Page 4

Prime and Calibrate should be done at the pump.

Cut off metal straps and unscrew the lid.

With the pump power on and the installation section complete the output hose should be in the

top of the Tote with the ball valve or at least the mating quick disconnect, connected.

Controller Calibration

The Touch Screen ------ all highlighted items are buttons on the touch screen

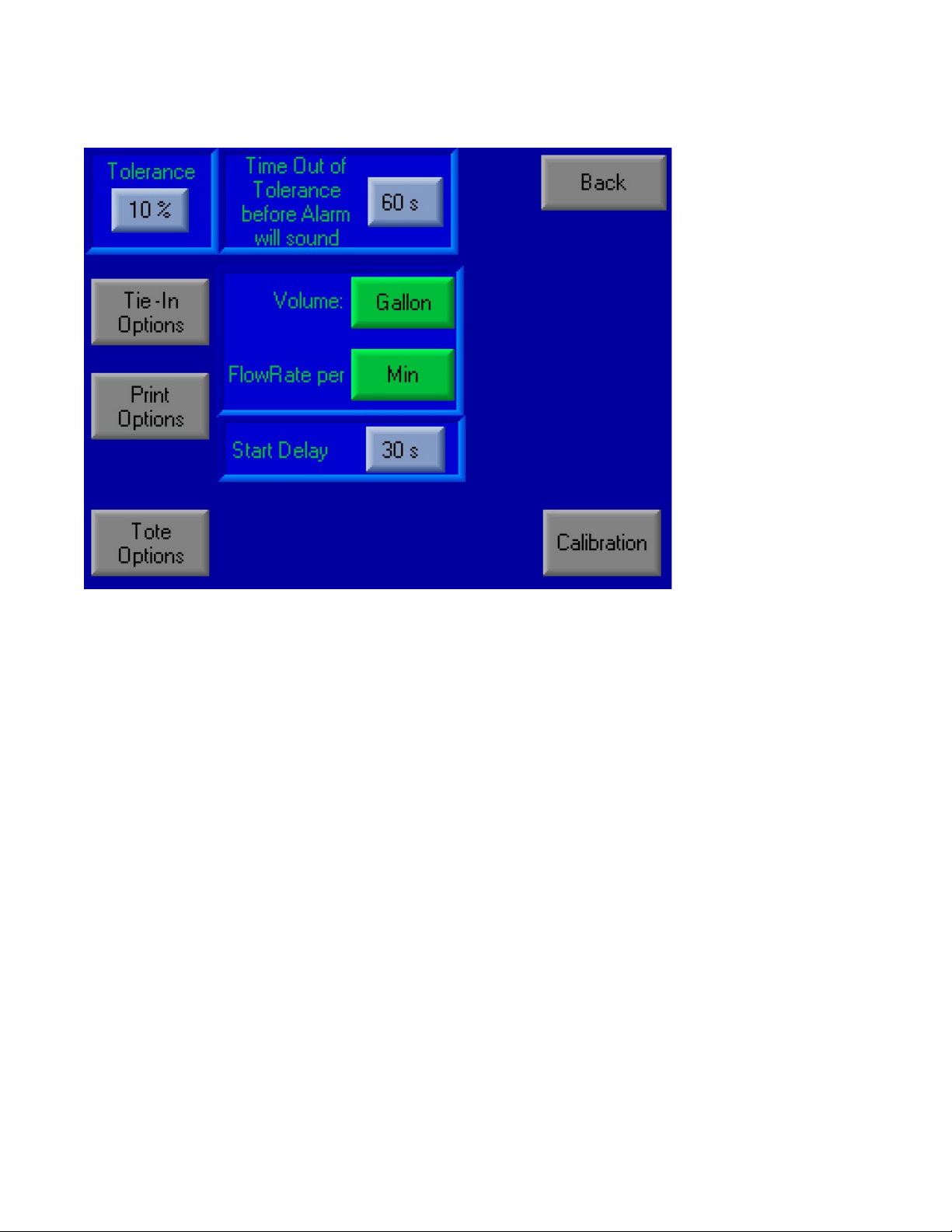

Press Settings, Calibration

Press PID ON --- This will change to PID OFF

Press to the right of VFD% and type in 100 and Press enter

Press Back

Set Start Delay to 0

Set Time out of Tolerance to 0

Press Back

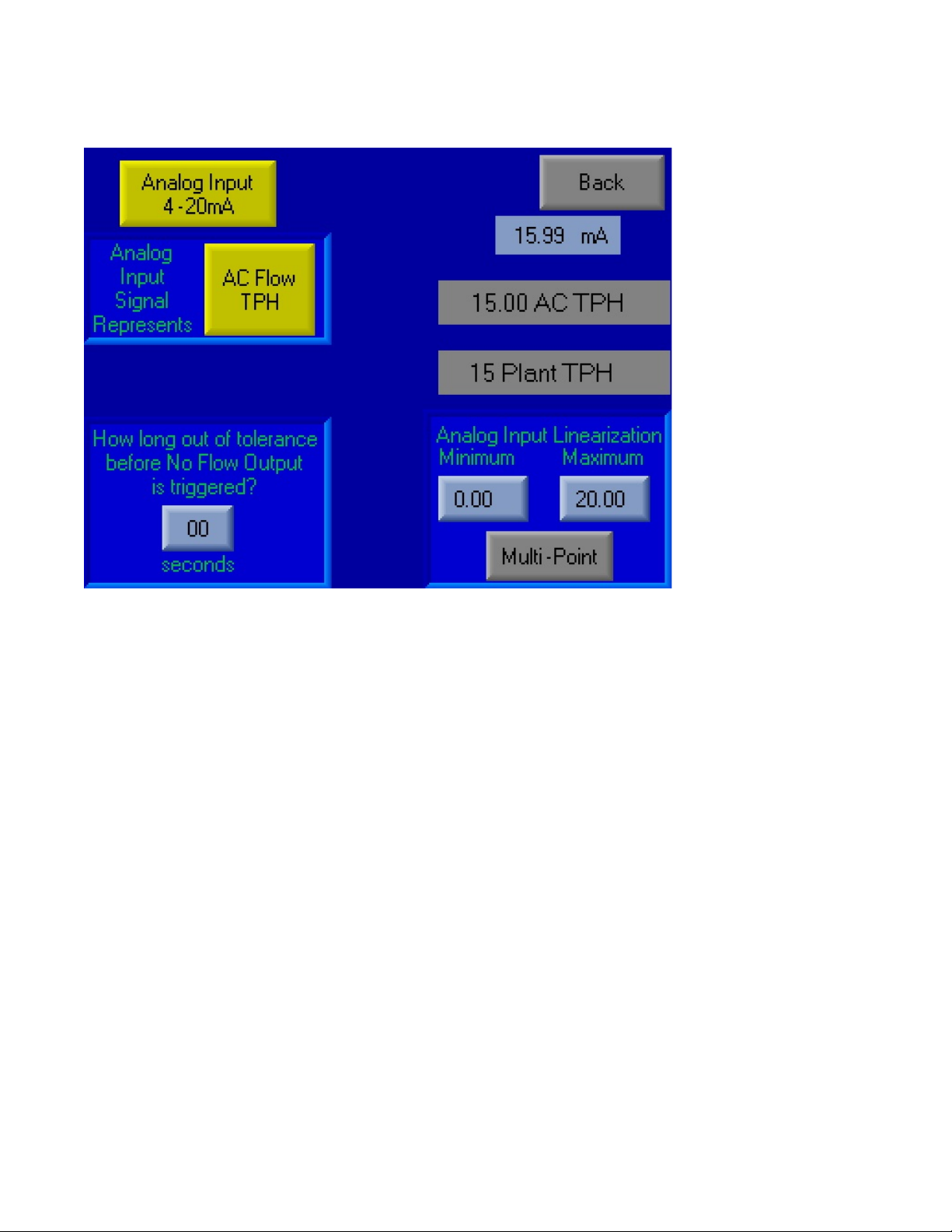

Set all options to a typical plant run. Ideally Target Flow Rate should be greater than 0.04

Press Start

Flow should begin shortly. Do not run for more than 3 min.

Once Steady flow is achieved

Press Stop ----- same location as start

Press Settings, Calibration

Press to the right of VFD% and type in 50 and Press enter

Press PID OFF --- This will change to PID ON

Press Auto Tune? --- This will change to Auto Tune On Next Run

Press Back, Back, Start

The frequency drive will go from 0 to 60 several times.

Once the Flow rate stabilizes (Less than 5 min on average) the Pump can be stopped and connected

as a typical run would be. Close the Tote lid and place Ball Valve onto the Injection site.