Hipac 120120 User manual

Door Top Alarm

Manual

Contents

1. Introduction

2. Components

3. Architrave detailing (single swing doors)

4. Premanufacturing Information - MUST RETURN TO HIPAC

5. Preparing the Door/Frame

6. Sign off Sheet - MUST RETURN TO HIPAC

7. Wiring Stages Connections

8. Testing/Checks

9. Changing of the Alarm delay time

10. Fail safe

11. Failsafe Alarm sounding

12. Operating Instructions

13. Trouble Shooting

14. Contact Details

15. HFM Electrical Transfer Hinge

1. Introduction

Hipac Door Top Alarms are available in 44m and 54mm thicknesses and to a width to suit the

door (made to measure). The solution is available for Non Fire and FD30 fire door application.

All components are quality checked, tested and signed off before dispatch. The importance

of correct installation, handling with care and connecting in the correct sequence cannot be

emphasised too strongly.

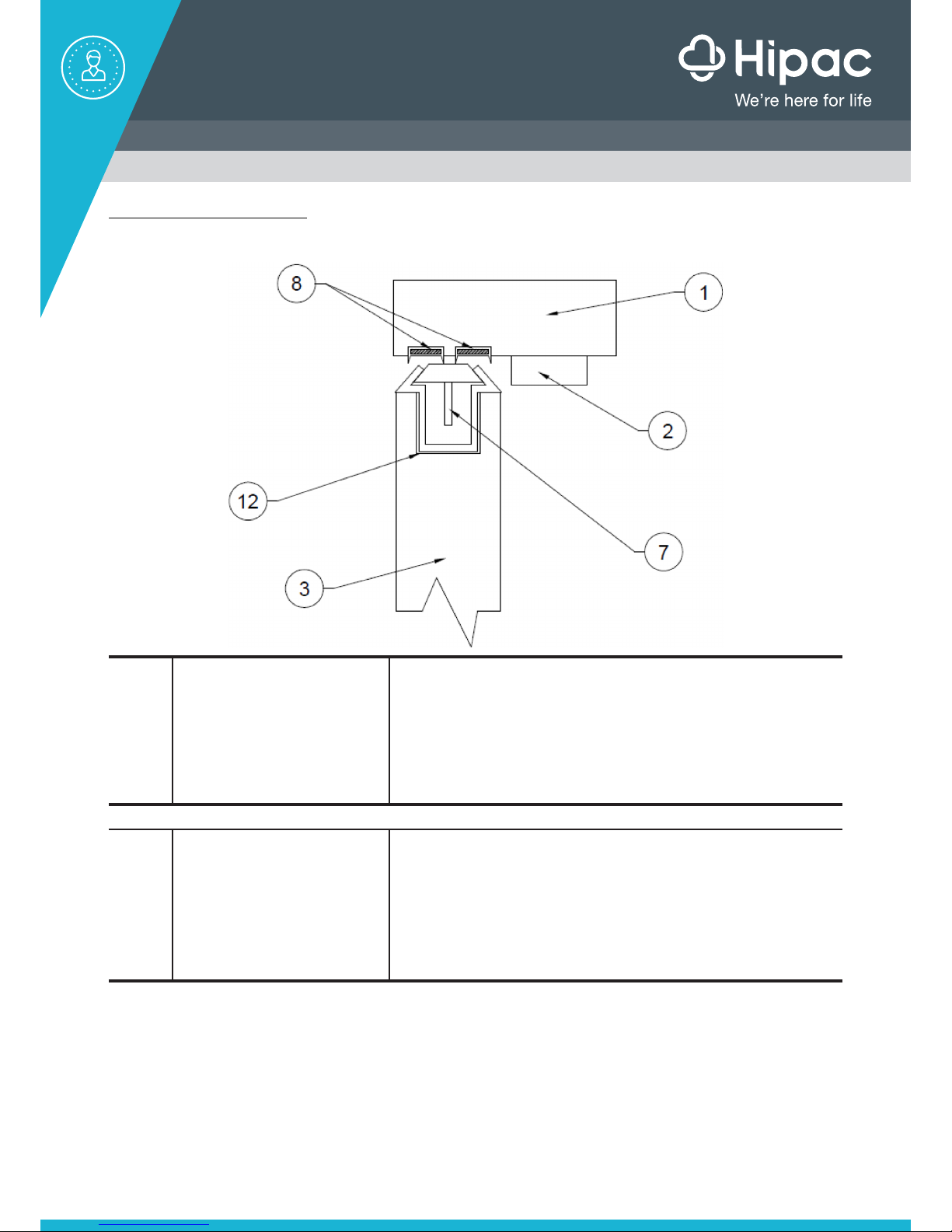

2. Components

3. Frame Architrave Detailing - Single Swing Doors

For reduced ligature when the Door Top Alarm is used on single swing doors (with

SECURAHinge), please note the below architrave detailing / modification is required to allow

for the Domed Cap on top of the hinge.

If new door-set, it is recommended this is planned in at design stage.

Domed Cap Modified Frame Architrave Detail

Domed Cap New Frame Architrave Detail

Door Top Alarm

Ordering Form

Project:

Company:

Checked By:

Duress System:

Date:

Signed:

Door Reference#

Door Width (mm)

Door Thickness (mm)

Hinge Type

Single

Action

Double

Action

Hinge

Fitment

Face Fixed

Single

Rebate

Double

Rebate

Door Type

Single Door

Double

Door

Fire Rating

Yes

No

Condition

New Door

Existing

Door

Door

Handing

(Refer

Diagram)

Figure 1

or 3

Figure 2

or 4

Please use this

diagram to determine

4. Pre Manufacturing Information (Multiple Doors)

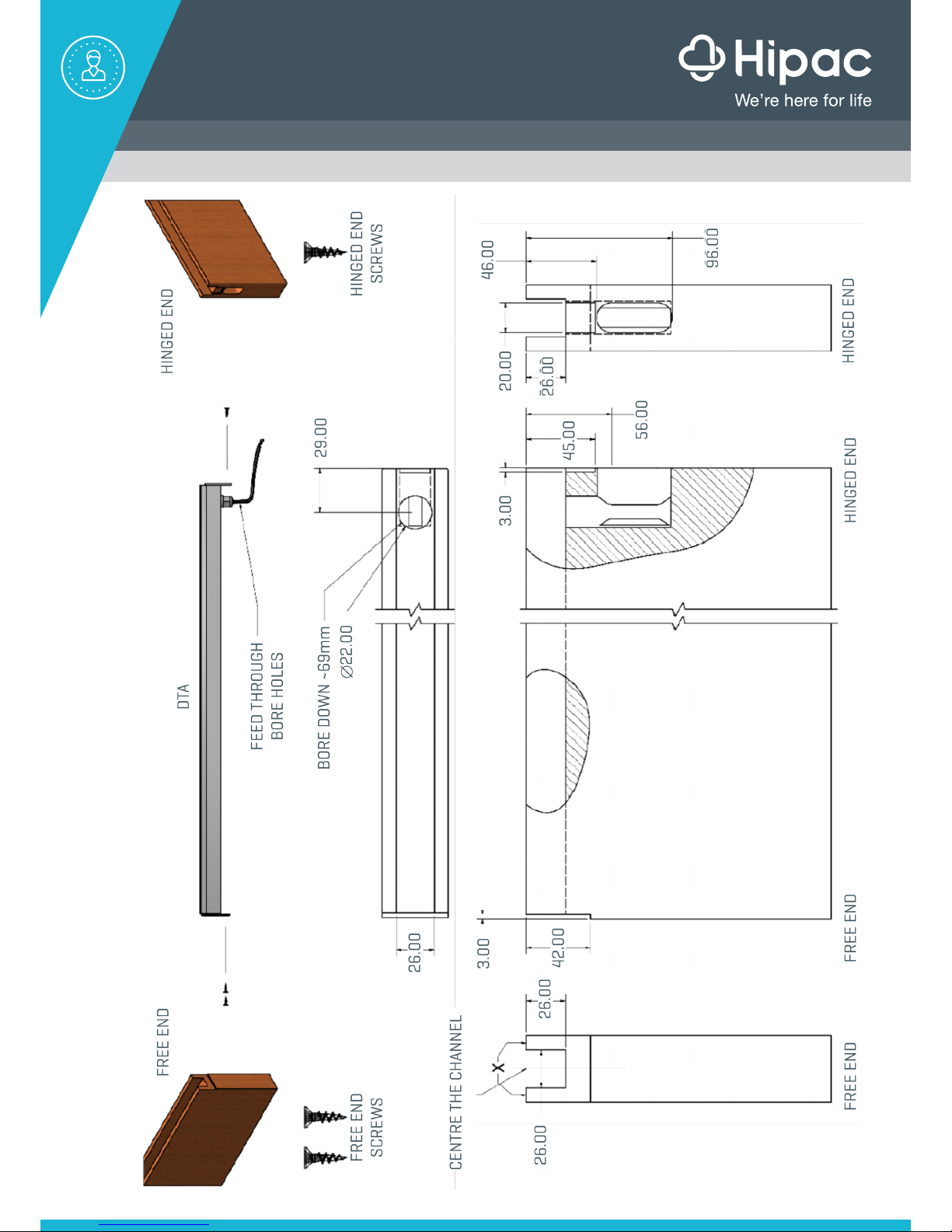

5. Preparing the door

Hipac Healthcare Pty Ltd can take no responsibility for incorrect operation of Door Top Alarms

that are not fitted as per directed in these instructions.

If retrofitting, then removal of the door is recommended.

Remove 12mm from the

top of the door

Bore down 69mm from above at 29mm

from the hinged end.

Meet this bore with another from the hinged

side.

This is a channel for routing the cables.

Make channel down centerline on

the top of the door:

• 26x26mm (Not Fire Rated)

• 28x28mm (FD30)

Feed cable and place DTA.

Screw in with fixings provided.

Wire Door top alarm and test.

Recess 3mm:

• HINGED END: From bottom of

channel 18mm and 25mm wide

• FREE END: From bottom of

channel 18mm and full width

FD30 Applications

Please note for the FD30 applications, the below door-set layout must be applied

8Frame intumescent 1

Supplier:

Reference:

Description:

Lorient Polyproducts Limited

LP1504DS Type 617

2NO. PVC encased sodium silicate based intumescent

strips incorporating elastometric fins, set 6 and 26 from the

exposed edge of frame head. 15 x 4

12 Alarm bar intumescent

Supplier:

Reference:

Description:

Overall size (t):

Intumescent Seals**

Therm-A-Strip**

A white phosphate-based intumescent compound with self-

adhesive tape on one side lining the walls and the bottom of

the alarm bar rebate in the head of the leaf.

1**

6. Door Top Alarm Wiring Test Sign Off Sheet

Overleaf is the completion sign off sheet for each stage of the installation. A completed

signed copy of the above must be returned to Hipac for their records. Failure to return will

invalidate the warranty.

NOTE - To be used in conjunction with the loaned Tested Box.

NOTE 2 - Sheet(s) to be controlled by Project Manager.

Project:

Sales Order Number:

Room

No.

Door Top Alarm

(Connect Alarm to

the hinge)

Electrically Modified

Hinge (Connect the

control cable to the

hinge)

DTA Wired into

Electronics Box

(to match the

connections in the

O&M manual)

Mains power Staff Attack

Interface Unit Magnet test on Door

Name Date Name Date Name Date Name Date Name Date Name Date

7. Wiring Stages / Connections

1) Door Top Alarm

2) Electrically Modified Hinge

3) Cable fed into the ceiling

4) Electronics Box (by others - electrician or staff attack co.)

5) Mains Power (by others - electrician or staff attack co.)

6) Staff Attach Interface Unit (by others - staff attack co.)

7) Staff Attack mains computer / nurses station / fobs (by others - staff attack)

NOTE - Each stage must be signed off on the ‘Sign Off Sheet’ before handing over a copy returned to Hipac. A battery

powered tested unit is loaned to the Door Top Alarm installers so they can sign off stages 1-3 before other companies

get involved.

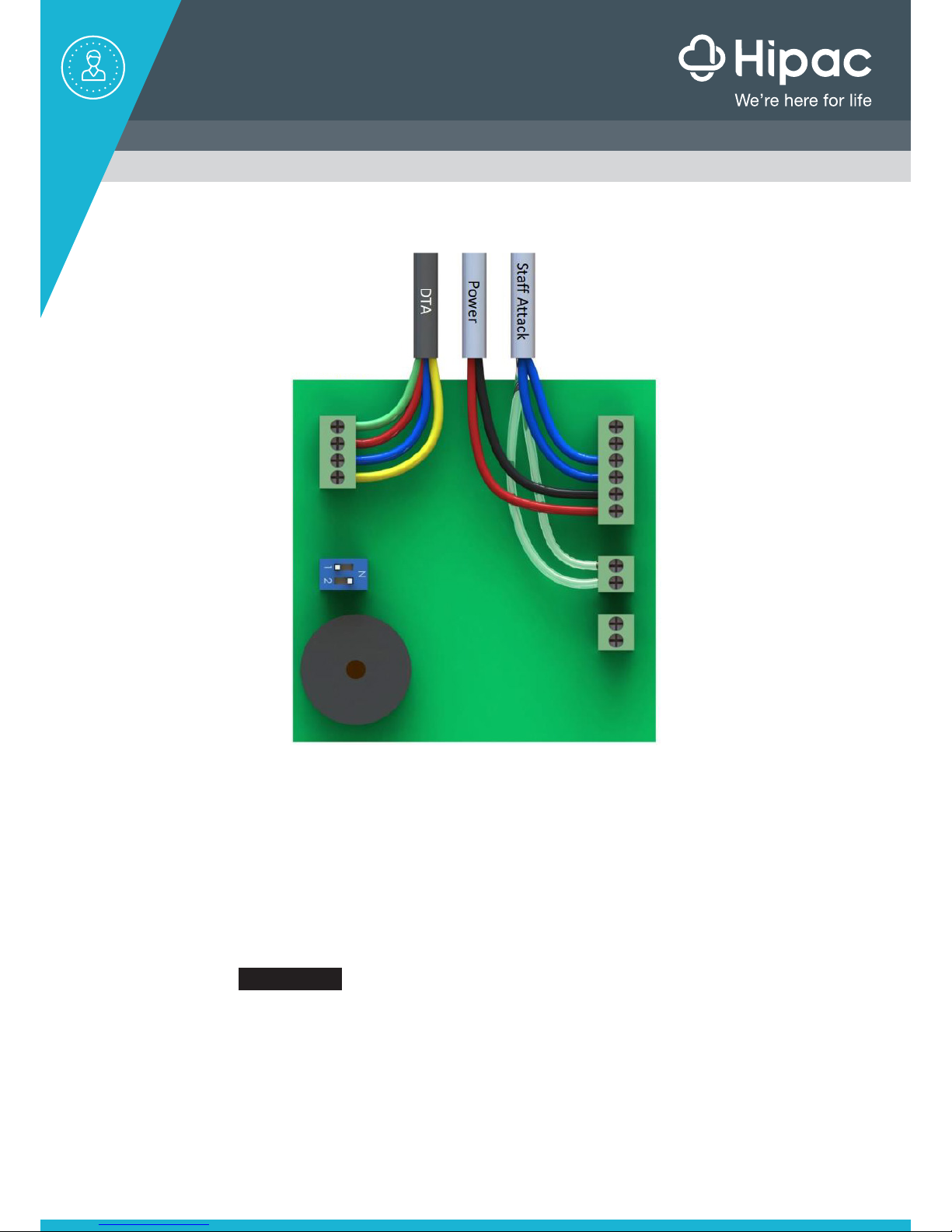

1. Door Top Alarm

The 4 coloured wires from the DTA cable fed into the ceiling, should be connected into the 4

connector block on the left hand side of the electronics boxes as shown.

It is extremely important the wires are connected in the correct junction box:

Green LED = Green Wire

Red LED = Red Wire

Switch = Blue Wire

Switch Common = Yellow Wire

Wiring into the electronics box should be as follows:

Green

Red

Blue

Yellow

Cables codes

Green - Green LED

Red - Red LED

Blue - Trigger switch

Yellow - Common

Staff attack wiring

Wire to normally closed (recommended)

or normally open.

Tamper loop

Tamper loop

Normally closed

Alarm contacts (NC)

PSU - (Black)

PSU + (Red)

Normally open

Alarm contacts (NO)

External sounder PSU-

External sounder open drain

2. Power

The power cable has 2 cables. The black cable is connected to the PSU (-) and the red wire is

connected to the PSU (+). The PSU connectors are located on the right hand side of the box.

The Power can either be from the Staff Attach System (if available)or mains power. If mains

power, it MUST BE transformed down to 12V.DC.

Once power is connected, the red LED on the outside of the box should light up.

If the power is connected without the Door Top Alarm in place, the unit will cycle through the

following sequence - Power LED (red) comes on and the Status LED will cycle green, amber,

and red then extinguish. When the pre-set delay time has elapsed, the LED will turn red and

the internal alarm will sound for approximately 5 seconds. After a total of 20 seconds, the

unit will return to standby mode.

3. Staff attack

The staff attack is connected into EITHER the Normally Closed OR Normally Open

connectors on the right hand side of the box.

Hipac recommend, where possible, the Normally Closed connections are used as this will

allow a notification alarm to sound if there is a power failure or wire breakage. In the Normally

Open connections re used, it may still be possible to obtain a non-audible notification if there

is a failure e.g. messages appears on nurse’s station display unit. Please consult the Staff

Attack supplier.

NOTE - The staff attack should not be connected until the Door Top Alarm and Power stages

have been signed off. (The alarm could go off as the Door Top Alarm has failsafe system built

in).

NOTE 2 - All the wiring should be checked and signed off at each stage on the supplied sign

off sheet during installation by the various contractors. If any problems occur during the

installation stages, Hipac will not attend site to carry out an investigation without proof that

all the stages have been signed (or stages up to when the problem has occurred). If Hipac

attend site and it is proved a stage was signed off in error, this will be chargeable at a day’s

rate.

8. Testing / Checks

The Door Top Alarms should be tested on a regular basis. Frequency of the testing is as per your

risk assessments policy.

To carry out the tests, place the supplied magnet just under the LED on the Door Top Alarm.

(The LED only lights up when a magnet is placed against it so it is not visible to patients).

Press and release the top bar on the DTA a couple of times and the LED should be green.

Press and hold the bar for 3 seconds and the LED should change to orange. When the orange

light is continuously on for a set period of time (factory setting = 10 seconds), the LED will

change to Red and the alarm will be registered. After approximately 20 seconds, the unit

will reset itself and the red LED will disappear. For risk assessment checks you could go to

the orange light state where the alarm does not go off and probably only allow 1 or 2 on a

random basis to go to red stage.

On the outside of the electronics box there is a matching tricolored LED labeled ‘Status’

which should also light up every time the top bar is pressed. This LED does not need a magnet to

light up.

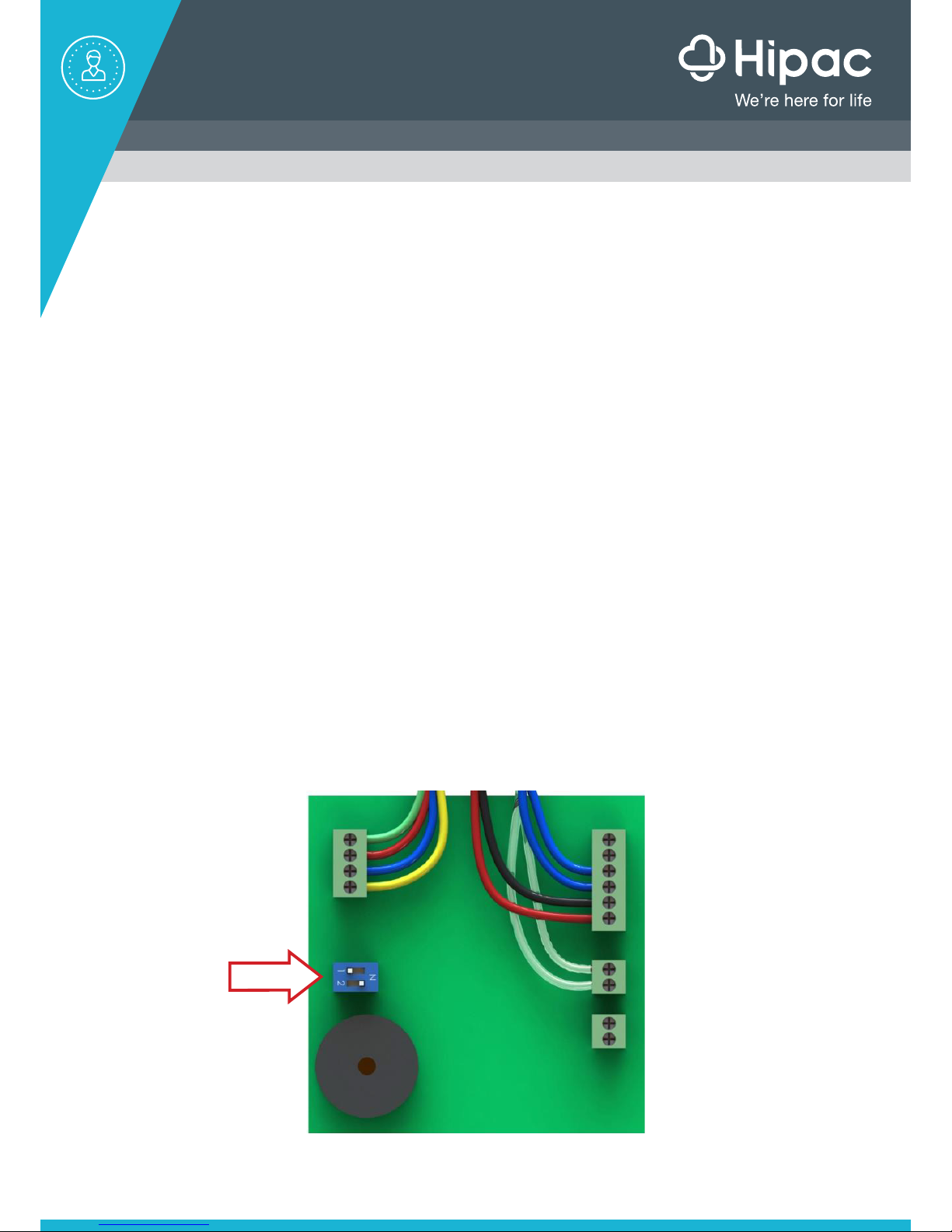

9. Changing of the Alarm delay time

The factory setting is set at a 10 second delay (continuous pressure on the door top bar). Other

standard options are 5, 20 or 30 seconds. Inside the electronics box, as shown on the below

photo, is a red or a blue box with 2 white switches.

10. Fail Safe

The Door Top Alarm includes a failsafe system, where the alarm will sound if there is a power

cut or a wire breakage. NOTE - this is only applicable if the staff attack system has been

wired into the Normally Closed terminals in the Hipac electronics box. It is possible to get

notification if the Normally Open terminals have to be used but this will not be an audible

alarm and is dependent on your staff attack company being able to send a failure message

back to say the main control panel at the nurses’ station.

The hinge is supplied in 2 pieces, the main section of the hinge which takes most of the

doors weight and the electrically modified section, at the top, which has the cables running

through it. The reason for this is for ease of service, so if at any time there is a problem, the

electrically modified piece can simply be taken out without having to take the door off.

The wiring to the electronics box should be checked (and signed off at each stage on

the supplied sign off sheet) with the tester box at each stage during installation by the

contractor.

5 Seconds10 Seconds

20 Seconds30 Seconds

11. Failsafe Alarm sounding

If this situation occurs, the alarm will keep sounding until action is taken. To switch off, locate

the bedroom referenced electronics box in the loft and disconnect the power. Either take

out the fusing the closely located transformer or if the power is via the staff attack system,

unscrew the power connection wires (shown previously) in the electronics box with a small

Phillips screwdriver. If the alarm continues to go off this is outside of the Hipac solution and

down to the programming of the staff attack system. Try disconnecting the staff attack wires

(also as shown previously) and if this fails to stop the alarm, immediately contact the staff

attack company to discuss and solve.

Once under control, please contact Hipac’s operations department to notify the problem,

explain what actions you have taken to silence and discuss / agree action plan to repair the

problem.

12. Operating Instructions

The Door Top Alarm will be passive the majority of the time, if there is nothing placed over

the door then the alarm will not be in use. When pressure is applied to the top of the door for

a preset period of time between 5 & 30 seconds this will trigger a relay inside the door top

alarm.

The relay inside will send a signal to our control unit situated out of sight.

This will trigger the staff attack system which will inform staff of an incident in accordance

with the staff attack system protocol.

Once the ligature has been removed from the top of the door, the alarm will automatically be

reset after 20 seconds and normal use will resume.

Please Note:

The Door Top Alarms should be tested on a regular basis. Frequency of the testing is as per

your risk assessments policy.

To carry out the tests, place the supplied magnet onto the edge of the LED on the Door Top

Alarm. (The LED only lights up when a magnet is placed against it so not visible to patients.)

Press and release the top once and the LED should shine green. Press and release the bar

again whilst the orange light is still on, and the LED should change to Orange. Then hold the

bar for a predetermined period (factory setting = 10 seconds), the LED will change to Red and

the alarm will be registered.

Note the alarm will sound if weight is applied to the sensor; edges 1.3kg centre 2.6kg dry

towel OK but wet towel not - suggest a ‘click’ style towel rail/rails.

Power, Connections and DTA working -

Green Light - Press the top bar once and move magnet around LED

Amber LED - indicates correct protocol for tamper setting

Red LED - DTA Alarm signal sent to Staff Attack System

After approximately 20 seconds, the unit will reset itself and the red LED will disappear.

The DTA resets but the staff attack system still needs resetting as per Staff Attack Instructions

13. Trouble Shooting Guide

Please Note: This guide is intended to help you diagnose a fault on the door top alarm, it may not

tell you how to repair it.

In normal operation the Door top alarm should remain passive until the bar on the top is

activated.

To test the alarm is working properly, you will need a magnet

Begin by closing the door and re-opening it.

• Without pressing on th bar put a magnet to the LED on the leading edge of the door. The

LED should remain clear and unilluminated.

If at this point the LED is presenting green then the fitting of the door is wrong and the DTA

is clashing with the frame causing it to activate. This can be fixed by wither channeling the

DTA deeper into the door or by slightly dropping the hinge. In this case Hipac do not need to

attend site.

• If when the door is first opened, the magnet remains clear then quickly press and release

the bar once (Keeping the magnet next to the LED). The LED should turn green. This

signals that you have power to the DTA.

If once pressed and released the LED doesn’t illuminate, then there is a power supply issue

somewhere on the circuit. The DTA control box should be located in the ceiling or a cupboard.

On the front of this is a red power LED, this should be illuminated. It this is not lit then there

is an issue with your power supply to thee box. In this case Hipac should not need to attend

site.

If the red LED is lit up but the LED on the DTA is not illuminating then there is an issue

between the control box and the DTA. Please ensure that the cables at the back of the hinge

and the DTA are both connected as they should be. If they are both connected correctly and

the LED on the box is lit, the Hipac may need to attend site.

If the LED does illuminate but the light is flashing or no a solid display in anyway, you may

need to check your power supply is running off DC and not AC. Hipac do not need to attend

site.

• If the LED did illuminate Green, then whilst it is still displaying green the quickly press and

release it once again. The LED should momentarily change from green to orange. Once

the bar is released the LED will change back to green. All the time you are doing this, the

magnet should be kept next to the LED.

If the LED stays orange once you have released the bar then the micro switches may be over

sensitive and will need adjusting. You can test this by rolling the bar to the side and seeing if

it sticks to one side, if it does Hipac will need to visit site.

If the bar is sticking but there is no side to side movement in the bar then you will need to

check the channeling the door to make sure it’s not too tight on the alarm. Hipac should not

need to visit site.

• Once you have seen the LED change to orange, hold the bar down for 10 seconds and the

LED will change to red and the alarm will sound.

If the LED changes to red but the alarm doesn’t sound, you need to speak to your staff attack

providers to make sure their system is wired correctly. Hipac do not need to attend site. If

the Led doesn’t cycle through the colours of green, amber, red as it should then the system

may be wired incorrectly. Please consult the Hipac O&M manual to make sure it’s wired as it

should be.

Please Note:

Once the alarm has been activated it will take approximately 30 seconds to

reset. If you keep the magnet to the LED, whilst it is still in alarm is will display red. If it has

gone back to clear then it has reset.

14. Contact Information

Hipac Healthcare Pty Ltd

36 Long Street

Goulburn NSW

2580

Telephone 02 4823 0000

Visit our website at www.hipac.com.au

15. HFM Electrical Transfer Hinge

Fitting Instructions

Fixings

(2x) M3 x 6mm (AUS 12mm), Countersunk, Security Torx screws in A2 Stainless steel.

(5x) No.8 x 1 1/2”, Countersunk, Security Torx wood screws in A2 Stainless steel.

Domed Cap (Optional extra).

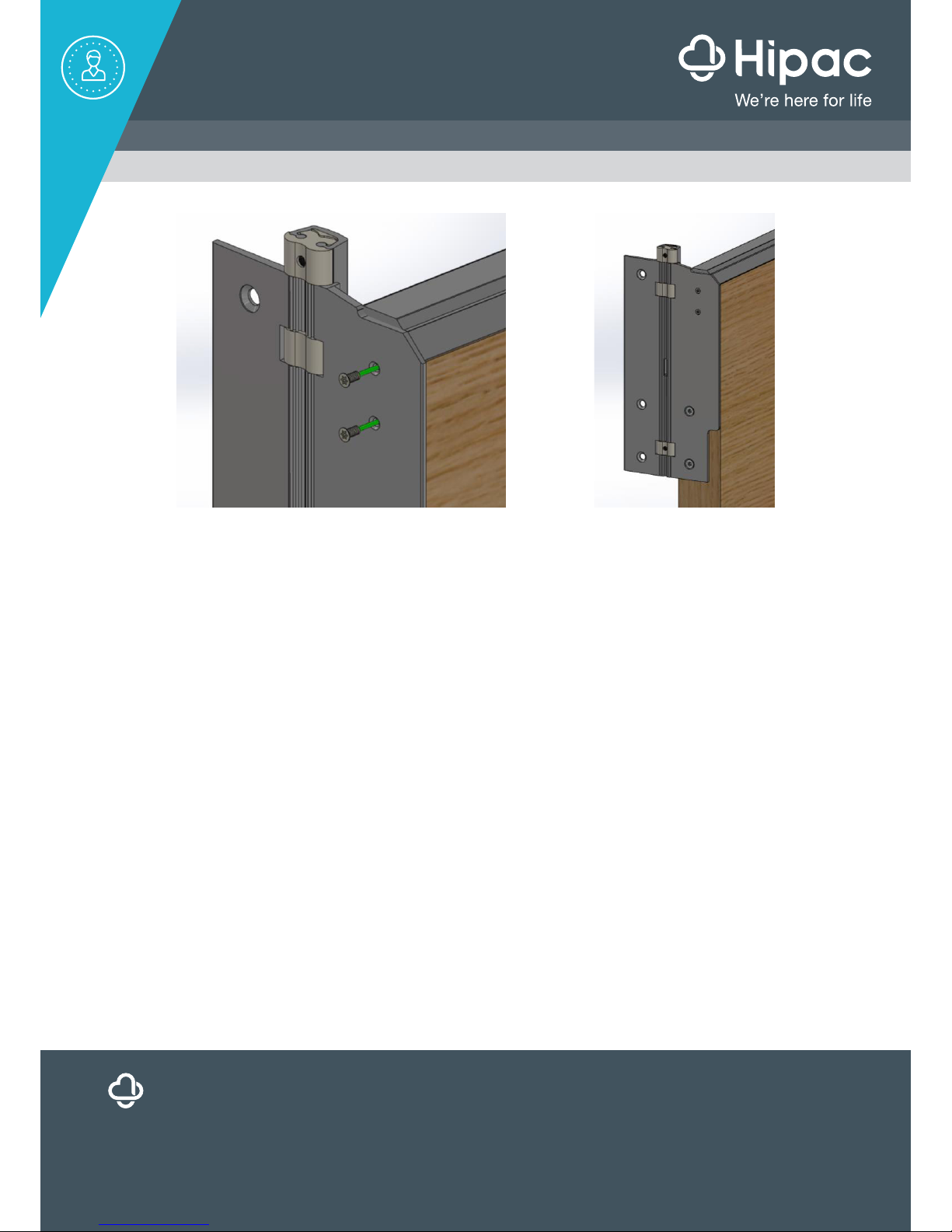

Note:

If the hinge is to be rebated, attach the EM hinge to the DTA using the M3 x 6mm

screws. Trace the profile and rebate before assembly.

Instructions

1. Fit the Door top alarm to the door.

2. Connect the DTA plug and the hinge plug on the side of the hinge which has been

profiled with extra holes. Ensure the plug is connected in the correct orientation

with the clip, passing over the latching arm.

3. Place the electrical transfer hinge against the door edge.

4. Screw the two M3 x 6mm fixings into the DTA first to position the hinge correctly.

The DTA should follow the profile of the hinge. Ensure that the cable from the EM

hinge isn’t trapped between the door and the hinge. The cabling should sit within

the recess in the door.

ABOUT HIPAC

We are an Australian healthcare company that guarantees to stand

behind all our medical products, both manufactured and imported,

because we’re here for the life of our products and clients.

PO Box 797, 36 Long St. Goulburn NSW 2580, Australia

SYDNEY | MELBOURNE | BRISBANE | ADELAIDE | PERTH

hipac.com.au

ABN 27 600 353 688

5. Use the hinge fixing holes as guidance to pilot drill holes using a 3.5mm drill.

6. Screw the EM hinge section to the door.

7. Then fit the full length hinge section referring to the HFM/HAL fitting instruc-

tions ensure the bottom of the EM hinge and the top of the full length hinge

are butted together leaving no more than a 0.5mm gap.

8. Push the EM hinge section up to within 0.5mm of the top of the frame.

9. Mark then pilot the fixing holes for the screws for both hinge sections.

10. Fix the door to the frame with the main section of the hinge, leaving the EM

section detached from the frame.

11. Connect the control cable from the frame to the other side of the hinge.

12. Open the hinge against the frame, ensuring the cable is not trapped then fix

the EM hinge to the frame.

13. Once all hinge sections are fitted, fit the domed cap on top of the hinge

knuckle, following domed cap fitting instructions.

14. Once installed, Hipac should be contacted to carry out the commissioning to

validate the warranty.

This manual suits for next models

1

Table of contents