1. Safety Summary

3A16381E84N-rev.1

• Do NOT install the unit in the following places. Doing

so can result in an explosion, fire, deformation,

corrosion, or product failure.

○Explosive or flammable atmosphere

○Where a fire, oil, steam or powder can directly

enter the unit, such as nearby or above a kitchen

stove.

○Where oil (including machinery oil) may be pres-

ent.

○Where corrosive gases such as chlorine, bromine,

or sulfide can accumulate, such as near a hot tub

or a hot spring.

○Where dense, salt-laden airflow is heavy, such as in

coastal regions.

○Where the air quality is of high acidity.

○Where harmful gases can be generated from de-

composition.

• Do NOT position the condensate pipe for the indoor

unit near any sanitary sewers where corrosive gases

may be present. If you do, toxic gases can seep into

breathable air spaces and can cause respiratory

injuries. If the condensate pipe is installed incorrectly,

water leakage and damage to the ceiling, floor,

furniture, or other possessions may result. If the

condensate pipe becomes clogged, water may drip

from the indoor unit. Do NOT install the indoor unit

where such dripping can cause moisture damage or at

uneven locations.

• During transportation, do NOT allow the backrest of

the forkli make contact with the unit, otherwise, it

may cause damage to the heat exchanger and also

may cause injury when stopped or started suddenly.

• Before performing any brazing work, be sure that

there are no flammable materials or open flames

nearby.

• Remove gas inside the closing pipe when the brazing

work is performed. If the brazing filler metal is melted

with remaining gas inside, the pipes will be blown o

and it may cause injury.

• Be sure to use nitrogen gas for the airtight test. If

other gases such as oxygen gas, acetylene gas or

fluorocarbon gas are accidentally used, it may cause

an explosion or gas intoxication.

• Perform a test run to ensure normal operation. Safety

guards, shields, barriers, covers, and protective

devices must be in place while the compressor/unit

is operating. During the test run, keep fingers and

clothing away from any moving parts.

• Do NOT install the indoor unit anywhere discharge

airflow can pass directly toward nearby heating

equipment (space heaters). It may interfere with the

combustion process in these units.

• When the indoor unit is operating with heating

equipment, ventilate the room suiciently. Any leaked

refrigerant gas that happens to come into contact with

any heat source can become toxic on contact and can

cause suocation in the immediate area.

• Do NOT install this system in close proximity to septic

sewer lines where flammable and toxic gases can

coalesce.

CAUTION

To reduce the risk of minor or moderate injury, the

following installation precautions must be followed.

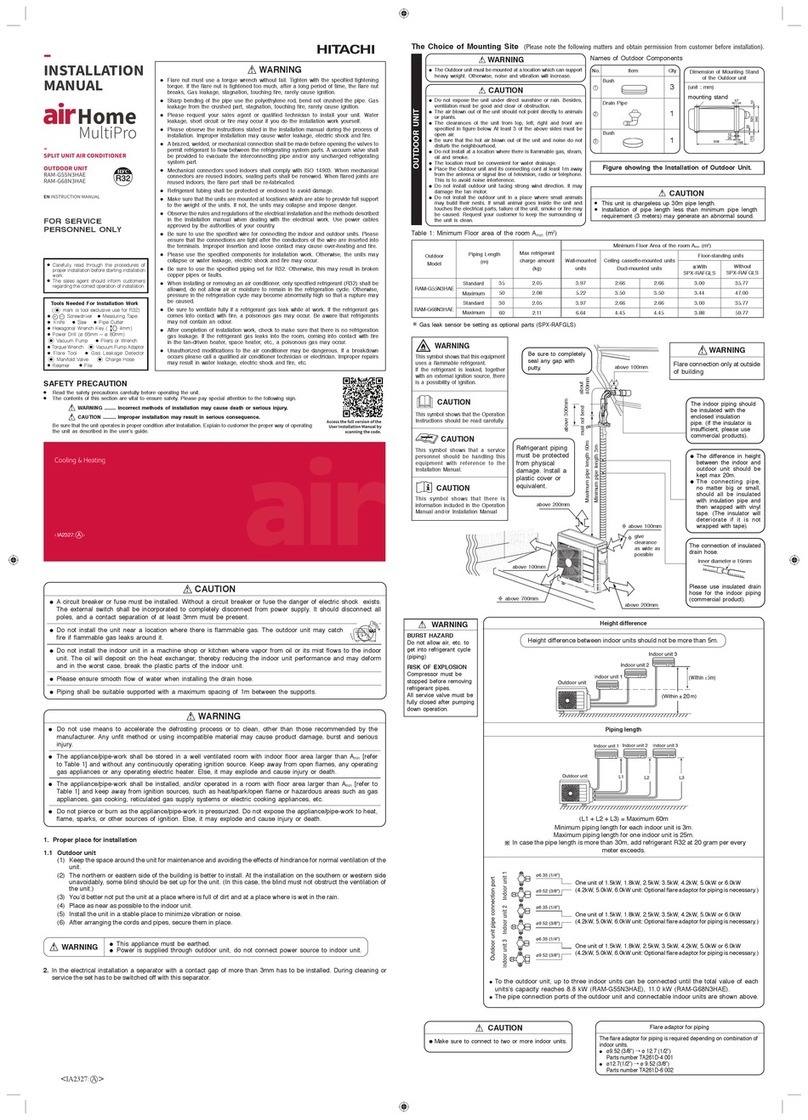

• Proper handling of this unit requires two people. Safe

handling and installation of the indoor unit requires

the strength of two people. Mounting the unit alone

may cause injury due to a fall of the unit. Although the

unit may be girded with plastic bands, do NOT use it

for transportation. Avoid contact with finned surfaces

of the heat exchanger as sharp edges can cause severe

injury to hands and fingers. Use appropriate work

gloves for the job.

Take the following precautions to reduce the risk of

property damage.

• The optional decorative panel can become deformed

if the positioning of the indoor unit's suspension

brackets is not stable or level. Condensation can

accumulate in low spots as a result due to escaping air

through any resulting gaps between the indoor unit

and the decorative panel.

• Check to ensure that the condensate hose discharges

moisture properly. If connected incorrectly, it can

result in leakage and cause damage to furniture.

• Make sure to use the factory-supplied condensate hose

and hose clamp. Non-factory supplied condensate

hose and hose clamp can cause water leakage.

• Do NOT bend or twist the factory-supplied condensate

hose. This could compromise the seal and result in

water leakage.

• Do NOT apply excessive force to the condensate

pipe connection. This can also compromise the seal

properties of the connection.

• Verify that the installed unit is level with floor and

ceiling surfaces. Any variance or inclination can

cause moisture to back up into the condensate pan,

overflow, and seepage onto ceiling or wall surfaces,

and cause damage to carpeted surfaces or furniture

below.

• Air circulation should be optimized to achieve the

best distribution pattern and not settled into isolated

pockets that can make people uncomfortable.

• Inspect the condensate pan before the onset of winter

to drain away all accumulated water in the pan.

• The heat exchanger of indoor unit overheats whenever

there is a slight amount of refrigerant circulating

during slowdown or stoppage. As a result, water in

the condensate pan evaporates and can condense on

ceiling or wall surfaces.

• Aer the drain check is completed, insert the rubber

plug again and seal the gap with a silicon sealant.

• Clean up the site when finished, remembering to

check that no metal scraps or bits of wiring have been

le inside the unit being installed.