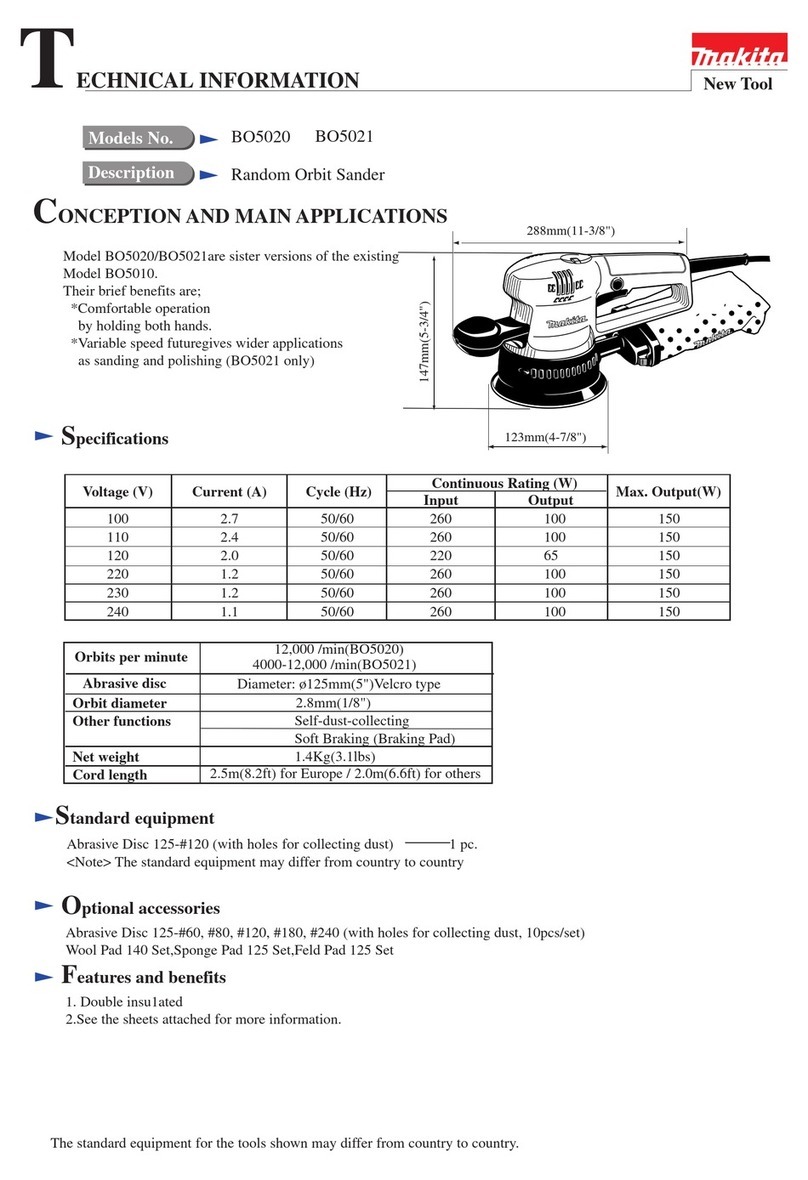

Specifications

Models No.

Description

PRODUCT

P 1 / 15

TECHNICAL INFORMATION

L

H

PV7000C, PV7001C, PV7001

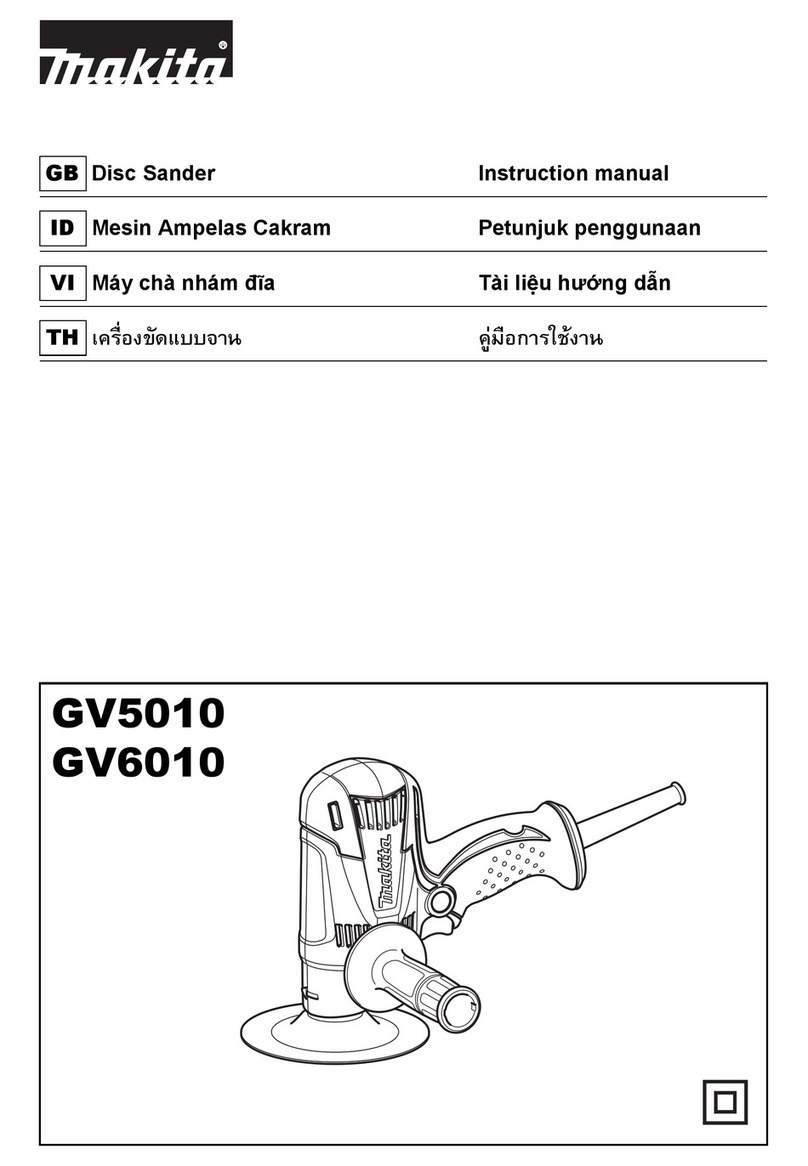

GV7000C, GV7000

CONCEPTION AND MAIN APPLICATIONS

PV7000C, PV7001C

PV7001

GV7000C

GV7000

Easy-to-control Disc Sander has been developed on the same concepts as

the PV line-up.

Features variable speed from 2,500 to 4,700 rpm. (without speed selecting

button)

The economy version of GV7000C ;

Features single speed without electronic control.

Dimensions : mm ( " )

Height (H)

Length (L)

Width (W)

210 (8-1/4)

220 (8-5/8)

82 (3-1/4)

Continuous Rating (W)

Voltage

(V)

Model

PV7000C

PV7001C

GV7000C

Current

(A)

Cycle

(Hz) Input Output

Max. Output

(W)

120

110 8.6 50/60 900

100 9.5 50/60 900 400 1,000

400 1,000

7.9 50/60 900

220 4.3 50/60 900

230 4.1 50/60 900

240 3.9 50/60 900

PV7001CPV7000C PV7001

No load speed : min-1=rpm 600 / 600 - 2,000 (Changeable) 1,700 4,7002,500 - 4,700

400 1,000

400 1,000

400 1,000

400 1,000

Continuous Rating (W)

Voltage

(V)

Model

PV7001

GV7000

Current

(A)

Cycle

(Hz) Input Output Max. Output

(W)

120

110 5.3

4.8

50/60

100 5.8 50/60 550 300 450

550 300 450

550 300 450

550 300 450

550 300 450

550 300 450

50/60

220 50/60

230 2.5 50/60

240 2.4 50/60

GV7000GV7000C

Polishing/sanding capacity : mm (") Wool bonnet 180 (7) Abrasive disc 180 (7)

Protection from electric shock

Overall length : mm (")

Net weight : kg (lbs)

Cord length : m (ft)

Speed electing button for Low (single)

or High (variable)

Yes

Yes

Yes

No

Yes NoNo

No

No

No

Double insulation By grounding

Yes

Yes

Yes

Double insulation

210 (8-1/4)

2.0 (4.4)

210 (8-1/4)

2.0 (4.4)

Electronic speed control

Electronic soft start

Variable speed control dial

No No

2.6

These polishers have been developed for the most controlled operation in

various polishing works, featuring ;

Compact and light-weighted body

*Protection from electric shock

Variable speed change dial and speed selecting button (low/high) for a

wide range of polishing works

Electronic control for the least speed reduction

PV7000C : double insulation, PV7001C : by grounding

The economy version of PV7001C ;

Features single speed without electronic control.

PV7000C, PV7001C, PV7001 : Polisher 180mm

GV7000C, GV7000 : Disc Sander 180mm

2.5 (8.2)

W

4.0 (13.1) for Europe