b) When blade is binding, or when interrupting a

cut for any reason, release the trigger and hold

the saw motionless in the material until the blade

comes to a complete stop. Never attempt to re-

move the saw from the work or pull the saw back-

ward while the blade is in motion or kickback

may occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

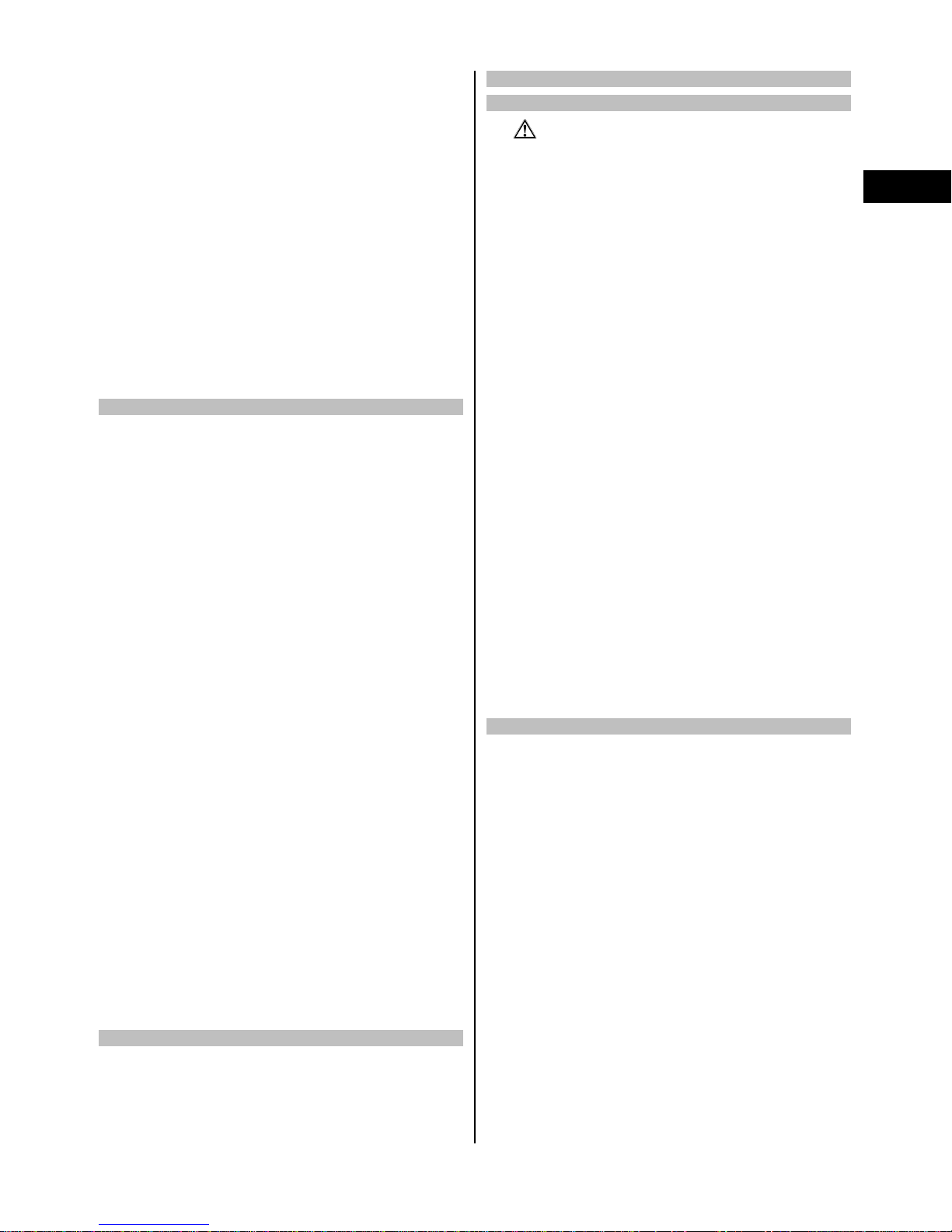

c) When restarting a saw in the workpiece, centre

the saw blade in the kerf and check that saw

teeth are not engaged into the material. If saw

blade is binding, it may walk up or kickback from the

workpiece as the saw is restarted.

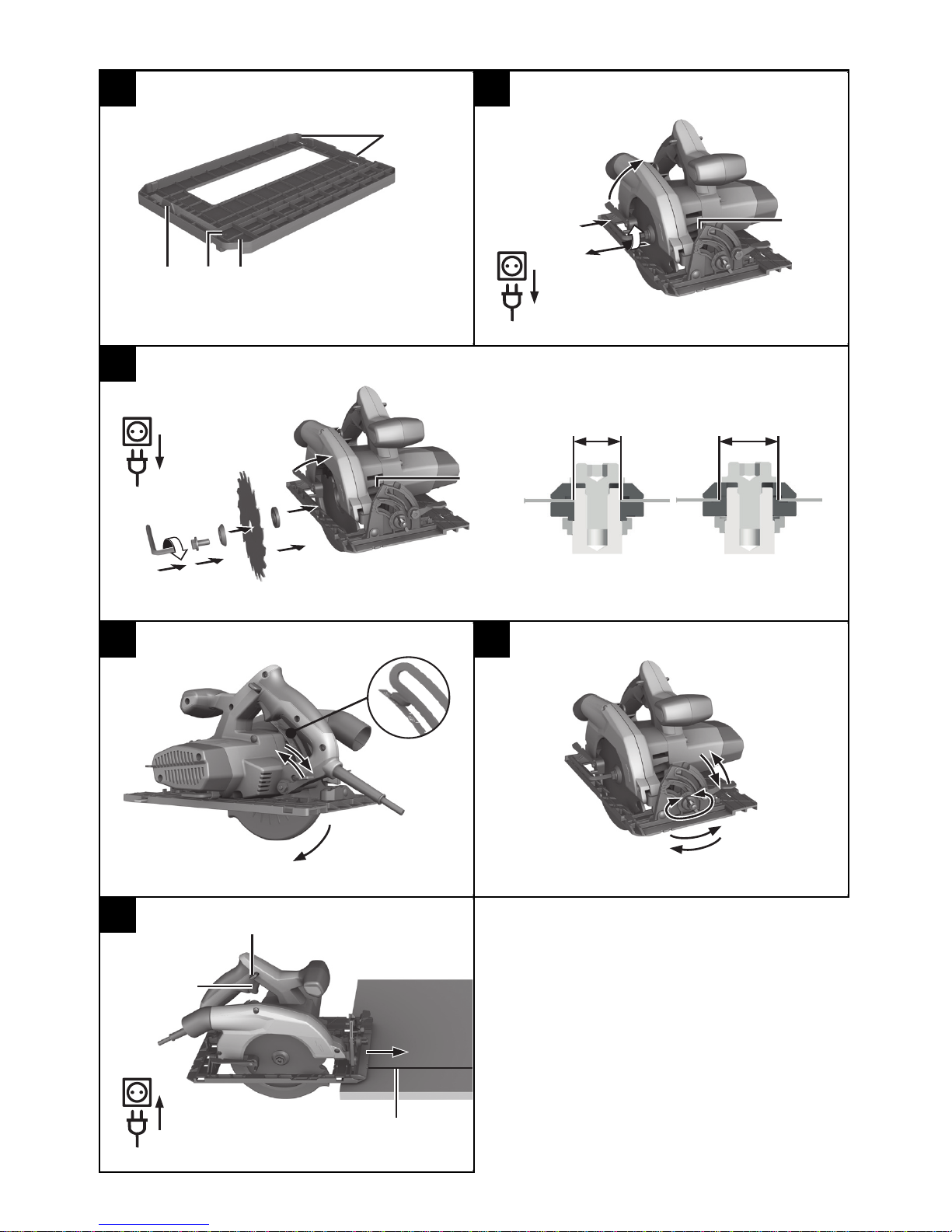

d) Support large panels to minimise the risk of blade

pinching and kickback. Large panels tend to sag

under their own weight. Supports must be placed

under the panel on both sides, near the line of cut

and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened

or improperly set blades produce narrow kerf causing

excessive friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

blade adjustment shifts while cutting, it may cause

binding and kickback.

g) Use extra caution when sawing into existing walls

or other blind areas. The protruding blade may cut

objects that can cause kickback.

2.2.3 Safety instructions for circular saws with

pendulum guard

Lower guard function

a) Check lower guard for proper closing before each

use. Do not operate the saw if lower guard does

not move freely and close instantly. Never clamp

or tie the lower guard into the open position. If saw

is accidentally dropped, lower guard may be bent.

Raise the lower guard with the retracting handle and

make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of

cut.

b) Check the operation of the lower guard spring.

If the guard and the spring are not operating

properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts,

gummy deposits, or a build-up of debris.

c) Lower guard may be retracted manually only for

special cuts such as “plunge cuts” and “com-

pound cuts.” Raise lower guard by retracting

handle and as soon as blade enters the mater-

ial, the lower guard must be released. For all other

sawing, the lower guard should operate automatic-

ally.

d) Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its

path.Beawareofthetimeittakesforthebladeto

stop after switch is released.

2.3 Additional safety instructions

2.3.1 Personal safety

a) Modification of the machine or tampering with its

parts is not permissible.

b) Wear ear protectors. Exposure to noise can cause

hearing loss.

c) Breathing protection must be worn if the power

tool is used without a dust removal system for

work that creates dust.

d) Do not operate the power tool without the pro-

tective devices that belong to it.

e) Improve the blood circulation in your fingers by

relaxing your hands and exercising your fingers

during breaks between working.

f) Switch the power tool on only after bringing it into

position at the workpiece.

g) Always guide the power tool away from your body

when working with it.

h) Do not work with the power tool overhead.

i) Do not attempt to brake the tool by applying

lateral pressure to the saw blade as this may

cause kickback.

j) Do not touch the clamping flange, the clamping

screw or the saw blade while the power tool is

running.

k) The kerf must be free of obstructions. Do not saw

into screws and nails etc.

l) Never press the drive spindle lock button while

the saw blade is rotating.

m) Never direct the power tool toward persons.

n) The appliance is not intended for use by debilit-

ated persons who have received no special train-

ing. Keep the appliance out of reach of children.

o) Adjust the forward pressure applied to the tool

according to the saw blade used and the material

to be cut, so that the blade doesn’t stall.

p) Avoid overheating the tips of the saw blade teeth.

q) When cutting plastics, melting of the plastic

should be avoided.

r) In the event of any damage to the power tool or

blade, disconnect the supply cord plug from the

power outlet immediately. Do not operate the tool

when parts are damaged or when the controls do

not function correctly. If necessary, have the tool

repaired at an authorized Hilti service center.

s) Working on the material may cause it to splinter.

Wear eye protection and protective gloves. Wear

breathing protection if no dust removal system is

used. Splintering material presents a risk of injury to

the eyes and body.

t) Before beginning the work, check the hazard clas-

sification of the dust that will be produced. Use

an industrial vacuum cleaner with an officially

approved protection classification in compliance

with locally applicable dust protection regula-

tions.

u) Dust from materials, such as paint containing lead,

some wood species, concrete / masonry / stone con-

taining silica, and minerals as well as metal, may be

harmful. Contact with or inhalation of the dust may

en

4

Printed: 21.05.2015 | Doc-Nr: PUB / 5223412 / 000 / 02