Hilltip Ice STRIKER 600 TR User manual

STRIKER

TM

Owner’s manual

600-1000 LITER POLY ELECTRIC TRACTOR SPREADER

19 November, 2021

Version 1.2

This manual replaces all editions with an earlier date.

2

IceStrikerTM

GENERAL INFORMATION ............................................ 3

Spreader parts .................................................. 3

Technical information ............................................. 4

SAFETY INFORMATION.............................................. 5

Safetydenitions ................................................ 5

Safety precautions ............................................... 5

Recommended vehicle requirements ................................. 6

Noise ......................................................... 6

Personal safety.................................................. 6

Emergency stop ................................................. 6

Warning and caution labels ........................................ 7

INSTALLATION AND OPERATION ..................................... 8

Control placement ............................................... 8

Vehicle side harness cable kit ...................................... 8

Accessory cables ................................................ 9

Mounting the top screen ........................................... 9

Mounting the Tarp cover assembly...................................10

Spreading pattern ................................................12

Rotate jammed auger manually .....................................12

LOADING ..........................................................13

Average material weights ..........................................13

Filling the integrated pre-wet tank ...................................13

MAINTENANCE .....................................................14

Maintaining the spreader ..........................................14

Storage ........................................................15

OPTIONAL LIQUID SYSTEMS.........................................16

Pre-wet (optional) ................................................16

Spray-bar (optional) ..............................................17

Bladder tank (optional) ............................................18

Hose reel (optional) ..............................................19

Liquid system clean-out instructions..................................19

ELECTRICAL SCHEMATIC ...................................... . . . . . 20

WARRANTY INFORMATION ..................................... . . . . . 21

CERTIFICATE OF CONFORMITY ................................. . . . . . 22

Read this manual before installing or

operating the spreader

CAUTION

!

3

IceStrikerTM

GENERAL INFORMATION

Spreader parts

Tarp cover

License plate kit and

rear light (optional)

Beacon light (optional)

Emergency stop button

Spinner

Auger

(inside hopper)

4

IceStrikerTM

Technical information

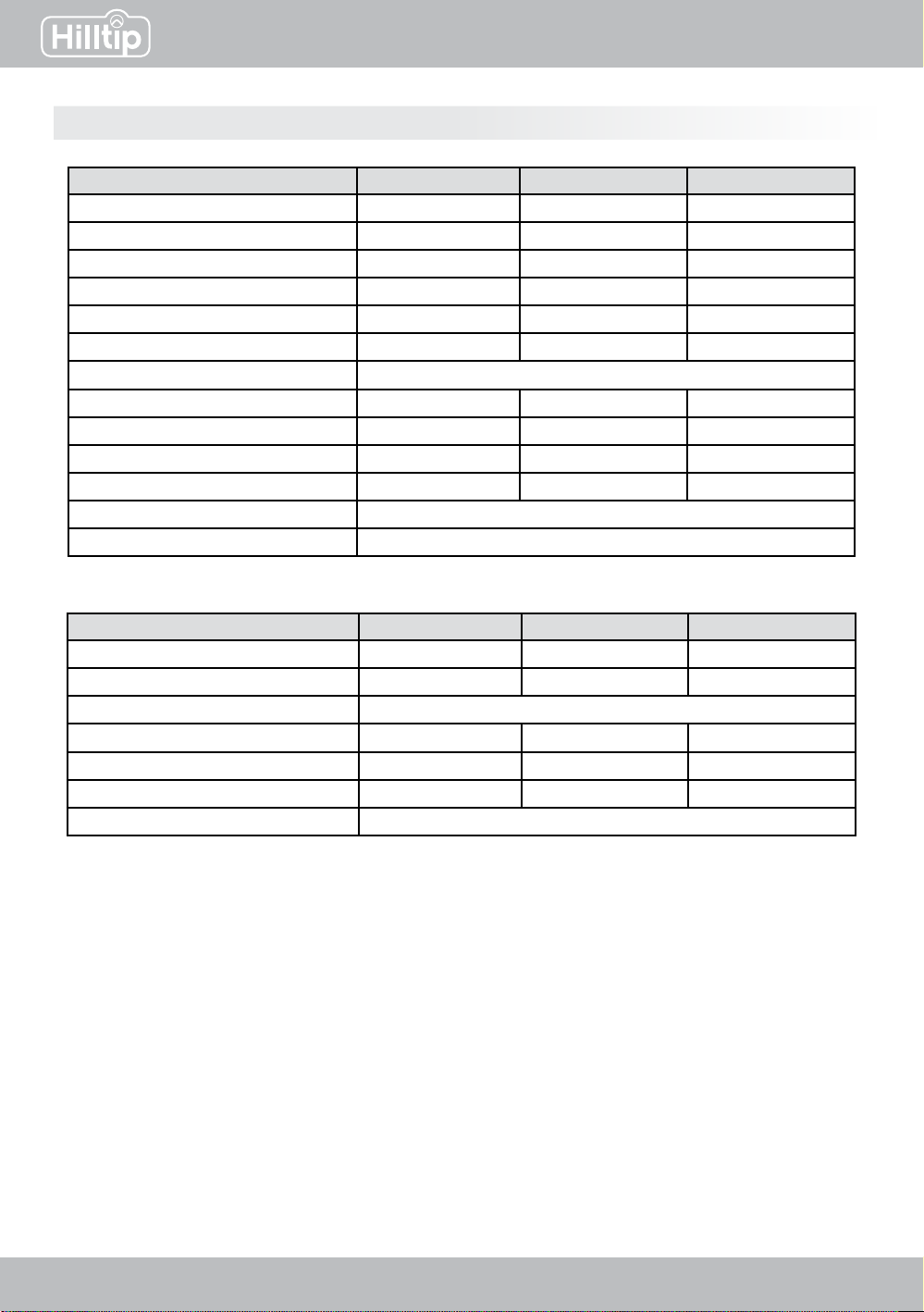

SPREADER SPECIFICATIONS 600 TR 800 TR 1000 TR

Overall width 1500 mm 1500 mm 1500 mm

Height 1500 mm 1650 mm 1800 mm

Capacity (water level) 550 l 750 l 950 l

Capacity (rounded) 630 l 850 l 1050 l

Weight (empty) 320 kg 360 kg 390 kg

Hopper construction Poly Poly Poly

Spreading width 1-8 m (may vary depending on material)

Spinner size 390 mm 390 mm 390 mm

Auger diameter 65 mm 65 mm 65 mm

Vibrator YES YES YES

GPS speed control YES YES YES

Vehicle Tractors/loaders

Material Salt, sand, granulat, mixed

OPTIONAL LIQUID SYSTEM 600 TR 800 TR 1000 TR

Pre-wet, Spray volume 3-12 l/min 3-12 l/min 3-12 l/min

Spraybar, Spray volume 5-25 l/min 5-25 l/min 5-25 l/min

Pre-wet, Spraying width 1-8 m (together with spreading material)

Spraybar, Spraying width 2-5 m 2-5 m 2-5 m

Pre-wet, liquid tank capacity 330 l 330 l 330 l

Spraybar, liquid tank capacity 330/900 l * 330/900 l * 330/900 l *

Spraying material Anti- and de-icing liquids, water, liquid fertilizers **

5

IceStrikerTM

Technical information

Implies a potentially hazardous

situation that, if not avoided, could

result in death or serious personal

injury.

Implies a potentially hazardous

situation that, if not avoided, may

result in minor or moderate injury.

It may also be used to alert against

unsafe practices.

Implies a situation or action that can

lead to damage to your spreader and

vehicle or other property. Other useful

information can also be described.

Safety denitions

1. Read this manual before operating the

spreader.

2. Before operating, make sure all the

equipment is securely mounted into place.

3. Check that there are no persons within the

spreader spray area when starting and

operating this spreader.

4. Do not exceed your vehicle total weight

beyond payload limits.

5. Alwaysturnothespreader before

cleaning, lubricating or unclogging

material jambs.

6. Never climb or ride on or in the spreader.

7. Ensure that you have fastened the

spreader to the vehicle according to

descriptions in this manual.

8. A spreader in need of repairs or

maintenance should not be operated.

9. Before removing or replacing any

electrical components, always disconnect

the battery.

10.Donotkeepgasolineorotherammable

liquids on the truck bed while spreader is

mounted on the truck bed.

Observe these safety precautions

before, during and after operating the

spreader. You can prevent injury to

persons and damage to the spreader

by following these precautions.

SAFETY INFORMATION

Safety precautions

Incorrect installation and operation can lead

to serious personal injury and/or damage

your equipment and property. Note and

ensure that you understand this manual and

all the labels before installing, operating or

making adjustments to the spreader.

!WARNING

iNOTE

!WARNING CAUTION

!

6

IceStrikerTM

Always keep bystanders a minimum

of 10 meters away when operating the

spreader.

Empty and clean the hopper after each

use. Unused spreading material left in

hopper could freeze or solidify, causing

the spreader to not work properly.

Use a good quality multi-purpose

greasetolubricategreasettingsafter

each use.

• To prevent accidents, secure long hair and do not wear jewelry or necktie, only wear tight-tting

clothes while working on your spreader or vehicle.

• Protect your eyes with safety goggles to avoid damage from battery acid, gasoline, dirt and dust.

• Always handle the solid and liquid materials carefully. Wear safety goggles, mouth mask, gloves

and protecting clothes to protect yourself from spattering material.

Wait for auger and spinner to stop and

lock out power before servicing the

spreader.

Personal safety

!WARNING !WARNING

iNOTE

CAUTION

!

The spreader has an emergency stop button located at the right side of the chute. All spreader

functions will immediately stop by pushing this button.

Emergency stop

Recommended vehicle requirements

This spreader is suitable for tractors and loaders with a minimum lift capacity of 2000 kg.

Noise

The noise caused by the running spreader does not exceed 70 dB

7

IceStrikerTM

Warning and caution labels

Please become familiar with warning and caution labels on the spreader.

- Visible when removing the spinner

assembly

Warning - Rotating auger! Keep

hands clear. Wrench might slip when

working with auger

Warning - Keep away from spinner

and spreader in motion. Stay clear

of turning spinner. Moving parts can

crush and cut

Warning - Handling of abrasive

and chemical material can cause

injury

- Located on the chute

8

IceStrikerTM

1

2

1

2

3

INSTALLATION AND OPERATION

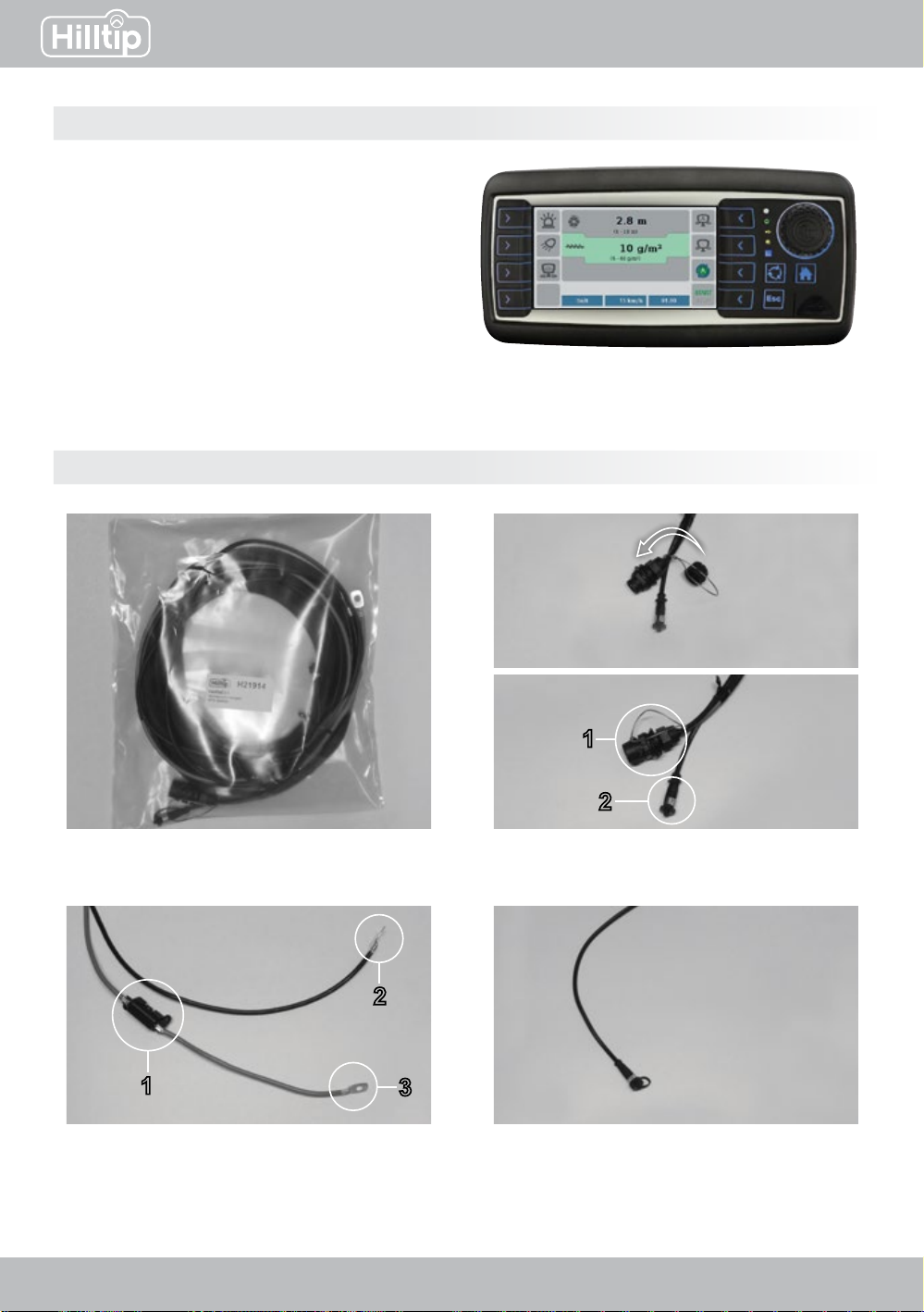

The controller should be mounted in a place

where it can easily be reached and doesn’t

interfere with the access to vehicle controls

or other equipment. Make sure that the

spreader control panel doesn’t block any

vehicle airbag areas. Protect the controller

from water, dirt and dust.

Control placement

Vehicle side harness cable kit

Vehicle side harness cable kit 1. Power connector to spreader

2. Data connector to spreader

To vehicle battery 1. 80A fuse

2. Black (-)

3. Red (+)

In-cabin connector

9

IceStrikerTM

Red = Emergency stop (standard)

Black = Water pump

Yellow = Beacon light

Blue = Camera power feed

White = LED worklight

Accessory cables

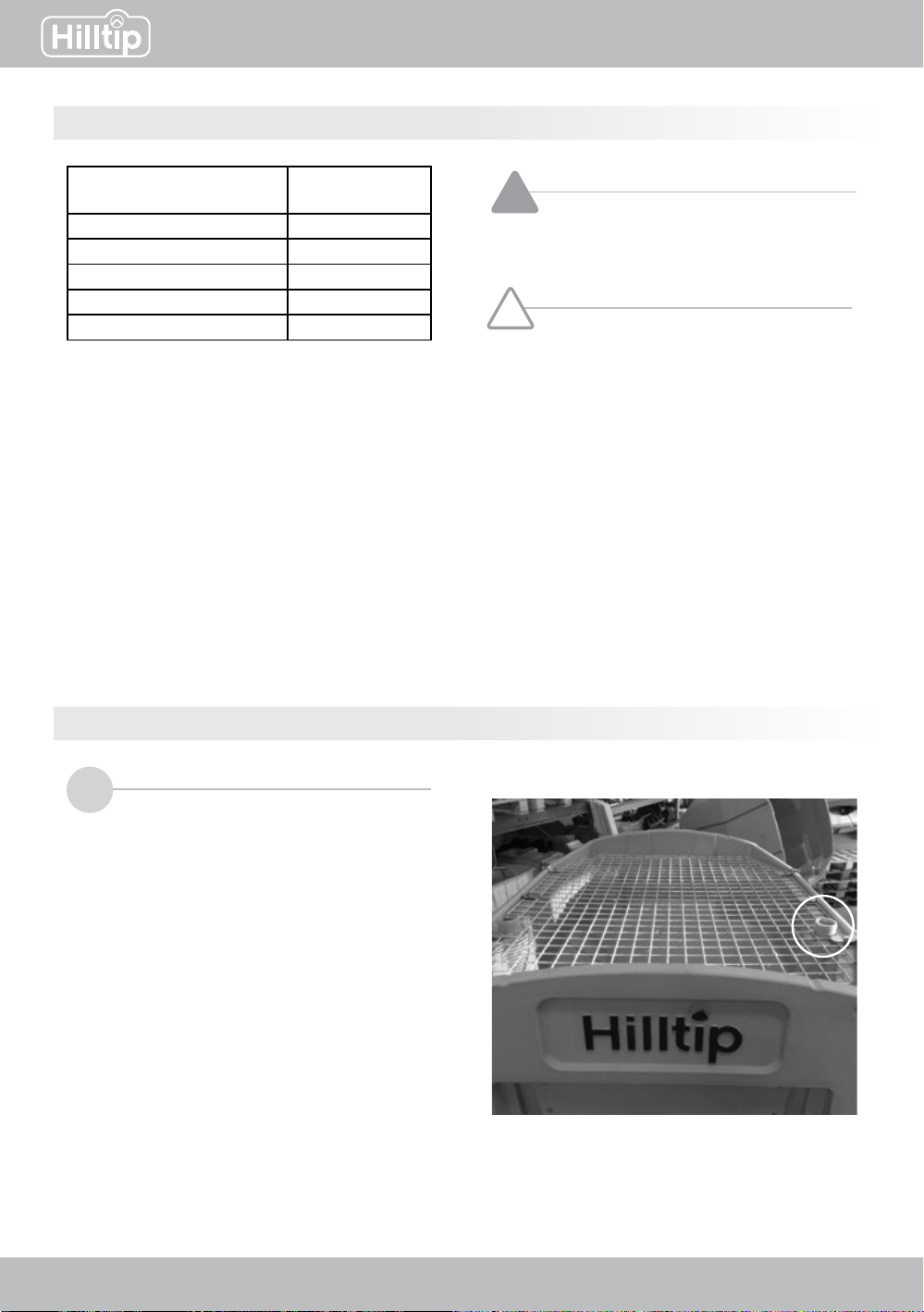

Mounting the top screen

Placethescreensothatittsthehopperopening.

Fasten the brackets on both sides of the screen,

theatbracketshouldbeinthemiddle.

10

IceStrikerTM

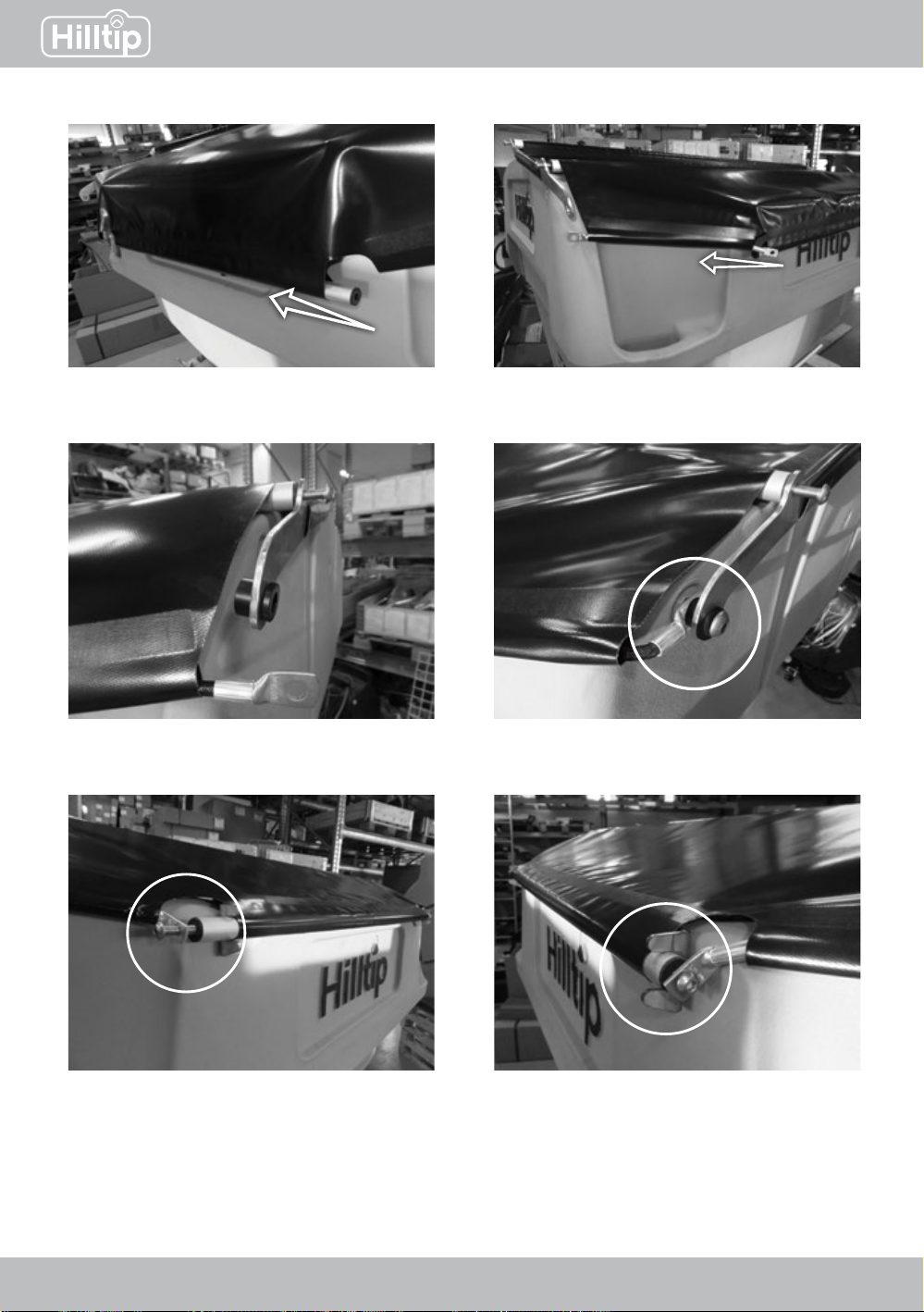

Mounting the Tarp cover assembly

Insert one of the longer pipes into the

opening in the cover (pre-mounted)

1Insert brackets in both sides.

2

Connect pipe and brackets with bolts in

both ends.

3Place the second long pipe under the

cover and connect to the brackets using

bolts

4

11

IceStrikerTM

Insert the short pipe into the cover,

parallel to the other pipes.

5Insert rubber wires into the two

remaining openings in the cover.

6

Connect washer, bracket, bush and

rubber wire with bolt.

8

Place washer and bush around the

bracket, as shown in the picture.

7

Fasten the rubber wire and the shorter

pipe with bolt.

9Fit pipe to the brackets attaching the

screen, and make sure the whole tarp

cover assembly is properly fastened

10

12

IceStrikerTM

Spreading pattern

Rotate the spinner plate to position the material drop point and change spreading pattern.

= material drop point

Drop point in center Spinner plate rotated cw Spinner plate rotated ccw

Rotate jammed auger manually

If the error code “Auger jammed” appears,

the auger can be rotated manually to release

anysolidiedmaterialorrocks.Alwaysturn

othespreaderbeforeservicingit.

Use a 17 mm socket wrench or similar tool

to turn the auger screw.

Rotate auger manually by turning it clockwise

13

IceStrikerTM

LOADING

Material Weight

(kg/m3)

Fine salt - dry 1201

Coarse salt - dry 721

Coarse sand - dry 1602

Coarse sand - wet 1922

Please see your local dealer for proper

vehicle applications.

Only use water or de-icing liquids

for the pre-wetting system

The hopper body has an integrated tank that

should be used only if you had the optional

pre-wetting system included to your spreader

package. Only use liquids recommended in this

manual.

The opening to the integrated pre-wetting tank is

covered by a lid, and located on the side, inside

the hopper body

Average material weights

Filling the integrated pre-wet tank

!WARNING

CAUTION

!

iNOTE

Do not overload your vehicle beyond

GVWR or GAWR, overloading could

result in accident or damage.

These material weights are only

guidelines, for more precise data,

read and adhere to the manufacturer’s

ice-control material package labeling,

including Material Safety Data sheet

requirements.

14

IceStrikerTM

Always close hopper lids to avoid

moisture build-up. Do not let spreader

sit idle with material in the hopper for a

longer time. This could lead to compact

material, reduced or blocked material

owandcausedamagetothehopper.

iNOTE

• Do not operate a damaged

spreader or a spreader in need of

maintenance

• Spreader should be emptied and

cleaned after each use. Left over

material could freeze or solidify in

the hopper causing the spreader

to not work properly.

Power should always be shut

obeforeandduringserviceor

maintenance of the sperader.

Never remove spreader with material

in hopper

Maintaining the spreader

!WARNING

!WARNING

CAUTION

!

Periodical maintenance checklist (check weekly in high-season)

Clean the hopper carefully inside and out with water. Avoid spraying water into bearings, motor

and electrical connections.

Check that all screws and fasteners are tight enough. If you notice any missing or damaged

fasteners or other parts, replace immediately.

Check that all installations and parts are still securely fastened to the spreader assembly.

Apply dielectric grease on all electrical connections.

Lubricategreasettingswithagoodqualitymultipurposegrease.

Yearly maintenance checklist (e.g. before or after putting your spreader away for storage)

Clean the hopper carefully inside and out with water, before putting it in storage. Avoid spraying

water into bearings, motor and electrical connections.

Clean and apply dielectric grease on all electrical plugs and connectors. Clean and install all

dust caps before placing your spreader in storage

Lubricategreasettingswithagoodqualitymultipurposegrease.

Check condition of bearings, replace if needed.

Cover the spreader with a tarp during storage, to protect it from sun fading and other weather

conditions and circumstances.

You must follow all the steps in these

maintenance checklists for warranty

to be valid.

iNOTE

MAINTENANCE

15

IceStrikerTM

Applytotheserecommendationsbeforeplacingyourspreaderino-seasonstoragetomaintainit

in a good condition.

• Cover your spreader using a tarp during storage periods

• Apply a protective compound such as dielectric grease on all electrical connectors and use caps

for protection before storage.

• Disconnect and remove the control unit from your vehicle. Store it in a dry and cool place, and

protect it from heat and moisture.

• Empty the hopper, remove all kinds of debris and clean the hopper from dirt before storage.

• Protect the hopper from excessive heat during storage periods.

Storage

IMPORTANT:

It is strongly recommended and of great importance that you

regularly apply dielectric grease on all electrical connections

and protect them with caps when not in use to prevent corrosion.

Always keep caps on when

the cables are not connected

or in use.

To prevent corrosion, use

dielectric grease on electrical

connectors before connecting

them.

While cables are connected,

also connect matching caps to

protect them from dirt and dust.

16

IceStrikerTM

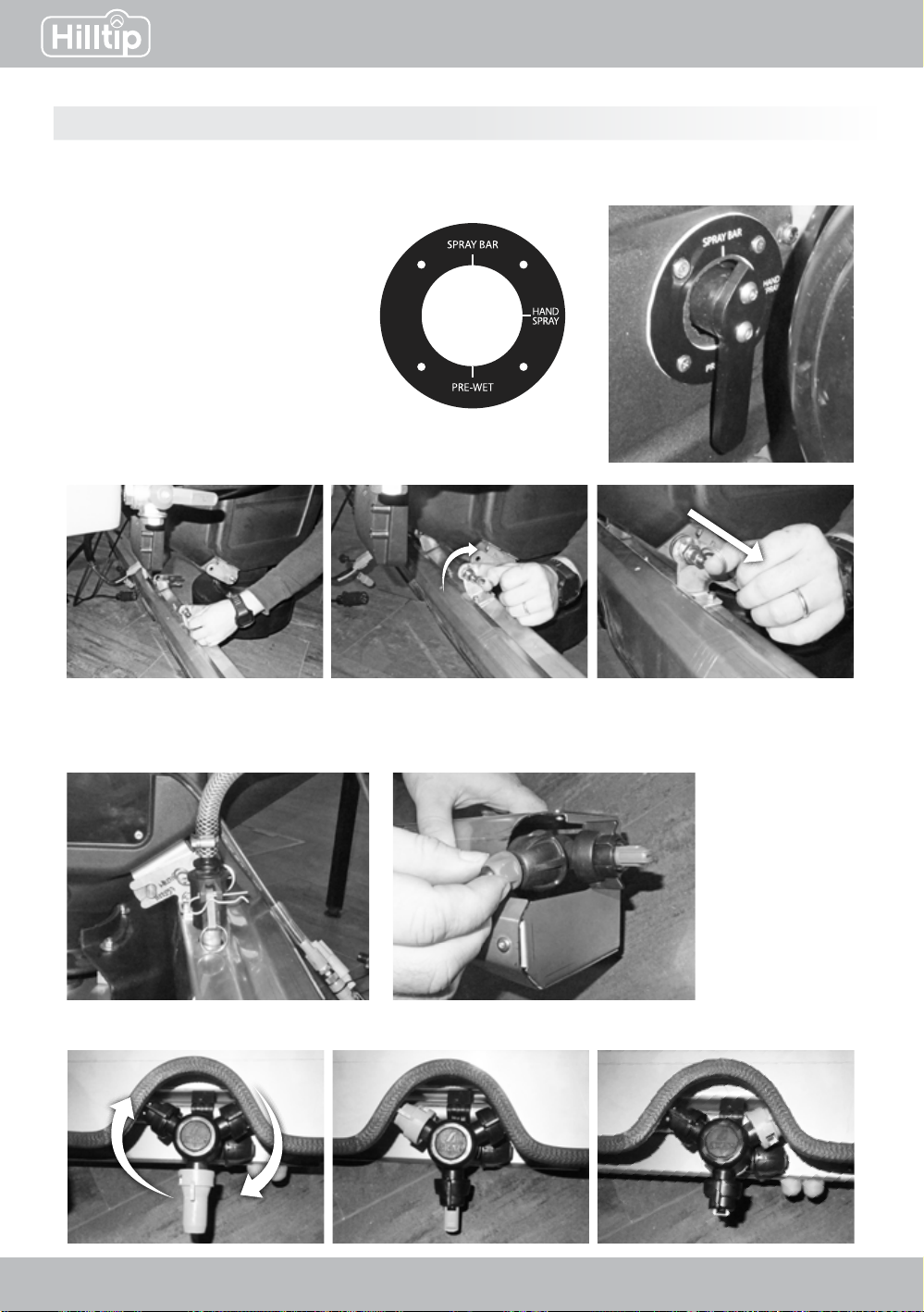

Pre-wet (optional)

2.Youwillndahandleontheright

side of the chute. Point the handle

towards PRE-WET

1. Start with selecting PRE-WET as spreading mode in the controller.

Go to: Main menu > Settings > Wetting > select Pre-wet

The liquid tank should always be emptied after each use (turn

theredhandle).Alsoemptythelter.Ifliquidsareleftinthe

tank for an extended period of time, it may freeze and cause

damage to your spreader.

Alsomakesuretocleanthelterregularly.

Caution!

OPTIONAL LIQUID SYSTEMS

17

IceStrikerTM

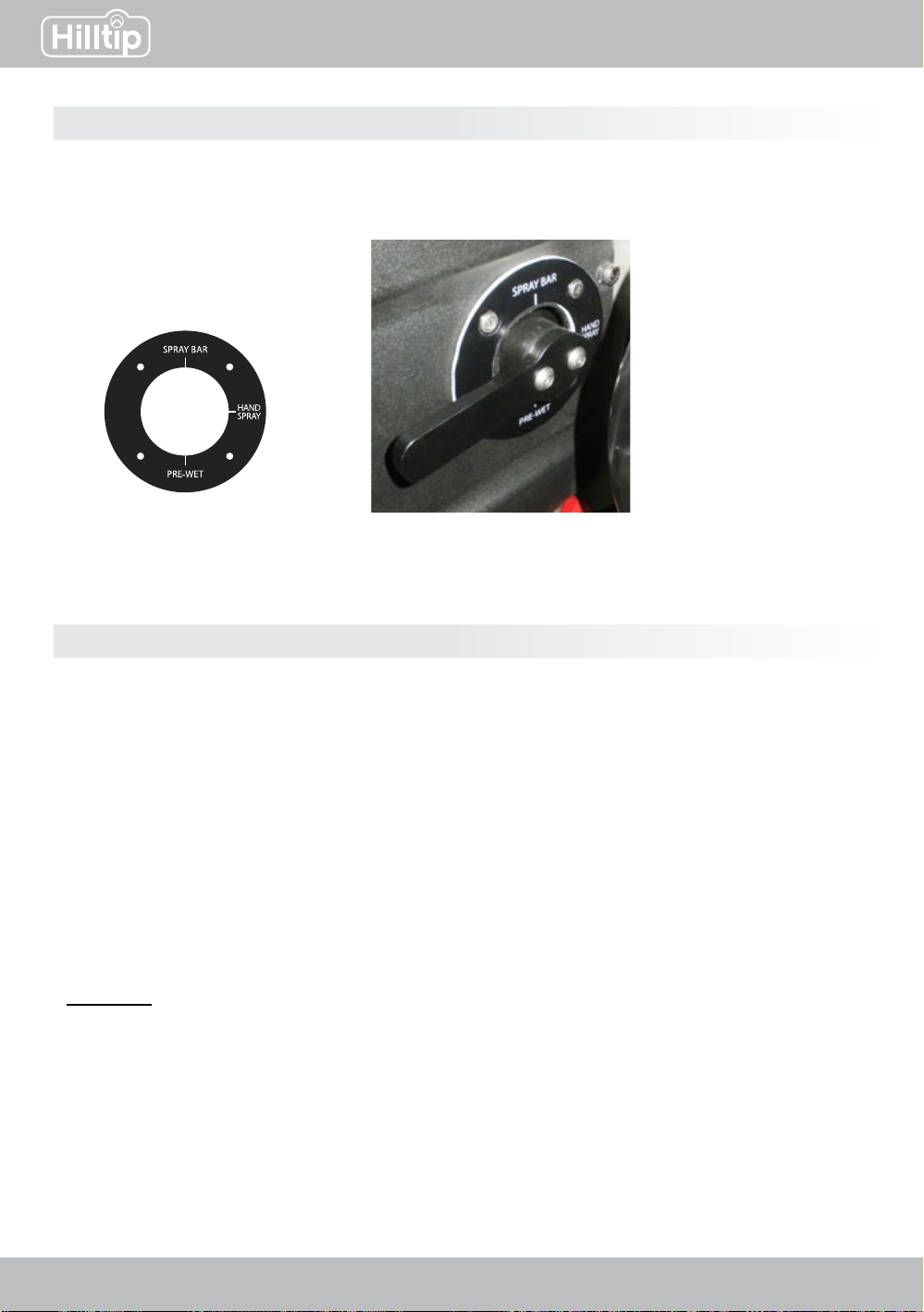

Spray-bar (optional)

1. Start with selecting Spray-bar as spreading mode in the controller.

Go to: Main menu > Settings > Wetting > select Spray-bar

2.Youwillndahandleonthe

right side of the chute. Point the

handle towards SPRAY BAR

4. Attach hose to the spray bar and

fasten the cotter pins on both sides

3. Attach spray-bar to the chute:

6. Turn nozzle to change nozzle type:

5.Turntheredcaptoturnontheliquidowtotheside

nozzles (will increase the spray width with 1-1,5 m on

each side)

Quick-disconnect point

18

IceStrikerTM

Bladder tank (optional)

2. Remove the plug from

the bottom of the spreader

1.Youwillndahandleon

the left side of the chute.

Point the handle towards

BLADDER TANK

3. Place the bottom support

plate and bladder tank.

Pull the hose trough the hole

of the plate and the hopper.

4. Place and fasten the metal

bars on top of the hopper,

strap the bladder tank to the

bar.

5. Fasten the hose from the

bladder tank to the spreader

liquid system (under the

hopper)

19

IceStrikerTM

Hose reel (optional)

1. Start with selecting Hand spray as spreading mode in the controller.

Go to: Main menu > Settings > Wetting > select Hand spray

2.Youwillndahandleonthe

right side of the chute. Point the

handle towards HAND SPRAY

IMPORTANT!

Liquid system clean-out instructions

1. Disconnect spraybar hose at rear of vehicle at Quick-disconnect point. (see page 17)

2. Turn on pump until the hopper tank is empty (alternatively pump the salt liquid back into your

storagetank).Onceempty,turnothepump.

3. Disassemblethelter.

4. Connect andpresstheclean-outhoseinstalledwithconeintopumpinletinsidelterhosing.

5. Add water and RV antifreeze into a barrel, where you put the other end of the clean-out hose.

6. Turn on pump.

7. Reinstall quick-disconnect hose to hosereel/spraybar.

8. Run pump until it is running clear out of each nozzle.

Attention! Ignoring these important steps may cause damage to the pump and the entire liquid

system. If damage is caused by avoiding these steps, the warranty will no longer be valid.

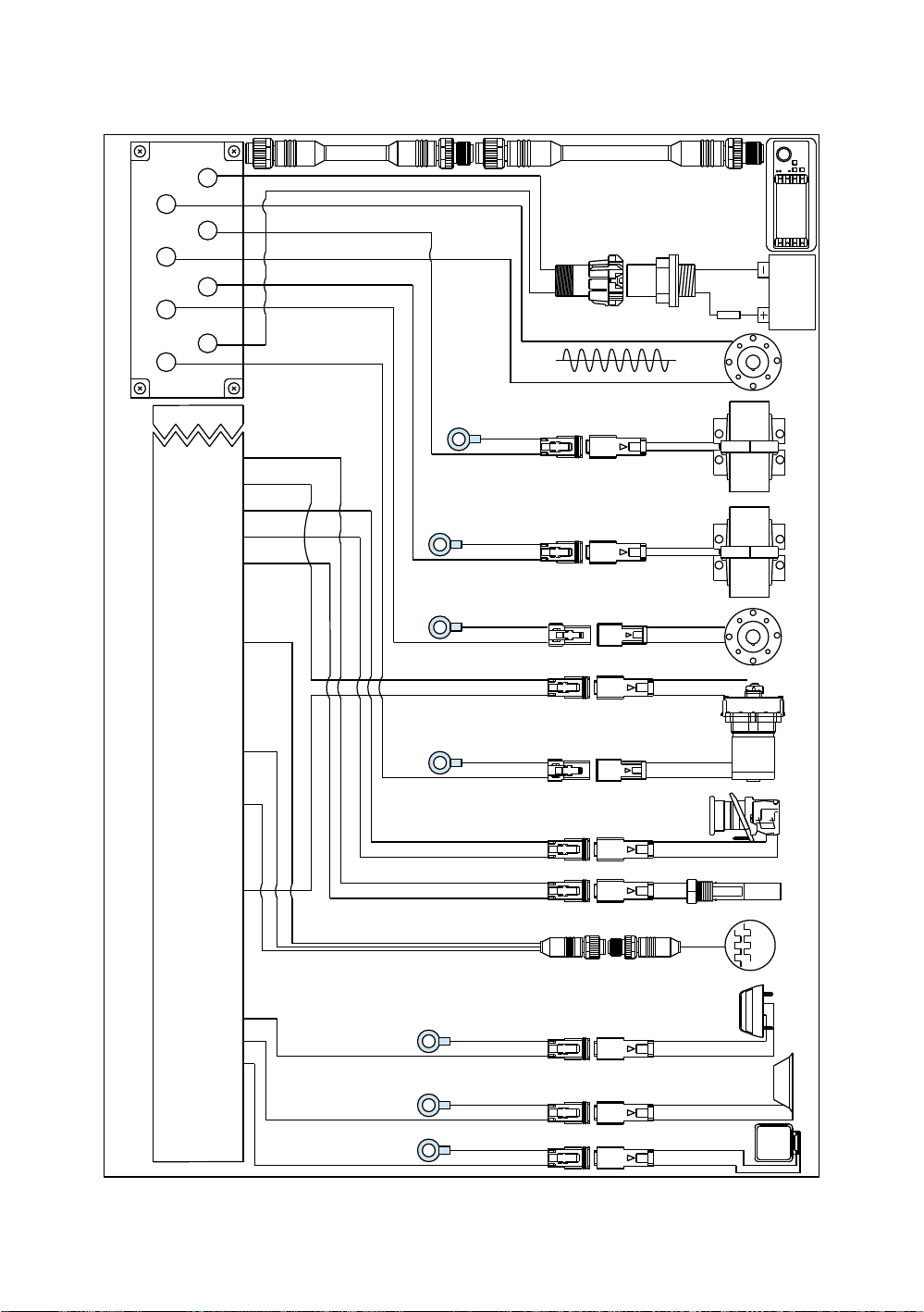

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Spreader module,

Main connector 35pin

Electrical schematics - IceStriker 600-1000 TR

Liquid

Pump Spinner Auger - Auger +

+12VDC Vibr 1 Vibr 2 GND

35

Battery

FUSE

80A

1

1

2

2

Esc

Auger

Motor

Vibrator 1

12

Spinner

Motor

12

21 21

Liquid Pump

(optional equipment)

1

1

2

2

12

21

Worklight Beacon

Camera +

Transmitter

+12V

Auger-

encoder

Auger-

encoder A/B

Level

sensor Emergency

Stop

1

1

2

2

1

1

2

2

1

1

2

2

1

1

2

2

1

1

2

2

white

black

brown

GND GND GND GND

Vibrator 2

(optional equipment)

12

21

GND GND

GND

This manual suits for next models

2

Table of contents

Popular Spreader manuals by other brands

SnowEx

SnowEx HELIXX installation instructions

Land Pride

Land Pride PS25120 Operator's manual

Durapac

Durapac DHS-05 instruction manual

Teagle

Teagle TITAN 6 Instruction book / parts list

Art's Way

Art's Way V180 Operator's manual and parts list

Fisher Engineering

Fisher Engineering TEMPEST S150A installation instructions

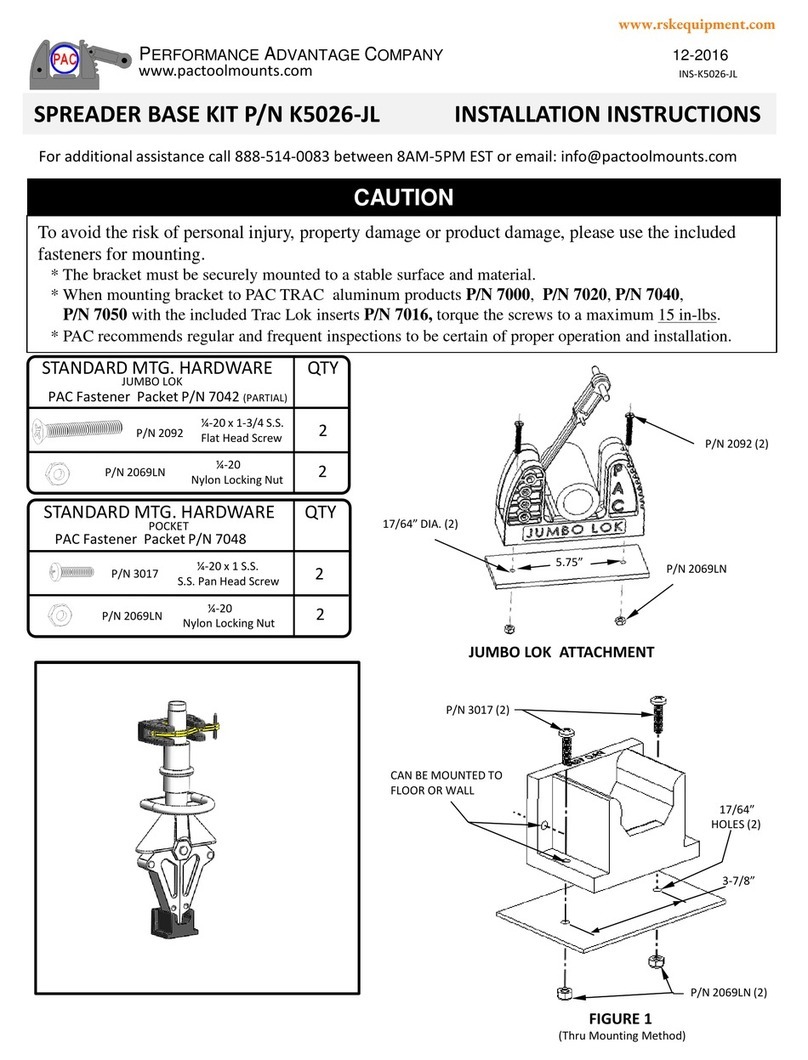

PERFORMANCE ADVANTAGE COMPANY

PERFORMANCE ADVANTAGE COMPANY K5026-JL installation instructions

SnowEx

SnowEx SP-575V Owner's/operator's manual

Wolf Garten

Wolf Garten WE-B Original manual

KUHN

KUHN ALTOR 6070 Operator's manual

Kubota

Kubota VS220-330 Technical & service manual

Gardol

Gardol GST-E 451 Original operating instructions