408- 10272

LightCrimp Plus ST Fiber Optic Connector Kit 2064757- 1

Rev C6 of 8 Tyco Electronics Corporation

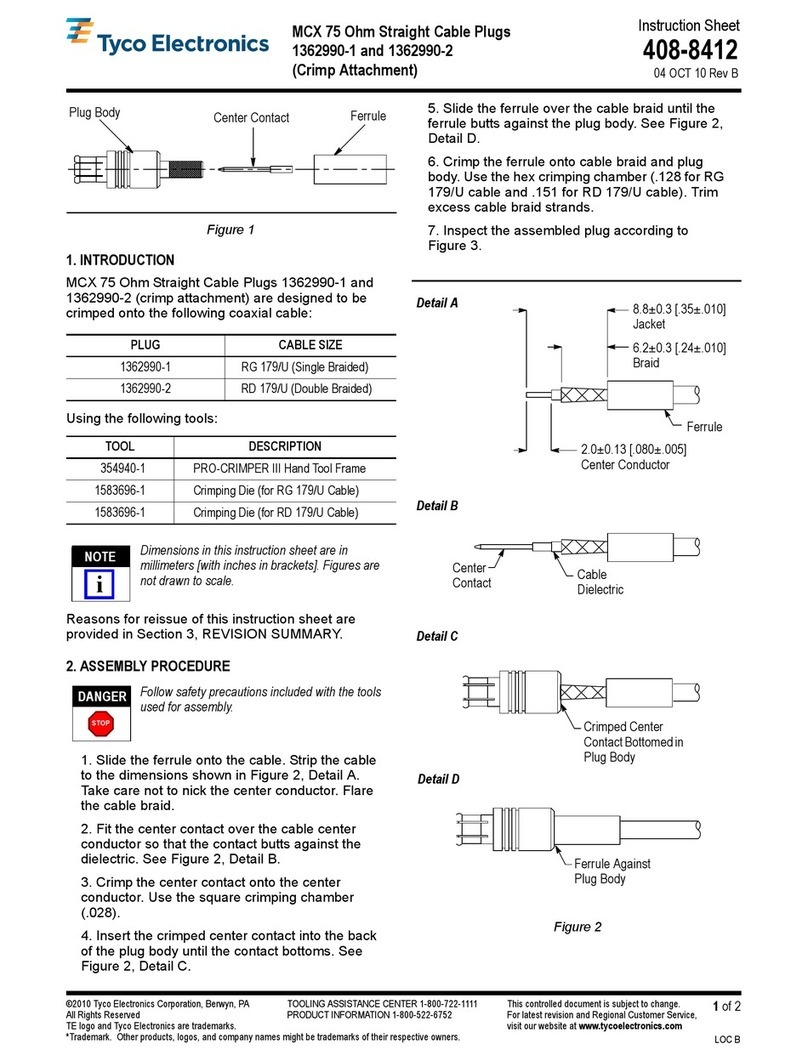

4. Gently close the fiber clamp, and slide the

carriage forward. DO NOT touch the button while

sliding the carriage. See Figure 5, Detail C.

5. Open the fiber clamp, and remove the cleaved

fiber, and properly dispose of the scrap fiber.

DO NOT attempt to clean the fiber after it has

been cleaved.

6. For loose jacketed cable, if the small white

tubing was not inserted into the plunger of the

connector assembly (in Step 4 of Paragraph 5.2),

slide the small white tubing over the fiber as shown

in Figure 5, Detail D.

6.2. Crimping (Figures 6, 7, and 8)

1. Open the cable clamp of the cable holder, and

hold the buffer (with the cleaved end of the fiber

facing the connector) inside the clamp. Pull the end

of the fiber even with the front of the arm of the

cable holder, and holding the buffer in place, close

the clamp. See Figure 6, Detail A.

2. Carefully insert the fiber into the plunger of the

connector assembly until the the fiber bottoms

against the internal fiber. Make sure that the

remaining mark on the buffer enters the plunger.

The resultant bend in the buffer should hold the

fiber against the internal fiber. See Figure 6,

Detail B.

It is important that the fiber bottoms against, and

remains against, the internal fiber. If the mark

does not enter the plunger or if the fiber does not

seem to bottom against the internal fiber, the

fiber may be caught on internal guides. Rotating

the connector and backing the fiber out a small

amount and re--entering may help. However, if

the mark will not enter the plunger, the fiber must

be re--stripped.

Make sure that the fiber does not pull rearward

from the contact (with the internal fiber) during

the crimping operation.

3. Squeeze the handles of the hand tool until the

ratchet releases. Allow the handles to open fully.

Gently close the handles until you hear three clicks

from the ratchet.

4. With the connector assembly in the cable

holder, position the ferrule in the upper cavity of the

front die and the plunger in the upper cavity of the

rear die. It is important to make sure that the tip of

the plunger sits in the channel of the rear die with

the protruding disk of the plunger flat against the

wall of the cavity. If the plunger is not positioned

correctly, it will be crushed when the tool is

actuated. See Figure 6, Detail C.

The arrows marked on the front die indicate the

direction that the ferrule must be pointing when

the connector is positioned in that cavity.

For proper placement, and to avoid damage to

the fiber, the direction of the arrows must be

observed. Refer to Figure 6, Detail C and

Figure 7, Detail A.

5. Gently push the buffer toward the connector to

make sure that the fiber is still bottomed, then

slowly squeeze the tool handles together (using

both hands) until the ratchet releases. Allow the

handles to open fully, and remove the connector

assembly from the dies.

6. Position the plunger of the connector assembly

in the first (smallest) cavity of the front die with the

shoulder of the plunger against the edge of the

groove in the die and the ferrule pointing in the

direction of the arrow. See Figure 7, Detail A.

7. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

8. Slide the crimp eyelet away from the connector

until the strength members are free, then slide the

crimp eyelet toward the connector until the strength

members and crimp eyelet butt against the

connector. See Figure 7, Detail B.

9. Slide the black tubing forward into the small

diameter end of the crimp eyelet until it butts

against the rear of the connector. See Figure 7,

Detail B.

10. Position the large diameter end of the crimp

eyelet in the last (largest) cavity of the front die

with the ferrule pointing in the direction of the

arrow. See Figure 7, Detail C. Slowly squeeze the

tool handles together until the ratchet releases.

Allow the handles to open fully.

11. Position the small diameter end of the crimp

eyelet in the middle cavity of the front die with the

ferrule pointing in the direction of the arrow. See

Figure 7, Detail D.

12. Slowly squeeze the tool handles together until

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

13. Install the ferrule dust cap onto the ferrule.

Open the cable clamp of the cable holder, and

remove the cable from the clamp. Slide the strain

relief over the crimp eyelet until the strain relief

butts against the connector. See Figure 8.

14. Remove the connector assembly from the

cable holder. If not connecting connectors, keep

the ferrule dust cap on the ferrule.

CAUTION

!

NOTE

i

CAUTION

!