ENGLISH

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

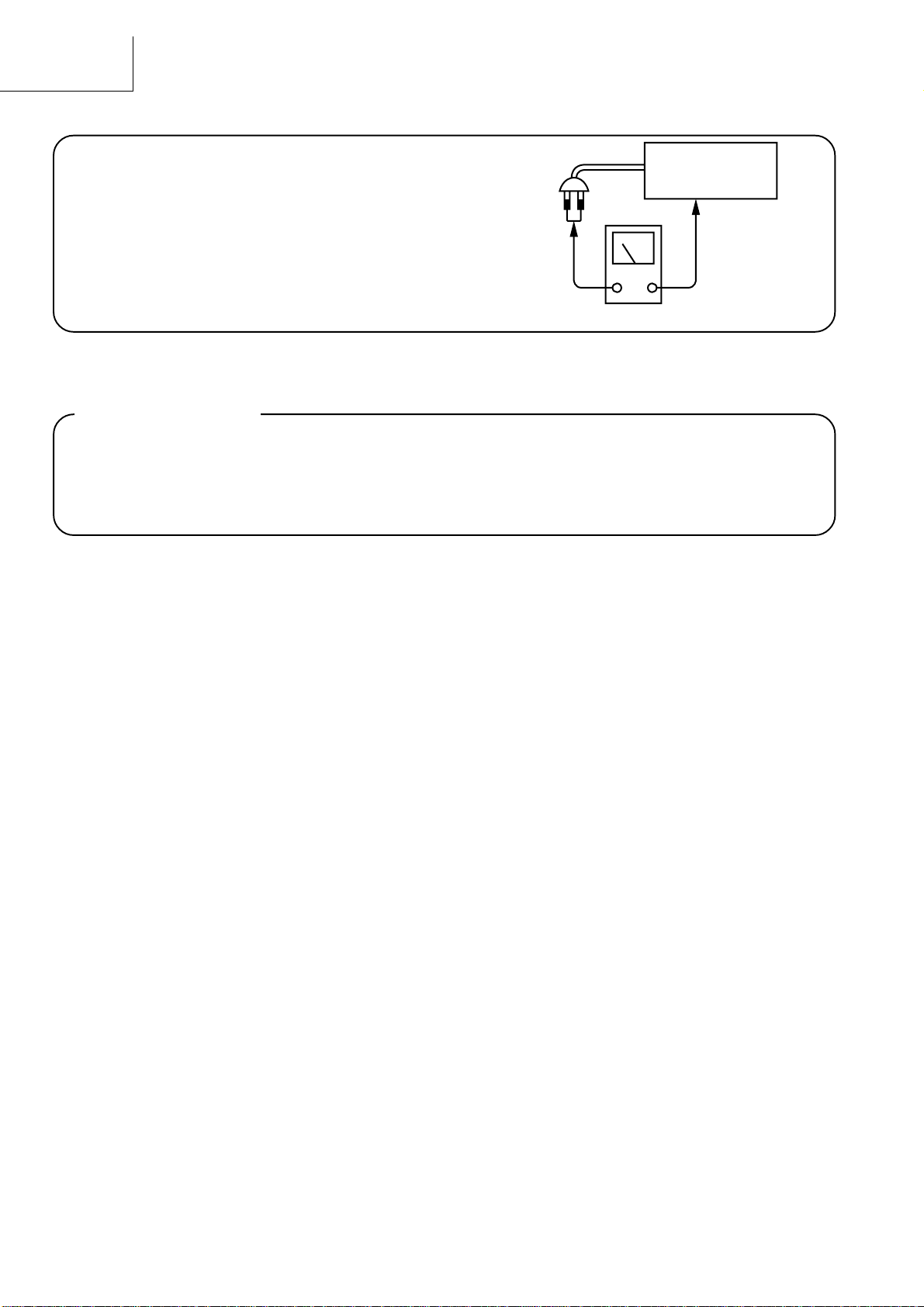

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. xtra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

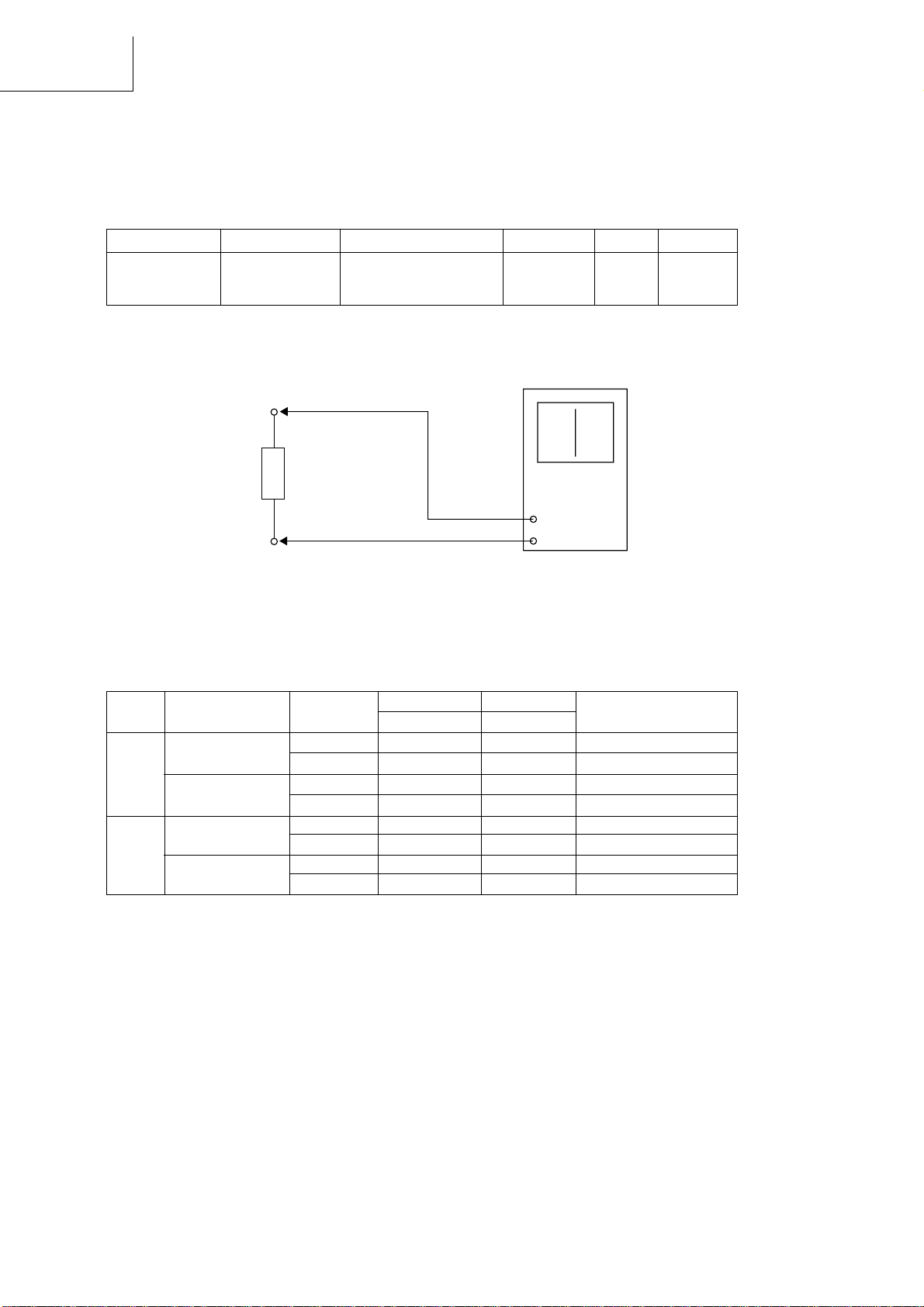

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the C mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the .H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

- 1 -