High-Flying HF-LPD100 User manual

HF-LPD100 Low Power WiFi Module User Manual

HF-LPD100

802.11a/b/g/n WiFi Module User Manual

V 1.3

Overview of Characteristic

Support IEEE802.11 a/b/g/n Wireless Standards, work in 2.4GHz and 5GHz dual band

Based onAndes Core,160MHz CPU, 192KB RAM, 2MB or 8MB Flash

Support UART Data Communication Interface

Support Work As STA/AP/AP+STA Mode

Support Sniffer Method SmartLink V8 Config

Support SoftAP Method SmartAPLink Config

Support WeChat Airkiss 2.0

Support Wireless and Remote Firmware Upgrade Function

Support Software SDK for Develop

Support Different Antenna Option

HF-LPD100:Internal PCB

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100

HF-LPD100 Low Power WiFi Module User Manual

HISTORY

Ed. V0.1 08-24-2017 Internal Version.

Ed. V1.0 10-26-2018 Released Version

Ed. V1.1 06-04-2019 Add HF-LPD130 Version

Ed. V1.2 09-29-2019 Add HF-LPD100 external pin antenna

Ed. V1.3 11-13-2019 Update PIN definition.

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

1.PRODUCT OVERVIEW

1.1. General Description

The HF-LPD100 support 2.4GHz and 5GHz dual band. It is a fully self-contained small form-factor,

single stream, 802.11a/b/g/n Wi-Fimodule,which provide a wireless interface to any equipment with a

Serial interface for data transfer.HF-LPD100 integrate MAC, baseband processor, RFtransceiver with

power amplifier in hardware and all Wi-Fi protocol and configuration functionality and networking stack,

in embedded firmware to make a fully self-contained 802.11b/g/n Wi-Fi solution for a variety of

applications.

The HF-LPD100 employs the world's lowest power consumption embedded architecture. It has been

optimized for all kinds of client applications in the home automation, smart grid, handheld device,

personal medical application and industrial control that have lower data rates, and transmit or receive

data on an infrequent basis.

1.1.1 Key Application

Remote equipment monitoring

Asset tracking and telemetry

Security

Industrial sensors and controls

Home automation

Medical devices

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

1.1.2 Device Paremeters

Table1. HF-LPD100 Module Technical Specifications

Class

Item

Parameters

Wireless

Parameters

Certification

TBD

Wireless standard 2.4GHz:802.11 b/g/n

5GHz:802.11 a /n

Frequency range 2.4G Wi-Fi:2412-2462 MHz

5G Wi-Fi B1: 5180-5240MHz, B4: 5745-5825MHz

2.4G Transmit Power 802.11b:20.76dBm ;802.11g:21.94dBm

802.11n20:20.62dBm;802.11n40:21.10dBm

5G Transmit Power

2.4G Receiver

Sensitivity

802.11b: -87.5 dBm (@11Mbps ,CCK)

802.11g: -73.5 dBm (@54Mbps, OFDM)

802.11n: -72.5 dBm (@HT20, MCS7)

5G Receiver Sensitivity

-73.5dBm (@54Mbps ,OFDM)

-72 dBm (HT20,MCS7)

Antenna PCB antenna

Hardware

Parameters

Data Interface

UART

GPIO,SPI

Operating Voltage

2.1~3.46V

Operating Current

Peak (Continuous TX): 345mA

Average(STA, No data): 44mA

Standby: 1.23mA(Reset set to low)

Operating Temp.

-20

℃

- 85

℃

Storage Temp.

-40

℃

- 125

℃

Density

<85%

Dimensions and Size HF-LPD100: 23.1mm x32.8mm x 3.5mm

Software

Parameters

Network Type

STA/AP/AP+STA

Security Mechanisms

WEP/WPA-PSK/WPA2-PSK

Encryption

WEP64/WEP128/TKIP/AES

Update Firmware

Local Wireless, Remote OTA

Customization

Support SDK for application develop

Network Protocol

IPv4, TCP/UDP/HTTP/TLS(SDK)

User Configuration AT+instruction set. Android/ iOS

SmartLink APP tools

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

802.11a:14.82dBm ;802.11n20:15.31dBm

802.11n40:15.84dBm

HF-LPD100 Low Power WiFi Module User Manual

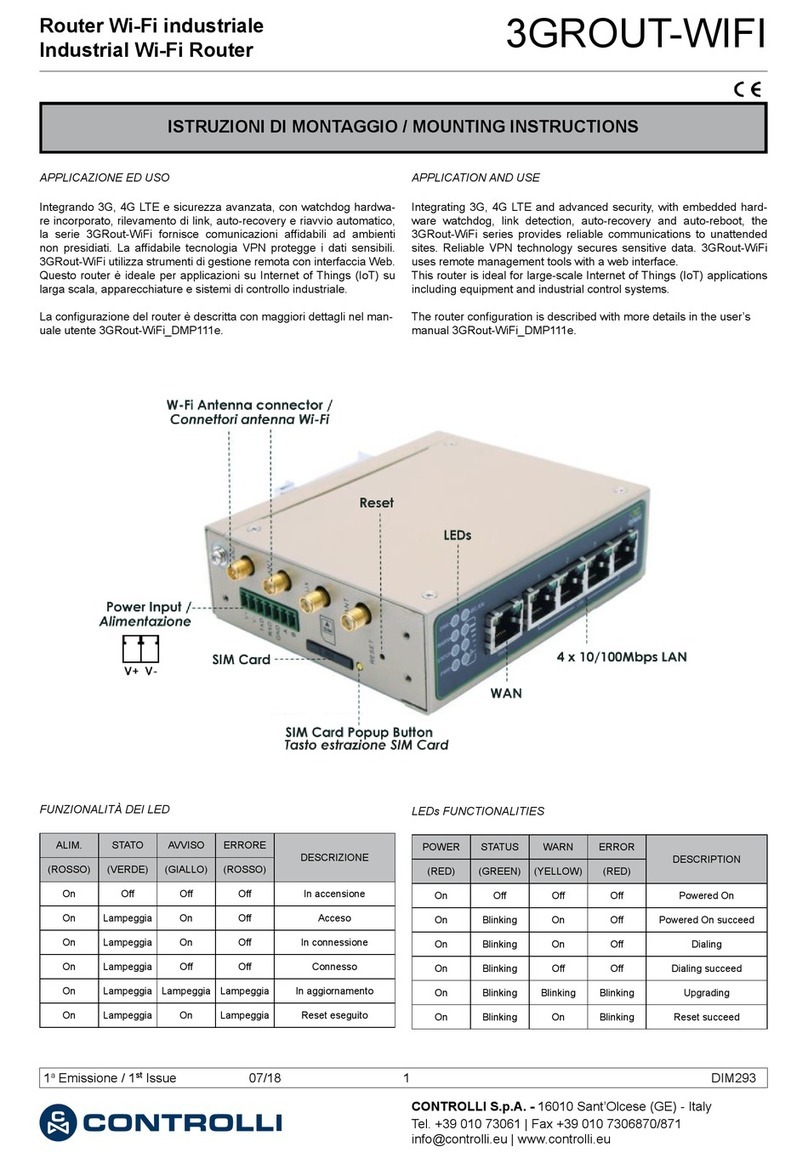

1.2. Hardware Introduction

HF-LPD100 series Wi-Fi module appearance is as following.

Figure 1. HF-LPD100 Appearance

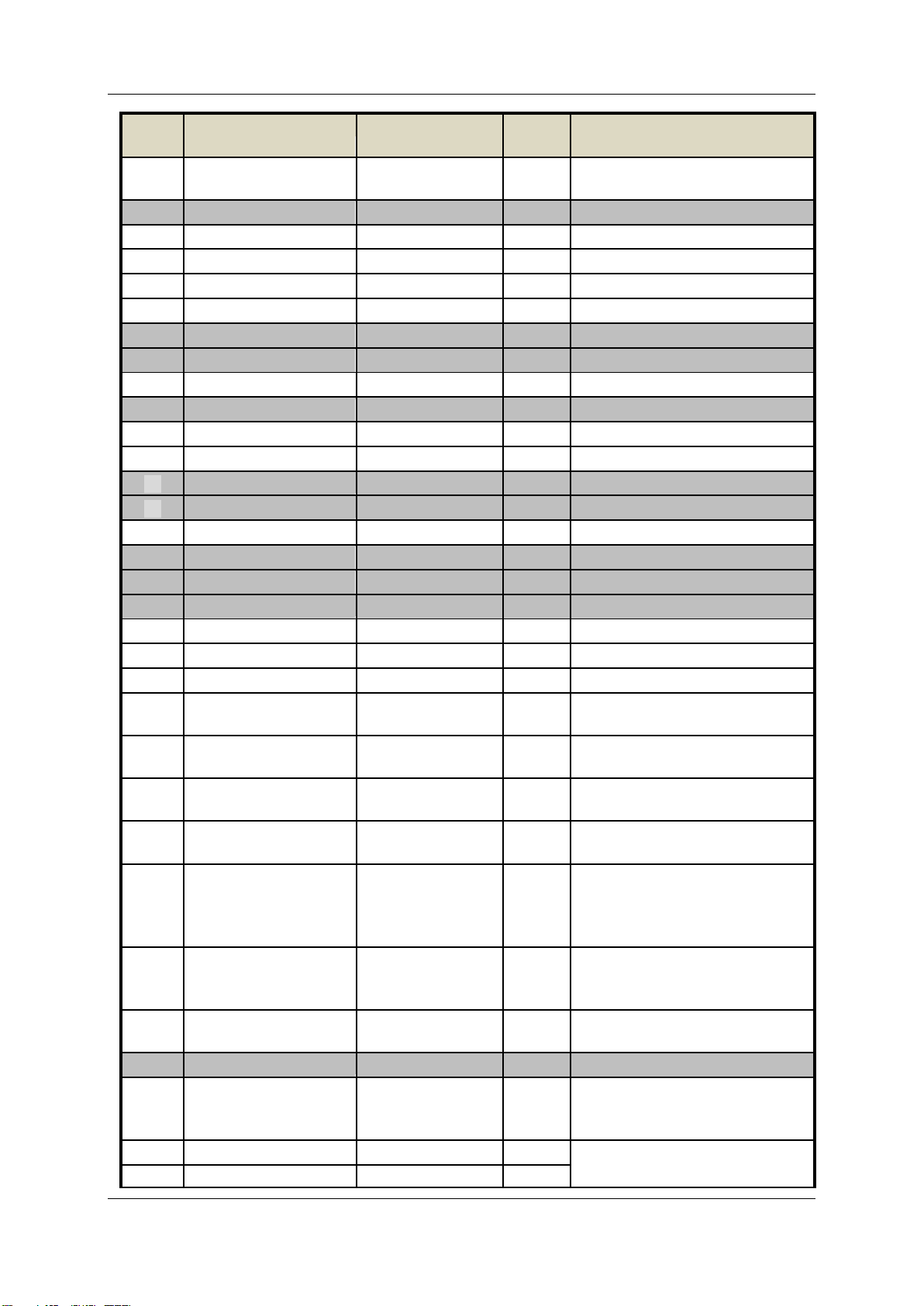

1.2.1. HF-LPD100 Pins Definition

Figure 2. HF-LPD100 Pins Map

Table2. HF-LPD100 Pins Definition

Pin

Describtion

Net Name

Signal

Type

Comments

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

Pin

Describtion

Net Name

Signal

Type

Comments

1,17,18

34,35,37

Ground GND Power

2

NC

3

GPIO00

GPIO00

I/O

PWM0

4

GPIO01

GPIO01

I/O

PWM1

5 USB+ HSDP I/O USB 2.0

6 USB- HSDN I/O USB 2.0

7

TEST

Test only. Leave it unconnected.

8

TEST

Test only. Leave it unconnected.

9,20

+3.3V

DVDD

Power

10

TEST

Test only. Leave it unconnected.

11

GPIO02

GPIO02

I/O

PWM2

12

GPIO04

GPIO04

I/O

PWM4

13

TEST

Test only. Leave it unconnected.

14

TEST

Test only. Leave it unconnected.

15 GPIO03 GPIO03 I/O PWM3

16 TEST Test only. Leave it unconnected.

19

NC

21

NC

22

GPIO11

GPIO11

I/O

23

GPIO05

GPIO05

I/O

24

GPIO09

GPIO09

I/O

25 UART0_TX UART0_TX O3.3V TTL UART0 Output

GPIO07

26 UART1_TX

D

EBUG_UART1_TX

I/O 3.3V TTL Debug UART1_TX

GPIO21, ADC1

27 UART0_RX UART0_RX I3.3V TTL UART0 Input

GPIO06

28

UART1_RX

DEBUG_UART1_RX

I/O

3.3V TTL Debug UART1_RX

GPIO22, ADC0

29 Wi-Fi Status nLink IPD/O “0” – Wi-Fi connect to router

“1” – Wi-Fiunconncted;

Detailed functions see <Notes>

GPIO12

30

Module Boot Up

Indicator

nReady

IPU/O

“0” – Boot-up OK;

“1” – Boot-up No OK;

GPIO08

31

Multi-Function

nReload

IPU/O

Detailed functions see

<Notes> GPIO13

32

N.C

33

Module Reset

RESET

I,PU

“Low” effective reset input.

There is RC reset circuit

internally.

35,37

Ground

GND

Power

Only HF-LPD100-2 has this three

pin for antenna interface

36

ANT

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

<Notes>

I — Input;O — Output

PU—Internal Resistor Pull Up; I/O: Digital I/O; Power—Power Supply nReload Pin (Button) function:

1. When this pin is set to “low” during module boot up, the module will enter wireless

firmware and config upgrade mode. This mode is used for customer manufacture.(See

Appendix to download software tools for customer batch configuration and upgrade

firmware during mass production)

2. After module is powered up, short press this button (0.2s < “Low” < 1.5s) and loose to make

the module go into SmartLink V8 config mode, when in SmartLink V8 config mode and short

press this button again to go into SmartAPLink config mode, waiting for APP to set router

SSID and password, config module connect to router. Recommend to use SmartAPLink

method config.

See Appendix to download SmartLink V8 and SmartAPLink APP

3. After module is powered up, long press this button ( “Low” > 4s ) and loose to make the

module recover to factory setting.

High-Flying strongly suggest customer fan out this pin to connector or button for

“Manufacture” upgrade or “ SmartLink” application.

nReady Pin (LED) function(Low effective):

1. OS initial finished indicator. Only after this pin output low, can the UART function be used.

nLink Pin (LED) function(Low effective):

1. At wireless firmware and config upgrade mode , this LED used to indicate configure and

upgrade status.

2. At “SmartLink” config mode, this LED is used to indicate APP to finish setting.

3. At normal mode, it’s Wi-Fi link status indicator. Output Low when STA mode connect to

router AP or other STA connect to it when in AP mode.

High-Flying strongly suggest customer fan out this pin to LED.

UART1 Debug :

1. Is used fordebug log

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

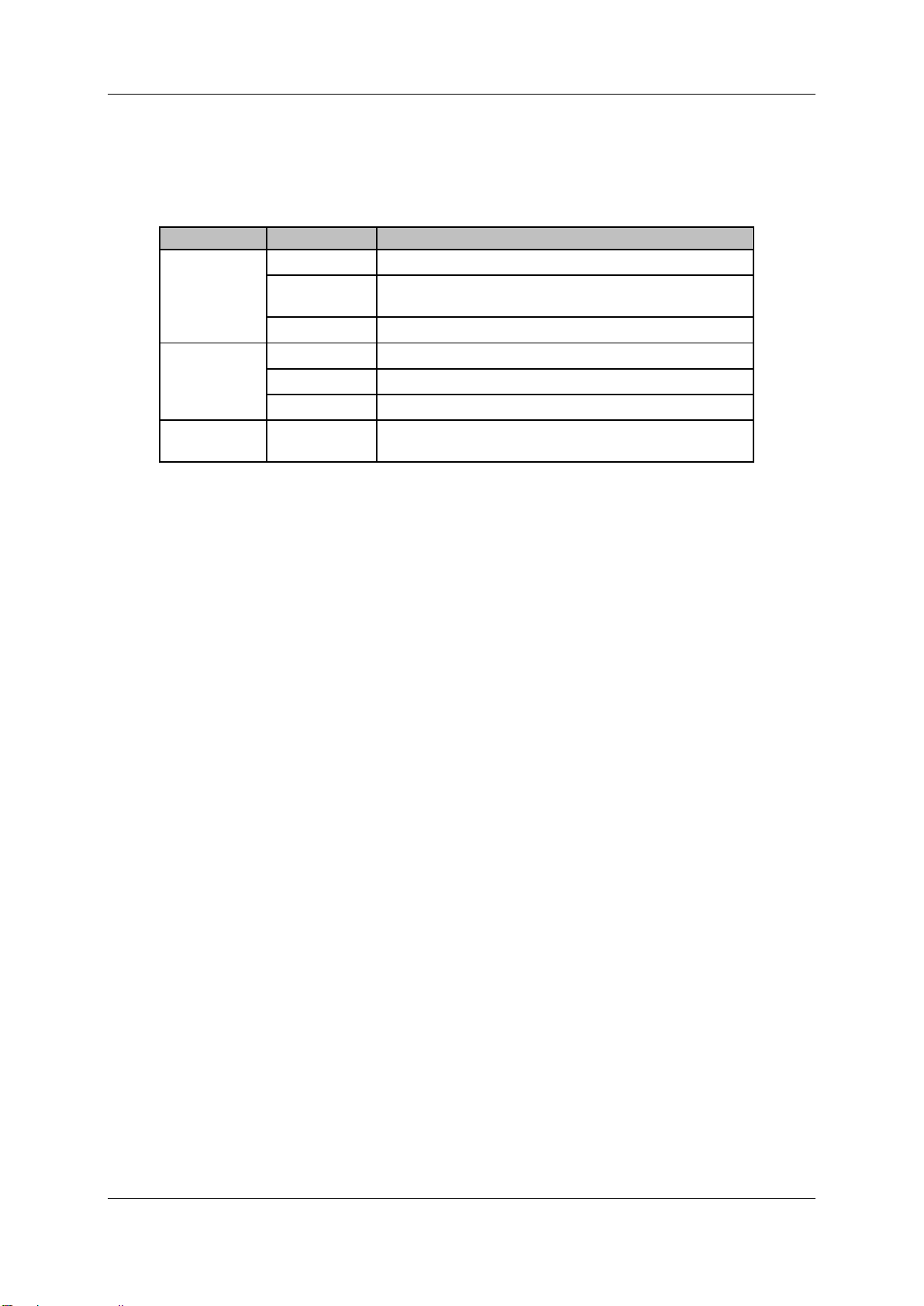

Table4. Power Supply & Power Consumption:

Parameter Condition Min. Typ. Max. Unit

Operating Supply voltage 2.1 3.3 3.46 V

Supply current, peak Continuous Tx 260 mA

Supply current, STA No data transfer 27 mA

Supply current, STA Continuous data transfer 35 mA

Supply current, AP 80 mA

GPIO sink current GND+0.5V 20 mA

GPIO pull current VCC-0.5V 20 mA

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

1.2.2. Electrical Characteristics

Table3. Absolute Maximum Ratings:

Parameter Condition Min. Typ. Max. Unit

Work temperature range -20 85 °C

Maximum soldering temperature IPC/JEDEC J-STD-020 260 °C

ESD (Human Body Model HBM) TAMB=25°C 2.5 KV

ESD (MM) TAMB=25°C 0.25 KV

HF-LPD100 Low Power WiFi Module User Manual

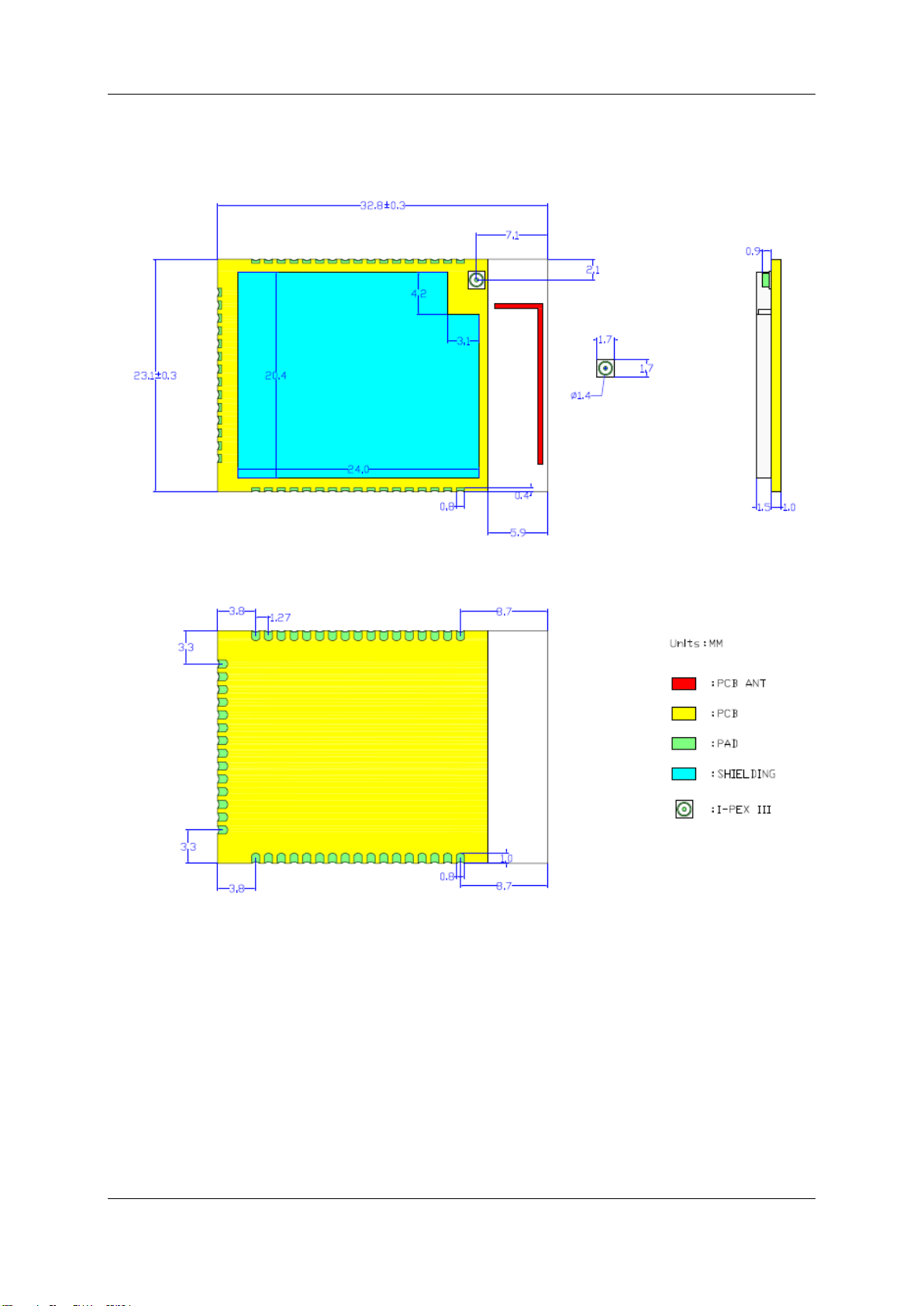

1.2.3. HF-LPD100 Mechanical Size

HF-LPD100 modules physical size (Unit: mm)as follows:

Figure 3. HF-LPD100-1 and -0 Mechanical Dimension

1.2.4. HF-LPD100 On-board PCB Antenna

HF-LPD100 module support internal on-board PCB antenna option. When customer select internal

antenna, you shall comply with following antenna design rules and module location suggestions:

For customer PCB, RED color region (8.3x18.4mm) can’t put componet or paste GND net;

Antenna must away from metal or high components at least 10mm;

Antenna can’t be shielded by any metal enclosure;

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

HF-LPD100 Low Power WiFi Module User Manual

Figure 4. Suggested Module Placement Region

High-Flying suggest module better locate in following region at customer board, which to reduce the

effect to antenna and wireless signal, and better consult High-Flying technical people when you

structure your module placement and PCB layout.

1.2.5.Evaluation Kit

High-Flying provides the evaluation kit to promote user to familiar the product and develop the detailed

application. The evaluation kit shown as below, user can connect to HF-LPD100 series module with

the RS-232 UART, USB (Internal USB to UART convetor) or Wireless interface to configure the

parameters, manage the module or do the some functional tests.

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

Figure 5. HF-LPD100 EVK

Notes: User need download USB to UART port driver from High-Flying web or contact with technical

support people for more detail.

HF-LPD100 Low Power WiFi Module User Manual

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

The external interface description for evaluation kit as follows:

Table6. HF-LPD100 Evaluation Kit Interface Description

Function Name Description

External

Interface RS232 Main data/command RS-232 interface

USB USB to UART interface, can be used for debug

UART log

DC5V DC jack for power in, 5~9V input.

LED Power Power LED

Ready nReady LED

Link nLink LED

Button nReload Smartlink and Restore factory default configuration.

See more for PIN Definition

HF-LPD100 Low Power WiFi Module User Manual

2.PACKAGE INFORMATION

2.1. Recommended Reflow Profile

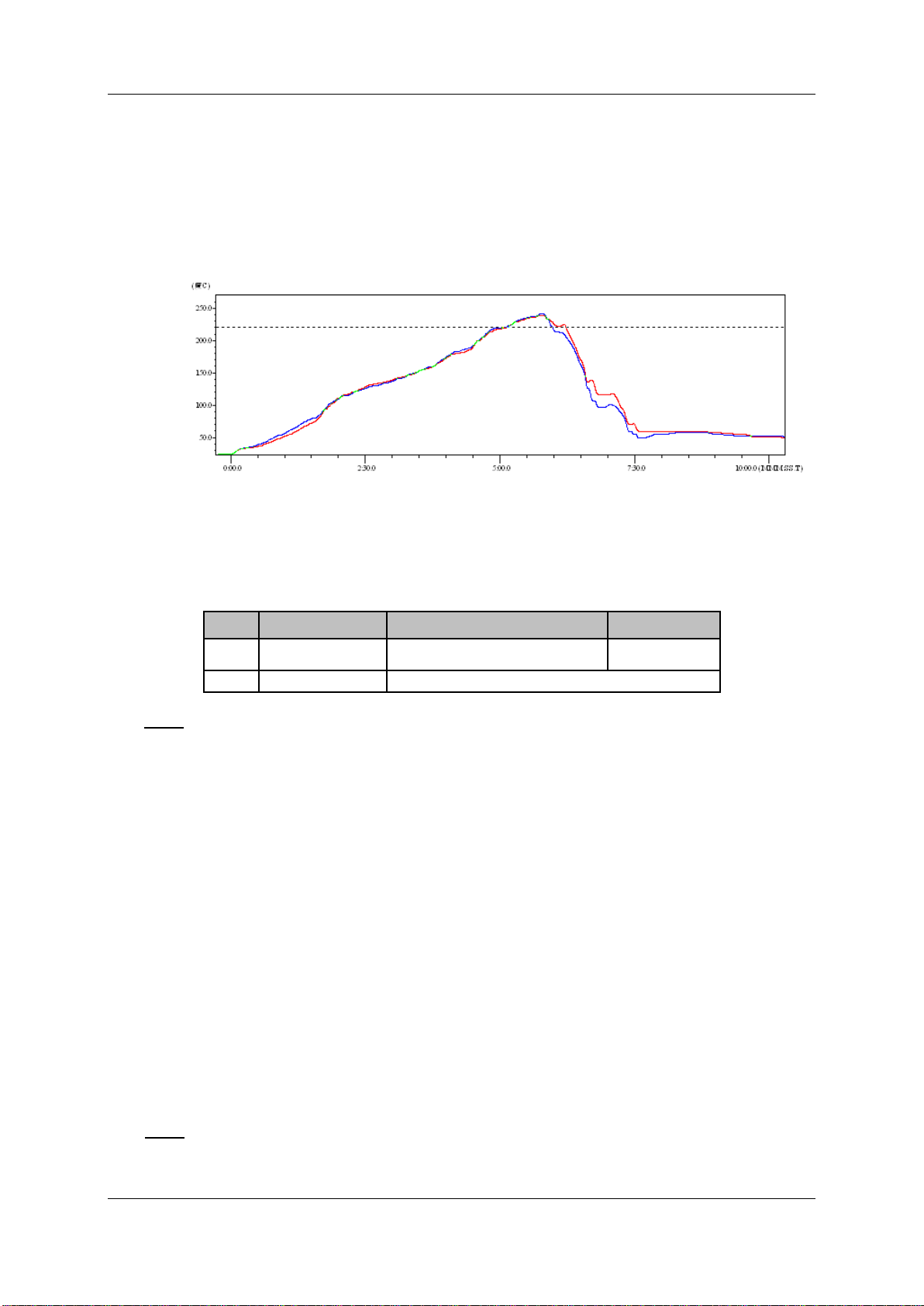

Figure 7. Reflow Soldering Profile

Table7. Reflow Soldering Parameter

Note: 1. Recommend to supply N2 for reflow oven.

2. N2 atmosphere during reflow (O2<300ppm)

2.2. Device Handling Instruction (Module IC SMT Preparation)

1. Shelf life in sealed bag: 12 months, at <30℃ and <60% relative humidity

2. After bag is opened, devices that will be re-baked required after last baked with window time

168 hours.

3. Recommend to oven bake with N2 supplied

NO. Item Temperature (Degree) Time(Sec)

1 Reflow Time Time of above 220 35~55 sec

2 Peak-Temp 260 max

High-Flying Electronics Technology Co., Ltd.(www.hi-flying.com)

4. Recommend end to reflow oven with N2 supplied

5. Baked required with 24 hours at 125+-5. 0℃ before rework process

6. Recommend to store at ≦10% RH with vacuum packing

7. If SMT process needs twice reflow:

(1) Top side SMT and reflow (2) Bottom side SMT and reflow

Case 1: Wifi module mounted on top side. Need to bake when bottom side process over 168

hours window time, no need to bake within 168 hours

Case 2: Wifi module mounted on bottom side, follow normal bake rule before process

Note: Window time means from last bake end to next reflow start that has 168 hours space.

OEM Guidance

1. Applicable FCC rules

2. The specific operational use conditions

This module can be used in IoT devices. The input voltage to the module is

nominally 2.1~3.46V DC. The operational ambient temperature of the module is

–40 °C ~ 65 °C. Only the embedded PCB antenna is allowed. Any other

external antenna is prohibited.

3. Limited module procedures

N/A

4. Trace antenna design

N/A

5. RF exposure considerations

The equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with

minimum distance 20cm between the radiator and your body. If the equipment

built into a host as a portable usage, the additional RF exposure evaluation may

be required as specified by 2.1093.

6. Antenna

Antenna type: PCB antenna Peak gain: 0dBi

7. Label and compliance information

An exterior label on OEM’s end product can use wording such as the following:

“Contains Transmitter Module FCC ID: 2ACSVHF-LPD100” or

“Contains FCC ID: 2ACSVHF-LPD100.”

OEM Guidance

1. Applicable FCC rules

This module is granted by Single Modular Approval. It complies to

the requirements of FCC part 15.247 and 15.407

8. Information on test modes and additional testing requirements

a)The modular transmitter has been fully tested by the module grantee on the required

number of channels,modulation types, and modes, it should not be necessary for the host

installer to re-test all the available transmitter modes or settings. It is recommended that the

host product manufacturer, installing the modular transmitter,perform some investigative

measurements to confirm that the resulting composite system does not exceed the spurious

emissions limits or band edge limits (e.g., where a different antenna may be causing

additional emissions).

b)The testing should check for emissions that may occur due to the intermixing of emissions

with the other transmitters, digital circuitry, or due to physical properties of the host product

(enclosure). This investigation is especially important when integrating multiple modular

transmitters where the certification is based on testing each of them in a stand-alone

configuration. It is important to note that host product manufacturers should not assume that

because the modular transmitter is certified that they do not have any responsibility for final

product compliance.

c)If the investigation indicates a compliance concern the host product manufacturer is

obligated to mitigate the issue. Host products using a modular transmitter are subject to all

the applicable individual technical rules as well as to the general conditions of operation in

Sections 15.5, 15.15, and 15.29 to not cause interference. The operator of the host product

will be obligated to stop operating the device until the interference have been corrected .

9. Additional testing, Part 15 Sub part B disclaimer The final host / module combination

need to be evaluated against the FCC Part 15B criteria for unintentional radiators in order

to be properly authorized for operation as a Part 15 digital device.

The host integrator installing this module into their product must ensure that the final

composite product complies with the FCC requirements by a technical assessment or

evaluation to the FCC rules, including the transmitter operation and should refer to guidance

in KDB 996369. For host products with certified modular transmitter, the frequency range of

investigation of the composite system is specified by rule in Sections 15.33(a)(1) through

(a)(3), or the range applicable to the digital device, as shown in Section 15.33(b)(1),

whichever is the higher frequency range of investigation When testing the host product, all

the transmitters must be operating.The transmitters can be enabled by using publicly-

available drivers and turned on, so the transmitters are active. In certain conditions it might

be appropriate to use a technology-specific call box (test set) where accessory 50 devices or

drivers are not available. When testing for emissions from the unintentional radiator, the

transmitter shall be placed in the receive mode or idle mode, if possible. If receive mode only

is not possible then, the radio shall be passive (preferred) and/or active scanning. In these

cases, this would need to enable activity on the communication BUS (i.e., PCIe, SDIO, USB)

to ensure the unintentional radiator circuitry is enabled. Testing laboratories may need to add

attenuation or filters depending on the signal strength of any active beacons (if applicable)

from the enabled radio(s). See ANSI C63.4, ANSI C63.10 and ANSI C63.26 for further

general testing details.

The product under test is set into a link/association with a partnering device, as per the

normal intended use of the product. To ease testing, the product under test is set to transmit

at a high duty cycle, such as by sending a file or streaming some media content.

FCC Warning:

Any Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment. This device complies with part 15 of the

FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) This device must accept any interference received, including

interference that may cause undesired operation

Table of contents

Other High-Flying Wireless Router manuals