HIPOTRONICS OC-DI Series User manual

I

Operating Instructions

OC-DI Series

Digital Interface

Oil Testers

Version 1.0

No. 145896

II

Title

Digital Interface Oil Testers

Date

06/2018

Revision History

V0.1

03/2018

MC

Initial draft of the document

III

This equipment contains exposed terminals carrying hazardous

voltages. There are no user serviceable components in the unit.

All repairs and upgrades that require the unit to be opened must

be referred to HIPOTRONICS or one of their nominated agents.

HIPOTRONICS and its sales partners refuse to accept any responsibility for consequential or

direct damage to persons and/or goods due to the lack of observance of instructions contained

herein or due to incorrect use of the equipment.

Further be aware that safety is the responsibility of the user!

Any correspondence regarding this instrument should include the exact type number,

instrument serial number and firmware version number. With the exception of the firmware

version number, this information can be found on the registration plate on the right panel of the

instrument. The firmware version can be found in the bottom right corner of the settings window.

Unauthorized opening of the unit may damage the EMI protection of the system and will reduce

its resistance to interference and transients. It may also cause the individual unit to be no longer

compliant with the relevant EMC emission and susceptibility requirements. If the unit has been

opened, the calibration will be rendered invalid and the warranty will be void.

Note

HIPOTRONICS has a policy of continuing improvement on all their products. The design of this

instrument will be subject to review and modification over its life. There may be small

discrepancies between the manual and the operation of the instrument, particularly where

software has been upgraded in the field.

HIPOTRONICS retains the right to modify the functionality, specification or operation of the

instrument without prior notice.

©All rights reserved. No section of this manual may be reproduced in any form, mechanical or

electronic without the prior written permission of HIPOTRONICS.

2018, HIPOTRONICS, USA

WARNING

Before operating the instrument, be sure to read and fully

understand the operating instructions. This instrument produces

hazardous voltages. It is the responsibility of the user to ensure

that the system is operated in a safe manner.

IV

Manual Conventions

In the manual, the following conventions are used:

Indicates hazards.

There is a risk of equipment damage or personal injury or death. Carefully read and follow

the instructions. Be sure to follow any safety instructions given in addition to those for the

site at which tests are being performed.

V

Foreword

Welcome, new user of the “OC-DI Series”. Thank you for placing your confidence in our

product.

With the purchase of this measuring instrument you have opted for all the advantages that have

built a world-wide reputation for a HIPOTRONICS Instrument: robustness, performance and

quality. As a result, this instrument provides a solution which achieves the optimal combination

of traditional know-how and leading edge technology.

This operating manual is designed for completeness and easy location of the required

information. Customers who already have experience with this kind of equipment will find this

document to be of assistance as an extended help.

If you find a mistake or inconsistency in the operating manual then please feel free to inform our

Customer Support department with your corrections so that other users may benefit.

VI

Contents

Manual Conventions IV

1Introduction 8

1.0 Receiving Instructions.................................................................................. 8

1.1 General........................................................................................................ 8

1.2 Scope of Supply........................................................................................... 8

1.2.1 Standard Scope of Supply............................................................... 8

1.3 Technical Data: OC60-DI............................................................................. 9

1.3.1 Physical and Environmental Specifications..................................... 9

1.3.2 Measurement .................................................................................. 9

2Safety 10

2.0 General...................................................................................................... 10

2.1 Essential Safety Recommendations .......................................................... 10

2.2 Summary.................................................................................................... 11

3Theory 12

3.0 Introduction................................................................................................ 12

3.1 Pre-Loaded Test Standards....................................................................... 12

3.2 Application ................................................................................................. 12

4Oil Tester Ports 13

4.0 Ports .......................................................................................................... 13

5Connection and Setup 14

5.0 Ground Connections.................................................................................. 14

5.1 Prepare Oil Test......................................................................................... 14

5.2 Main Menu................................................................................................. 15

5.3 Basic Mode................................................................................................ 16

5.4 Multi-Step Mode......................................................................................... 18

5.5 Reports ...................................................................................................... 20

5.6 Settings...................................................................................................... 21

6Troubleshooting 22

6.0 Diagnostics ................................................................................................ 22

6.1 Warning and Error Messages .................................................................... 22

7Miscellaneous 23

7.0 Care and Maintenance............................................................................... 23

7.0.1 Cleaning the Instrument................................................................ 23

7.0.2 Instrument Calibration................................................................... 23

VII

7.1 Instrument Storage .................................................................................... 23

7.2 Packing and Transport............................................................................... 24

7.3 Recycling ................................................................................................... 24

8Customer Support 25

9Appendix 26

9.0 Declaration of Conformity........................................................................... 26

9.1 Hipotronics, Inc.......................................................................................... 26

9.2 Warranty .................................................................................................... 27

9.3 Returned Material (RMA)..............................Error! Bookmark not defined.

8

1 Introduction

1.0 Receiving Instructions

When received, any possible transport damage should be noted. A written record should be made of

any damage. A suitable remark should be recorded on the delivery documents.

A claim for damage must be reported immediately to the transport company and to the Customer

Support Department of HIPOTRONICS or the local agent. It is essential to retain the damaged

packing material until the claim has been settled.

Check the contents of the shipment for completeness immediately after receipt (See chapter “Scope

of Supply”). If the shipment is incomplete or damaged, then this must be reported immediately to the

transport company and the Customer Support Department of HIPOTRONICS or the local agent.

Repair or replacement of the instrument can then be organized immediately.

1.1 General

The OC60-DI Liquid Dielectric Tester accurately and reliably tests dielectric strength of insulating

liquids used in a wide variety of electrical apparatus. The rugged, lightweight and portable design

ensures years of safe and trouble-free operation both in the field and in the laboratory.

1.2 Scope of Supply

1.2.1 Standard Scope of Supply

The following items are supplied with the standard instrument:

Qty

Description

1

Oil Tester Instrument

1

Power Cord

1

Operation Manual in English

1

Calibration Certificate

1 Introduction

9

1.3 Technical Data: OC60-DI

1.3.1 Physical and Environmental Specifications

Operating temperature

14…122° F (-10 .. 50°C)

Storage temperature

-4…158° F (-20 .. 70°C)

Humidity

5 ... 95 % r.h. non-condensing

Dimensions (W x D x H)

OC60-DI: 16” x 13” x 15” (41cm x 33cm x 38cm)

Weight

OC60-DI: 60lbs (25kg)

1.3.2 Power Specifications

Power Input

90 –264VAC 50 or 60Hz 200VA

Battery Power

12VDC NiMH 8.4Ah

1.3.3 Measurement

Breakdown Voltages

Accuracy: +/- 2% F.S.

Resolution: 0.1kV

Voltmeter

Accuracy: +/- 1% F.S.

Resolution: 0.1kV

10

2 Safety

Remember:

Hazardous voltage can shock, burn or cause death !

The unit should only be operated after carefully reading the user manual, which is an

integral part of the instrument.

HIPOTRONICS and its sales partners refuse to accept any responsibility for consequential

or direct damage to persons and/or goods due to none observance of instructions

contained herein or due to incorrect use of the equipment.

Further be aware that Safety is the responsibility of the user!

2.0 General

Safety is the most important aspect when working on or around high voltage electrical equipment.

Personnel whose working responsibilities involve testing and maintenance of the various types of high

voltage equipment must have understood the safety rules written in this document and the associated

safety practices specified by their company and government. Local and state safety procedures

should also be consulted. Company, regional or national regulations must be fulfilled beyond

HIPOTRONICS recommendations.

If the instrument is damaged or it is possible that damage has occurred, for example during

transportation, do not apply any voltage. The instrument may only be used under dry operating

conditions.

Do not open the unit; it contains no user replaceable parts.

People with heart pacemakers should not be in the vicinity of this system during operation.

Safety is the responsibility of the user. Always operate the equipment in accordance with

the instructions, always paying full attention to local safety practices and procedures.

This equipment must be operated only by trained and competent personnel who are aware

of the dangers and hazards involved in testing transformers.

2.1 Essential Safety Recommendations

Every terminal should be checked and verified before connection of the instrument. Ground

connections may be left in place.

2 Safety

11

Never operate the equipment in an explosive environment or where there are flammable

gases or fumes

The instrument must always be connected to a grounded power outlet (i.e. a safety earth).

It must never be operated in a non-grounded configuration as this may result in electrical

shock to the user or damage to the instrument.

2.2 Summary

Note: Many accidents that happen around high voltage equipment involve personnel who are not

familiar, or perhaps too familiar, with high voltage equipment. Staying alert and ever watchful requires

constant training and awareness of the inherent hazards. The greatest hazard is the possibility of

getting on a live circuit. To avoid this requires constant vigilance - for oneself and for one's fellow

workers.

In addition to the obvious dangers, personnel should be alert to recognize subtle dangers as well.

Therefore, all terminals of a device under test, unless grounded, should be considered to be

live while the test is in progress.

Remember: Safety, FIRST, LAST, and

ALWAYS !

12

3 Theory

3.0 Introduction

This model is designed to meet testing specifications from all parts of the world with test cells

available for ASTM D877, ASTM D1816 and IEC 156 testing standards. The OC60-DI offers the

ability to use one of the pre-programmed rates of voltage rise or allows the operator to create their

own tests using Basic mode. An internal kilovoltmeter automatically records the breakdown

voltage for each test sample. Each test can be saved into the unit’s internal memory or to a USB

drive.

3.1 Pre-Installed Test Standards

ASTM D877A NF EN 60156

ASTM D877B UNI EN 610156

ASTM D1816 SABS EN 60156

IRAM 2341 PA SEV EN 60156

JIS C 2101 (M) / (S) CEI EN 60156

AS1767.2.1 BS EN 60156

VDE 0370 IEC 60156

3.2 Application

Testing of insulating dielectric liquid that are used in :

▪Transformers

▪Bushings

▪Switchgear

▪Capacitors

▪Hydraulics

4 Oil Tester Ports

13

4 Oil Tester Ports

4.0 Ports

LCD Touchscreen Interface: Use to control software to setup and implement oil tests

Mains Input: Insert power cord to power or recharge unit. When charging, make sure that the input

switch is in the ‘ON’ position

Ground Terminal: Connect chassis to proper ground

Power Button: Turn on/off unit interface. When the unit is on, the power symbol on the button will be

lit up green. To turn off the interface, press and hold the power button for a couple of seconds

USB Port: Insert USB drive to export test data

14

5 Connection and Setup

5.0 Ground Connections

First make sure to connect the unit to a proper ground through the ground screw located on the

left side of the oil tester.

5.1 Prepare Oil Test

Make sure the oil cup is properly cleaned twice before each oil sample test to ensure accurate

results. Fill the oil cup with the specified amount according to the standard being tested to. Carefully

place the oil cup into the slot holders of the transformer inside the test chamber.

6 Operating Modes

15

6 Operating Modes

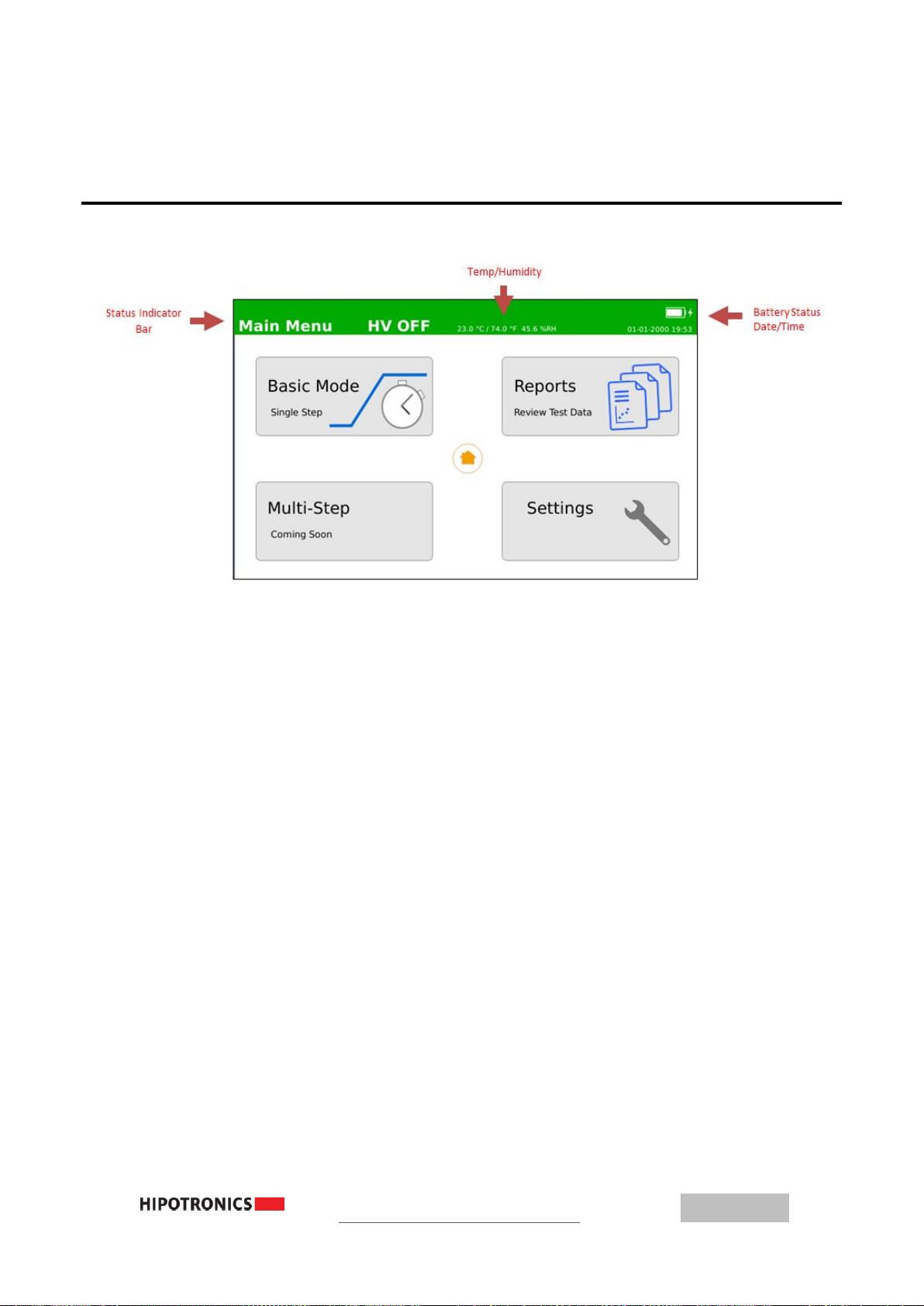

6.0 Main Menu

Upon turning the unit on, the interface will load to the Main Menu window. The top bar is the

status indicator at all times. It will be green when high voltage is off, and red when high voltage is on.

The left corner of the bar will display what window is currently displayed. In the center, the temperature

and humidity will be shown; and in the right corner will be the battery level status, and the current

date/time.

There are four windows that you can access from the Main Menu window. Basic Mode is the

standard automatic oil test that ramps up to a desired voltage until breakdown. Multi-Step is a custom

test where the user can program several ramping stages. Reports will allow the user to view and export

previously saved tests. Lastly, in the Settings window, the user can configure basic test or system

parameters.

16

6.1 Basic Mode

Although Basic Mode is the simple automatic ramping oil test, the user now has the ability to set

many different parameters and options to make the test as easy and hands-free as possible.

If testing to a common industry standard, the user can select the clipboard icon to view a list of

pre-loaded standards that will automatically populate all of the parameter fields for that test. The right

half of the window will show a visual of the test voltage sequence.

To edit the parameters, click on the buttons on the left half of the window or on the bottom bar.

The number of tests dictates how many times the unit will ramp up voltage in one test sequence. The

ramp rate will set how fast the voltage increases during the test. The wait time is the period between

each individual breakdown test, and the dwell time is the period that the voltage will hold at when it

reaches its maximum limit without a breakdown occurring.

The OC60-DI also has an Ethernet port in the HV chamber where you can plug in the motor

stirrer accessory. This Ethernet port will provide power to the motor stirrer if the stir option is selected,

and a test is running. The user can also select the type of electrode being used with the test, for

reference that will be saved in the report.

The last two parameter buttons on the right side of the bottom bar will allow the user to select

the maximum voltage that the unit will ramp to, up to 60kV; and the output frequency of the high voltage

waveform.

6 Operating Modes

17

After pressing the ‘START’ button, the chosen test sequence will commence, and a new

window will show all of the test parameters. The high voltage will ramp up to the selected target voltage,

at the selected ramp rate, and then remain at that voltage for the chosen dwell time. Once the dwell

time expires, or a breakdown occurs, the test will shut off high voltage and wait for the selected wait-

time before starting a next ramp test, (if they were multiple number of tests selected). The voltage

measurement in the top left will show the real-time voltage across the electrodes. The dwell and wait

time counters will always be displayed, and will count down when they are active. The total elapsed test

time and the current test number are shown in the bottom left.

The right half of the test screen will display the breakdown voltages and graph them on a plot. If

the test chamber cover is opened at any time during a test, the high voltage output will shut off and the

test will pause until the lid is closed again.

At the conclusion of a test sequence, a small window will pop-up showing a summary of the

test, and the user can either save the test data to a report, or press ‘Ok’ to return to the original basic

mode window.

18

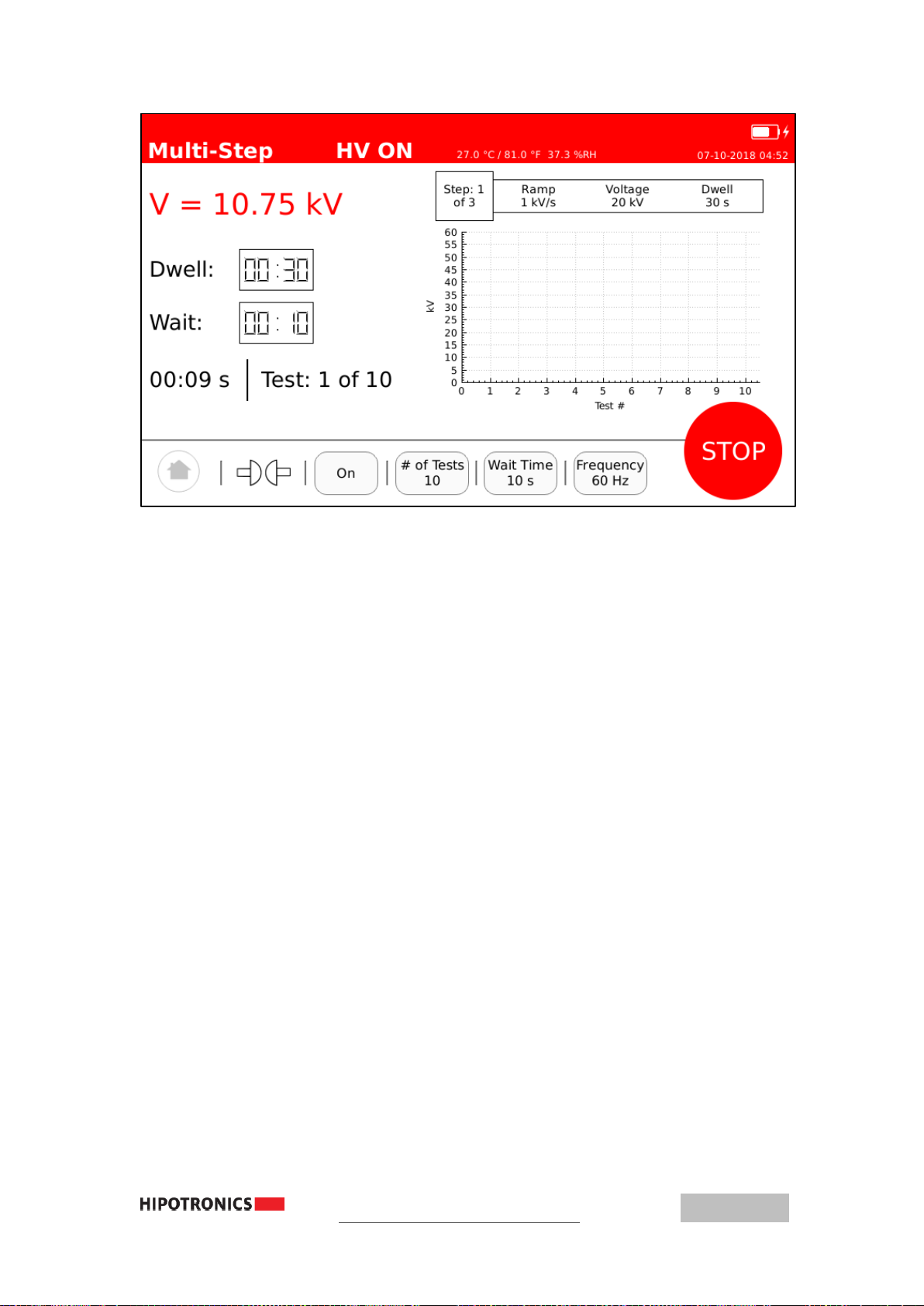

6.2 Multi-Step Mode

In Multi-Step mode, each test has the capability to customize multiple ramping sequences for

unique testing scenarios. By clicking on the cells in the table, the user can select the ramp rate, target

voltage, and dwell time for each sequence in the test. To add a step in the test sequence, click the ‘plus-

sign cell’ at the bottom of the table, and then click each cell in the row to select the parameters for that

step. To remove the last step in the sequence, click the ‘x-button’ in the bottom left of the table. The

sequence table will only ever show three steps at a time; to view the other steps currently in the test

sequence, scroll up or down with the ‘arrow keys’ to the right of the table.

Similar to Basic Mode, you can adjust other test parameters on the bottom of the screen, such

as electrode type, stir option, number of ramp tests to be cycled, the wait time in between tests, and the

output frequency. Once, all of these options are selected, begin the test sequence by clicking the

‘START button’.

6 Operating Modes

19

During a test sequence, the left side of the screen will display similar information to Basic Mode

(see Section 5.3 for detailed information). The right side of the screen will display all of the breakdowns

for the test cycle, and the current step in the sequence. At the start of the test, the voltage will ramp up

to the first step’s target voltage, at the selected ramp rate, and then dwell at that voltage for the selected

dwell time. Once that step’s dwell expires, the voltage will start ramping up to the next step’s target

voltage, at the next step’s selected ramp rate, and then proceed to dwell. This will continue until all of

the steps in the sequence have been performed, or a breakdown occurs. High voltage will be shut off,

and the unit will wait for the chosen wait-time before commencing another test, if multiple number of

tests were selected.

20

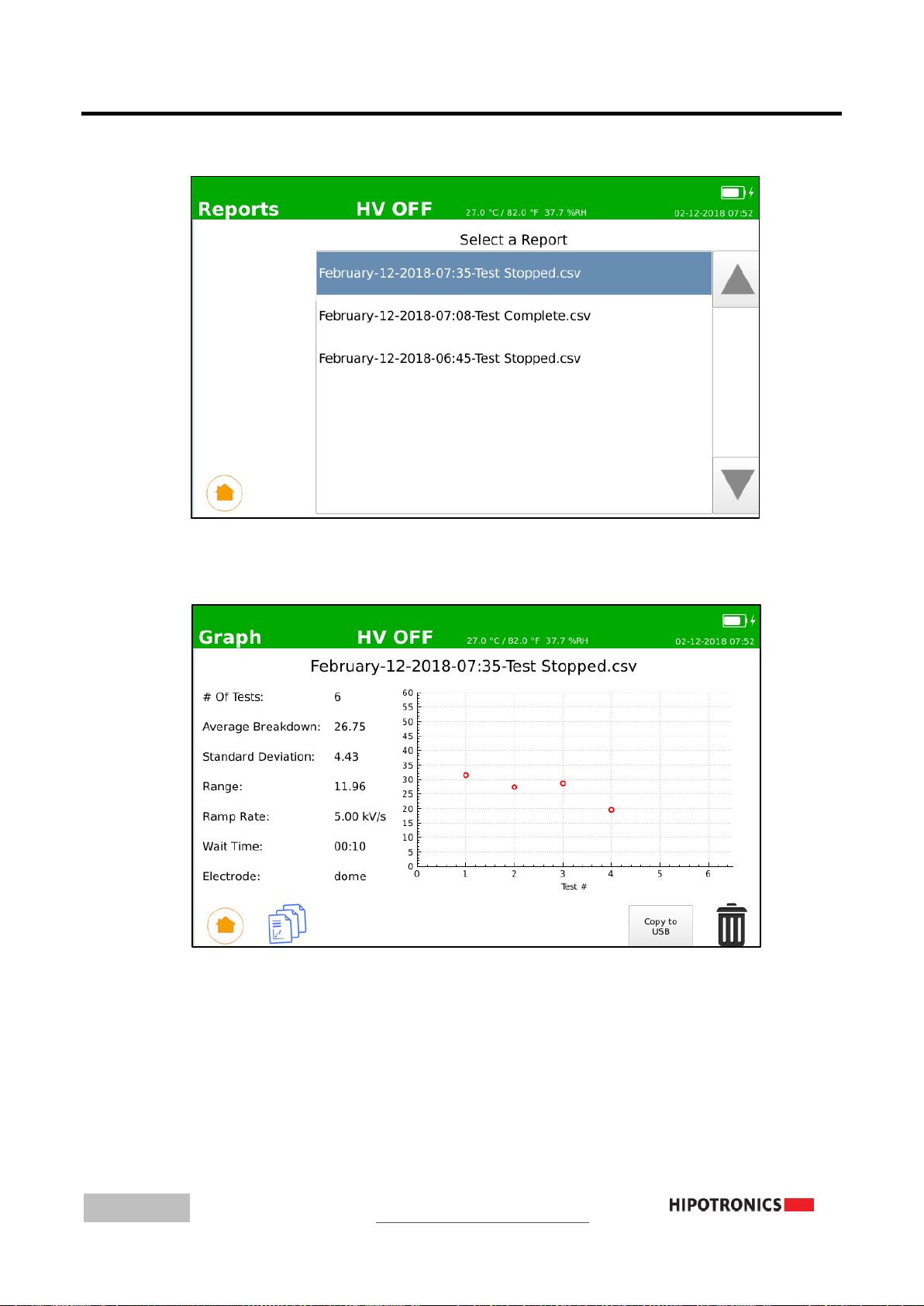

6.3 Reports

In the Reports window, all of the previously saved test data will be in a report labelled by its date and time

of test. Use the touchscreen to select a report to view.

When viewing a report on the unit, several of the chosen test parameters will be displayed, along with the

calculated average breakdown voltage, standard deviation of the breakdowns, the breakdown range, and a

graph of the breakdowns. The user can also export the test report to a USB drive that is inserted into the unit’s

USB port, and press the ‘Copy to USB’ button. The exported report will contain more information, such as

each breakdown, the frequency, stir, and temperature/humidity during the test.

This manual suits for next models

1

Table of contents

Other HIPOTRONICS Test Equipment manuals