HIOS Neji Taro III HS III-10 User manual

Automatic Screw Feeder

Neji Taro

HS series

HS -10 HS -12 HS -14 HS -17

HS -20 HS -23 HS -26 HS -30

Instruction Manual

Readthismanualbeforeusingthisdevice.

CurrentasofSeptember2018

18B

No. ET-D004

HIOS Inc.

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan

TEL: +81-47-392-2001 FAX: +81-47-392-7773

-2-

CONTENTS

1) BEFOREUSE......................................................................................................................................................1

2) FORSAFEUSE..................................................................................................................................................1

3) NAMEOFMACHINEPARTS........................................................................................................................3

4) ADJUSTMENTSANDCHECKSBEFOREUSE..........................................................................................4

5) OPERATINGINSTRUCTIONS.................................................................................................................... 12

6) REPLACEMENTOFCONSUMABLEPARTS.......................................................................................... 13

7) TROUBLESHOOTING.................................................................................................................................. 18

8) SPECIFICATIONS........................................................................................................................................... 23

9) EXTERNALDIMENSIONS........................................................................................................................... 25

10) THEFOLLOWINGTABLEISFORCHINARoHS2................................................................................ 26

Cautions

Besuretofollowthecautions,oritcouldlead

toseriousdamage,suchasinjuries,electric

shock,anddamageproperties.

-1-

1) BEFORE USE

ThankyouverymuchforselectingourAutomaticScrewFeeder“HSIIIseries”.Pleasecheckthefollowingaccessoriesbefore

operatingthemachine.

•CD-ROM,1

•ACadapter,1piece

•Hexagonalwrench,1piece

•Screwdriver,1piece

*ForfeedermachinespurchasedoutsideofJapan,noadaptorwillbesuppliedwiththefeeder.

Pleasepurchaseaseparateadapterwithequivalentoutputspecicationasrequired.

2) FOR SAFE USE

ReadthefollowingCautionsthoroughlyforthesafeuseofthismachine.Keeptheminmindduringtheoperationofthemachine

inordertopreventinjuriesanddamagetoproperty.

Installation

Caution:InstallationInstallthemachineonalevel,stablelocationthatcanendureit’sweightandrunningconditions.Ifthe

machinefallsdownorturnsoverduetoimproperinstallation,injuriesorpropertydamagemayoccur.

OperatingEnvironment

Caution:Donotoperatethismachinewhereflammableorcorrosivegasispresent.Itisextremelydangeroustousethis

machineundersuchcircumstances.Donotoperatethismachineinenvironmentofhighhumidity.

ACadapter

ForfeedermachinespurchasedoutsideofJapan,noadaptorwillbesuppliedwiththefeeder.Pleasepurchaseseparateadapter

withequivalentoutputspecicationasrequired.

-2-

Thetransformer-typeACadapterattachedtothemachinehasnominaloutputofDC12V-500mA;duringapplication,itisdesigned

tosupply an average output atabout15Vtothescrewfeeder.Inthecasewhereadierenttype of adapter or externalpower

sourceisused,itisrecommendedtousea15Vswitchingtypeadapter,orregulatedpowersupplywhichcanprovideconstant

outputat15V.

Rail

Caution:Donotdamagenoroiltherail.

Screwcompatibility

Caution:Donotusescrewswithgrease,dirtyscrewsoranyscrewotherthanthoseprescribed.

Accessofscrews

Caution:Donotexertexcessiveorimpactiveforcewhenaccessingthescrews.

Whenmachineisnotinuse

Caution:BesuretounplugtheACadapterfromthewalloutletduringclosinghoursandifthemachinewillbeleftunattended

foranyextendedperiodoftime.

Abnormalitiesduringoperation

Caution:Stopoperationandunplugimmediatelywheneveryousenseabnormalitiesorunusualmachinebehaviorsduringthe

operationofthismachine,suchasapungentodor.TurnothepowerswitchanddisconnecttheACadapterfromthe

receptacle.Continued operation may cause re,electricshock,malfunctionorpersonalinjury.Immediatelycontact

thedealerfromwhichyoupurchasedtheproduct.

Servicing

Caution:Donotattempttorepair,disassembleormodifythismachineexceptwherespeciedbythismanual.

Consultyourdealerforserviceandrepairofthismachine.

-3-

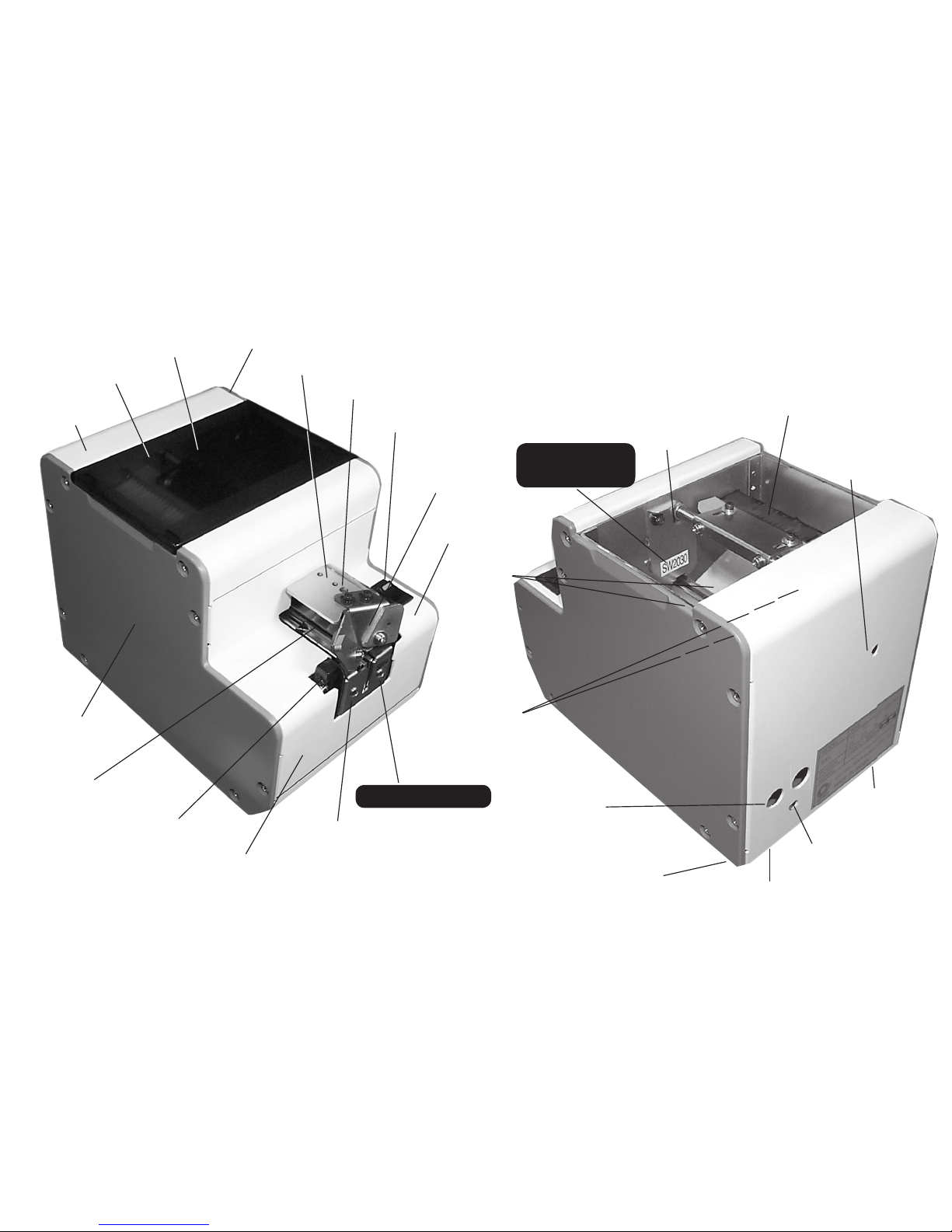

3) NAMES OF MACHINE PARTS

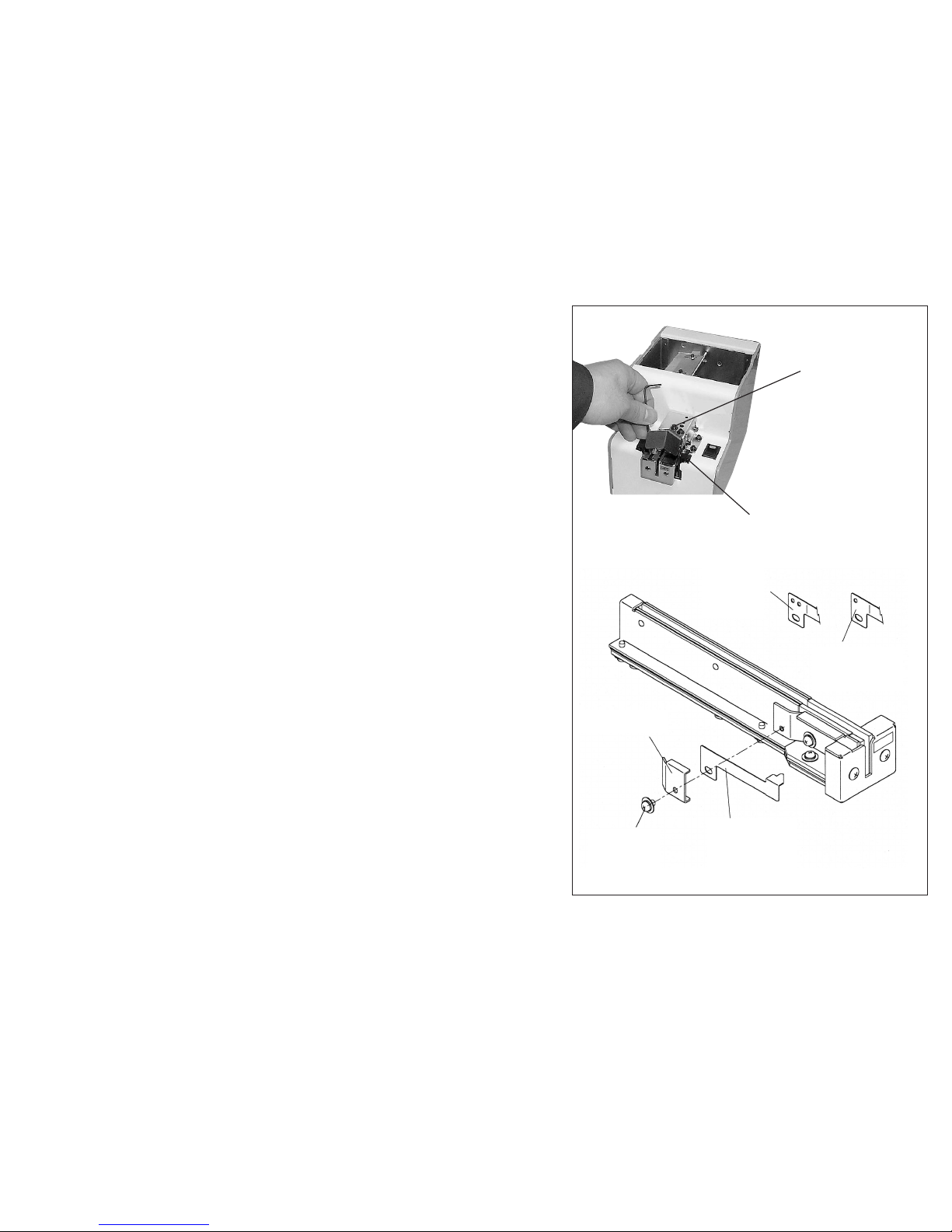

Rightsidecover

Bitguideassembly

Railxingbolt

Powerswitch

Bitguide

Light-receiving

sensor

Railassembly

Frontcover

Light-emittingsensor

Holdingplate

Leftsidecover

Rearcover

Uppercover

Scoopingchamber

Scooping

chamber

Passingplate

Brush

Timerknob

Tiltingbolt(under

themachine)

Vibrationadjusting

platexingbolt

Vibrationadjustingbolt

(underthemachine)

Tiltingbolt

(underthemachine)

DCjack

Scoopingblock

(leftandright)

(movingupanddown)

Passingplate

indenticationseal

Railidenticationseal

-4-

4) ADJUSTMENTS AND CHECKS BEFORE USE

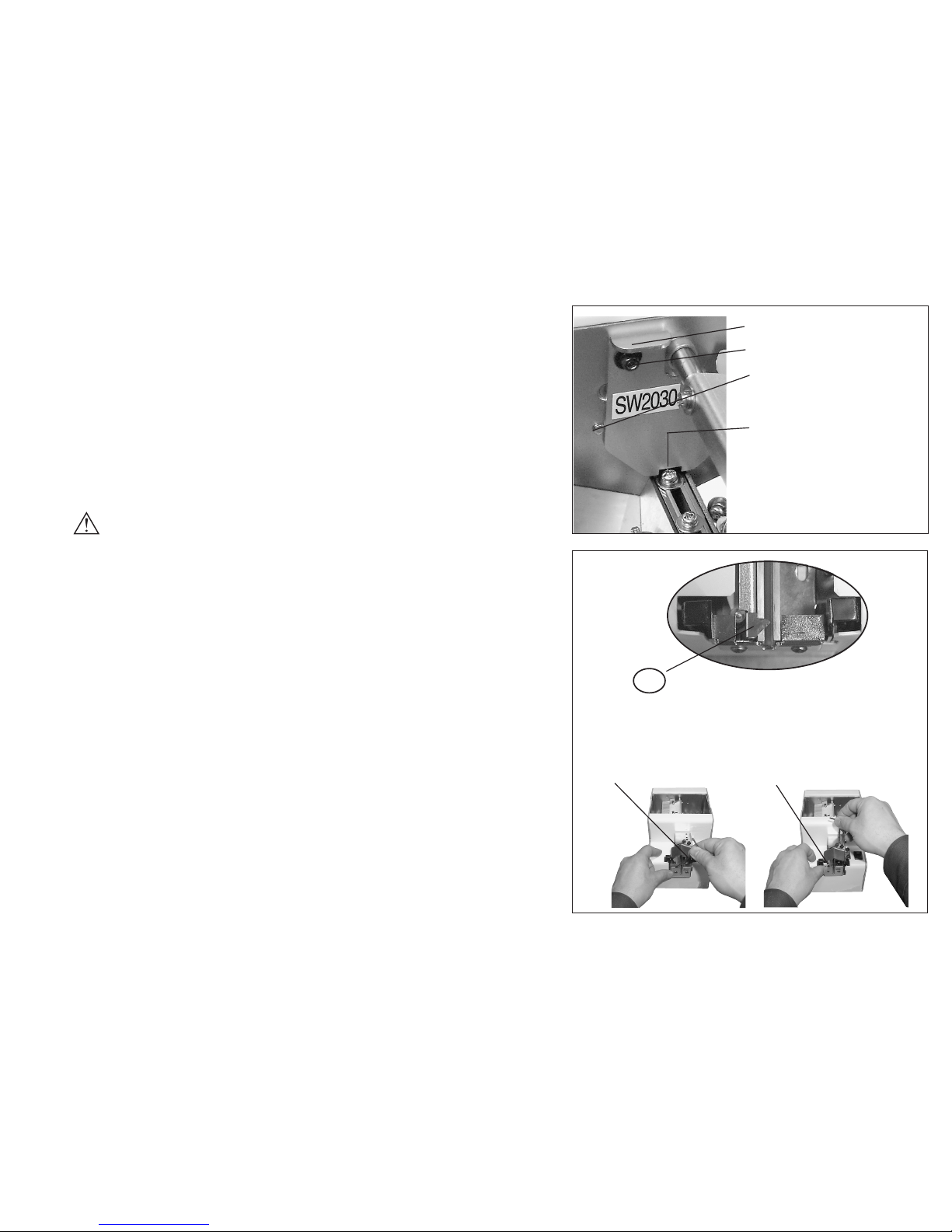

Beforeusingthemachine,pleasecheckiftherailandcomponentsinstalledonthemachineissuitableforthescrewapplied.Therailisφ1.0

toφ 3.0dependingonthenominaldiameter.Itisdeterminedbytheidenticationsealonarailfrontcover.Therearetwokindsofpassage

plates,namelyoneforφ1.0toφ1.7andoneforφ2.0toφ3.0.Itisdeterminedbyanidenticationsealaxedonapassageplate.

◆ When there is no rail installed on the machine, please install the rail before use.

First,unfastentherailxingboltthroughtheupperbitguideholder.

Inserttherailintothefurthestpoint.

Fastenthexingbot.

◆ Quantity of screws thrown in

Iftoomanyscrewsarethrownin,orientationandtransferofthe

screwswillbeseriouslyaected.Seethediagramontherightforthe

maximumnumberofthethrowscrewsinthe[scoopingchamber].

•Setthe[scoopingblock]inthelowestpossibleposition.

•

Throwinscrewsuptoapositionof2mmto3mmbelowtherailgrooveface.

•Inthiscondition,ensurethatthefrontinclined-faceoftherampis

nothiddenbythescrews.

Thesepartsoftheinclinedfaceoftherampshouldbeuseunderline.

Ensurethattherailgroovefaceisnothiddenbythescrews.

(Screwsshouldbepositioned2to3mmbelowtherailgroove.)

-5-

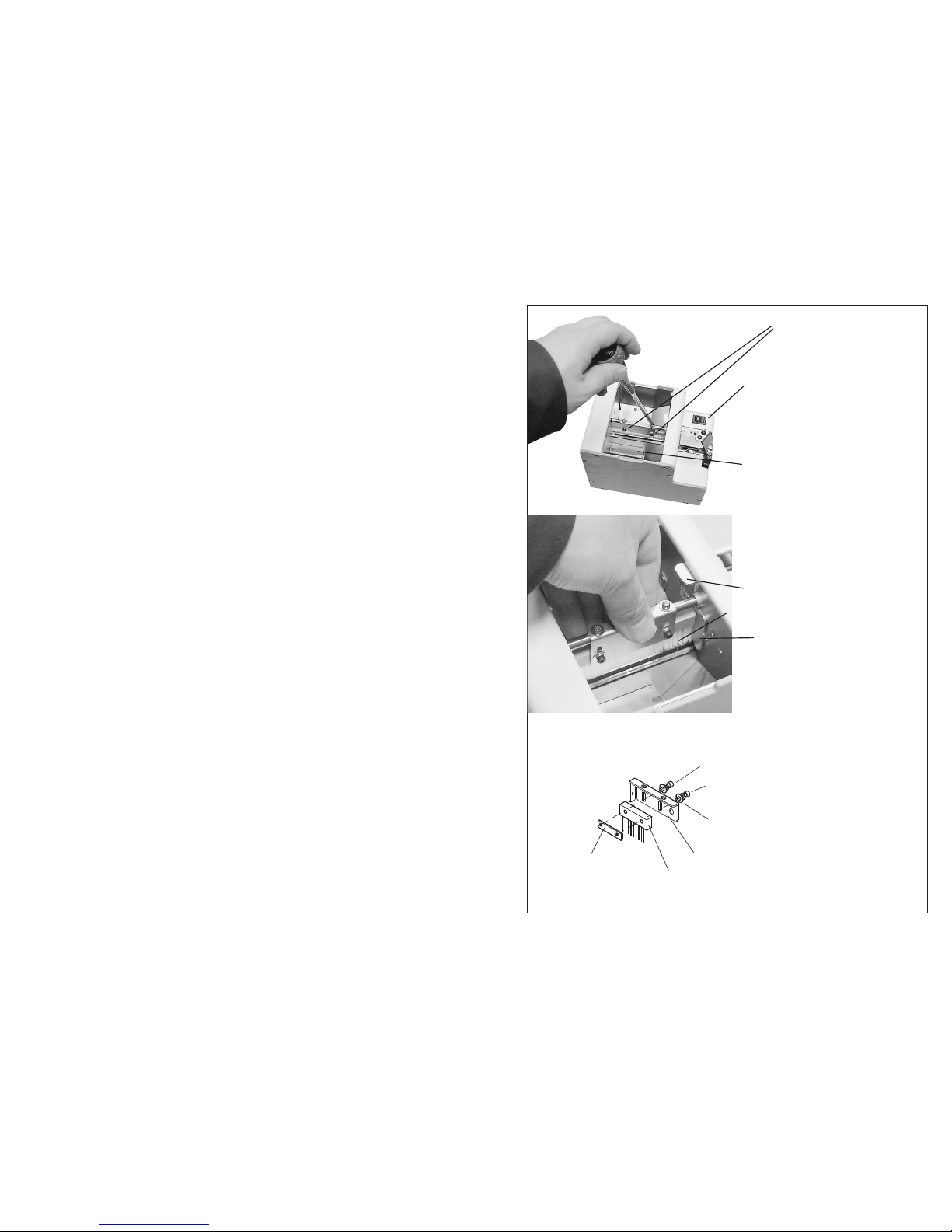

◆ Adjustment of the brush

Checktheheightofthebrush.

•Asinthepictureontheright,setthebrushtoanapproximatelylevel

position.

•Ensurethattheedgeofthebrushisgrazingthescrew’shead.

•Iftheheightofthebrushiseithertoolowortoohigh,orientation

andtransferofthescrewswillbeseriouslyaected.

•Ifadjustmentisnecessary,adjustitbylooseningthebrushheight

adjustingscrew.

Ensurethattheedgeofthebrush

isgrazingthescrew'shead.

Adjustmentscrew

forthebrush

Brush

Screws

Turnthepowerswitchon

&o,andsetthebrushon

thelevel.

-6-

Thegapbetweentheholdingplateandtheheadof

screwsshouldbe0.2mmto1mm.Theholdingplateand

therailshouldbeparallel,too.

Thebitguidebracketattachingscrews

Adjustmentof

theheight

Matchthecenterofthe

holdingplateoutletand

therail.(Itisnotnecessary

toremovethebitguide.)

Attachingscrews

◆ Adjustment of the holding plate

Checkthepositionoftheholdingplate.

•ensurethatthegapbetweentheheadoftheusedscrewintherail

grooveandtheholdingplateisapproximately0.2mmto1mm.

•Ifthereisnogap,thescrewgetscaught.Ifthegapistoolarge,the

screwoverlapsorjutsout.

•Ifadjustmentisnecessary,adjustitupordownbylooseningthebit

guidebracketattachingscrew.

Easily adjust it by using the 0.35 mm gauge plate.

Loosenthebitguidebracketattachingscrew.Insertthegauge

betweenscrewsontherailandtheholdingplate.Tightenthebit

guidebracketattachingscrewwhentheholdingplateistouchingthe

frontandthebackofthegaugeequally.

Caution:Matchingthecenteroftheholdingplateoutletandtherail

centermaybenecessary.

•Ensurethatthecenteroftheholdingplateoutletmatchestherail

center.

•Ifnot,adjustitbylooseningtheattachingscrew.

Holdingplate

-7-

◆ Adjustment of the passage plate

Checktheheightofthepassageplate.

•Ensurethatthepassageplateisadjustedataheightwheretheused

screwcanmanagetopass.

•Ifthepassageplateistoolow,thescrewcannotpass,andiftoo

high,thescreweasilygetscaught.

•Ifadjustmentisnecessary,adjustitbylooseningthepassageplate

attachingscrew.

Caution:Slidethehalfblankingatbothsidesofthepassageplateup

anddowntheguide.

◆ Adjustment of the rail

Checkthephysicalrelationshipofthestopperandsensor.

•ensurethattherailisxedsothat“A”portionofthestopperis0mm

to0.5mmaheadofthesensoropticalaxis.

•Ifadjustmentisnecessary,adjustthelocationbylooseningtherail

attachingscrew.

Ensurethescrewpasses

throughthewindowwithno

extraspace.

Screw

Passageplate

Passageplateattachingscrew

Halfwayhole

(Onbothsidesofthepassage

plate)

Lookingdownfromthetop,aportionofthestopperis

stickingout0to0.5mmmoreforwardthanthesensor's

opticalaxis.(It'snotnecessarytoremovethebitguide.)

Adjusttherailbackandforth.

A

Loosentherailattachingscrew.

-8-

◆ Check/adjustment of the bit guide

Checkthepositionofthebitguide.

•

Adjustthebitguidetoapositionwhereausercaneasilytakescrews.

Actuallypickupscrewsafewtimestoadjustit.

Adjustitbylooseningtheattachingscrews.

Caution:Therailisadjustedaccordingtothephysicalrelationship

withthesensorasontheprecedingpage,sobasicallythe

railisnotadjustedhere.

◆ Adjustment of the left and right guide pieces

Pleasecheckandadjustpositionoftheguidepieceasnecessary.

Thebitguideisoriginallysetatapproximately3mmatthefront

opening,andshallbeadjustedasneededbytheuser.

•Unfastenthefrontxingscrews,insertdriver-bittobeusedand

adjusttheslitopening,sothatthebitcanmovefreely.

•Aftertheadjustment,trytopickupascrewandcheckitsworking

conditionbeforeturningonthepower.

◆ Check/adjustment of rail vibration

Transferspeedsofscrewsdieraccordingtoscrewtype.

Thismachinecanchangerailamplitudeandadjustthetransferspeed.

•Toadjustamplitude,loosenanamplitudexingscrewattherear

ofthismachineandturntheamplitudeadjustingscrewatthe

bottomofthemachine.

•Toadjustamplitude,loosenanamplitudexingscrewattherear

ofthismachineandturntheamplitudeadjustingscrewatthe

bottomofthemachine.

Thebitguideattachingscrew

Bitguide

Screw

(Assy.attachingscreews)

Adjustment

Amplitudexingscrew

LargerVibration

Amplitude(Vibration)

adjustmentscrew

SmallerVibration

-9-

Viewingitfromthebottom,ifturnedclockwise,theamplitudebecomeslarger,andifturnedcounterclockwise,theamplitudebecomes

smaller.

•Ifyoumaketheamplitudetoolargeinordertospeedupthetransfer,itmaybecomediculttopullupscrews.So,adjustit

toappropriateamplitudeforthetypeofscrewbeingused.

•Afteradjustmentiscompleted,besuretotightentheamplitudexingscrewontherearofthemachine.

◆ Adjustment of the tilting bolts

Astheoriginalsetting,theautomaticscrewfeedershallbe

horizontalwhensetonasurface.

Dependingonspecictypeofscrewapplied,theremaybecases

thatthescrewscannotmovesmoothly.Atsuchinstance,please

checkthe“Adjustmentoftherail”sectionlistedinthisoperation

booklet,oradjusttiltingangleofthemachineasnecessary.

•Thetiltingboltsarelocatedonbottomrearendofthe

machine.

•Whentheseboltsareused,theyshallbesetatthesame

heightandangleonbothsides.

•Sincetheboltsdonothavestoppersequippedinside,please

becarefulnottodetachthemfromthemachinebody.

•Aftertheadjustment,pleaseverifyifscrewdeliveryfunctions

properlybeforeapplication.

Tiltingbolt

• Loosenthetiltingbolts,toadjustangleof

themachine.

• Keepbothsidesasthesameheight.

-10-

◆ Check of the sensor’s optical axis

Ifthereisnoscrewatthestoppersection,thismachinecontinuesoperation,andiftherearescrews,itstopsafteracertainperiodoftime

haspassed.Thismachinehasthelevelofthescrew/noscrewsensoradjustedbythereferencerailonshipment.Inreality,however,alevel

adjustmentofthesensormaybecomenecessarywhenusingthin-headscrewsorduetooccurrenceofthevariationonrailreplacement.

Then,followthedirections(1)and(2)fortheadjustment.

(1) •Loosethesensorattachingscrewonthesidelitupasmuchasitmovesbypickingupthesensorholderwithngers,and

turnonthepowerswitch.

•Placeascrewonthefailwithinthesensorrange.

•Holdtherailendlightlywithngersasmuchasitdoesn’tvibratesothatscrewsdoesn’tpassthrough.

•Whenthesensorholderismovedupanddown,thereisapositionthesensorofthereceivinglightsidedefectsascrewhead

andstopsthevibration.Tightthesensorattachingscrewatthisposition.

•Conrmwhetheritreallyworks or not. See ifascrewpasses

throughandthesensordetectsifandstops.

(2) •Removethemachinebodyrearcover,andmeasurethe

voltagelevel.AdjusttheIC40507th-pinvoltagelevel.The

ground,whenmeasuringit,isthebody’smetalpart.

•

Adjustmentisnotnecessaryifthevoltageleveliswithin0.25to

1.5Vwhenarailisandifthereisnoscrewatthestoppersection.

•Whenadjustmentisnecessary,loosenthesensorattaching

screwontheside.Adjustthevoltagelevelbymovingitup

anddown.(Itiseasiertomakeanadjustmentifconnectorof

themainmotorisremoved.)

•Aftertheadjustment,throwinthescrewsandrunitpractically

inordertochecktheoperation.

Note:Whennoloadedscrewsare:0.25Vto1.5VWhenloaded

screwsare:3.5Vormore.

Adjustingthesensorattachment

upanddownonthesidelitup

Thesensorattaching

screwonthesidelitup

No.7pinofIC4050

-11-

◆ Adjustment and Check of the timer

Thespeedofscrewdeliverydependsontheactualkindofscrew.Byadjusting

thetimerofthemachinethescrewsarepickedupsmoothly.

•Ifascrewispickeduponthestopperandthescrewcomingnextisnot

pickedupforacertainamountoftime,theunitstopstheoperation.Then

ifyoupickupthescrew,itstartsoperatingagain.Youcanchangethetime

byadjustingthetimerwithin1to6seconds.

•Timechangesafteradjustingthetimessettingvolumeontherearofthe

machineasshownontheright.Viewingtheunitfromtheback,ifit’sturned

clockwise,thetimebecomeslonger,andifit’sturnedcounterclockwise,the

timebecomesshorter.

•Donotuseexcessiveforcewhilemakinganadjustment.Turnitonlyas

muchasthepossiblerotatingrangeallows.

Caution:Usethescrewdriverprovidedwiththemachine.Usingother

screwdriversmaydamagecircuitcomponents.

◆ The operation check of the overload protection circuit

Foroverloaddetectionandcheckofprotectioncircuits:Trytoforcethe

movementofthescoopingblocktostop,tochecktheoperationofoverload

detectionandoverloadprotectioncircuits.Ifyouforcethemovementofthe

scoopingblock to stop for about4.5secondsorless,themainmotorstops

afterrepeatingrotationsofreverse->forward->reverse->.

Tocanceltheaboveoperationalcheck,turnoandthenturnonthepower

switchagain.

Checkoverloaddetectionandprotection

circuitsbyforcingtheup-and-down

movementofthescoopingblocktostop.

Timersettingvolume

Toreducetime

Toincreasetime

-12-

5) OPERATING INSTRUCTIONS

◆ Supplying screws (Refer to P. 4)

•Setthe[scoopingblock]tothelowestpossibleposition.Removethetopcoverofthe[scoopingchamber].Throwinscrews

uptoapositionof2mmto3mmbelowtherailgroovetopface.

•Inthiscondition,ensurethatthefrontinclined-faceoftherampisnothiddenbythescrews.

Caution:Anexcessivequantityofscrewsthrowninmaycauseamachinemalfunction.

◆ Switch-on

•PlugtheprovidedACadapterintoawalloutletandintothemachine.

•Turnonthepowerswitch.Thepowerswitchlampwilllightup.

•Theup-and-downmovementofthescoopingblockandback-and-forthmovementoftherailwillactivate.

•Subsequently,screwsaresuccessivelysenttotheoutletdirection.Unlessyoupickupthescrewsinthestoppersection,the

sensorsensesitandthemachinestopsoperation.

•Ifyoupickupthescrewsinthestoppersection,thesensorsensesitandthemachineresumesoperation.

◆ Picking up screws

•Whenpickingscrewsup,useabitthattsthescrewdiameterandgroovewidthoftheholdingplate.

•Makeamotor-drivendriver’sbitupright,putitdowntotheverticaldirectionalongtheVgrooveofthebitguidewhile

turningit,andpullitouttowardyourselfwhencrossrecessonthescrewhead.

Caution:Donotexertanyexcessiveforcetotherailatthistime.Itmaycausethemachinetomalfunction.

◆ Timer settings (Refer to P. 11)

•Ifyoupickupscrewsofthestoppersectionandthendonotpullupthenextscrewsforacertainperiodoftime,themachine

stops.Operationwillresumeagainafteryoupickupscrews.

•

Thetimeuntilthemachinestopsisadjustablewithin1to6seconds.Adjustitaccordingtotheprocedureinthediagramontheright.

Caution:AlwaysunplugtheACadapterfromthewalloutletbeforemakinganyadjustmentstoavoidinjury.

-13-

6) REPLACEMENT OF CONSUMABLE PARTS

Replacement of brushes

• Ifthetipofthebrushwearsoutanddoesnotwipeoascrew

fromanabnormalposition,replaceitwithanewbrush.

• Turnthemachine’spowerswitchonandoffandpositionthe

brushasinthediagramontheright.(PositionitsothattheBrush

assemblymountingscrewscanbeeasilyremoved.)

• Afterreassembly,ensurethatthebrushandthepassageplatedo

notclashwhentheBrushassemblymoves.Thegapisideally“0” .

• RefertoP.5,“Check/adjustmentofthebrush”formounting

adjustments.

Part number of brush assembly:

• HS3-02053

Brushassembly

attachingscrew

Brushassembly

Whenthebrushis

operating,itshouldnot

comeincontactwiththe

passingplate.

Powerswitch

Passingplate

Brush

Brushbracket#2

Brush

Brushbracket#1

Springwasher

M2.6

Plainwasher

M2.6

Hexsocketheadsmallbolt

M2.6×10

-14-

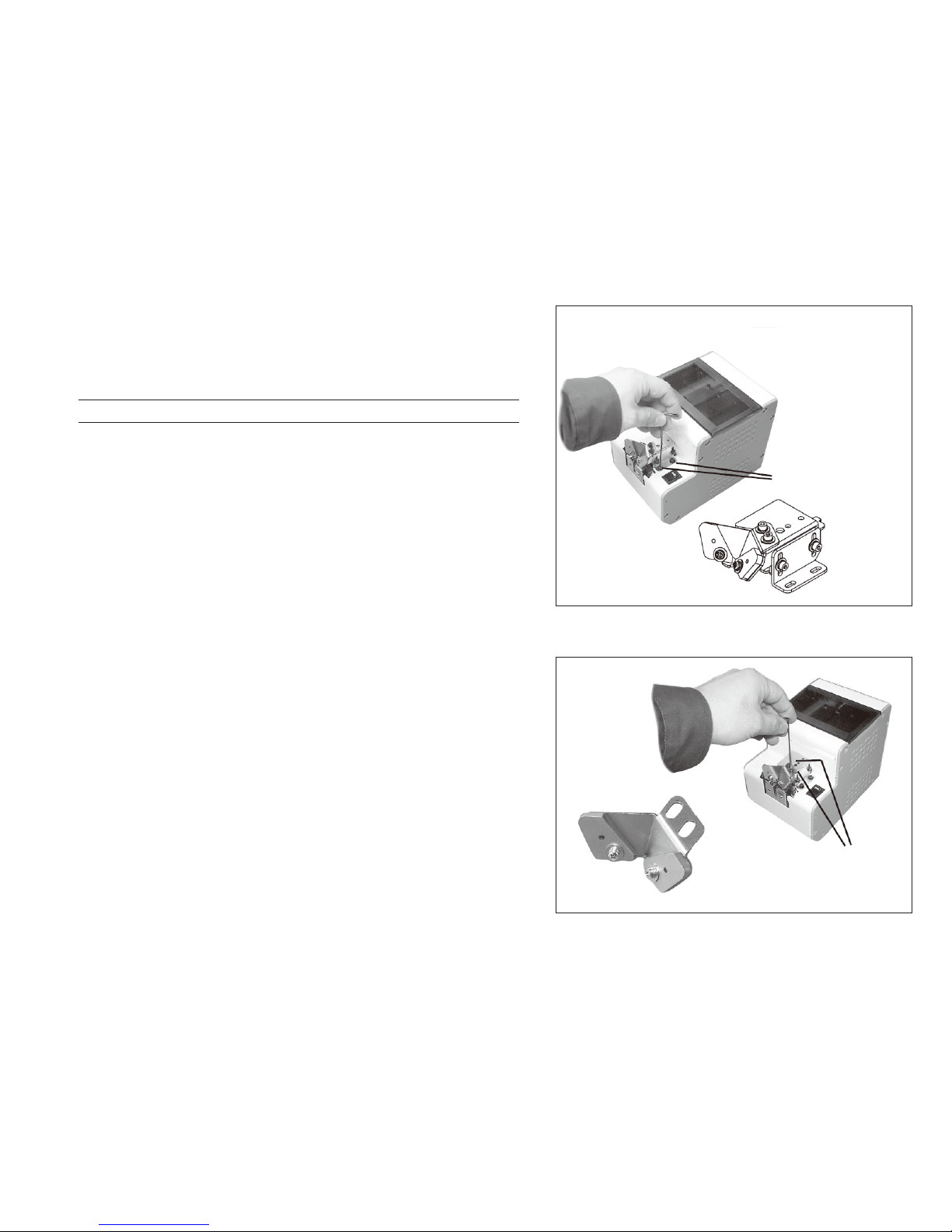

Replacement of the bit guide unit

Replacetheholdingplatewhenthereisdicultyinusingit,such

asafterexcessivewear.

Whenreplacingtheholdingplate,removethebitguidesectiono

thebodytopreventamountingscrewfromfallinginsidethebody.

•Asinthediagramontheright,removethebitguidesectionand

replacetheholdingplate.

•RefertoP.6,“Check/adjustmentoftheholdingplate”for

mountingadjustments.

Replacement of the bit guide assembly

Replacethebitguidewhenthereisdicultyinusingit,suchasafter

excessivewear.

•Asinthediagramontheright,removethemountingscrewsand

replaceit.

•RefertoP.8,“Check/adjustmentofthebitguide”formounting

adjustments.

Removethebitguide.

Fixingscrews,2pieces

Removethebitguide.

Fixingscrews,2pieces

-15-

◆ Replacement of the stopper

Replacethestopperwhenthereisdicultyinusingit,suchasafter

excessivewear.

•Asinthediagramontheright,loosentherailxingscrewsandpull

outtherailfromthebody.

•Thestoppercanbechangedasinthediagramontheright.

•Therearethreetypesofstoppers.

•Becarefultocorrectlymatchthenewstoppertothenominal

diameterbeingused.Determinethetypeofstopperbyexamining

theholeofthemountingsection.

Railxingscrew

Pullouttherailtowardyou.

Thisshapeis

for∅ 1.0.

Thisshapeisfor

∅ 1.2and∅ 1.4.

Stopperxingplate

Stopper

(Thisshapeisfor∅1.7-∅ 3.0.)

Fixingscrew

M2.6 × 4

-16-

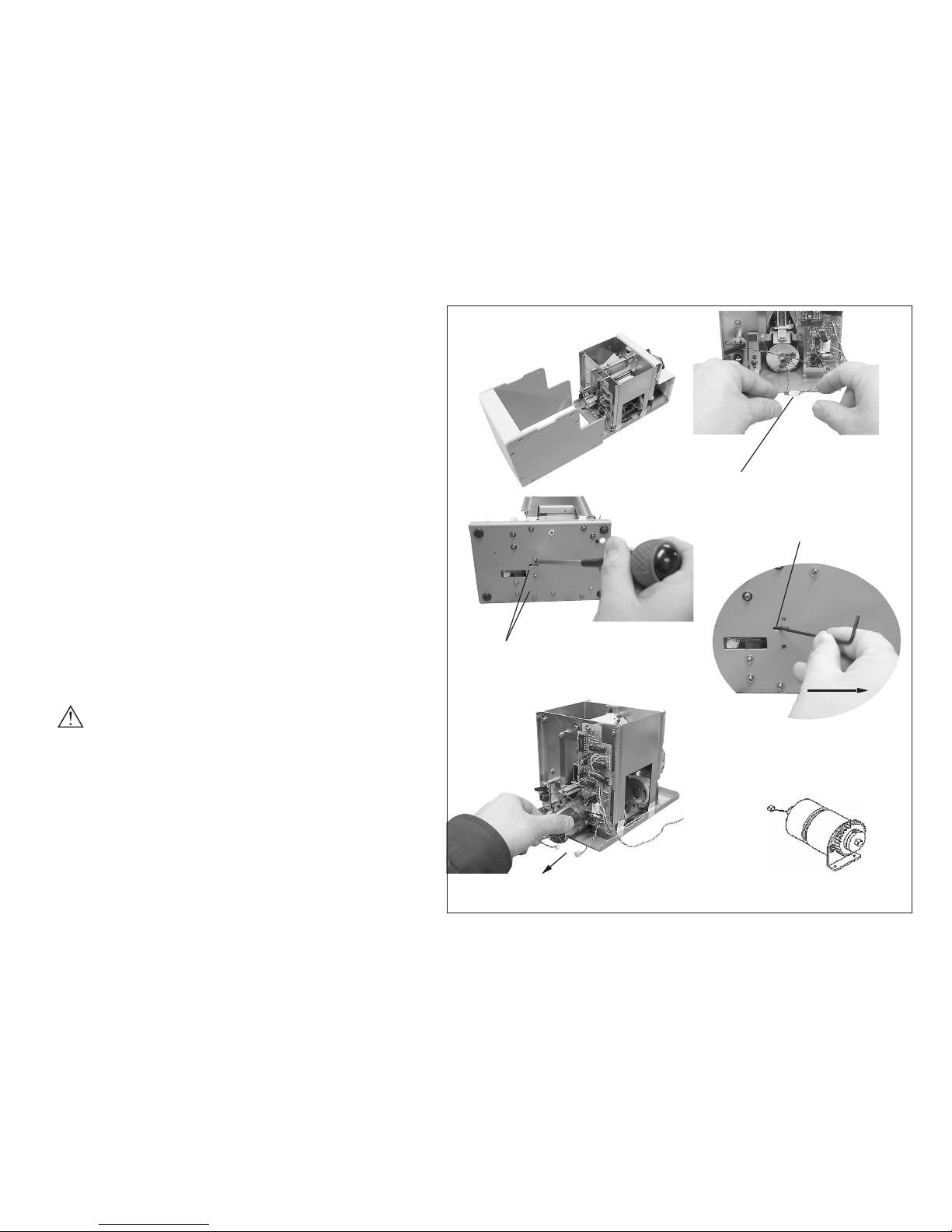

Replacement of the main motor unit

Replacethemotorafteritisdamaged.

•Removethecoverfromthebody.(Duringremoval,

asinthediagramontheright,thecovermounting

screwsshouldberemovedtogetherwiththefront

cover,leavingthefourscrewsoftherearinplace.)

•Removethemotortrunkconnector.

•Removethemotormountingscrewsonthemotor’s

bottomface.

•Pulloutthemotorsectionfromtherearofthebody.

(Tofacilitateremoval,insertahexagonalwrench

orthelikeintothelongholeofthebodybaseand

pushthemotormountingbracketbackward.)

•Becarefulnottobreakmotorwiresbyusingoverly

excessiveforce.

Caution:UnplugtheACadapterfromthewalloutlet

beforedisassemblyofthemotorsection.

Removethecover.

Removethemotortrunkconnector.

Removethemotormounting

screws(M2.6 × 82pieces)

Pushthemotormounting

braketbackwrd.

Thelonghole

Pulloutthemotorsection

fromtherearofthebody.

Mainmotorunit

-17-

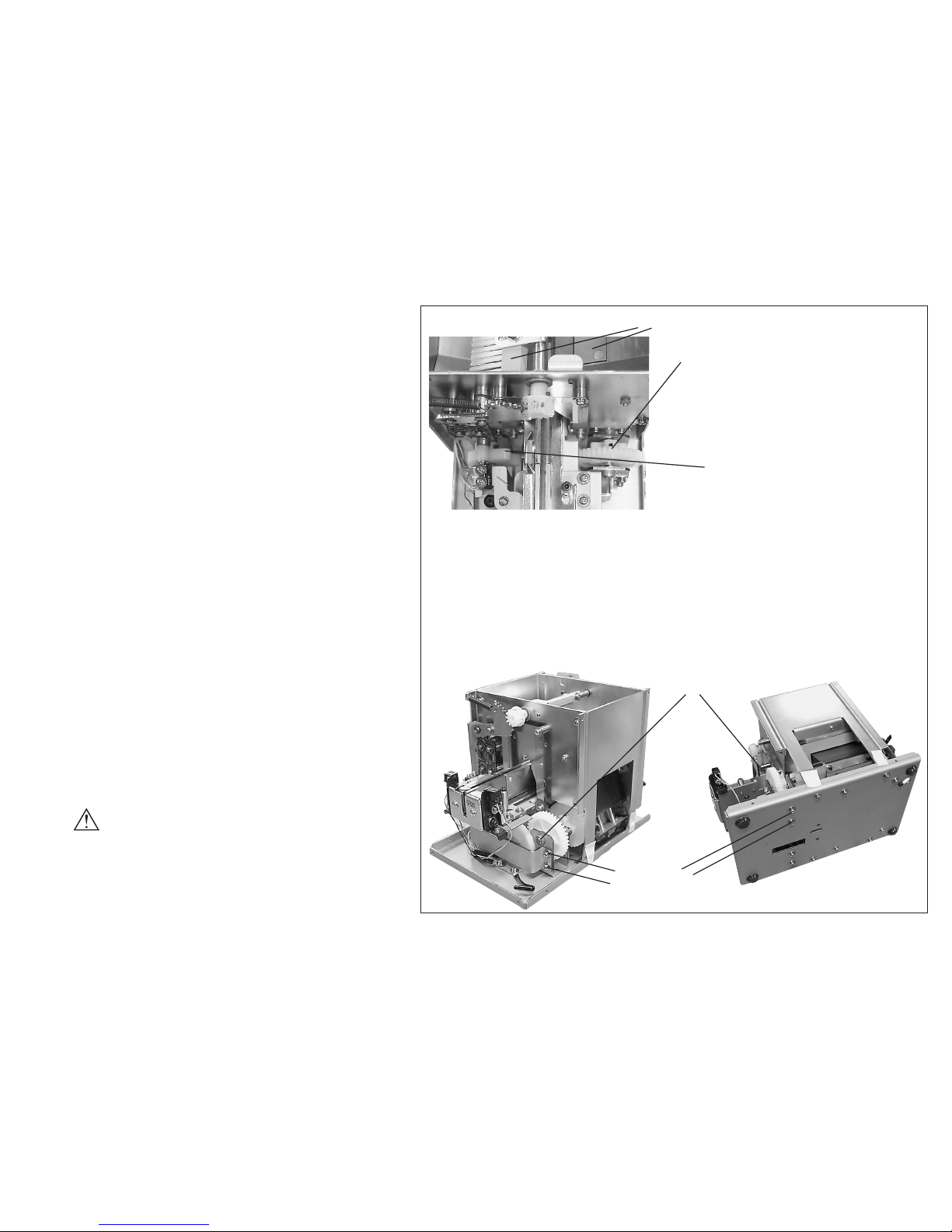

Movement timing when replacing a motor

•

Totimeamovementofthe[scoopingblock]

andthatofabrush,thegearsmustbeinmesh.

• Ifonlythemotorsectionisremovedfrom

thebody,themovementscanbetimedby

reassemblingthemotorsectionaccordingto

thetiminginthediagramontheright.

• Ifitisdiculttomeshthedrivinggearofthe

motorsectionwiththerightandlefttrailing

gears.Assemblycanbemadeeasierby

looseningthe mountingoftherightdriving

shaftbracket(seethediagramontheright).

Besuretorefastentheloosenedscrewsafter

mountingthemotorsection.

• Aftermounting,startthemotorandcheck

themovementtiming.(Therightandleft

[scoopingblocks]mustmoveupanddown

almostsimultaneously.)

•

Aftercheckingthemovement,refertothe

wiringdiagramandproperlypositionthe

wiring.(Avoidwiresbeingcaughtwhen

mountingthecoverandbecarefulnottobreak

motorwiresbyusingoverlyexcessiveforce.)

Caution:UnplugtheACadapterfromthe

walloutletbeforedisassemblyofthe

motorsection.

•

Assemblethemotorwhen[scoopingblock]isontherightandleftasmuchaspossible.

• Inordertomaketheheightof[scoopingblock]isontherightandleftjustabout

thesame,thedrivinggearattachedtothemotoraxisandthesub-drivinggearon

therightandleftmustbeinmesh.Then,tightenthescrews(M2.6×8,2pieces)for

themotorbracket.

When the gears do not t:

Loosenthefollowingscrewsandfreethedrivingshaftbracket,anditmakesthe

geareasiertobeinmesh.

Drivingshaftbracket

Attachingscrews

in4places

Drop[scoopingblock]ontherightandleftasmuchaspossible.

Thepinisapproximatwlyvertical.

Thepinisapproximatwly

inclned46degrees.

-18-

7) TROUBLESHOOTING

Caution:Forsafety,alwaysunplugtheACadapterfromthewalloutletbeforemakinganyadjustments.

Trouble Cause Corrective measures

7-1

Themachine

doesnotoperate

thoughthepower

switchisturned

ON.

• Powerisnotsupplied.

• Themachinehasnotunloadedscrewsfromthe

pickupsiteforacertainamountoftime.

• Toomanyscrewswereloadedintothescooping

chamber.

• Aforeignobject(forexample:ascrew)intruded

intothemainbody.

• TheACadapterisfaulty.

• Checktheconnectionofthepowersupplyof

theACpoweradapter.

• Takeoutthescrewfromthepickupsite.

• Adjustthetimersettingknob.

• Reducethequantityofscrewsinthescooping

chambertoaproperloadlevel.

• Removetheforeignobject.

• Consultourservicesection.

This manual suits for next models

7

Table of contents

Popular Sander manuals by other brands

Black & Decker

Black & Decker KA75 user manual

Alpha Professional Tools

Alpha Professional Tools AIR-680 instruction manual

Steel City

Steel City TITANIUM Series owner's manual

FESTA

FESTA 28040 Manual for use

Silver Eagle

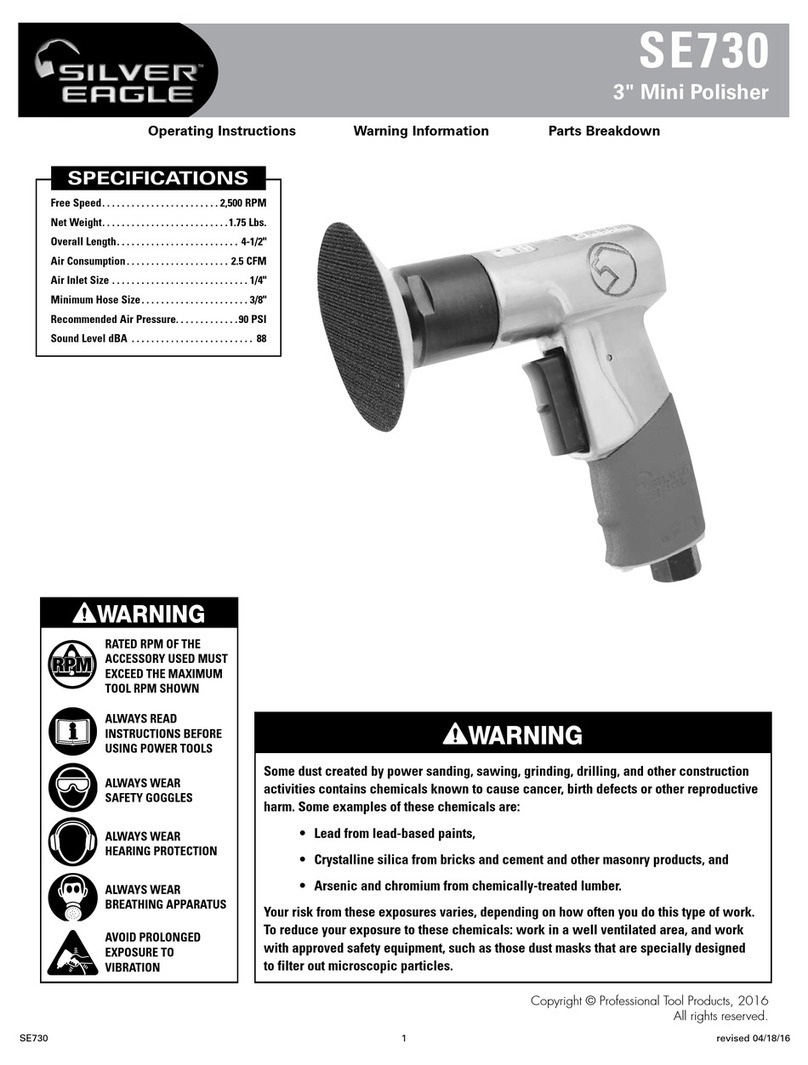

Silver Eagle SE730 operating instructions

Bosch

Bosch GWS 22-180 H Professional Original instructions