IMPORTANT NOTICE

˗HITACHI pursues a policy of continuing improvement in design and performance of products. The

right is therefore reserved to vary specification without notice.

˗HITACHI cannot anticipate every possible circumstance that might involve a potential hazard.

˗No part of this manual may be reproduced without written permission.

˗Signal words (DANGER, WARNING and CAUTION)are used to identify levels of hazard

seriousness. Definitions for identifying hazard levels are provided below with their respective signal

words.

Immediate hazards which WILL result in severe personal injury or

death.

Hazards or unsafe practices which COULD result in severs personal

injury or death.

Hazards or unsafe practices which COULD result in minor personal

injury or product or property damage.

Useful information for this operation and/or maintenance.

˗If you have any questions, contact your contractor or dealer of HITACHI.

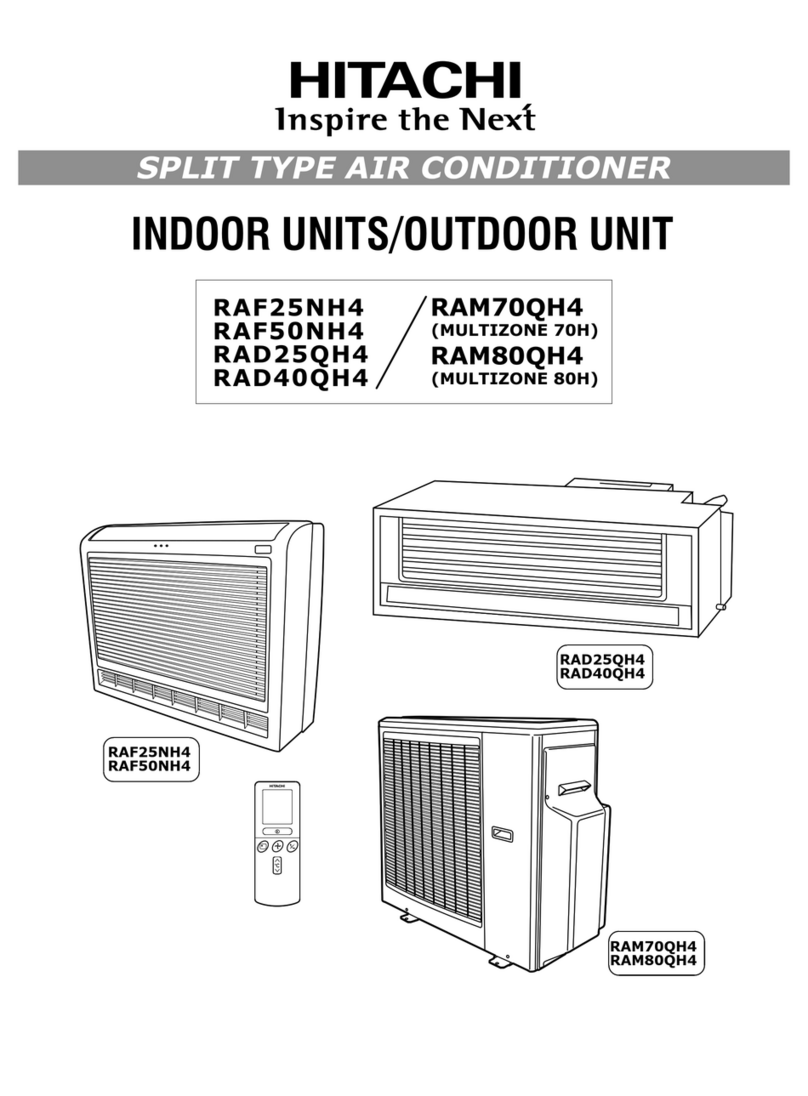

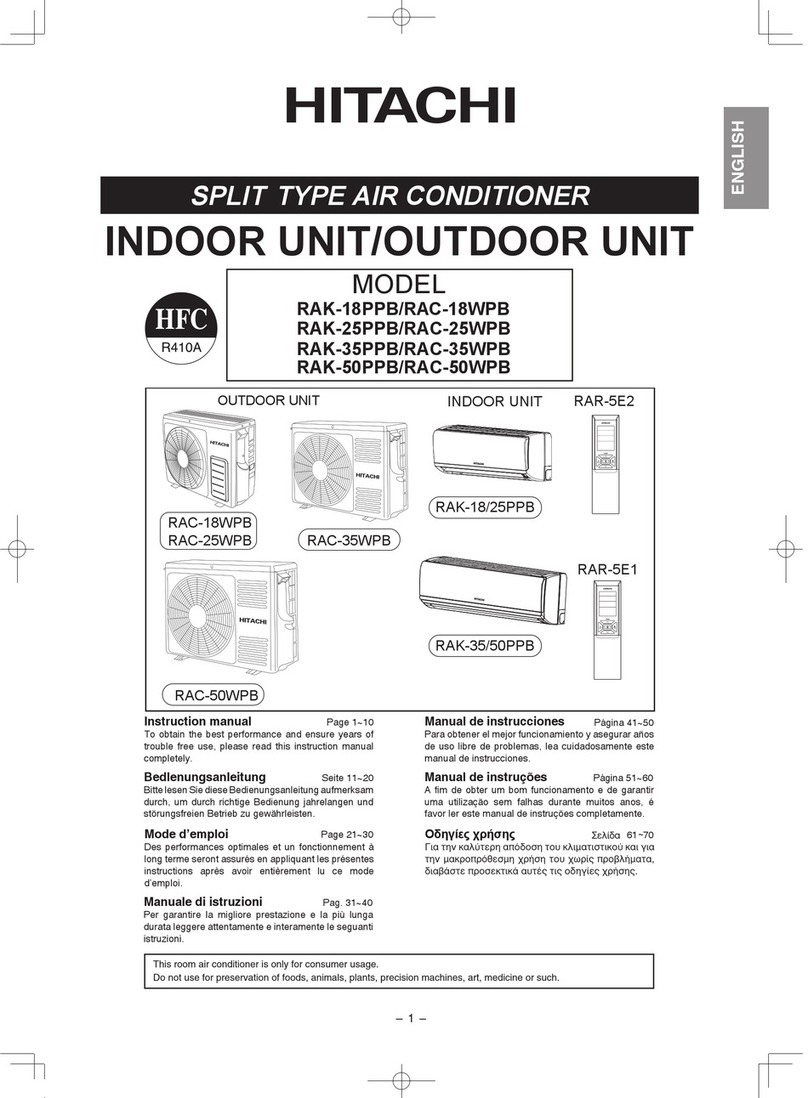

˗This manual gives a common description and information for this air conditioner which you operate

as well as for other models.

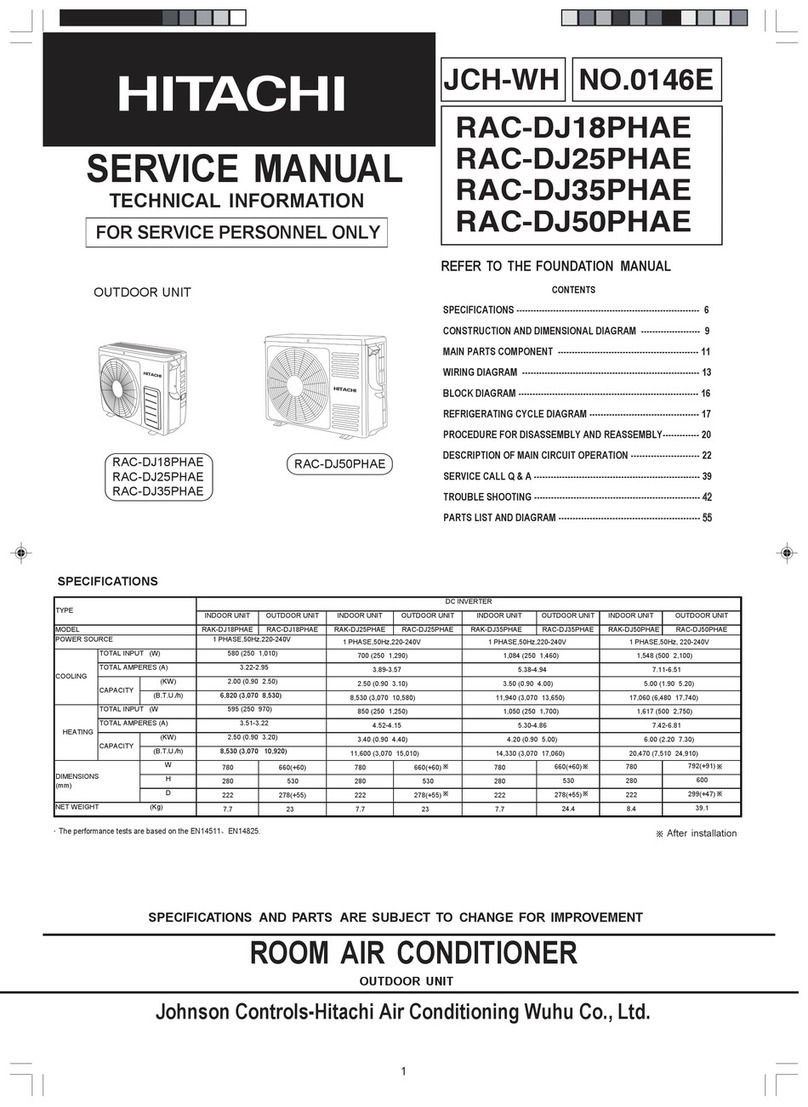

˗This air conditioner has been designed for the following temperatures. Operate the air conditioner

within this range.

Condenser Air Inlet Temperature and Evaporator Air Inlet Temperature

Model

Condenser Air Inlet Temperature

Evaporator Air Inlet Temperature

All Models 52°C

125°F

20°C

68°F

35°C / 21.5°C

95°F / 70.5°F

19.5°C / 14°C

67°F / 57°F

NOTES:

1. When the unit is operating at a condenser air inlet temperature of 52°C DB (125°F DB), the

maximum evaporator air inlet temperature shall be 18°C WB (64.4°F WB).

2. RUA-NP4ATS,RUA-NP5ATS,RUA-NP9ATS and RUA-NP10ATS: 80% to 120% of Nominal

Air Flow.RUA-NP6ATS and RUA-NP8ATS: 80% to 115% of Nominal Air Flow.

Hitachi’s air conditioners are designed and manufactured based on using the specified refrigerants. The applicable

refrigerants are specified to each unit models. However, in the global sites, it is revealed that charging different type

of refrigerants instead of the specified refrigerants. This action may cause mechanical troubles, malfunction and

failure, and in the worst case, it endangers safety seriously and may cause a fire or an explosion.

Therefore, Do Not charge the non-specified refrigerants or others in the refrigerant cycle of the unit as follows:

˗Hydrocarbon Refrigerants such as Propane or etc.

˗Oxygen, Flammable Gases such as Acetylene or etc.

˗Poisonous Gases.

The types of charging refrigerants are indicated in the Installation and Maintenance Manuals, Technical Catalogs,

Service Manuals and the specification label in the each unit. Be aware that Hitachi does not take any

responsibility for unit failure, troubles of malfunction, and any accidents caused by charging the

non-specified refrigerants or others such as above.

DANGER

烉

ˏDANGER

ˏ

ˏCAUTION

NOTE