BIFFI ALGAS User manual

Installation, Operation and Maintenance Manual

MAN 604A Rev. 5

June 2020

Bif ALGAS

Spring-Return Pneumatic Actuator

Copyright © Bif. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.bif.it or from your nearest Bif Center:

Bif Italia s.r.l. - Strada Bif 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – bif_italia@bif.it

MAN 604A Rev. 5

Installation, Operation and Maintenance Manual

June 2020

Revision Details

Revision Details

Rev. Date Description Prepared Checked Approved

5 June 2020 General update (Migration to new template)

4March 2018 Updated data-plate Ermanni Oreci Vigliano

3April 2016 Updated applicable regulation (chapter 1.1.1) Ermanni Oreci Vigliano

2June 2012 Updated chapter 5 Ermanni Stoto Vigliano

1 January 2012 Added vertical assembly description Ermanni Stoto Vigliano

Revision Details

i

MAN 604A Rev. 5

Table of Contents

Installation, Operation and Maintenance Manual Table of Contents

Table of Contents

Section 1: General Warnings

1.1 Generalities................................................................................................... 1

1.1.1 Applicable Regulation ........................................................................ 1

1.1.2 Terms and Conditions......................................................................... 1

1.2 Identication Plate ........................................................................................ 2

1.3 Description of the Actuator........................................................................... 2

Section 2: Installation

2.1 Checks to Be Carried Out on Receiving the Actuator...................................... 4

2.2 Storage ......................................................................................................... 4

2.3 Assembling the Actuator onto the Valve ....................................................... 5

2.3.1 Types of Assembly.............................................................................. 5

2.3.2 Valve Stem with Vertical Axis ............................................................ 13

2.3.3 Valve Stem with Horizontal Axis........................................................ 17

Section 3: Operation and Use

3.1 Setting of the Angular Stroke ...................................................................... 19

3.1.1 Travel Stop Screw Screwed on the End Flange of

Pneumatic Cylinder .......................................................................... 19

3.1.2 Stop Screw Screwed on the End Flange of Spring Container.............. 21

3.2 Calibration of Micro-switches (If Foreseen).................................................. 23

3.3 Calibration of Operating Time..................................................................... 23

3.4 Preparation for Start-up .............................................................................. 24

3.4.1 Pneumatic Connections ................................................................... 24

3.4.2 Electrical Connections...................................................................... 25

3.5 Start-up ...................................................................................................... 25

Section 4: Operational Tests and Inspections

Operational Tests and Inspections......................................................................... 26

June 2020

ii

MAN 604A Rev. 5

Table of Contents

Table of Contents Installation, Operation and Maintenance Manual

June 2020

Section 5: Maintenance

5.1 Routine Maintenance .................................................................................. 27

5.2 Extraordinary Maintenance ......................................................................... 28

5.2.1 Replacement of Cylinder Seals ......................................................... 30

5.3 Lubrication of Mechanism........................................................................... 34

5.4 Dismantling and Demolition ....................................................................... 35

Section 6: Troubleshooting

6.1 Failure or Breakdown Research.................................................................... 36

Section 7: Layouts and Sectional Drawings

7.1 Parts List for Maintenance and Replacing Procedure.................................... 37

Section 8: Spare Parts

Spare Parts............................................................................................................ 42

Section 9: Date Report for Maintenance Operations

Date Report for Maintenance Operations .............................................................. 43

1

MAN 604A Rev. 5

General Warnings

Section 1: General Warnings

NOTICE

The manual is an integral part of the machine, it should be carefully read before carrying

out any operation and it should be kept for future references.

1.1 Generalities

Bif Italia s.r.l. actuators are conceived, manufactured and controlled according to the

Quality Control System in compliance with EN-ISO 9001 international regulation.

1.1.1 Applicable Regulation

EN ISO 12100:2010: Safety of machinery – General principles for design –

Risk assessment and risk reduction

2006/42/EC: Machine directive

2014/68/EU: Directive for pressure PED equipment

2014/35/EU: Directive for low voltage equipment

2014/30/EU: Directive for the electromagnetic compatibility

2014/34/EU: Directive and safety instructions for use in hazardous area

1.1.2 Terms and Conditions

Bif Italia s.r.l. guarantees that all the items produced are free of defects in workmanship

and manufacturing materials and meet relevant current specications, provided they

are installed, used and serviced according to the instructions contained in the present

manual. The warranty can last either one year from the date of installation by the initial

user of the product, or eighteen months from the date of shipment to the initial user,

depending on which event occurs rst. All detailed warranty conditions are specied in the

documentation forwarded together with the product. This warranty does not cover special

products or components not warranted by subcontractors, or materials that were used or

installed improperly or were modied or repaired by unauthorized staff. In the event that

a fault condition be caused by improper installation, maintenance or use, or by irregular

working conditions, the repairs will be charged according to applicable fees.

The warranty and Bif Italia s.r.l. liability shall lapse in the event that any modication

or tampering whatsoever be performed on the actuator.

Section 1: General Warnings

NOTICE

Bif Italia has taken every care in collecting and verifying the documentation contained in

this instruction and operating manual. Nevertheless Bif Italia does not provide any

guarantees for this instruction manual. Bif Italia will not be responsible for any mistakes

contained in it or for any damage either accidental or due to the use of this manual.

The information herein contained is reserved property of Bif Italia and is subject to

being modied without notice.

Installation, Operation and Maintenance Manual

June 2020

2

MAN 604A Rev. 5

General Warnings

June 2020

Installation, Operation and Maintenance Manual

1.2 Identication Plate

! WARNING

It is forbidden to modify the information and the marks without previous written

authorization by Bif Italia s.r.l. The plate fastened on the actuator contains the following

information (Figure1).

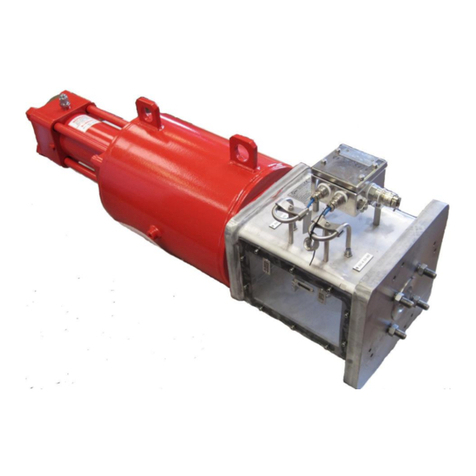

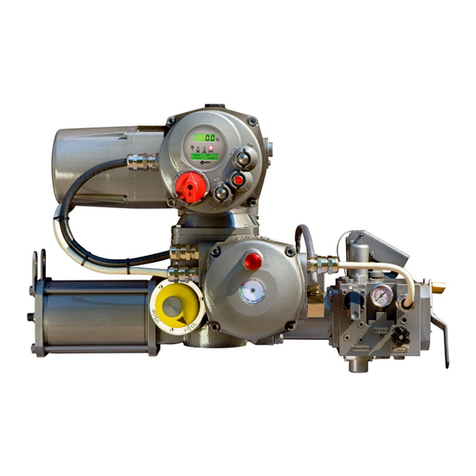

1.3 Description of the Actuator

ALGAS low pressure pneumatic spring-return, are suitable for the operation of

quarter-turn valves (ball valves, buttery valves, plug valves) in both ON-OFF and

modulating heavy-duty service.

The actuator is made up of a weatherproof scotch yoke mechanism transforming the linear

movement of the pneumatic cylinder (or mechanical manual override, if foreseen) and of

the spring into the rotary movement, which is necessary for operation.

The spring-return pack incorporates up to four springs, fully encapsulated in a factory

welded cartridge: this ensures safety to personnel and simplies assembly. The spring

action can be easily changed in the eld from to close in to open or from to open in to close

(modular design).

The angular stroke of the yoke is adjustable between 82° and 98° by means of the external

mechanical stops screwed into the end ange of the pneumatic cylinder and into the end

ange of the spring-return pack. The cover of the scotch yoke mechanism is arranged for

the assembly of the required accessories (position-transmitter, signaling-limit switches,

positioner, etc.) by means of proper matching units. The above mentioned accessories are

operated by the actuator drive sleeve.

The housing of the scotch yoke mechanism has a ange with threaded holes to x the

actuator to the valve either directly or, if required, with the interposition of an adaptor

ange or a mounting bracket.

The actuator yoke has a hole with keyways suitable for the assembly of an insert bush or a

stem extension. Their internal hole is machined (by Bif or at Customer's care), according

to the shape and dimensions of the valve stem.

Bif can supply different types of control system following Customer's requirements.

Section 1: General Warnings

Figure 1 Data Plate

3

MAN 604A Rev. 5

General Warnings

Section 1: General Warnings

Code: ALGAS XXX K - YYYYY -ZZZZ - F SC

Actuator series

Scotch yoke mechanism size

Yoke shape

C Canted

S Symmetric

Spring cartridge size

Cylinder size

Internal diameter in mm

Spring action

CL Closing

OP Opening

Service

Blank Standard

QA Quick acting

Manual override

Blank No manual override

MHP Manual handpump

MHW Manual handwheel

MRHW Manual reduced handwheel

The expected lifetime of actuator is approximately 25 years.

Installation, Operation and Maintenance Manual

June 2020

Table 1. Selection Guide

4

MAN 604A Rev. 5

Installation

Section 2: Installation

2.1 Checks to Be Carried Out on Receiving

the Actuator

1. If the actuator arrives already assembled onto the valve, the settings of the

mechanical stops and of the micro switches (if existing) has already been made

by the person who assembled the actuator onto the valve. If the actuator arrives

separately from the valve, the settings of the mechanical stops and of the

micro switches (if existing) must be checked and, if necessary, carried out while

assembling the actuator onto the valve.

2. Check that the actuator has not been damaged during transport. If necessary,

repair all damages to the paint-coat, etc.

3. Check that the model, the serial number of the actuator and the performance

data written on the data plate are in accordance with those described on the order

acknowledgement, test certicate and delivery note.

4. Check that the tted accessories comply with those listed in the order

acknowledgement and the delivery note.

2.2 Storage

(For handling and lifting procedure, please refer to Figures 10, 11 and 12).

The actuators leave the factory in excellent working conditions and with an excellent

nish (these conditions are guaranteed by an individual inspection certicate); in order to

maintain these characteristics until the actuator is installed on the plant, it is necessary to

observe a few rules and take appropriate measures during the storage period.

1. Make sure that plugs are tted in the air connections and in the cable entries. The

plastic plugs, which close the inlets, do not have a weatherproof function, but are

only a means of protection against the entry of foreign matter during transport.

If long-term storage is necessary and especially if the storage is outdoors, metal

plugs must replace the plastic protection plugs, which guarantee a complete

weatherproof protection.

2. If the actuators are supplied separately from the valves, they must be placed

onto a wooden pallet so as not to damage the coupling ange to the valve. In

case of long-term storage, the coupling parts (ange, drive sleeve, insert bush)

must be coated with protective oil or grease. If possible, blank off the ange

by a protection disk.

3. In case of long-term storage (>1 years), it is advisable to keep the actuators in a

dry place or to provide at least some means of weather protection. If possible, it is

also advisable, to periodically operate the actuator with ltered, dehydrated and

lubricated air; after such operations all the threaded connections of the actuator

and the valves of the control panel (if existing) should be carefully plugged.

Section 2: Installation

June 2020

Installation, Operation and Maintenance Manual

5

X

P

K

ØM

Ø d1 max

Ø d4

h1

Ø d3 ±0.2

H max

45°

W

0.1 220 102 M10 50 4 7 17 121 22 25 32

MAN 604A Rev. 5

Installation

Section 2: Installation

2.3 Assembling the Actuator onto the Valve

2.3.1 Types of Assembly

For coupling to the valve, the housing is provided with a ange with threaded holes

according to Bif standard tables (SCN6200; SCN6200-1; SCN6201; SCN6201-1

SCN6201-3 SCN6201-5). The number, dimensions and diameter of the holes are made

in accordance with ISO 5211, but for actuator models 0.3 to 6 the holes are drilled on

the centreline in order to allow an easier assembly of an intermediate ange, when

required. This intermediate ange (or spool-piece) can be supplied when the valve ange

cannot directly match the actuator ange in its “standard” conguration. For the biggest

actuator models, the actuator ange can be machined in accordance with the valve

ange dimensions.

The yoke has bored with keyways for coupling to the valve stem, the dimensions of which

are according to Bif standard tables SCN6200* and SCN6201*.

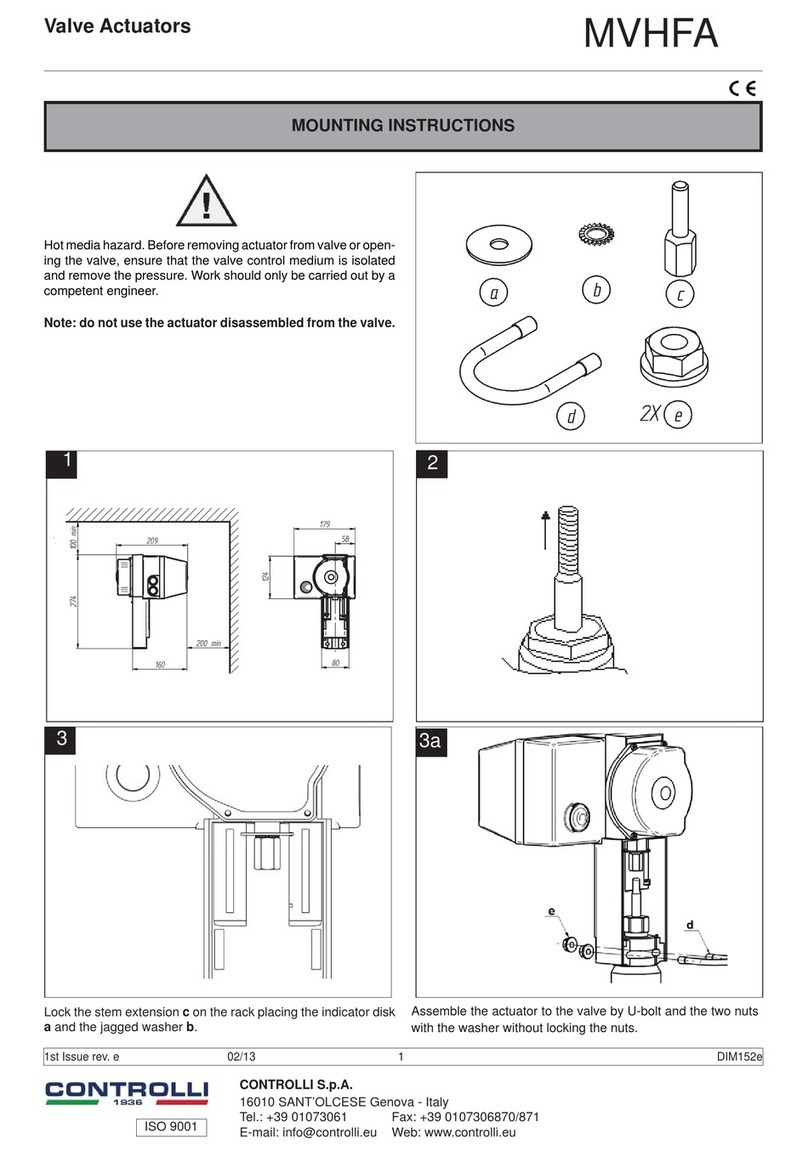

Figure 2

N. THREADED HOLES

PCD, holes, number and

size according to ISO 5211

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Drive sleeve

Flow line

Dimensions in millimeters

Actuator model Ø d1Ø d3Ø d4ØM N P h1H max WK X

Installation, Operation and Maintenance Manual

June 2020

Table 2.

6

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d5+0.2

+0.1

K+0.4

0

Ø d3±0.2

h1 +0.5

0

H max

45°

WD10

0.3 240 93 165 M20 4 5 17 127 70 12 75.6

0.9 310 112 254 M16 8 519 150 86 14 96.6

1.5 360 144 298 M20 8619 190 112 18 119.0

3 430 195 356 M30 8 9 23 200 157 25 167.8

6 520 250 406 M36 8 14 29 260 200 28 212.8

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimeters

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 3

Drive sleeve

N. THREADED HOLES

PCD, holes, number and size

according to ISO 5211

(but the holes are on centerline

instead of straddle the centerline)

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

N.8 holes angeN.4 holes ange

June 2020

Installation, Operation and Maintenance Manual

Table 3.

7

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d5+0.2

+0.1

K+0.4

0

Ø d3±0.2

h1 +0.5

0

H max

WD10

14 580 250 483 M36 12 10 29 340 175 45 195.8

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimeters

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 4

Drive sleeve

N. THREADED HOLES

PCD, holes, number and

size according to ISO 5211

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

Installation, Operation and Maintenance Manual

June 2020

Table 4.

8

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d3±0.2

h1 +0.5

0

H max

Ø d5+0.2

+0.1

K+0.4

0

WD10

18 680 290 603 M36 16 12 32 350 200 45 220.8

32 780 290 603 M36 16 12 32 400 220 50 242.8

35 780 315 603 M36 16 11 32 400 240 50 242.8

42 840 310 603 M36 16 12 32 400 220 50 242.8

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimeters

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 5

Drive sleeve

N. THREADED HOLES

PCD, holes, number and

size according to ISO 5211

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

June 2020

Installation, Operation and Maintenance Manual

Table 5.

9

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d3±0.2

h1 +0.5

0

H max

Ø d5+0.2

+0.1

K+0.4

0

WD10

50 800 315 698 M36 24 10 32 430 240 56 264.8

60 840 315 698 M36 24 10 32 430 240 56 264.8

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimetersw

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 6

Drive sleeve

N. THREADED HOLES

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

Installation, Operation and Maintenance Manual

June 2020

Table 6.

10

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d3±0.2

h1 +0.5

0

H max

Ø d5+0.2

+0.1

K+0.4

0

WD10

65 910 370 813 M42 24 12 37 540 280 46 327.4

80 910 370 813 M42 24 12 37 540 280 46 327.4

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimeters

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 7

Drive sleeve

N. THREADED HOLES

PCD, holes, number and

size according to ISO 5211

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

June 2020

Installation, Operation and Maintenance Manual

Table 7.

11

Ø d1 max

Ø d4

h2

Ø d2+0.1

0

Ø d3±0.2

h1 +0.5

0

H max

Ø d5+0.2

+0.1

K+0.4

0

WD10

100 1200 450 1042 M42 32 8 57 600 300 70 328.8

MAN 604A Rev. 5

Installation

Section 2: Installation

Dimensions in millimeters

Actuator model Ø d1Ø d2Ø d3Ø d4N h1h2H max Ø d5WK

Figure 8

Drive sleeve

N. THREADED HOLES

PCD, holes, number and size

according to ISO 5211

(but the holes are on centerline

instead of straddle the centerline)

Top view of the scotch yoke mechanism

(actuator shown in closed position)

Flow line

Installation, Operation and Maintenance Manual

June 2020

Table 8.

12

MAN 604A Rev. 5

Installation

Section 2: Installation

If required, for the standard models size 0.3 to 6, Bif can supply an insert bush with

unmachined bore in accordance with Bif standard table SCN6202. On request the insert

bush bore can be machined by Bif to couple the valve stem, provided its dimensions

match the maximum stem acceptance of the bush according to Bif table TN1005,

enclosed. The particular execution of the ange and bushing allow the actuator to

be rotated by 90° in 4 different positions according to the Figure 9.

The Bif insert bush with 2 external keys at 45° allows to position the keyway for the valve

every 90°. Consequently actuator can be mounted in 4 positions at 90° on top of the valve.

For biggest actuator models, the bore of the yoke can be machined according to the

dimensions of valve stem.

Flow line

N.4 holes ange N.8 holes ange

Drive sleeve

Snap ring

Housing

Insert bush

Insert bush

Adaptor ange

Drive sleeve

Standard position 1

Position 2 Position 3 Position 4

Position 2 Position 3 Position 4

Rotate insert-bush 180° around

vertical-standard position (1)

Rotate insert-bush 180° around

axis A-A, from position (2)

Rotate insert-bush 180° around

axis A-A, from position (1)

Insert bush turned upside down

Figure 9 Insert bush + intermediate coupling ange

June 2020

Installation, Operation and Maintenance Manual

Table 9.

13

MAN 604A Rev. 5

Installation

Section 2: Installation

Figure 10 Example of hook with safety latch

Figure 11

2.3.2 Valve Stem with Vertical Axis

NOTICE

The lifting and handling of the actuator must be done by qualied personnel and in

accordance with the laws and regulations in force.

! WARNING

The actuator must be lifted by means of a suitable lifting apparatus. The weight of the

actuators is indicated in the technical documentation attached to the equipment itself.

For lifting and moving the actuator, use only hooks tted with safety latch, like the one, for

example, shown in follow Figure 10.

Installation, Operation and Maintenance Manual

June 2020

Lifting points: 1-2 (mandatory), 3 (balancing)

14

MAN 604A Rev. 5

Installation

Section 2: Installation

Spring cartridge

Lifting eyelet

Pneumatic cylinder

Lifting eyelet

Lifting point applicable for ALGAS models:

3-6-14-18-32-50-80

Lifting eyelet

Lifting point applicable for ALGAS models:

0.3-0.9-1.5

Figure 12

Lift ALGAS actuators (pneumatic spring-return) by means of the proper lifting points

represented and indicated on actuator by sticking labels. Also refer to Figure 12 for lifting

points positions.

• For lifting unbalanced loads, use ropes of different lengths or chains with

adjustable length.

• Check each time the conditions of all lifting equipment used and discard it if

not in perfect working order.

• Do not knot or twist the ropes so as not to reduce the lifting capacity or

produce torsional effects on the load being lifted.

• Use the utmost caution and remain at a safe distance from lifted actuator

unless absolutely necessary; do not stand or pass under suspended loads.

• Pay attention in putting under tension the ropes to prevent the load shifting

sideways in an uncontrolled manner.

• Use slings of such length that the angles of the leg from vertical are as narrow

as possible (αMAX < 20°).

• During handling, do not transport the suspended actuator above staff

members in charge of the operation.

! WARNING

Do not use the lifting eyelets on actuator to lift valve + actuator assembly.

June 2020

Installation, Operation and Maintenance Manual

15

MAN 604A Rev. 5

Installation

Section 2: Installation

Figure 13

! WARNING

Any lifting method different from what described above is strictly forbidden. Bif reject any

responsibility for damages to goods or injuries to persons coming from wrong lifting operations.

The actuator can be assembled onto the valve ange either by using the actuator-housing

ange with threaded holes, or by the interposition of an adaptor ange or a spool piece.

The actuator drive sleeve is generally connected to the valve stem by an insert bush or a

stem extension.

The assembly position of the actuator, with reference to the valve, must comply with the

plant requirements (cylinder axis parallel or perpendicular to the pipeline axis).

To assemble the actuator onto the valve proceed as follows:

1. Check that the coupling dimensions of the valve ange and stem, or of the

relevant extension, meet the actuator coupling dimensions.

2. Bring the valve to the position related to the actuator spring operation.

3. Lubricate the valve stem with oil or grease in order to make the assembly easier.

Be careful not to pour any of it onto the ange.

4. Clean the valve ange and remove anything that might prevent a perfect

adherence to the actuator ange and especially all traces of grease, since the

torque is transmitted by friction.

5. If an insert bush or stem extension for the connection to the valve is supplied

separately, assemble it onto the valve stem and fasten it by tightening the proper

stop dowels.

6. Bring the actuator to the position caused by the spring operation.

Installation, Operation and Maintenance Manual

June 2020

BIFFI IS NOT LIABLE FOR ANY

PERSONEL INJURY DUE TO

INCORRECT USE

DO NOT DISASSEMBLE TOP OR

BOTTOM COVER.

SPRING LOADED.

POTENTIAL ELECTROSTATIC CHARGE HAZARD

REFER TO IOM

LIFTING LUGS TO BE USED FOR THE

ACTUATOR ONLY. DO NOT LIFT

VALVE AND ACTUATOR TOGETHER

16

M8 20

M10 40

M12 70

M14 110

M16 160

M20 320

M22 420

M24 550

M27 800

M30 1100

M33 1400

M36 1700

MAN 604A Rev. 5

Installation

Section 2: Installation

7. Connect a sling to the support points of the actuator and lift it: make sure the

sling is suitable for the actuator weight. When possible, it is easier to assemble the

actuator to the valve if the valve stem is in the vertical position. In this case the

actuator must be lifted while keeping the ange in the horizontal position.

8. Clean the actuator ange and remove anything that might prevent a perfect

adherence to the valve ange and especially all traces of grease.

9. Lower the actuator onto the valve in such a way that the insert bush, assembled

on the valve stem, enters the actuator drive sleeve. This coupling must take place

without forcing and only with the weight of the actuator. When the insert bush

has entered the actuator drive sleeve, check the holes of the valve ange. If they

do not meet with the holes of the actuator ange or the stud bolts screwed into

them, the actuator drive sleeve must be rotated; feed the actuator cylinder with

air at proper pressure, indicated on data sheet for actuator.

10. Tighten the nuts of the connecting stud bolts evenly with the torque prescribed in

the table. The stud bolts must be made of ASTM A320 L7 steel; the nuts must be

made of ASTM A194 grade 2 steel. See Table 10.

11. If possible, operate the actuator to check that it moves the valve smoothly.

Thread Size Recommended Tightening Torque (Nm)

Table 10.

June 2020

Installation, Operation and Maintenance Manual

Table of contents

Other BIFFI Controllers manuals

BIFFI

BIFFI OLGA Series User manual

BIFFI

BIFFI ALGA-EAC Series User manual

BIFFI

BIFFI OLGA User manual

BIFFI

BIFFI GIGS 0.3 User manual

BIFFI

BIFFI HLAS-C Series User manual

BIFFI

BIFFI F01-2000 Parts list manual

BIFFI

BIFFI RPHD-10 User manual

BIFFI

BIFFI OLGAS-QA User manual

BIFFI

BIFFI OLGAS-H User manual

BIFFI

BIFFI RPS Series User manual

BIFFI

BIFFI ALGAS-MHW User manual

BIFFI

BIFFI HLAS User manual

BIFFI

BIFFI OLGA-H User manual

BIFFI

BIFFI FCB Series Operating instructions

BIFFI

BIFFI EFS2000v4 Parts list manual

BIFFI

BIFFI COMPACT Series User manual

BIFFI

BIFFI GIGS Series User manual

BIFFI

BIFFI TPS Series User manual

BIFFI

BIFFI ALGA - EAC User manual

BIFFI

BIFFI PLA User manual