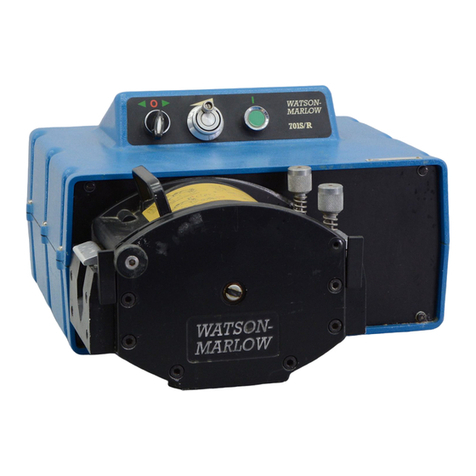

Watson-Marlow 720UN User manual

This manual suits for next models

1

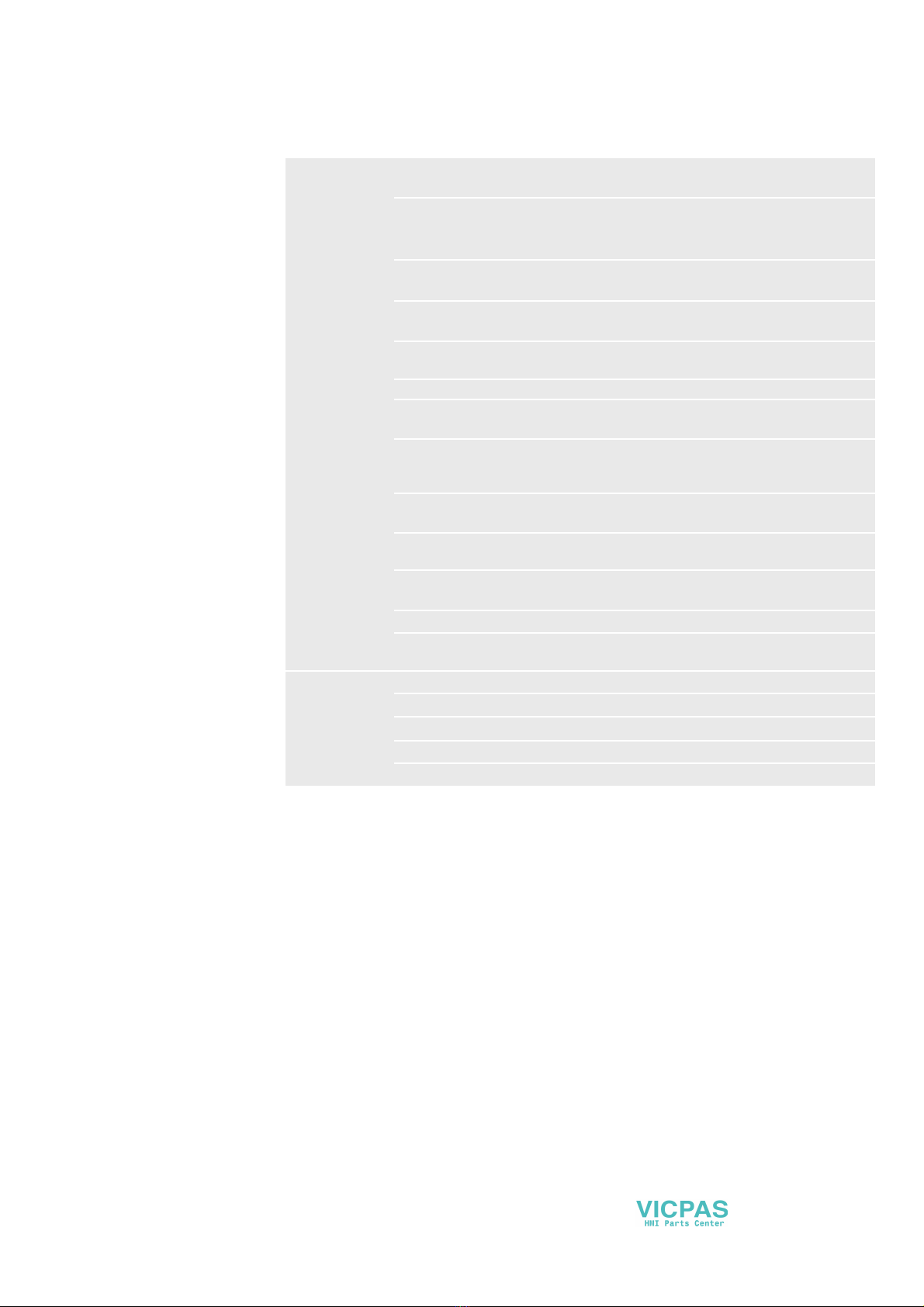

Other Watson-Marlow Water Pump manuals

Watson-Marlow

Watson-Marlow qdos30 User manual

Watson-Marlow

Watson-Marlow 501RLA User manual

Watson-Marlow

Watson-Marlow MasoSine EC 25 User manual

Watson-Marlow

Watson-Marlow MasoSine SPS 600 Guide

Watson-Marlow

Watson-Marlow qdos H-FLO User manual

Watson-Marlow

Watson-Marlow Bredel DuCoNite 25 User manual

Watson-Marlow

Watson-Marlow 100 Series User manual

Watson-Marlow

Watson-Marlow 323S User manual

Watson-Marlow

Watson-Marlow 323E User manual

Watson-Marlow

Watson-Marlow 620RA User manual

Watson-Marlow

Watson-Marlow 630 U Installation guide

Watson-Marlow

Watson-Marlow qdos20 User manual

Watson-Marlow

Watson-Marlow 120 User manual

Watson-Marlow

Watson-Marlow 701RA User manual

Watson-Marlow

Watson-Marlow qdos 20 User manual

Watson-Marlow

Watson-Marlow Bredel 265 User manual

Watson-Marlow

Watson-Marlow Alitea 114 Series User manual

Watson-Marlow

Watson-Marlow 530 Du User manual

Watson-Marlow

Watson-Marlow 120 Installation guide

Watson-Marlow

Watson-Marlow 604S/R User manual

Popular Water Pump manuals by other brands

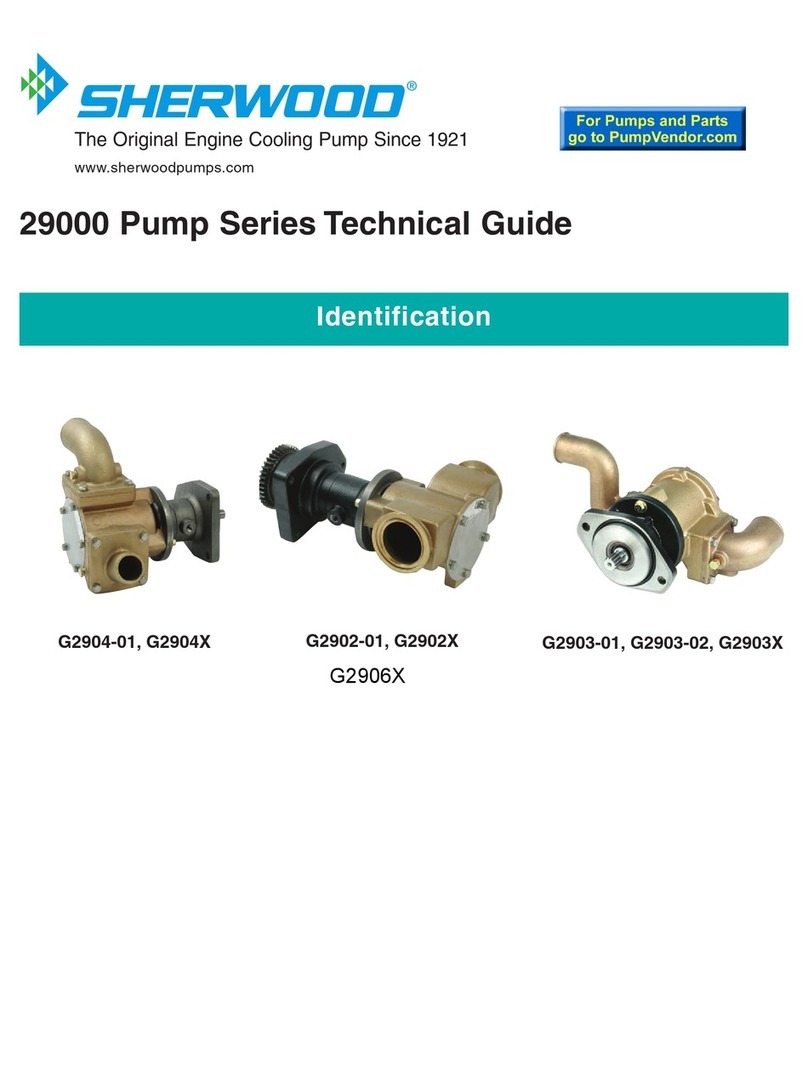

Sherwood

Sherwood G2906 Series Technical guide

Flotec

Flotec ergon 5000 Use and maintenance manual

Weir

Weir Roto-Jet RO III 3x2 Disassembly-assembly manual

Grundfos

Grundfos SRP Series Installation and operating instructions

Enerpac

Enerpac PC-115 instruction sheet

Briggs & Stratton

Briggs & Stratton 73001 owner's manual