HILL PUMPS EC-3000 Operator's manual

Rev 5 May 2022

USER INSTRUCTION MANUAL

EC3000 PORTABLE AIR COMPRESSOR

2

Rev 5 May 2022

Contents

Parts Included……………………………………………………………………………..3

Set Up……………………………………………………………………………………...4-6

Operating Instructions:

Connecting to a vessel…………………………………………………………….6

Switching on power………………………………………………………………...7

Setting target pressure…………………………………………………………….7

Starting a fill…………………………………………………………………………8

Pausing a fill………………………………………………………………………...9

Auto Cooling………………………………………………………………………...9

Auto Cut-Off & Depressurisation…………………………………………………10

Lubrication check timeout…………………………………………………………10

Setting units of pressure…………………………………………………………..11

Trimming calibration……………………………………………………………….12

Troubleshooting…………………………………………………………………………..13

Closedown………………………………………………………………………………...13

Storage…………………………………………………………………………………….13

Maintenance………………………………………………………………………………13

DO

3

Rev 5 May 2022

Parts Included

1x EC-3000 Compressor

1x Power Cable

1x High Pressure Filling Hose 1/8” and male Quick Release Coupling

1x Hill A73 Crank Oil

1x Hill A72 Silicone Oil

4

Rev 5 May 2022

SET UP

CAUTION - Please read and understand the following instructions

before use.

CAUTION - Once the compressor has been correctly filled with

lubricants, the compressor must be kept upright at all

times. Ensure the compressor is used on an anti-slip floor,

preferably placed on anti-slip matting.

1) Crank Oil Level

With the compressor positioned on a level surface, check that the oil

level meets the red dot on the sight glass.

Top up as necessary as per the following procedure:

— Ensure the correct oil type is used.

— Remove red crank case cap by unscrewing (anti-clockwise).

— Slowly squeeze the Hill A73 crank oil into the exposed hole until

the lubricant level meets the red dot in the sight glass. This

should approximately use a full bottle (50ml).

— Replace the red cap finger tight (clockwise).

DO NOT MIX CRANK OIL AND SILICONE OIL

DO NOT OVERFILL

After an oil change or fill, leave the oil to settle for 5 mins, if the

oil level drops below the red dot, top up with more oil until the level is

maintained.

5

Rev 5 May 2022

2) Silicone Oil Level

Top up the silicone oil reservoir as per the following procedure:

— Ensure the correct oil type is used.

— Remove silicone oil reservoir blue cap by unscrewing

(anti-clockwise).

— Slowly squeeze the Hill A72 silicone oil into the exposed hole until

the lubricant level meets the blue max level line indicated on the

reservoir. Ensure that the silicone oil uptake straw is submerged

in the reservoir.

— Replace the blue cap finger tight (clockwise).

DO NOT MIX CRANK OIL AND SILICONE OIL

DO NOT OVERFILL

6

Rev 5 May 2022

3) Power connection

Insert the C13 power cable into the C14 socket on the left hand side

of the compressor.

Please avoid using any electrical extension leads if possible.

However, if you must use a third-party extension lead, this must be as

short as possible and must be rated to minimum of 110V / 16A

or 230 V / 13 A depending on your local power supply. If unsure,

please determine what your local power supply is before operating

the compressor.

4) Connecting to a vessel

Connect filling probe to hose, ensure spanner tight or use Quick

Release Coupling fitted.

Connect filling probe to vessel.

Ensure bleed screw is closed (finger tight).

CAUTION: If using a quick release coupling, always check and

make sure the collar on the female quick disconnect is

in the forward position and secure on the male fitting

you are connecting it to. It is recommended that you

check the connection by attempting to pull the female

and male ends apart while the fitting is in the forward

position before pressurizing.

7

Rev 5 May 2022

Switching on power

Power up the compressor using the red switch on the left hand side.

The display will briefly show the Hill logo, the firmware version and the

running time.

Next, the compressor will request the user to confirm the lubricant

levels have been checked and are correct.

Press the rotary control knob to confirm the lubricant check. After this,

the display will show the first page of the main menu; the target

pressure display.

Operang Instrucons

Setting Target Pressure

The target pressure is the pressure at which the compressor will

automatically stop filling a vessel.

To set the target pressure, first navigate to the “Target Pressure”

display. This is the first display in the main menu, which appears after

the lubricant check described above.

With the target pressure display visible, press the rotary control knob

once to enable selection mode. A selection arrow will appear next

to the pressure value. With the selection arrow visible, rotate the

rotary control knob clockwise or anti-clockwise to Increase or

decrease the target pressure setting.

Once the desired target pressure is displayed, press the rotary control

knob once to confirm the target pressure selection. After confirming

the target pressure selection, the start display at the end of the main

menu will appear.

8

Rev 5 May 2022

Starting a fill

First navigate to the start display by rotating the rotary control knob

clockwise while in the main menu.

The start display shows the current cylinder block temperature and

the selected target pressure.

If the compressor detects that there is high pressure (roughly greater

than 70 BAR / 1015 PSI) in the system, this pressure will be displayed

on the lower left of the start display. The target pressure is displayed

on the lower right.

If no high pressure is detected in the system, only the target pressure

will be displayed.

With the start display visible, press the rotary control knob once to

start the compressor. After starting the compressor, the running

display will appear.

If the pressure in the system is low (roughly less than 70 BAR

/ 1015PSI), the display will show “Pressurising”.

If the pressure in the system is above this, the display will show

the current pressure on the lower left side and the target pressure on

the lower right.

9

Rev 5 May 2022

Pausing a fill

A fill can be paused at any time by pressing the rotary control knob

once.

After pausing a fill, rotating the rotary control knob in either direction

will cycle between the option to resume or abort the current fill.

Auto Cooling

The compressor is designed to operate within a specific temperature

range. The operating temperature range varies depending on the

pressure in the system.

The compressor will automatically pause for cooling when it detects

that the running temperature has exceeded the maximum operating

temperature. This is normal and no operator intervention is required.

The compressor will automatically resume after a sufficient period of

cooling.

When auto cooling is in progress, the display shows the “cooling”

indicator.

10

Rev 5 May 2022

Auto Cut-Off & Depressurisation

When the target pressure has been reached, the display will show

“Fill Complete”. It is normal for the achieved pressure to reduce by up

to 5% after the fill has completed, particularly in smaller vessels. This

is due to the effect of cooling and flow losses. To compensate for this,

the user may wish to increase the target pressure, permitting that the

vessel is sufficiently rated.

DO NOT disconnect the vessel until the compressor has been

fully depressurised.

Depressurise the compressor by unscrewing the bleed screw; using a

rag for this is advised. Whilst depressurising, some moisture and

silicone may be expelled from the water separator.

Suitable precautions should be taken to protect any floor coverings

under the compressor.

The display will show the progress of the depressurisation.

When the compressor detects that the pressure is low (roughly below

70 BAR / 1015PSI) the display will return to the main menu.

The bleed screw should remain unscrewed to allow the compressor to

fully depressurise. After this, the vessel can be safely disconnected.

Lubrication check timeout

During long fills, the compressor will occasionally automatically stop

and request that the lubricant levels are checked.

At this time it is also necessary to fully bleed the water separator to

prevent excess moisture accumulation. If connected to a vessel

without a non-return valve, close the valve on the bottle and bleed the

compressor as described above. Users in particularly humid climates

may need to bleed the water separator more often.

11

Rev 5 May 2022

Setting units of pressure

The unit of indicated pressure used throughout the operation of the

compressor is user selectable as BAR, PSI or MPa.

The unit of indicated pressure can be selected on the first page of the

settings menu. The settings menu is accessible from the second page

of the main menu.

Press the rotary control knob once to enter the settings menu.

“set units” is the first page of the settings menu.

Press the rotary control knob a second time to enable selection mode.

A selection arrow will appear next to the currently selected unit of

pressure.

Rotate the rotary control knob in either direction to cycle between the

selectable units. Once the desired unit is visible, press the rotary

control knob once to save the selection. The compressor will retain

the selected pressure unit, even after being powered off.

To exit the settings menu, rotate the rotary control knob clockwise

until “Main Menu” is displayed and press the rotary control knob once.

12

Rev 5 May 2022

Trimming Calibration

The compressor is factory calibrated and should accurately sense its

internal pressure out of the box. It is however possible that over many

hours of use, some pressure sensor drift could occur.

To compensate for the occurrence of slight pressure sensor drift, the

compressor features a trim calibration setting. This allows the user to

apply a scale and offset to the factory calibration.

Trim calibration is the second page in the settings menu; accessed as

described in the previous chapter.

The default settings for trim calibration are 100% scale and 0 BAR

offset. It is NOT advised that users change these settings without

having observed a consistent inaccuracy in indicated pressure.

Sensor drift is not to be confused with the effects of post-fill cooling

as described on page 10.

NOTE: The trim calibration setting should NOT be used to attempt

running pressures higher than the maximum operating

pressure of the compressor (310 BAR / 4500 PSI). Changes

to this setting are recorded and any obvious intentional misuse

will void the warranty.

ACTUAL Pressure Displayed pressure

without trim Displayed pressure with

a trim of 101% + 1 BAR

100 102 100

300 304 300

The scale and offset are applied to the TRUE pressure.

For a given target pressure setting:

A scale setting of 105% will increase the achieved pressure by 5%.

An offset of 5 Bar will increase the achieved pressure by 5 Bar.

As an example of how this feature can be used, consider a sensor

with a measured drift of +2 BAR at 100 BAR and +4 BAR at 300

BAR (as shown in the table below). To increase the accuracy of this

sensor, the following trim can be applied: 101% + 1 BAR.

13

Rev 5 May 2022

Troubleshoong

- Compressor will not turn on:

Make sure that the power cable is inserted correctly and that the fuses in the power cable

plug and next to the compressor switch are present and functional.

- Pressure does not exceed 50 BAR and/or air escapes from the Pressure Relief Valve (PRV):

With the bleed screw open, run the compressor for 5 mins and then attempt another fill. If

the problem persists, contact your retailer.

- Pressure achieved in the bottle is lower than the target pressure:

The differential pressure across the bottle valve and hose, combined with the effects of

cooling may cause a small pressure loss. This will differ from one vessel to another.

Adjust the target pressure on the compressor to compensate.

- Motor will not start

As a built in safety feature the compressor will not start if the block temperature is

extremely low, due to the possibility of internal ice crystals. Thaw the compressor out in a

warm room to raise the block temperature.

Shung the compressor down

Make sure that the cylinder is removed and bleed screw is opened to release pressure. With the motor

at rest, turn the compressor off at the switch to the left of the consol.

Storage

Keep upright at all times. Do not store below 5°C (41°F)

Maintenance

Change crank oil every 50 running hours or once yearly (whichever comes first).

Unscrew sight glass to change Crank Oil (make sure you have a suitable container underneath) and

drain.

Regularly check that the Silicone lubrication is free from dirt and debris.

Service kits containing replacements for wearing components are available for specific running time

intervals. These intervals are: 50 hours, and 100 hours. The running hours are briefly displayed on the

console whenever a compressor is switched on.

Timely servicing is recommended to maximize the longevity of the unit. Heavy users such as clubs,

may find that they reach servicing intervals within the warranty period. in this case the services must be

carried out in order for the warranty to remain in force.

14

Rev 5 May 2022

DO NOT LEAVE THE COMPRESSOR UNATTENDED WHEN IN USE!

IN THE UNLIKELY EVENT OF MALFUNCION, PLEASE CONTACT THE DISTRIBUTOR FOR AD-

VISE BEFORE ATEMPTING REPAIRS.

PLEASE RETAIN THE ORIGINAL RECEIPT OF PURCHASE, AND ANY RECIEPTS FOR SERVICE

KITS PURCHASED.

The most up to date version of this manual will be available at: www.airiflepump.com Please check this

website regularly.

Other manuals for EC-3000

2

Table of contents

Other HILL PUMPS Air Compressor manuals

Popular Air Compressor manuals by other brands

Black & Decker

Black & Decker BD 195/6-NK instruction manual

Clarke

Clarke WIZ - MINI Operating and maintenance instructions

Faithfull

Faithfull FAIAUTYINFLO user manual

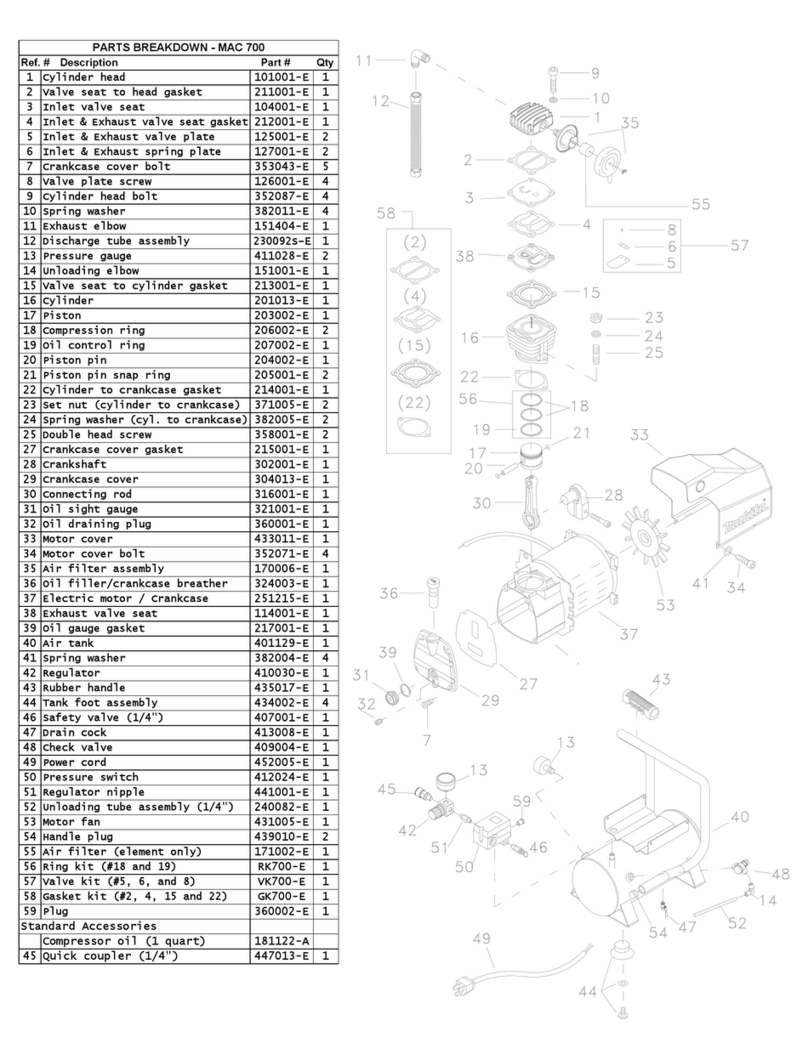

Makita

Makita MAC700 Parts Breakdown

Daewoo

Daewoo DAAX24L-OF user manual

Trane Technologies

Trane Technologies CSHW047 installation instructions