Flomatic FCEL User manual

1) General

All Flomatic Electric Actuators are thoroughly tested and checked before shipment . If

installation will not occur immediately, actuator should be kept in a dry place. Please

D N T remove plugs from conduit entries until ready for wiring.

2) Operation

2.1) Auto/Manual Operation

Auto/ Manual Shift operation as follows:

1) Manual verride: Caution: Before engaging manual override power must be

off. Push or Pull the hand/auto declutching lever to engage clutch. (Handwheel

may have to be “jockeyed” slightly.) After engaging clutch, turn handwheel

either to “ pen” or “Closed”.

2) Auto peration by Motor: nce wiring is complete actuator is ready for

operation and will instantly operate once electric power is energized. If in

manual mode when electric power is re-energized, actuator will automatically

declutch and operate.

2.2) Valve Position Indication-

Actuator Top mounted Visual position indication shows “ PEN” and “CL SED”

valve position.

3) Wiring onnections

3.1) Top Housing over Removal

Remove the 4 Socket head Housing Capscrews with a hex key wrench. Lift

housing cover from actuator base. Look for wiring diagram in plastic envelope.

aution!! Read Before Operation!!

When the actuator is operated for the 1

st

time it is important to check the

correct rotation of the motor. Otherwise serious damage may occur.

1) Place Valve position at 45 degrees by turning the handwheel , energize

the actuator to open or close and check proper valve rotation direction.

2) If Rotation direction is reverse, stop immediately and recheck wiring.

F EL Electric Actuator Operating Manual

70113Rev1

3.2) Wiring

1) Connect power and control connections to the terminal strip per wiring

2) 2 Ground Connections need to be wired . (1 internal- identified by sticker

and 1 external located between the two mechanical stops)

3.3) onduit Entries (3/4 inch NPT)

SEAL All conduit entries even if not used!!

4) Limit Switches (LS) - am activated snap action switches,

4.1) Setting the losed Limit Switch: (Lower am and Lower Switch)

1) Pull the declutch lever and turn Handwheel clockwise to move the valve to fully

losed position.

2) Using a hex key wrench, loosen the lower cam screw. ( losed LS)

3) Adjust the cam to trip the lower cam switch (LS), then tighten screw.

4.2) Setting the Open Limit Switch: (Upper am and Upper Switch)

1) Pull the declutch lever and turn Handwheel counter-clockwise to move the valve

to the fully pened position.

2) Using a hex key wrench, loosen the upper cam screw. (Opened LS)

3) Adjust the cam to trip the upper cam switch (LS), then tighten screw.

4.3) Mechanical Travel Limit Stops: (TLS)

1) Closed Travel Limit Stop is on Left and pen Travel Limit Stop is located on right.

2) Set each mechanical (TLS) bolt 1 turn beyond the Limit Switch trip point.

3) If the stop bolts make contact before the /C LS trips, rotate bolt 2 turns counter-

Clockwise.

4.4) Limit Switch/Travel Stop Operation Test

To test pen/Closed Limit Switch and Mechanical TLS operate the valve to pen-Closed

Several times with Limit Swtches wired to control panel to check pen/closed indicator

Lights.

5) Torque Switch

70113Rev1

Torque switches are factory set to actuator rated torque and should not be necessary

to reset. all factory if you have special requirement. Torque switches set with

special tools to protect the actuator. If re-set without factory consultation warranty

may be voided.

6) Adaptation mounting for Actuator and valve

6.1 Drive Bushing

1) Removal

An internal actuator drive bushing is assembled on the bottom of the actuator with 4

retaining screws. Socket hex-key wrench is required for their removal.

2) Machining

The Drive bushing is machined to adapt to valve shaft ( or mounting coupler if

actuator is not direct mounted to the valve.) If key/keyway adaptation is used the

directionof keyway should align with one of the drive busing screws.

6.2 Reassembling the drive bushing

1) heck the relative position of valve and actuator ( pen-Closed).

If not rotate the actuator to same position as valve.

2) Line UP actuator key way or other shaft configuration ( Square, etc.) with valve

Shaft or coupler Key Way, etc. ** Actuator can mount in one of 4 quadrants as determined by

the drive busing installed position.

3) Insert the drive bushing back into the actuator with the 4 retaining screws.

Trouble shooting

70113Rev1

Mechanical Trouble

Valve will not operate 1) Try moving the valve with the Manual Handwheel after

Pulling the declutch lever.

2) Watch mechanical position On top of actuator for movement

3) If Handwheel will not move, the valve is stuck. Valve needs to

disassembled and repaired.

4) If Handwheel moves well without interruption, check the

adapter connecting the valve and actuator.

5) If Handwheel moves check electrical functioning.

Electrical Trouble

1)

heck Main Power Supply, relays, fuses, lamps, switches

heck Main 2) If the problem is the control panel- replace defective parts.

ontrol Panel 1

st

If NO ontrol Panel problem heck Actuator

Then Actuator 3) heck the Actuator Motor and replace if necessary.

4) Torq Switch Tripping- turn main power off and follow

Mechanical Trouble Shooting procedure

5) heck for faulty Limit switch with circuit check,

adjust or replace.

6) All other electrical problems can be resolved by parts

Replacement.

F EL Actuators are designed for long life under normal operating conditions. It is

Recommended to make an operational check 2X’s per year.

Flomatic warrants all products to be free of defects in workmanship and materials for 1 Year

from date of shipment.

15 Pruyn's Island Drive Glens Falls, New York 12801

Phone (800) 833-2040 www.flomatic.com Fax (518) 761-9798

Table of contents

Other Flomatic Controllers manuals

Popular Controllers manuals by other brands

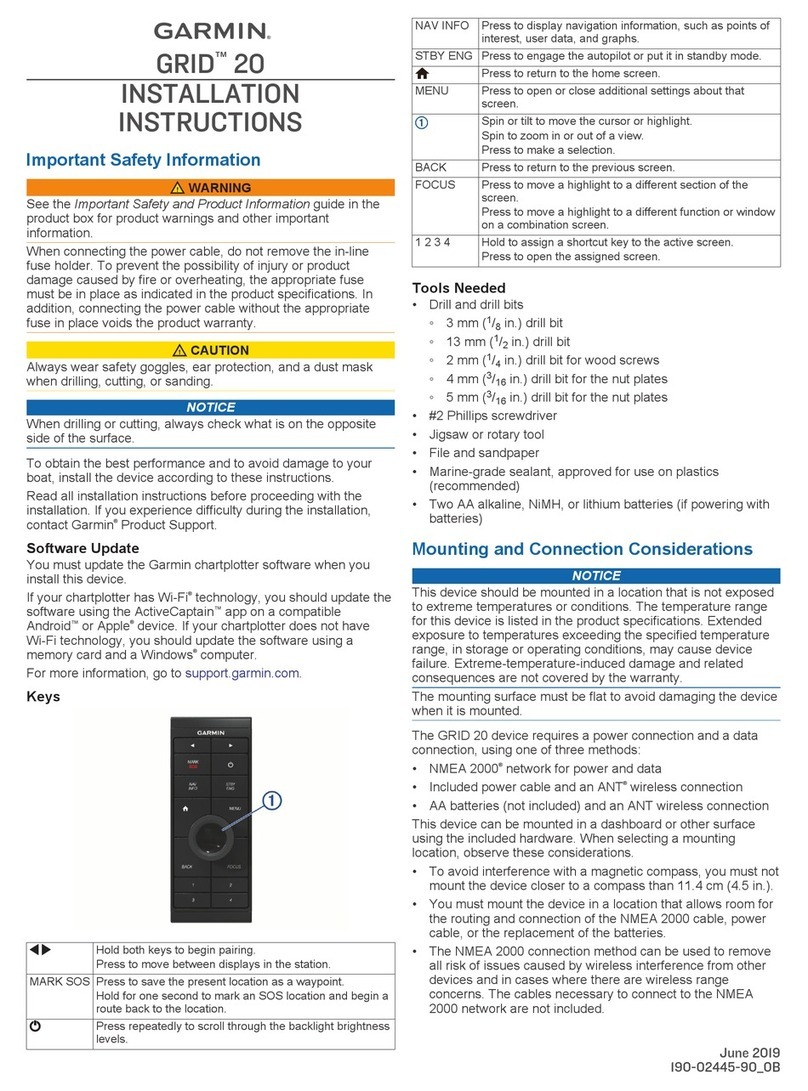

Garmin

Garmin GRID 20 installation instructions

Pfeiffer Vacuum

Pfeiffer Vacuum CenterOne installation instructions

Signature

Signature EZ Pro Jr. Indoor Installation and programming guide

Danfoss

Danfoss DMS 300 operating instructions

Omron

Omron E5CN-HT Communications manual

FXLuminaire

FXLuminaire Luxor ZD quick start guide