutdown

12= Evaporator water pump thermal protection alarm/ supply fan thermal protection alarm

13= Condenser water pump thermal protection alarm

14= Condenser flow switch alarm

15= not used

0

15

CF10 ID5 configuration

0= 1st compressor thermal protection

1= Condenser fan thermal protection

2= Evaporator flow switch alarm

3= Remote On/off

4= Cooling/Heating

5= 2nd compressor thermal protection

6= 2nd compressor or step request (Motocondensing unit)

7= End defrost

8= Energy Saving

9= Anti Freeze alarm

10= 1st and 2nd compressor thermal protection

11= General alarm for total unit shutdown

12= Evaporator water pump thermal protection alarm/ supply fan thermal protection alarm

13= Condenser water pump thermal protection alarm

14= Condenser flow switch alarm

15= not used

0

15

CF11 Pb4 configuration in digital input mode

0= 1st compressor thermal protection

1= Condenser fan thermal protection

2= Evaporator flow switch alarm

3= Remote On/off

4= Cooling/Heating

5= 2nd compressor thermal protection

6= 2nd compressor or step request (Motocondensing unit)

7= End defrost

8= Energy Saving

9= Anti Freeze alarm

10= 1st and 2nd compressor thermal protection

11= General alarm for total unit shutdown

12= Evaporator water pump thermal protection alarm/ supply fan thermal protection alarm

13= Condenser water pump thermal protection alarm

14= Condenser flow switch alarm

15= not used

0

15

CF12 ID1 input polarity

0= active for closed contact

1= active for open contact

0

1

CF13 ID2 input polarity

0= active for closed contact

1= active for open contact

0

1

CF14 ID3 input polarity

0= active for closed contact

1= active for open contact

0

1

CF15 ID4 input polarity

0= active for closed contact

1= active for open contact

0

1

CF16 ID5 input polarity

0= active for closed contact

1= active for open contact

0

1

CF17 Pb1 input polarity

0= active for closed contact

1= active for open contact

0

1

CF18 Pb2 input polarity

0= active for closed contact

1= active for open contact

0

1

CF19 Pb4 input polarity

0= active for closed contact

1= active for open contact

0

1

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 12 di 20

CF20 RL4 configuration of the relay 4

0 = Alarm relay

1 = compressor 1 capacity step

2 = compressor 2

3 = ON/OFF ventilation

4 = reversing valve

5 = anti-freezer heaters / integration heater n.1

6 = solenoid valve on water circuit

7 = solenoid valve on water circuit only for heat pump

8= anti-freezer heaters / integration heater n. 2

9 = evaporator water pump / supply fan (air / air unit)

10= condenser water pump

0

10

CF21 RL5 configuration of the relay 5

0 = Alarm relay

1 = compressor 1 capacity step

2 = compressor 2

3 = ON/OFF ventilation

4 = reversing valve

5 = anti-freezer heaters / integration heater n.1

6 = solenoid valve on water circuit

7 = solenoid valve on water circuit only for heat pump

8= anti-freezer heaters / integration heater n. 2

9 = evaporator water pump / supply fan (air / air unit)

10= condenser water pump

0

10

CF22 4mA / 0,5V corresponding to the pressure value of the transducer

0.0

0 50.0

725 Bar

Psi Decimal

integer

CF23 20mA / 5V corresponding to the pressure value of the transducer

0.0

0 50.0

725 Bar

Psi Decimal

integer

CF24 Pb1 Offset -12.0

-21 12.0

21 °C

°F Decimal

integer

CF25 Pb2 Offset -12.0

-21 12.0

21 °C

°F Decimal

integer

CF26 Pb3 Offset -12.0

-21

-12.0

-174

12.0

21

12.0

174

°C

°F

Bar

Psi

Decimal

Integer

Decimal

integer

CF27 Pb4 Offset -12.0

-21 12.0

21 °C

°F Decimal

integer

CF28 Chiller or Heat Pump configuration

0= chiller and heat pump selected by keyboard

1= chiller and heat pump selected by digital input

2= chiller and heat pump selected by probe

3= only chiller unit

4= only heat pump unit

0

4

CF29

A

utomatic Changeover Setpoint

-50.0

-58 110

230 °C

°F Decimal

integer

CF30 Differential for functioning mode

0.1

0 25.0

45 °C

°F Decimal

integer

CF31 Chiller or Heat pump key configuration

0= chiller / heat pump

1= chiller / heat pump

0

1

CF32 Celsius or Fahrenheit selection

0= °C / °BAR

1= °F / °psi

0

1

CF33 Power supply frequency

0= 50 Hz

1= 60 Hz

2 = DC power supply (PWM configrured as output for an external alarm relay)

0

2

CF34 Serial Address for monitoring 1

247

CF35 Remote terminal keyboard

0= Not used

1= 6 keys

2= 6 keys with NTC probe mounted on board

0

2

CF36 Default viewing of upper display

of the controller

0 = PB1 visualization

1 = PB2 visualization

2 = No visualization

3 = PB4 visualization

4 = Real working set point (set point modified from Energy Saving, Dynamic set point, function for units

without water storage tank)

5 = Unit status

6 = No visualization

7 = No visualization

8 = Working differential

9 = Unit set point (parameter value)

0

8

CF37 Firmware Release

CF38 Eeprom

–

Parameter mapping

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 13 di 20

CF39 RL2 configuration

0 = Alarm relay

1 = compressor 1 capacity step

2 = compressor 2

3 = ON/OFF ventilation

4 = reversing valve

5 = anti-freezer heaters / integration heater n.1

6 = solenoid valve on water circuit

7 = solenoid valve on water circuit only for heat pump

8= anti-freezer heaters / integration heater n. 2

9 = evaporator water pump / supply fan (air / air unit)

10= condenser water pump

0

10

CF40 RL3 configuration

0 = Alarm relay

1 = compressor 1 capacity step

2 = compressor 2

3 = ON/OFF ventilation

4 = reversing valve

5 = anti-freezer heaters / integration heater n.1

6 = solenoid valve on water circuit

7 = solenoid valve on water circuit only for heat pump

8= anti-freezer heaters / integration heater n. 2

9 = evaporator water pump / supply fan (air / air unit)

10= condenser water pump

0

10

CF41 Open collector output configuration

0 = Alarm relay

1 = compressor 1 capacity step

2 = compressor 2

3 = ON/OFF ventilation

4 = reversing valve

5 = anti-freezer heaters / integration heater n.1

6 = solenoid valve on water circuit

7 = solenoid valve on water circuit only for heat pump

8= anti-freezer heaters / integration heater n. 2

9 = evaporator water pump / supply fan (air / air unit)

10= condenser water pump

0

10

CF42 Switching time of reversing valve when the compressor is switched off

0

250

CF43 Default viewing of lower display of the controller

0 = PB1 visualization

1 = PB2 visualization

2 = PB3 visualization

3 = PB4 visualization

4 = Real working set point (set point modified from Energy Saving, Dynamic set point, function for units

without water storage tank)

5 = Unit status

6 = Clock

7 = No visualization

8 = Woking differential

9 = Unit set point (parameter value)

0

8

CF44 Default viewing of upper display of the remote keyboard

0 = PB1 visualization

1 = PB2 visualization

2 = no visualization (display off)

3 = PB4 visualization

4 = Real working set point (set point modified from Energy Saving, Dynamic set point, function for units

without water storage tank)

5 = Unit status

6 = No visualization (display off)

7 = No visualization (display off)

8 = Woking differential

9 = Unit set point (parameter value)

0

8

CF45 Default viewing of lower display of the remote keyboard

0 = PB1 visualization

1 = PB2 visualization

2 = PB3 visualization

3 = PB4 visualization

4 = Real working set point (set point modified from Energy Saving, Dynamic set point, function for units

without water storage tank)

5 = Unit status

6 = Clock

7 = No visualization

8 = Woking differential

9 = Unit set point (parameter value)

0

8

CF46 Controller: visualization in Std-by mode

0 = default visualization (CF36 and CF43 parameters)

1 = the display visualizes “OFF”

2 = the display visualizes “StbY”

0

2

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 14 di 20

CF47 Remote keyboard: visualization in Std-by mode

0 = default visualization (CF36 and CF43 parameters)

1 = the display visualizes “OFF”

2 = the display visualizes “StbY”

0

2

CF48

A

nalog output configuration

0 = 4..20mA

1 = 0..10V

0

1

Pr2 Password value 0

999

Dynamic Setpoint

Paramete

r

Description Min

Max Meas Resolution

Sd01 Dynamic Setpoint

0= Not enabled

1= Enabled

0

1

Sd02 Maximum summer dynamic Offset -

30.0

-54 30.0

54 °C

°F Decimal

integer

Sd03 Maximum winter dynamic Offset

-

30.0

-54 30.0

54 °C

°F Decimal

integer

Sd04 External air d. setpoint during summer -50.0

-58 110

230 °C

°F Decimal

integer

Sd05 External air d. setpoint during winter -50.0

-58 110

230 °C

°F Decimal

integer

Sd06 External air differential during summer -

30.0

-54 30.0

54 °C

°F Decimal

integer

Sd07 External air differential during winter -

30.0

-54 30.0

54 °C

°F Decimal

integer

Pr2 Password value 0

999

Energy Saving

Paramete

r

Description Min

Max Meas Resolution

ES01 Energy saving starting hour (0÷24) 0

23.50 Min 10 Min

ES02 Energy saving ending hour (0÷24) 0

23.50 Min 10 Min

ES03…ES09 Monday…Sunday

0 = Not enabled

1= Enabled

0

1

ES10 Energy saving setpoint offset in chiller -30.0

-54 30.0

54 °C

°F Decimal

integer

ES11 Energy saving differential in chiller 0.1

0 25.0

45 °C

°F Decimal

integer

ES12 Energy saving setpoint offset in heatpump -30.0

-54 30.0

54 °C

°F Decimal

integer

ES13 Energy saving differential in heat pump 0.1

0 25.0

45 °C

°F Decimal

integer

Pr2 Password value 0

999

Compressor parameters

Paramete

r

Description Min

Max Meas. Resolution

CO01 Minimum ON time 0

250 Sec 10Sec

CO02 Minimum OFF time 0

250 Sec 10Sec

CO03 ON delay time between two compressors or Comp. and valve

1

250 Sec

CO04 OFF delay time between two compressors or Comp. and valve

0

250 Sec

CO05 Output time delay after power supply start-up 0

250 Sec

10Sec

CO06 Compressor On delay time after Pump/”Supply fan” activation

1

250 Sec

CO07 Compressor OFF delay time after Pump/”Supply fan” de-activation

0

250 Sec

CO08 Compressor rotating control

0= Enabled

1= Fixed sequence

0

1

CO09 Time delay for solenoid valve of water side 0

250 Sec

CO10 Stage vale polarity

0= Capacity stage ON

1= Capacity stage OFF

0

1

CO11 Water pump / Supply fan operating mode

0= Not used

1= Always on (ON/OFF output)

2= ON if the compressor is on (ON/OFF output)

3= Always on (420mA output)

4= ON if compressor is ON (420mA output)

0

4

CO12 Compressor 1

0 = Enabled

1 = OFF

0

1

CO13 Compressor 2 / Stage valve.

0 = Enabled

1= OFF

0

1

CO14 Hour counter setpoint for 1st compressor 0

999 Hr 10 Hr

CO15 Hour counter setpoint for 2nd compressor 0

999 Hr 10 Hr

CO16 Hour counter setpoint for pump/”Supply fan” 0

999 Hr 10 Hr

Unloading evaporato

r

CO17 Unloading set point (evaporator side) -50.0

-58 110

230 °C

°F Dec

int

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 15 di 20

CO18 Unloading Differential (evaporator side)

0.1

0 25.0

45 °C

°F Dec

int

CO19 Delay unloading function (evaporator side) 0

250 Sec 10 Sec

CO20 Maximum unloading operation time in case of high evaporator temperature

0

250 Sec 10 Sec

Unloading condense

r

CO21 Unloading pressure set point in chiller mode (condenser side)

0.0

0 50.0

725 Bar

Psi Dec

int

CO22 Unloading pressure differential in chiller mode (condenser side)

0.0

0 12.0

174 Bar

Psi Dec

int

CO23 Unloading pressure set point in heat pump mode (condenser side)

0.0

0 50.0

725 Bar

Psi Dec

int

CO24 Unloading pressure differential in heat pump mode (condenser side)

0.0

0 12.0

174 Bar

Psi Dec

int

CO25 Maximum unloading operation time in condenser side 0

250 Sec

10 Sec

Water pump condense

r

CO26 Condenser water pump operating mode

0= Not used

1= Continuous opeartion

2= Only for compressor demand

0

2

CO27 Delay between condenser pump shutdown and compressor shutdown

0

250 Sec

CO28 SET hour counter of water condenser pump 0

999 Hr 10 Hr

Compressors in tandem mode

CO29 Maximum continuous operating time of a compressor 0

250 Min

CO30 Compressor start-up delay after activation of the water solenoid valve

0

250 sec 10 Sec

Modulating evaporator water pump

CO31 Peak time of modulating pump at maximum speed required by regulation

0

250 sec

CO32 Minimum speed % of modulating pump in operation with enabled compressor (Chiller)

30

100 %

CO33 Minimum speed % of modulating pump in operation with enabled compressor (Heat Pump)

30

100 %

CO34 Speed % of modulating pump in operation with enabled compressor

30

100 %

CO35 Set point modulating pump in chiller mode (evaporator outlet temperature)

-50.0

-58 110

230 °C

°F Dec

int

CO36 Temperature control band for the modulating pump in chiller function

0.0

0 25.0

45 °C

°F Dec

int

CO37 Delay for switching off compressor by heat regulation with water pump < 100 % in chiller function

0

250 sec

CO38 Set point modulating pump in heat pump mode (evaporator outlet temperature)

-50.0

-58 110

230 °C

°F Dec

int

CO39 Temperature control band for the modulating pump in heat pump function

0.0

0 25.0

45 °C

°F Dec

int

CO40 Delay for switching off compressor by regulation with water pump < 100 % in HP function

0

250 sec

Pr2 Password 0

999

Condenser Fan control paramete

r

Paramete

r

Description Min

Max Meas. Resolution

FA01 Fan output

0= Not enabled

1= Enabled

0

1

FA02 Fan regulation

0= On when compressor On

1= ON / OFF

2= Proportional speed control

0

2

FA03 Fan related to compressor

0= With compressor

1= Independent from compressor

0

1

FA04 Maximum speed time when the fan starting 0

250 Sec

FA05 Phase difference fan 0

20 Micro

Sec 250

s

FA06 Not used

FA07 Cooling pre-ventilation before ON compressor 0

250 Sec

FA08 Minimum fan speed in summer

30

100 %

FA09 Maximum fan speed in summer

30

100 %

FA10 Temperature / pressure setpoint for minimum speed in summer

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA11 Temperature / pressure setpoint for maximum speed in summer

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 16 di 20

FA12 Proportional band in summer 0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

Integer

FA13 CUT-OFF differential in summer

0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA14 Override CUT-OFF in summer

0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA15 Delay time for CUT-OFF 0

250 Sec

FA16 Fan speed in summer night function 30

100 %

FA17 Minimum fan speed in winter 30

100 %

FA18 Maximum fan speed in winter 30

100 %

FA19 Temperature / pressure setpoint for minimum speed in winter

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA20 Temperature / pressure setpoint for maximum speed in winter

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA21 Proportional band in winter 0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA22 CUT-OFF differential in winter

0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA23 Override CUT-OFF in winter 0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

FA24 Fan speed in winter night function 30

100 %

Hot Start Function

Paramete

r

Description Min

Max Meas. Resolution

FA25 Hot Start Setpoint -50.0

-58 110

230 °C

°F Decimal

integer

FA26 Hot Start differential 0.1

0 25.0

45 °C

°F Decimal

integer

Pr2 Password 0

999

Anti-freeze / Heater parameters

Paramete

r

Description Min

Max Meas. Resolution

Ar01 Minimum value of Anti-Freeze Setpoint -50.0

-58 Ar03 °C

°F Decimal

integer

Ar02 Maximum value of Anti-Freeze Setpoint Ar03 110

230 °C

°F Decimal

integer

Ar03

A

nti-freeze Setpoint in chiller mode

A

r01

A

r02 °C/°F Dec/int

Ar04

A

nti-Freeze Differential in chiller mode 0

0 25.0

45 °C

°F Decimal

integer

Ar05

A

nti-Freeze alarm delay 0

250 Sec

Ar06 Maximum number of Anti-Freeze alarm events in 1 hour

0

16

Ar07

A

nti-Freeze alarm delay after starting in Heat Pump 0

250 Sec

Ar08

A

nti-Freeze Setpoint of the electrical heater in Chiller mode

-50.0

-58 110

230 °C

°F Decimal

integer

Ar09

A

nti-Freeze Setpoint of the electrical heater in Heat Pump mode

-50.0

-58 110

230 °C

°F Decimal

integer

Ar10

A

nti-Freeze Setpoint of external electrical heater (water/water units)

-50.0

-58 110

230 °C

°F Decimal

integer

Ar11

A

nti-Freeze Differential in Chiller

0.1

0 25.0

45 °C

°F Decimal

integer

Ar12

A

nti-Freeze Differential in Heat Pump 0.1

0 25.0

45 °C

°F Decimal

integer

Ar13

A

nti-freeze electrical heater regulation

0= enabled during regulation control

1= enabled active during regulation an defrost

0

1

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 17 di 20

Ar14

A

nti-freeze electrical heater regulation in Chiller mode

0= OFF in chiller

1= ON in chiller

0

1

Ar15

A

nti-freeze electrical heater regulation in H.P. mode

0= OFF in Heat Pump

1= ON in Heat Pump

0

1

Ar16

A

nti-freeze control probe in Chiller mode

0= Pb1

1= Pb2

2= PB3 probe control

3= PB4 probe control

0

3

Ar17

A

nti-freeze control probe in Heat Pump mode

0= Pb1

1= Pb2

2= PB3 probe control

3= PB4 probe control

0

3

Ar18 “Water pump”/ “Anti-freeze electrical heater” control with unit in OFF or Stand-by

0= Regulation not enabled

1= Regulation enabled

2= Regulation of water pump/anti-freezer on probe PB4 configured as esternal temperature probe

3= Regulation of water pump / anti-freezer heaters on probe PB4 and separate set points

0

3

Ar19 “Water pump”/ “Anti-freeze electrical heater” control for faulty probe

0= output OFF for faulty probe

1= output ON for faulty probe

0

1

Boiler Function

Paramete

r

Description Min

Max Meas. Resolution

Ar20 Boiler function

0= Integration control

1= Heating control

0

1

Ar21 External air Setpoint for Boiler heater activation -50.0

-58 110

230 °C

°F Decimal

integer

Ar22 Boiler function differential 0.1

0 25.0

45 °C

°F Decimal

integer

Ar24

A

ctivation delay time of heater n° 2 0

250 Min

Ar25 Outside air set point for disabling the compressors -50.0

-58 110

230 °C

°F Dec

Int

Ar26 Outside air differential for enabling the compressors 0.1

0 25.0

45 °C

°F Dec

int

Anti-freezer alarm in HP function

Ar27

A

nti-freeze alarm set point in heat pump mode

A

r01

A

r02 °C /°F

Dec/int

Ar28

A

nti-freeze alarm differential in heat pump mode 0

0 25.0

45 °C

°F Dec

int

Evaporator water pump functioning / condenser of ambientprobe

Ar29 Evaporator/condenser water pump set point with external temperature regulation

-50.0

-58 110

230 °C

°F Dec

int

Ar30 Evaporator/condenser water pump differential with external temperature regulation

0.1

0 25.0

45 °C

°F Dec

int

Condenser water pump functioning

A

r

31 Regulation of condenser water pump/ anti-freeze heaters in OFF

–

standby mode.

0= de-activated

1= Switched on in OFF or standby mode

2= Regulation of water pump/ anti-freeze heaters with probe PB4 configured as ambientprobe

3= Regulation of the water pump / anti-freeze heaters with probe PB4 configured as ambient probe and

separate set points.

0

3

Ar32

A

ctivation of condenser water pump / anti-freeze heaters in case of probe failure.

0= Off with probe fault

1= On with probe fault

0

1

Pr2 Password 0

999

Defrost Parameters

Paramete

r

Description Min

Max Meas. Resolution

DF01 Defrost control

0= No

1= Yes

0

1

DF02 Defrost type

0= Temperature / pressure

1= Time

2= External contact

0

2

DF03 Temperature / pressure Setpoint for starting the defrost cycle

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

DF04 Temperature / pressure Setpoint for stopping the defrost cycle

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

DF05 Minimum delay time before starting a forced defrost cycle

0

250 Sec

DF06 Minimum defrost duration 0

250 Sec

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 18 di 20

DF07 Maximum defrost duration 0

250 Min

DF08 Compressor Off time before starting a defrost cycle 0

250 Sec

DF09 Compressor Off time after a defrost cycle 0

250 Sec

DF10 Interval time between defrost cycles 1

99 MIN

DF11 Temperature setpoint to start a combined defrost cycle after the DF10 counting time

-50.0

-58 110

230 °C

°F Decimal

integer

DF12 Temperature Setpoint to stop a combined defrost -50.0

-58 110

230 °C

°F Decimal

integer

DF13 Forced activation of the 2nd compressor in defrost

0= Not enabled

1= Enabled

0

1

DF14 Forced fan activation during defrost and draining times

0= Not enabled

1= Enabled only for defrost

2= Enabled for defrost and draining time (dF09)

0

2

DF15 Temperature/Pressure Setpoint to start a forced condensing fan control in defrost cycle

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

DF16 Low alarm control during defrost

0= Not enabled

1= Enabled

0

1

DF17 Low alarm delay time after changing the status of the 4-ways valve

0

250 Sec

DF18 4-ways reversing valve

0= ON in cooling

1= ON in heating

0

1

DF19 Temperature/pressure Setpoint to start a forced defrost cycle

-50.0

-58

0.0

0

110

230

50

725

°C

°F

bar

psi

Decimal

integer

Decimal

integer

DF20 Forced defrost cycle differential

0.0

0

0.0

0

25.0

45

50.0

725

°C

°F

Decimal

Integer

Decimal

Integer

DF21 Fan status during defrost 0

1

Pr2 Password 0

999

Alarm Parameter

Paramete

r

Description Min

Max Meas. Resolution

AL01 Low pressure alarm delay time

0

250 Sec

AL02 Maximum low pressure alarm events in 1 hour 0

16

AL03 Low pressure alarm with off compressor

0= Not enabled when compressor Off

1= Enabled when compressor Off

0

1

AL04 “Water flow/Supply fan thermal protection” alarm delay after “water pump / supply air fan” starting.

0

250 Sec

AL05 Maximum duration of the flow switch alarm before it becomes manual and blocks the water pump

0

250 Sec

AL06 “Water flow/Supply fan thermal protection” input activation duration

0

250 Sec

AL07 “Water flow/Supply fan thermal protection” input de-activation duration

0

250 Sec

AL08 Thermal protection alarm delay after starting the compressor

0

250 Sec

AL09 Number of maximum thermal protection alarm events.

0

16

AL10 Maximum number of high temperature / condenser pressure alarm interventions per hour

0

16

AL11 Condensing temperature/pressure high alarm setpointfor input probe

-50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

AL12 Temperature/pressure high alarm differential for input probe

0

0

0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

AL13 Low pressure alarm delay for input probe 0

250 Sec

AL14 Low pressure alarm Setpoint for input probe -50.0

-58

0.0

0

110

230

50

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

AL15 Low pressure differential for input probe 0

0

0

0

25.0

45

50.0

725

°C

°F

Bar

Psi

Decimal

integer

Decimal

integer

AL16 Maximum number of the low alarm events in 1 hour for input probe

0

16

AL17

A

larm relay and buzzer activation when the unit is Off or stand-by

0= Alarm relay and buzzer enabled

1= Alarm relay and buzzer disabled

0

1

AL18

A

larm relay output/open collector polarity

0= Output without voltage in normal conditions,with voltage when there is an alarm

1= Output with voltage in normal conditions, without voltage when there is an alarm

0

1

IC100CX SERVICE MANUAL

Manual IC100CX GB Page 19 di 20

AL19

A

llows to choose the probe for the anti- freezer heater alarm.

0= Relative to Ar16 parameters in chiller mode - Ar17 in hp.

1= on Pb1 probe

2= on Pb2 probe

3= on Pb3 probe

4= on Pb4 probe

0

4

AL20 Maximum number of general unit block alarm interventions per hour

0

16

AL21 General alarm delay starting from digital input activation

0

250 Sec

AL22 Delay to reset the general alarm starting from digital input de-activation

0

250 10 sec

10 sec

AL23 General alarm type:

0 = signaling only does not depend on AL20 (alarm relay and buzzer enabled), always reset automatically

1= the alarm blocks the unit; resetting of the alarm depends on the value of the AL20 parameter

0

1

AL24 System’s inlet water high temperature alarm set point -50.0

-58 110

230 °C

°F Dec

int

AL25 System’s inlet water high temperature alarm differential

0.1

0 25.0

45 °C

°F Dec

int

AL26 Delay time for signaling the system’s inlet water high temperature alarm

0

250 10 sec

10 sec