-8-

• Silicone application points

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

1. Reassembly of bearing holder (A) ass'y

(1) Coat Threebond 1401B to the threaded portions of two Bearing Pins (B) [55].

(2) Insert a 0.6-mm thickness gauge between the Ball Bearings 606VV [52] and lightly press the Ball

Bearings 606VV [52] each other. Then tighten two Bearing Pins (B) [55].

2. Reassembly of bearing holder (B) ass'y

(1) Coat Threebond 1401B to the threaded portion of two Bearing Pins (B) [55].

(2) Insert a 0.6-mm thickness gauge between the Ball Bearings 606VV [52] and lightly press the Ball

Bearings 606VV [52] each other. Then tighten two Bearing Pins (B) [55].

3. Reassembly of the handle set and the housing set

When reassembling the Handle Set [2] and Housing Set [12], be careful not to catch the internal wires of

the stator ass'y, controller ass'y, LED ass'y, volume ass'y, indicator ass'y, capacitor ass'y, and battery

terminal in the Stator FET PCB [13] between handles (A) and (B) of the Handle Set [2], between housings

(A) and (B) of the Housing Set [12], and the Frame [40].

NOTE: Refer to "5. Reassembly of the power supply unit and stator FET PCB" on the next page.

4. Reassembly of the gear box ass'y

(1) Replace all the six gears of Planet Gear (A) Set [20] with new ones.

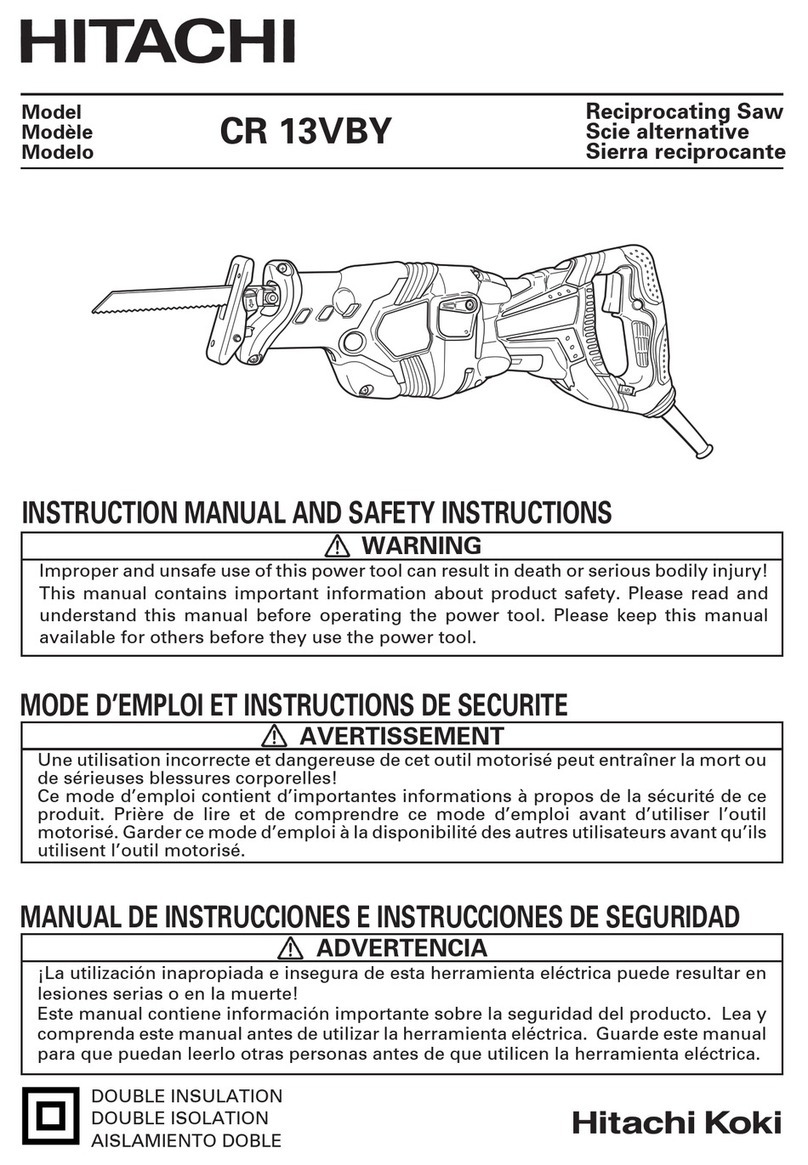

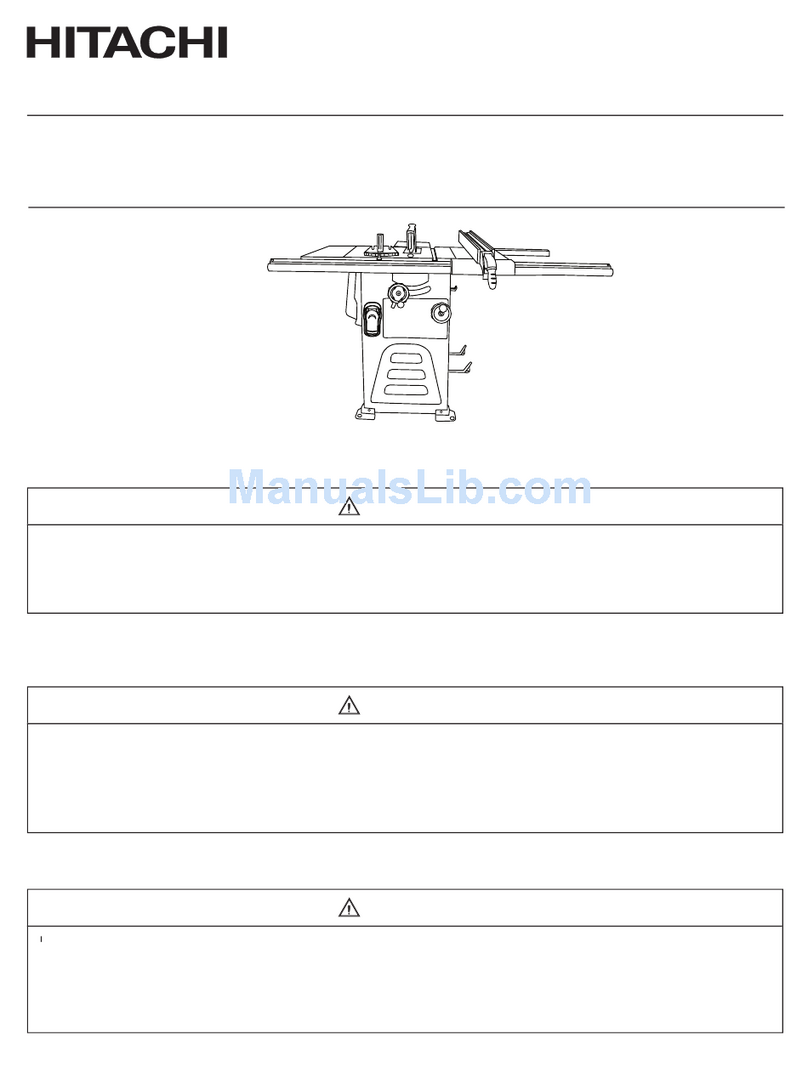

(2) Apply Shin-Etsu Silicone KE347B to the points shown in the figure below before mounting the Gear

Case Cover [18] to the Gear Case [25].

(3) After reassembly, check that Pulley Shaft (A) [23] turns smoothly.

Reassembly

Gear case side

[25] [19]

Apply about 0.8 gram of silicone to the edge of the Lock

Washer [19] (entire circumference) to fill the gap with the

Gear Case [25].

NOTE: Apply silicone to the stopper portions of the

Lock Washer [19] so that the concave portions

are completely covered.

Stopper portions of [19]