Hit Productsc Rain Pro User manual

Rain Pro

Intelligent Irrigation Solutions

Operating Manual

4 or 6 Station

Hit Products Corporation

Read Entire Instruction Booklet Before Installation

English

December 2012

HDC

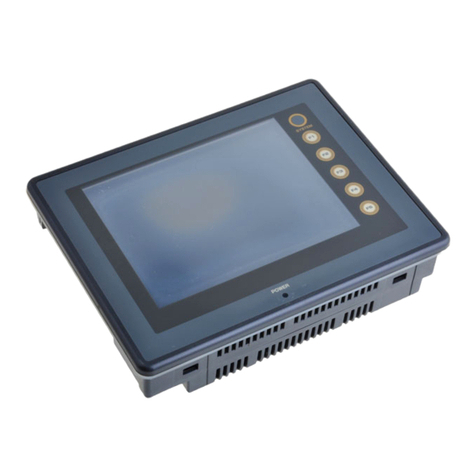

Controller

TABLE OF CONTENTS

Mounting the HDC Controller ................................ 4

Connecting Valve.................................................... 4

Wires to Controller ................................................. 4

Connecting Power Source ..................................... 5

Master Valve/Pump Start/Sensor .......................

Programming the Controller .................................. 8

Schedule/Calendar Options ............................

Dial Positions and Functions ............................... 15

Manual Station/Program .................................

......................... 18

.................................. 19

Trouble Shooting Guide ....................................... 20

..................................................

TERMINAL BLOCK:

RS RS =

SPECIFICATIONS:

2

3

CONNECTING VALVE WIRES TO CONTROLLER

MOUNTING THE HDC CONTROLLER

3

1)

2)

3)

Remove lower panel cover.

Connect one wire from each valve to the desired

corresponding number on the terminal.

Connect the remaining valve wire from all the valves

to the “Com” or common terminal. It is suggested

to use a dierent color wire for the common wire

to help keep organized. “Common” wires may be

bundled or wired together with all other common

wires from all the valves to the “Com” terminal of

the controller.

CONNECTING VALVE WIRES TO CONTROLLER

Locate controller within 5 . of a standard electrical

outlet that provides continuous, uninterrupted power.

Do not install controller within 15 . of a pump, pump

start relay or any high voltage junction boxes or elec-

tric motors.

Choose desired location and install one screw for top

keyhole into wall. Remove bottom panel and insert

two additional screws in each of the bottom corners in

the holes provided. Use screw anchors if attaching to

drywall or masonry.

1)

2)

MOUNTING THE HDC CONTROLLER

Note: All in-eld wire splices should be made using

a dry type waterproof, gel-lled Hit Products DBC-Y

type connector or equivalent.

4)

5)

Wire sizing should be of signicant size to allow a

maximum of 5 volts drop between controller and

valves. Use Ohms’ Law to calculate wire voltage

drop.

Replace cover.

Leave electrical power unattached until all valve

wires are connected to the controller.

Remove lower panel cover to gain access to the

terminal connectors. Insert the two wires from

the plug-in transformer into the two terminals

m a r k e d ‘A C ’ “A C ”.

Replace cover.

1)

2)

3)

4

CONNECTING POWER SOURCE

4

5

MASTER VALVE/PUMP START WIRING

If a master valve or pump start relay is being used in

conjunction with this controller, wire as follows.

Hit Products oers a wide range of pump start relays

for most applications that are compatible with the

HDC controller.

Note: DO NOT connect controller directly to pump.

Controller will be damaged if controller is connected

directly to pump.

a) Located at least 15 feet from controller.

b) Have a maximum rated inrush current less

then 350MA at 24 VAC, and be properly

sized for your application.

Connect one wire to the “MV” terminal and one

to the “Com” terminal.

If using a pump start relay, it must be;

1)

2)

6

Remove lower cover.

Route the 2 wires from the sensor to the bottom of

the controller and connect one each wire to the two

“RS” terminals.

If the “RAIN SENSOR” switch on the front of the

faceplate is in the “ON” position and no sensor is

connected. e display will show a ashing “SEN

SOR” and no irrigation will occur. To override the

problem when no sensor is connected-always leave

the “RAIN SENSOR” switch on the front panel in

the “OFF” position.

1)

2)

3)

SENSOR WIRING

A rain sensor or any other type of normally closed

micro-switch sensor may be used in conjunction

with this controller. Sensor activation will interrupt

controller output.

6

SENSOR WIRING

7

DEFAULT PROGRAM, POWER

FAILURE,

LOW BATTERY OR

NO BATTERY INSTALLED

e controller does not require a default program aer

a power outage. e controller has non-volatile memory

to retain your custom program. Four AAA Alkaline bat-

teries maintain the real time clock and calendar.

(Batteries should be changed annually.)

Should there not be sucient battery power to maintain

the real time clock and calendar and there is a power

outage; when the electrical power returns, the controller

will default to midnight and Saturday.

8

Note: e controller will Run scheduled programs

according to the displayed Day and Time. You will need

to reset the controller to current time and calendar.

DISPLAY CURRENT CONDITION

NOPO No AC power to controller

LOBA Low battery or no battery

NOPO will blink on-o it no AC power is available

and battery is installed and charged.

LOBA will blink on-o if low battery or no battery.

Rotating the dial will stop blinking for one minute and

display will return to normal for programming or to

review program.

Display will return to blinking aer one minute if low

battery or no battery condition exists. If LOBA ashes

aer a power disruption, the clock and calendar may

have to be reset, as no AC power or battery power was

available to keep real time.

PROGRAMMING THE CONTROLLER

To successfully program controller, all three programming

elements must be completed.

ey are:

8

9

Program Start Times (Time of day a complete

programmed irrigation cycle will start).

Station Run Times (e length of time each

station/valve will irrigate).

Calendar/Schedule (e days of week/calendar

that you desire to irrigate).

10

11

BASIC PROGRAMMING FEATURES

To program the controller, you are provided + or – buttons

that will change the value of the “Flashing display”. e

or change the subject of information that is ashing.

e subject or “Flashing display” is in sequence and can

be scrolled forward or backward to access all desired

programming options.

ree independent programs are available

“A”, “B” and “C”.

ree program start times are available per

program.

Calendar/schedule, days of week or ODD/

EVEN days.

Individual station run times.

1)

2)

3)

4)

11

Turn the dial to the CURRENT DATE/TIME.

Use the + and – buttons to select the current year.

Push the button to activate the month.

e month will be ashing. Use the + and – buttons

to select the current month. Press the button to

set the day.

e day will be ashing. Use the + and – buttons to

select the current date. Push the button to set

current time.

e time will be displayed. Use the + and – buttons

to select the current AM or PM hour notation. Press

the button to go to hours. Hours will be ashing.

Use the + and – buttons to set the current hour.

Push the button to set minutes.

1)

2)

3)

4)

5)

BASIC PROGRAMMING FEATURES

INPUT THE CURRENT DATE AND TIME

12

Rotate the dial to program “START TIMES”.

Choose program A, B or C. To change program

from existing program, push the PRG button.

Use the + and – buttons to adjust to desired start

time. Start times are available every 15 minute

increment of the hour. is represents the time of

day the irrigation cycle will commence. All stations

with programmed run time on this program (A, B

or C) will come on, one at a time, sequentially, on all

active days, commencing at this time of day. Up to

three start times can be scheduled per day.

Push the button to add another start time or the

PRG button to set the next program.

If all 3 programmed start times are turned “OFF”

then that specic program will not start.

To eliminate a start time, set dial to “START TIMES”.

Use the + button to scroll to 11:45 PM. en push

the + button once to attain the “OFF” display.

1)

2)

3)

4)

5)

6)

SETTING PROGRAM START TIMES

is is the setting for establishing how long each

independent “valve” or “station” will be on to irrigate.

Each station will come on in numeric sequence

for this duration as set for each Station Run Time.

13

If two or more programs are to start at the same

time, only the rst program will start and run. At

the completion of that program running, the next

program will run, and so on until all multiple

start times are run. is is called “stacking”.

7)

Rotate dial to the “Station Run Times” position.

Choose program A, B or C. To change program from

existing program, push the PRG button.

Press the + or – button to increase or decrease the

length of time you desire this specic station (valve)

to be “ON” each time this valve is activated on this

specic program.

1)

2)

3)

ESTABLISHING INDIVIDUAL

STATION RUN TIMES

14

SETTING THE CALENDAR

Press the button to go to the next station.

Repeat steps 3 and 4 for each station that is to be active

on each specic program. For stations/valves that are

to be inactive on each specic program, put “Station

Run Time” at “0”.

Each individual “Station Run Time” can range from

1 minute to 6 hours in duration.

Rotate dial to “RUN” to enter this new data into

controller.

4)

5)

6)

7)

Rotate dial to the Calendar/Schedule position.

Choose program A, B or C. To change program from

existing program, push the PRG button.

Using the + and – buttons will make a day either active

or inactive. “+” indicates an active day or non-circled.

Press the “-” button to change to a circled day, which

indicates an inactive day. Press the button to advance

to the next day.

1)

2)

3)

DIAL POSITIONS AND FUNCTIONS

“RUN”

Rotate the dial counter clock wise to the “RUN” position

aer completing any programming to enter this new data

in controller. Leave the dial in the RUN position to have

the controller operate as programmed automatically.

RAIN/OFF

Rotate the dial to the “RAIN/OFF” position to stop all

output of the controller. All irrigation will stop. Display

will ash “OFF”. To return to normal operation, rotate

dial back to “RUN”.

15

Repeat step 3 for each day of the week. e button

may be used to advance to a particular day of the

week. To operate “odd” or “even” days of the month,

continue advancing the button and then activate

“odd” or “even” as described in step 3 above.

4)

16

MANUAL STATION

To manually activate a single station for one watering

cycle for a programmed length of time.

MANUAL PROGRAM

Rotate dial to “Manual Station”.

Push to desired station number.

Push + or – buttons to input length of time, this station

will now operate this programmed time.

Rotate dial to “RUN” position, valve will now turn on.

Upon completion of this station operating manually

for length of time programmed, controller will revert

back to “RUN” and operate as previously programmed.

1)

2)

3)

4)

5)

Rotate dial to “Manual Program”.

Choose program A, B or C. To change program from

existing program, push the PRG button.

1)

2)

To manually activate one complete cycle of either program

“A”, “B” or “C”.

17

Push the button to choose the rst station in the

sequence of the manual program to start.

e “run time” for each station will be displayed as

currently programmed. For this cycle only, you can

customize each station run time without eecting the

individually programmed station run times within a

program.

Push the button to sequence through all the stations,

using the + or – buttons to select the desired run times

for this cycle only.

Push the button until the station number appears of

which you want to start this custom cycle.

Rotate dial to “RUN” to start this custom, one-time

cycle. It will start with station number displayed in

Step 6. Once completed, controller will revert to

programmed “automatic” operation.

3)

4)

5)

6)

7)

MANUAL PROGRAM

18

19

SEASONAL ADJUST

e seasonal adjust feature provides a one step universal

run time adjustment in 10% increments up or down for all

programs. It eects all station run times in all programs.

In hotter, drier weather, you can increase the water budget

in 10% increments up to 200% of originally programmed

station run times. In periods of cooler/wetter weather, you

can water budget downwards – in 10% increments to as

low as 10% of originally programmed station run time.

Rotate dial to Seasonal Adjust % position.

Use the + or – buttons to adjust the percentage desired.

Actual run times for each station will be a %

of the time programmed for station runtime.

e display always shows 100% setting.

1)

2)

3)

RE-SETTING OR ERASING CONTROLLER

MEMORY

If you want to eliminate all past programming input

to controller, as if to start over as new, with no data in

controller, proceed as follows:

Press the , the – button and the PRG buttons

simultaneously.

Controller will now display 12:00 a.m. and all

the entered data has been erased.

e controller can now be programmed as if

brand new.

1)

2)

19

Note: is is recommended on new installations

before programming for the rst time.

20

ICONS ON THE THC DISPLAY

TROUBLE SHOOTING GUIDE

No Display

information.

Display reads

“Sensor O”.

Controller is irrigating at

incorrect start time.

Controller is operating

properly but valve or

valves do not activate.

Check AC Power Supply,

power at the controller

should be 24-26 VAC.

Check AC wiring. Check

power at wall plug.

Check Programming,

Day, Time, AM-PM.

Start Times and Active

Day.

Check both station and

common wiring and

connections between

controller and valves.

Check for 24 VAC at

valve solenoid.

Slide Rain Sensor switch

to “o” or install a sensor

jumper wire on terminal

strip connecting “RS”

and “RS” terminals.

Table of contents