S-BT-ER and S-BT-EF screw-in stainless steel and carbon

steel threaded studs for electrical connections

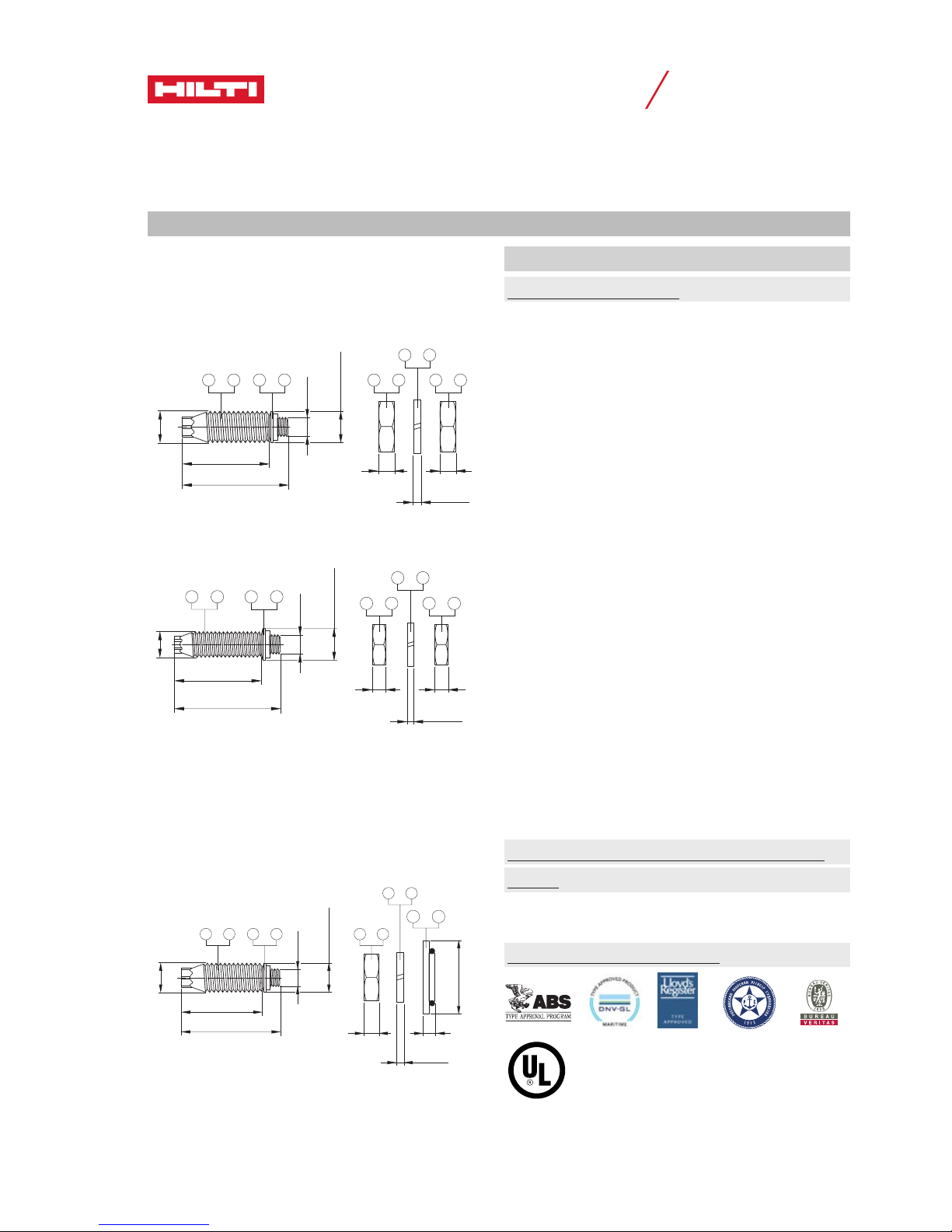

Dimensions

Product data

S-BT-ER M10/15 SN 6

S-BT-ER W10/15 SN 6

S-BT-EF M10/15 AN 6

S-BT-EF W10/15 AN 6

S-BT-ER M8/15 SN 6

S-BT-EF M8/15 AN 6

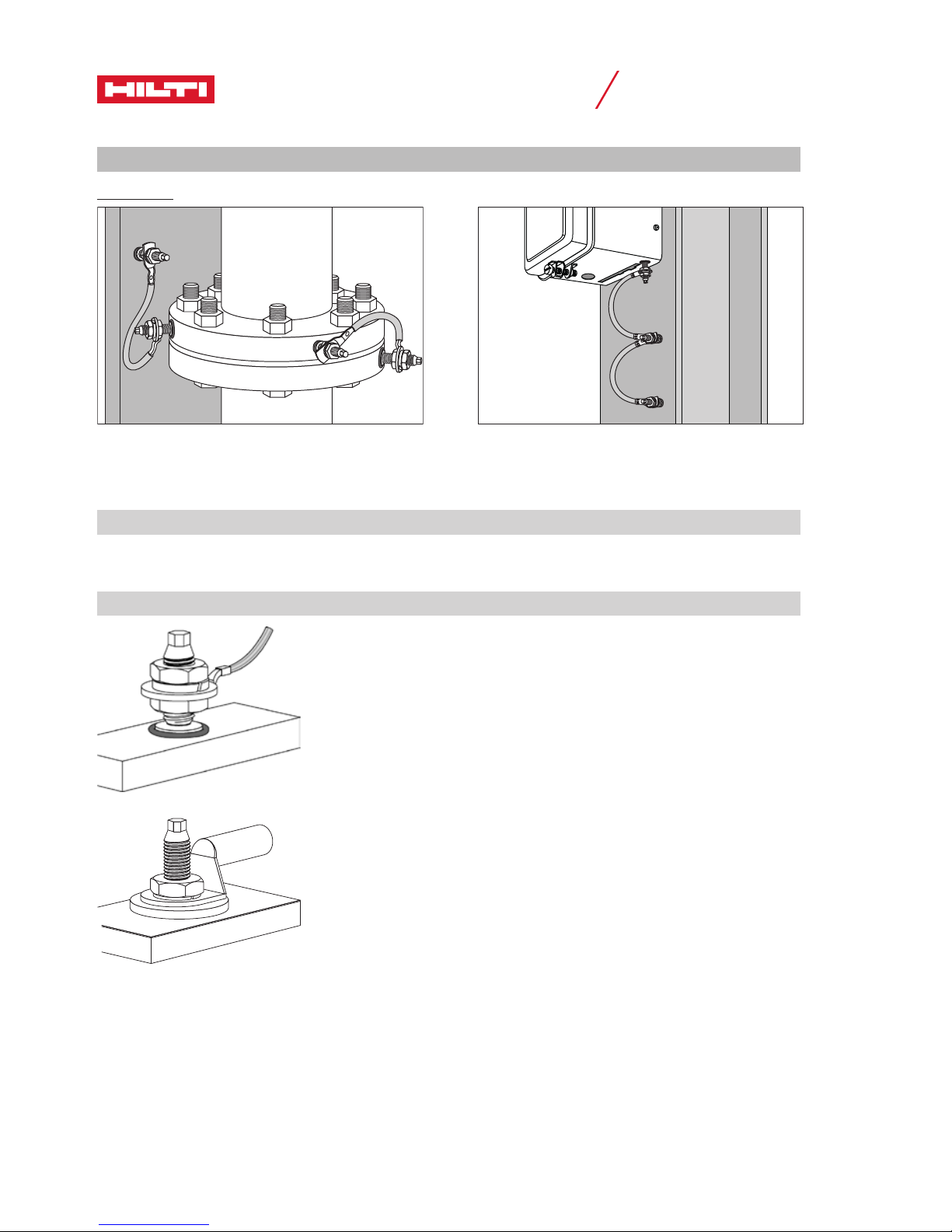

General information

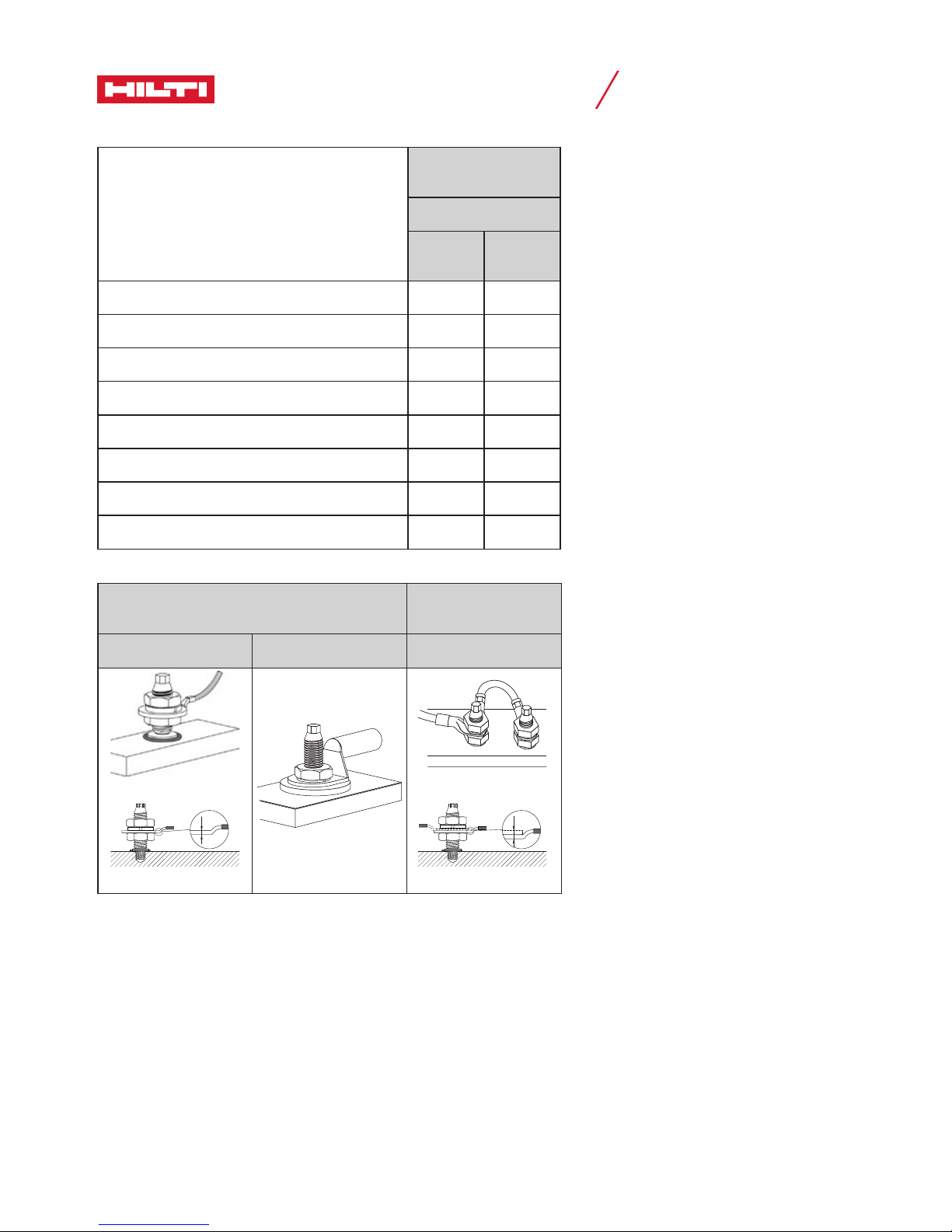

Material specifications

ÀThreaded shank: Stainless steel (S-BT-ER)

“S 31803 (1.4462)”

zinc-coated

Á Threaded shank: Carbon steel (S-BT-EF)

“1038 / duplex-coated”

SN12-R washers: Ø 12 mm [0.47”]

Stainless steel (S-BT-ER)

“S 31603 (1.4404)”

à AN10-F washers: Ø 10 mm [0.39”]

Aluminum (S-BT-EF)

ÄNut: Stainless steel (S-BT-ER)

grade A4 / AISI 316 material

Å Nut: Carbon steel (S-BT-EF)

HDG

Æ Lock washer: Stainless steel (S-BT-ER)

grade A4 / AISI 316 material

Ç Lock washer: Carbon steel (S-BT-EF)

HDG

È Conductivity disc: Ø 22 mm [0.866”]

(HC 35/AWG2)

Copper alloy CuSn8

(tin-coated) with sealing ring

É Conductivity disc: Ø 32 mm [1.260”]

(HC 120/AWG4/0)

Copper alloy CuSn8

(tin-coated) with sealing ring

Sealing ring of

sealing washers: Chloroprene rubber CR

3.1107, black, resistant to

UV, salt water, water, ozone,

oils etc.

Conductivity discs: Resistant to UV, salt water,

water, ozone, atmospheric

conditions etc.

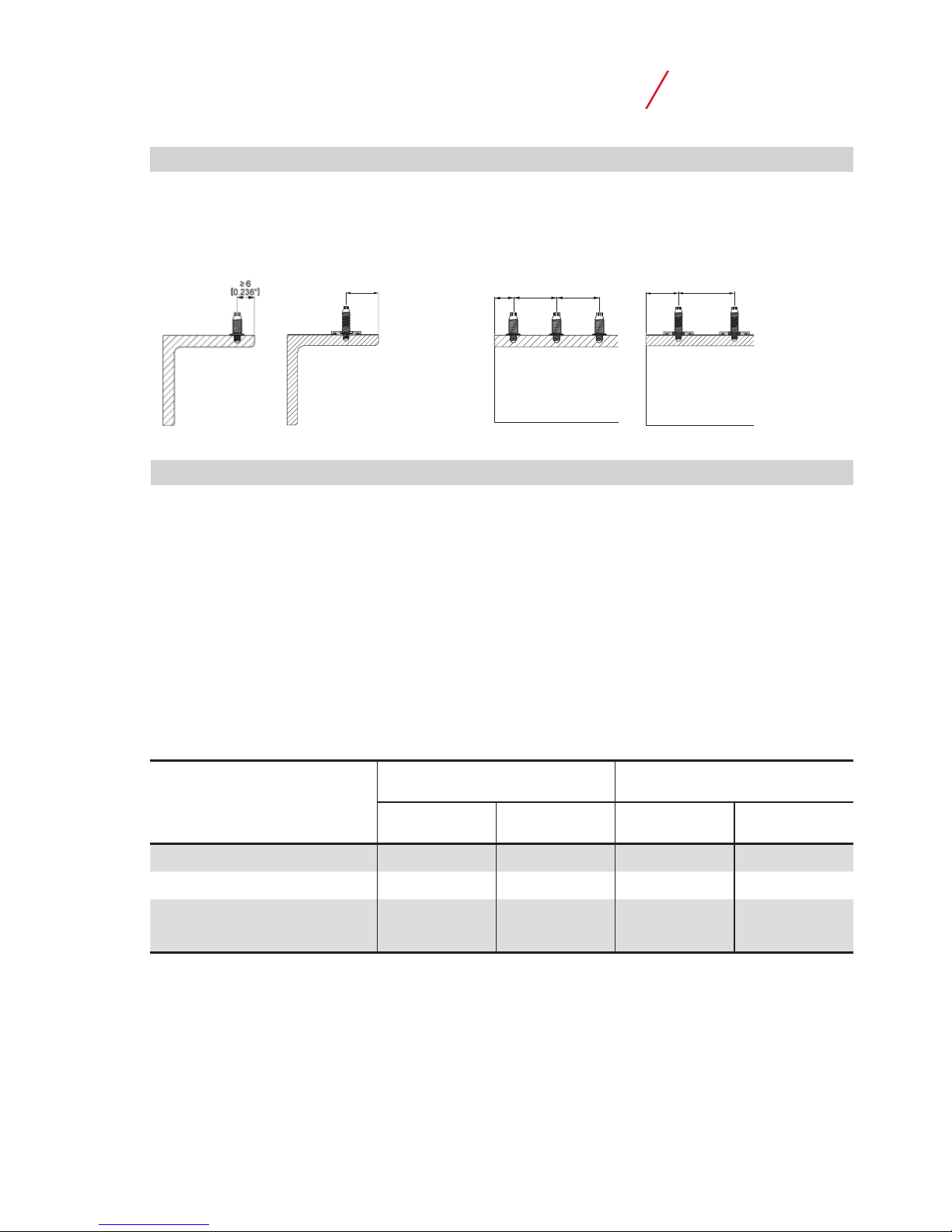

Drilling tool, setting tool, accessories and

inserts

Refer to section “Fastener selection and system

recommendation” for more details.

Reports and type approvals

27.75 [1.1"]

33.9 [1.33"]

21or 43oror