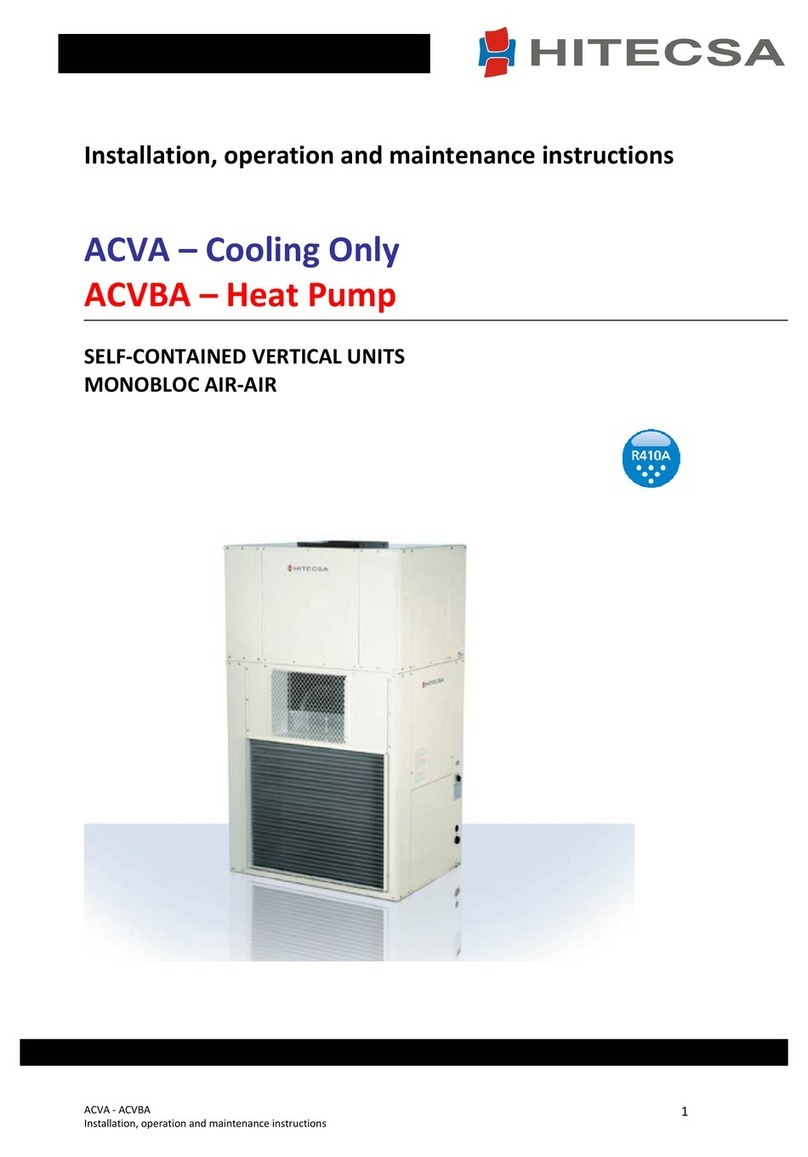

Hitecsa ACHIA User manual

Model 301

Heating capacity: 5,2 kW

Cooling capacity: 7,2 kW

11.16 207464 Rev.106

Cooling only Cooling only

INSTALLATION, OPERATION AND MAINTENANCE

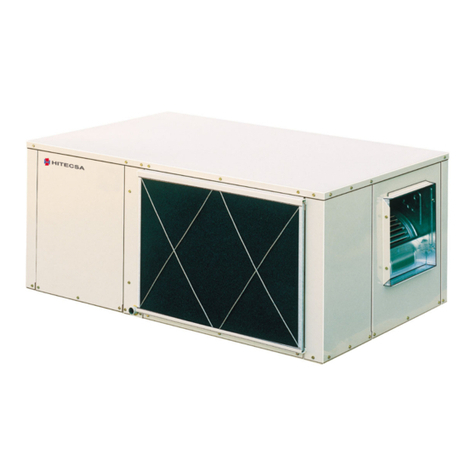

ACHIA ECHIA/CCHIA

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIBA ECHIBA/CCHIBA

Cooling only Cooling only

2

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

Thank you for trusting in Hitecsa Products. Our company has been offering the market an extended range of specialized units for

air conditioning and cooling installations for over 30 years. Our approach is based on efficiency, adaptability, usability and practical

solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to contribute solutions, almost tailored to each project’s specifications, in search of a

solution to every problem that arises in design and implementation of air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much

3

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

INTRODUCTION....................................................................................... 04

SAFETY PRECAUTIONS ......................................................................... 05

RECEPTION.............................................................................................. 06

Inspection upon receipt........................................................................ 06

Rigging................................................................................................. 06

Storage ................................................................................................ 06

INSTALLATION LOCATION..................................................................... 07

Service area (mm) ............................................................................... 07

Weight distribution (kg) ........................................................................ 08

Unit settlement..................................................................................... 08

START UP................................................................................................. 09

Operation limits.................................................................................... 10

Electrical data ...................................................................................... 10

Drainage .............................................................................................. 11

Air ducts............................................................................................... 11

Compressor lubricant........................................................................... 11

TECHNICAL DATA................................................................................... 12

DIMENSIONS............................................................................................ 13

REFRIGERANT LINES............................................................................. 16

REFRIGERANT CHARGE ........................................................................ 19

MAINTENANCE........................................................................................ 20

APPENDIX: SAFETY DATA R410A......................................................... 21

INDEX

4

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

INTRODUCTION

The contents of this manual are designed to assure the correct installation, adjustment and

maintenance of the unit, therefore:

• Read the instructions with due care and attention.

• The appliance must be installed, tested and serviced by properly qualified staff licensed in accordance with the

established legislation.

• The manufacturer declines all liability and warranty coverage is automatically waived, if electrical and/or mechanical

modifications to the unit. Tampering and unauthorized repairs or modifications to the unit will automatically void the

warranty.

• Observe the safety regulations in force at the time of installation.

• Make sure that the characteristics of the mains network conform to the data on the serial number plate placed on the

unit.

• Keep this manual and the wiring diagram with care and make sure that they are available for consultation by the

operator whenever necessary.

• Packing materials (plastic wrappings, expanded polystyrene, etc) are potentially hazardous and must be kept out of

reach of children. Recycle packing materials in accordance with local legislation.

• The units must be used only for the purpose for which they are designed .The manufacturer bears no responsibility in

the case of applications other than the specified use.

• Disconnect the unit in the event of breakdowns or malfunctions.

• If repairs are necessary, use only HITECSA approved service centres and always insist on original spare parts. The

use of non-original parts and/or unauthorized service centres may result in unsafe operation of the unit.

Regulations and certifications

ISO 9001:2008 CERTIFICATION: HIPLUS AIRE ACONDICIONADO S.L., trying always to find the customer satisfaction,

has obtained the ISO 9001:2008 Quality System referred to its production activity. This will results in a continuous

determination to improve quality and reliability of all our products; commercial activities, design, raw materials, production

and after-sales service, are the means to reach our goal.

CE MARKING: Our machines have got the CE mark, in conformity with the essential requirements

of the applicable EC directives and their last modifications as well as with the national legislation of

each country.

5

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

SAFETY PRECAUTIONS

• Installation and maintenance of air conditioning equipment can be dangerous because the system is under

pressure, because some of its elements have high temperatures and include electrical components.

• Only qualified and trained service staff should install, commission and carry out maintenance works. Unqualified staff

should only carry out basic tasks such as cleaning and replacement of filters, etc.

• In every visit, all precautions should be taken into account: those recommended in the Installation, operation and

maintenance instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any other

safety codes.

• Use safety glasses, work gloves and any other safety accessory necessary.

• For brazing operations use a quenching cloth and have at close distance a fire extinguisher.

• When repairing the unit, use only original spare parts and install them properly in the same position where

old parts were placed.

• These units are designed to operate using 100% recycled air. For installations that use the support of ambient air,

please consult with our commercial department.

• This product contains flourine-based greenhouse gases.

• Do not install the unit in explosive atmosphere.

Before starting installation, service or maintenance, turn off the main power switch in

order to avoid electrical shock that may cause personal damages.

6

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

RECEPTION

INSPECTION UPON RECEIPT

• Units are delivered with special protective packing; therefore when it arrives, please inspect it carefully to check that no

damage has occurred during transport and that the unit has been supplied complete with all parts specified in the order.

If any damage is found, immediately file a claim with the transport company. (first 48h)

• Verify the correct voltage of the nameplate and make sure it’s in accordance with local power supply.

• In case of any flaw or anomaly detected, please contact HITECSA

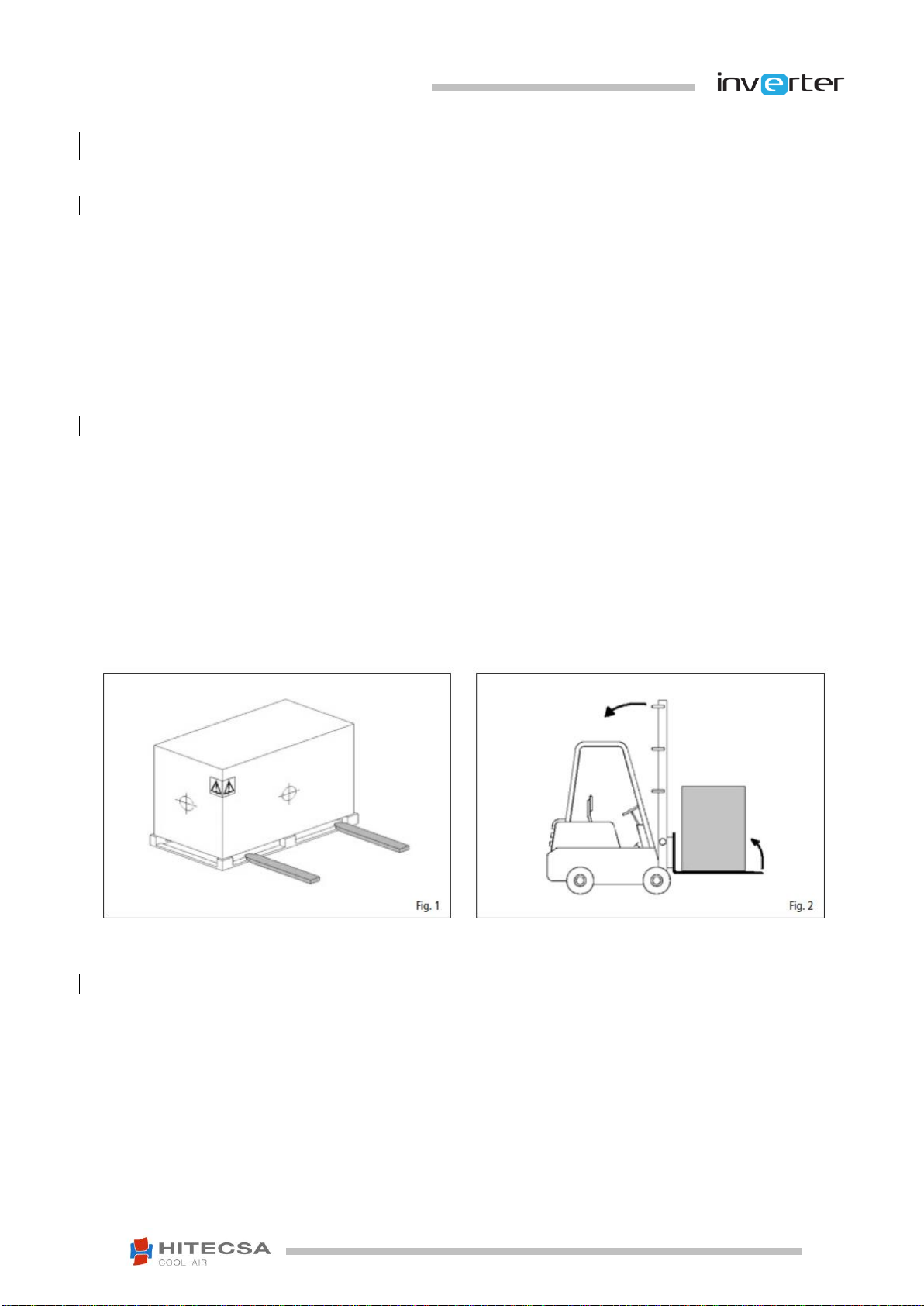

RIGGING

• Before moving the unit, make sure that all panels are well fixed.

• Raise and set down the equipment carefully.

• Do not tilt the unit more than 15 degrees during transportation.

• When lifting the unit, make sure that it’s balanced and stable; bear in mind that the heaviest part is where the

compressor is installed.

• Check minimum length of wire rising.

STORAGE

If the equipment is going to be stored please follow the instructions below in order to avoid damages, corrosion or

deterioration:

• Keep the unit away from direct sunlight, rain, sand, wind or temperatures above 50ºC

• Prolonged storage temperature: maximum 50ºC, minimum 0ºC

• Maximum humidity: 90%

7

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

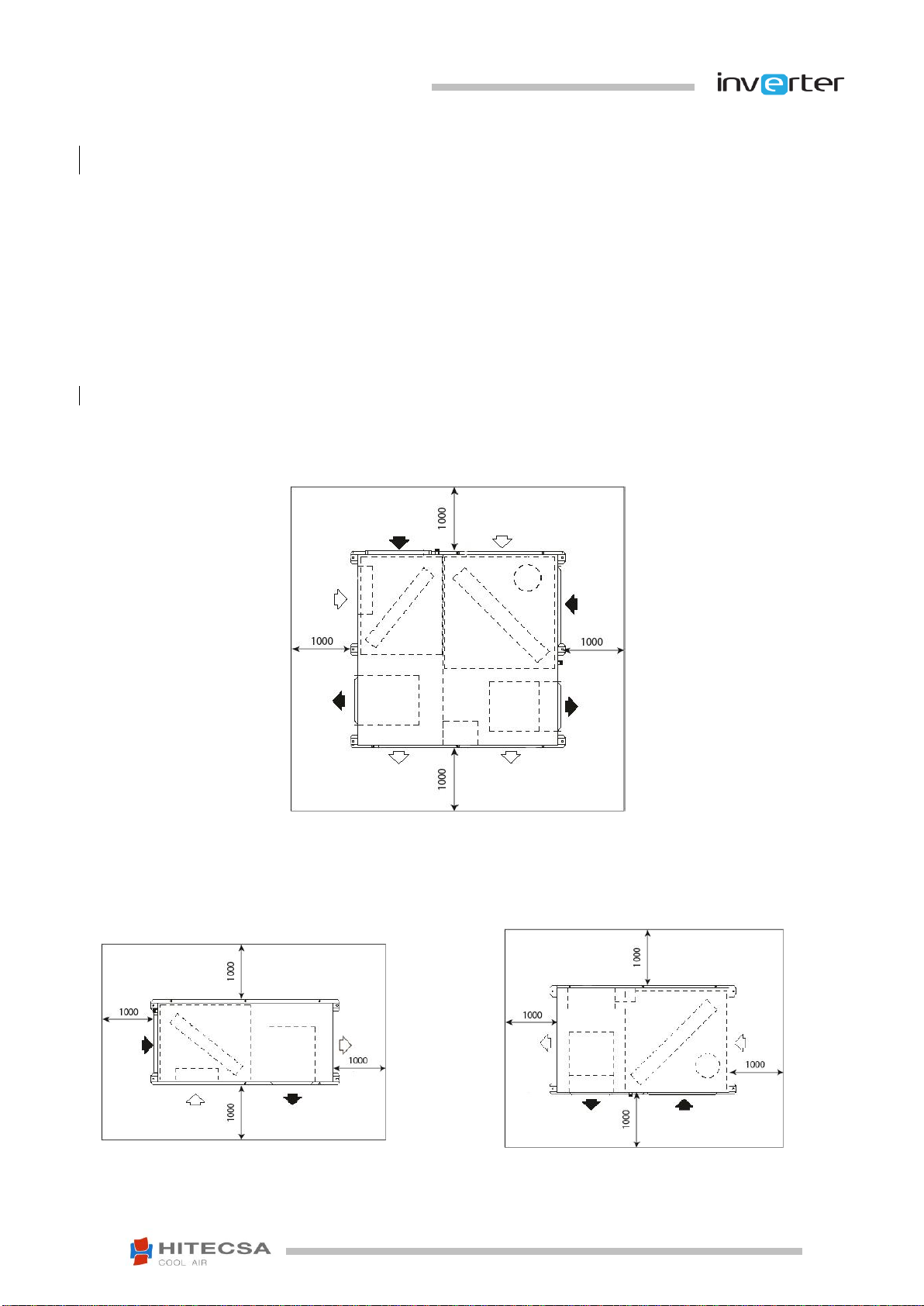

INSTALLATION LOCATION

• Check if the base is able to support the weight of unit during operation.

• Reserve a minimum service area according to Fig. 2.

• Choose a place free of dust or any other foreign material that could clog or damage the condenser coil. The location

should also be a place that cannot be flooded.

• Consult and respect all regulations concerning installation of air conditioning systems.

• Check if sound waves do not disturb anyone.

SERVICE AREA (mm)

SPLIT

EVAPORATOR UNIT ECHIA-ECHIBA

COMPACT

ACHIA-ACHIBA

CONDENSATOR UNIT CCHIA-CCHIBA

8

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

WEIGHT DISTRIBUTION (kg)

MODEL 301

1

2

3

4

TOTAL

ACHIA-ACHIBA

75

43

50

52

220

ECHIA-ECHIBA

15

23

26

17

83

CCHIA-CCHIBA

34

39

30

45

148

UNIT SETTLEMENT

• Make sure that the unit is correctly levelled.

• T he bed frame should be strong and solid enough to support the weight of the machine.

• Verify that the indoor drain is working properly.

ACHIA-ACHIBA

CCHIA-CCHIBA

ECHIA-ECHIBA

9

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

START UP

• Start up should be performed by qualified technical people.

• Use a start up check list: record inlet and outlet temperatures and pressures, outdoor air temperature, volts and amps

of each compressor and each fan motor, suction and discharge pressure of each compressor.

• Use a similar check list for service and maintenance works.

• Remember that after 4 hours of operation, it is necessary to clean the filters.

• Monitor at least 3 cooling cycle operations.

• Due to the unit has frequency converters for compressor and fans, it’s essential that the supply be at minimum 300 mA

to prevent supply cuts caused by the differential switch.

1.Main power 230/1/50 + ground

2.Ground

3.Remote control

POWER SUPPLY

220 v AC

Fig. 5

BELDEN TYPE

SHIELDED AND TWISTED

1

2

3

L N

Check the following points:

• Wires are well tightened.

• Panels are firmly secured with screws.

• There are no oil or refrigerant leaks.

• The unit is correctly leveled.

• There is enough space for service and maintenance.

• Drainage is not blocked.

• Crankcase heater has been working at least 24 hours prior to the start-up.

• Air filters are clean and correctly mounted.

• Grilles, air diffusers, air ducts and flexible connections are in good condition.

• Electrical power source is in accordance with what is said in the nameplate.

• Fans rotate in the right direction.

BEFORE START UP

10

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

OPERATION LIMITS

OUTDOOR AIR

INDOOR AIR

DRY

WET

DRY

WET

COOLING

ºC

ºC

ºC

ºC

Standard

35ºC

-

27ºC

19ºC

Minimum

20ºC*

-

20ºC

15ºC

Maximum

46ºC

-

32ºC

23ºC

HEATING

ºC

ºC

ºC

ºC

Standard

7ºC

6ºC

20ºC

-

Minimum

-12ºC

-13ºC

20ºC

-

Maximum

24ºC

18ºC

26ºC

-

Units can operate at a maximum altitude of 1.500 meters.

*For temperatures of less than 20ºC, it is necessary to use the condensation control optional.

For other conditions, please consult.

• Main power supply of the unit should agree with the data shown on the nameplate. HITECSA will not be held

responsible for damages resulted from non observance of the above.

• Always use the wiring diagram sent with the unit to make electrical connections

• Check that the crankcase heater has been working at least 24 hours prior to the start up of the unit.

• Current supply should be within 10% of Volts indicated on the unit nameplate.

• Do not operate the unit at different current from that shown on the unit nameplate.

• The installer should put line protection elements in compliance with current legislation.

• The interconnecting wires should be protected with a tube or put inside a groove channel.

Before starting installation, service or maintenance, turn off the main power switch in

order to avoid electrical shock that may cause personal damages.

1.Main power 230/1/50 + ground

2.Ground

3.Remote control

POWER SUPPLY

220 v AC

BELDEN TYPE

SHIELDED AND TWISTED

L N T

BELDEN TYPE

SHIELDED AND TWISTED

EXTERIOR UNIT

INTERIOR UNIT

1

2

3

2

1

L N T

11

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

INSTALLATION

ELECTRICAL DATA

(1) Cooling: Compressor frequency: 80Hz. Outdoor dry temperature: 35 °C. Indoor Dry / Wet air temperature: 27ºC / 19 °C. Indoor airflow: Medium.

(2) Heating: Compressor frequency: 80Hz. Outdoor dry /wet air temperature: 7ºC / 6 °C. Indoor dry temperature: 20 °C. Indoor airflow: Medium.

(3) Cooling maximum: Compressor frequency: 110Hz. Outdoor dry temperature: 35 °C. Indoor Dry / Wet air temperature: 27ºC / 19 °C. Indoor airflow: High.

(4) Heating maximum: Compressor frequency: 120Hz. Outdoor dry /wet air temperature: 7ºC / 6 °C. Indoor dry temperature: 20 °C. Indoor airflow: High.

DRAINAGE

• Indoor drainage (of condensate water) has a 3/4” MPT

connection.

• Condensate drain line diameter should be equal or larger

than the unit connection depending on line length and

general building configuration.

• Drainage line should have a minimum inclination of 2% for

proper water evacuation.

• When drainage line is exposed to temperatures below

0ºC, it is necessary to provide thermal insulation or

electrical heating wire to avoid water freezing and tube

damages

• It is advisable to install a trap with proper dimensions.

Serie Inverter 301

ACHIA/ACHIBA

CCHIA/CCHIBA

ECHIA/ECHIBA

ELECTRICAL CHARACTERISTICS IN COOLING MODE (1)

Voltage

V/ph/Hz

220-240 / I / 50

Absorbed power

KW

3,1

Absorbed current

A

14,3

ELECTRICAL CHARACTERISTICS IN HEATING MODE (2)

Voltage

V/f/Hz

220-240 / I / 50

Absorbed power

KW

2,6

Absorbed current

A

12,6

ELECTRICAL CHARACTERISTICS IN COOLING MODE (3)

Voltage

V/f/Hz

220-240 / I / 50

Absorbed power

KW

3,5

Absorbed current

A

16,0

RATED ELECTRICAL CHARACTERISTICS IN COOLING MODE (4)

Voltage

V/f/Hz

220-240 / I / 50

Absorbed power

KW

2,9

Absorbed current

A

14,0

12

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

AIR DUCTS

• Air duct dimensions will be determined according to the airflow and available static pressure.

• Ducts must be designed by qualified technical people.

• Use ducts made of non-inflammable materials in order to avoid any emission of gas in case of fire. It is advisable to use

metal plate duct with insulation.

• Use flexible ducts to connect air ducts into the unit and thus avoid vibration and noise transmission.

COMPRESSOR LUBRICANT

Compressors with R410a refrigerant use PVE oil, each manufacturer using specific oil for his product. The system must

not remain open to the atmosphere more than 15 minutes.

Due to oil qualities affect directly the correct work of compressor, you must be very careful during manipulation: Do not

mix the oil with other substances.

13

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

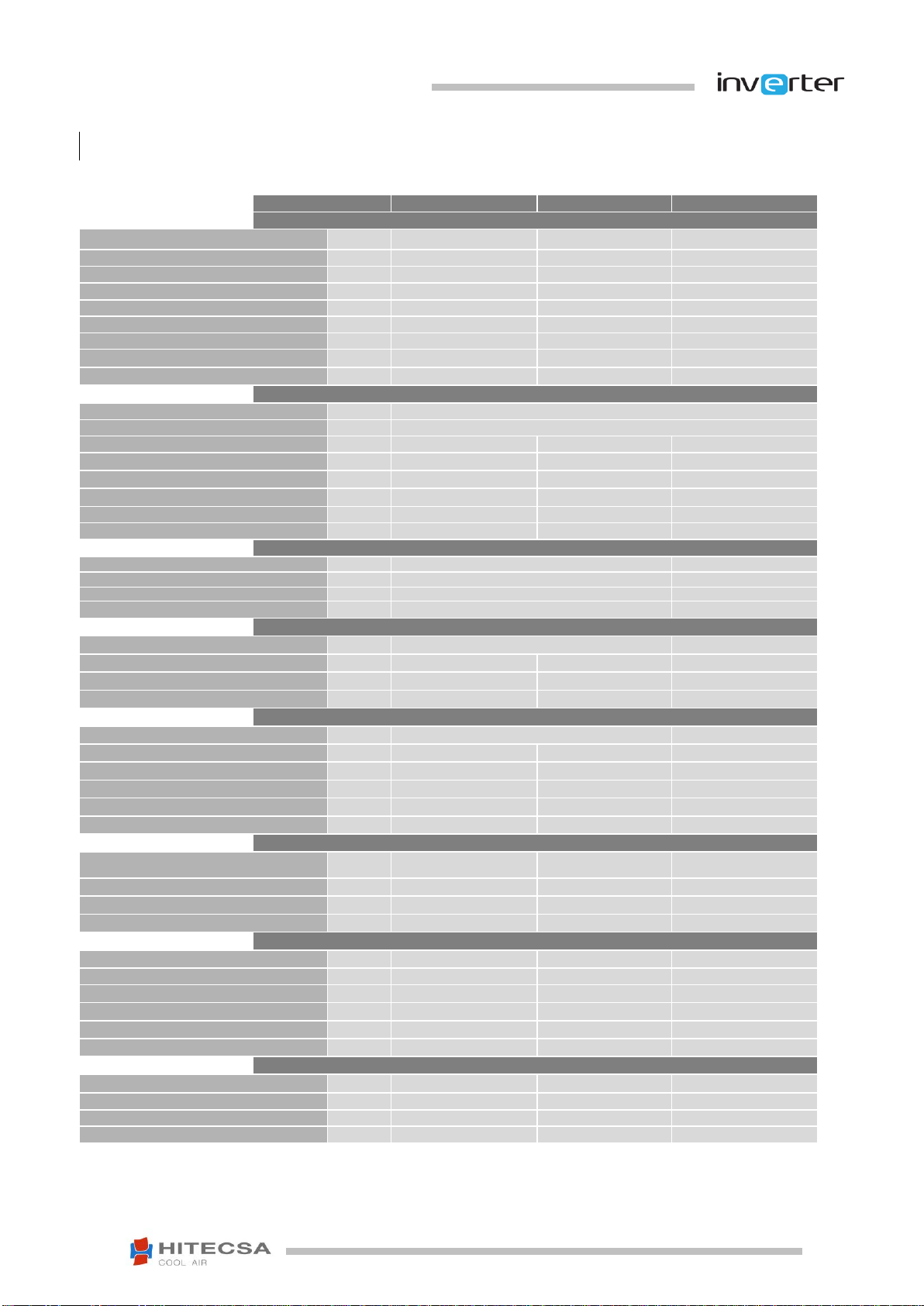

TECHNICAL DATA

Inverter 301 Serie

ACHIA/ACHIBA

CCHIA/CCHIBA

ECHIA/ECHIBA

CAPACITIES

Cooling capacity (1)

KW

7,4

7,4

7,4

Cooling capacity (20 - 100 - 110 Hz)

KW

1,2 –7,4 –8,1

1,2 –7,4 –8,1

1,2 –7,4 –8,1

Heating capacity (2)

KW

7,5

7,5

7,5

Heating capacity (20 - 100 - 110 Hz)

KW

1,3 –7,5 –8,3

1,3 –7,5 –8,3

1,3 –7,5 –8,3

EER

---

>8

>8

>8

SEER

---

4,6

4,6

4,6

Class (Cooling mode)

---

B

B

B

SCOP (Warm zone)

---

4,1

4,1

4,1

Class (Heating mode)

---

A+

A+

A+

REFRIGERANT

Type

R-410A

Global Warming Potential (GWP)

2088

Number of cooling circuits

1

1

1

Refrigerant load

Kg

3,5

3,5

-

Refrigerant connections (liquid line)

‘’

-

3/8

3/8

Refrigerant connections (gas line)

‘’

-

1/2

1/2

Max length between units (horizontal)

m

-

30

30

Max height between units (vertical)

m

-

20

20

COMPRESSOR

Type

SCROLL

---

Quantity

1

---

Type of lubricant

Ester VG74

---

Load of lubricant

lt

0,65

---

OUTDOOR EXCHANGER

Type

Copper tubes and aluminum fins

---

Surface area

m²

0,366

0,366

---

Steps

mm

2,1

2,1

---

Tube diameter

‘’

5/16

5/16

---

OUTDOOR FAN

Type

Double intake centrifugal fan

---

Model

10/10 DD

10/10 DD

---

Motor capacity

KW

0,55

0,55

---

Maximum air flow

m³/hr

3.000

3.000

---

Available static pressure

Pa

50

50

---

Speed

RPM

1.014

1.014

---

INDOOR EXCHANGER

Type

Copper tubes and

aluminum fins

---

Copper tubes and

aluminum fins

Surface area

m²

0,252

---

0,252

Steps

mm

2,1

---

2,1

Tube diameter

‘’

3/8

---

3/8

INDOOR FAN

Type

Double intake centrifugal

---

Double intake centrifugal

Model

10/10 DD

---

10/10 DD

Motor capacity

KW

0,55

---

0,55

Maximum airflow

m³/hr

1800

---

1800

Available static pressure

Pa

50

---

50

Speed

RPM

870

---

870

DIMENSIONS

Length

mm

1445

1405

1405

Width

mm

1339

825

600

Height

mm

504

504

504

Weight

Kg

220

148

83

(*) All indoor units and the outdoor units which have “FLARE” valve are pre-charged with nitrogen.

14

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

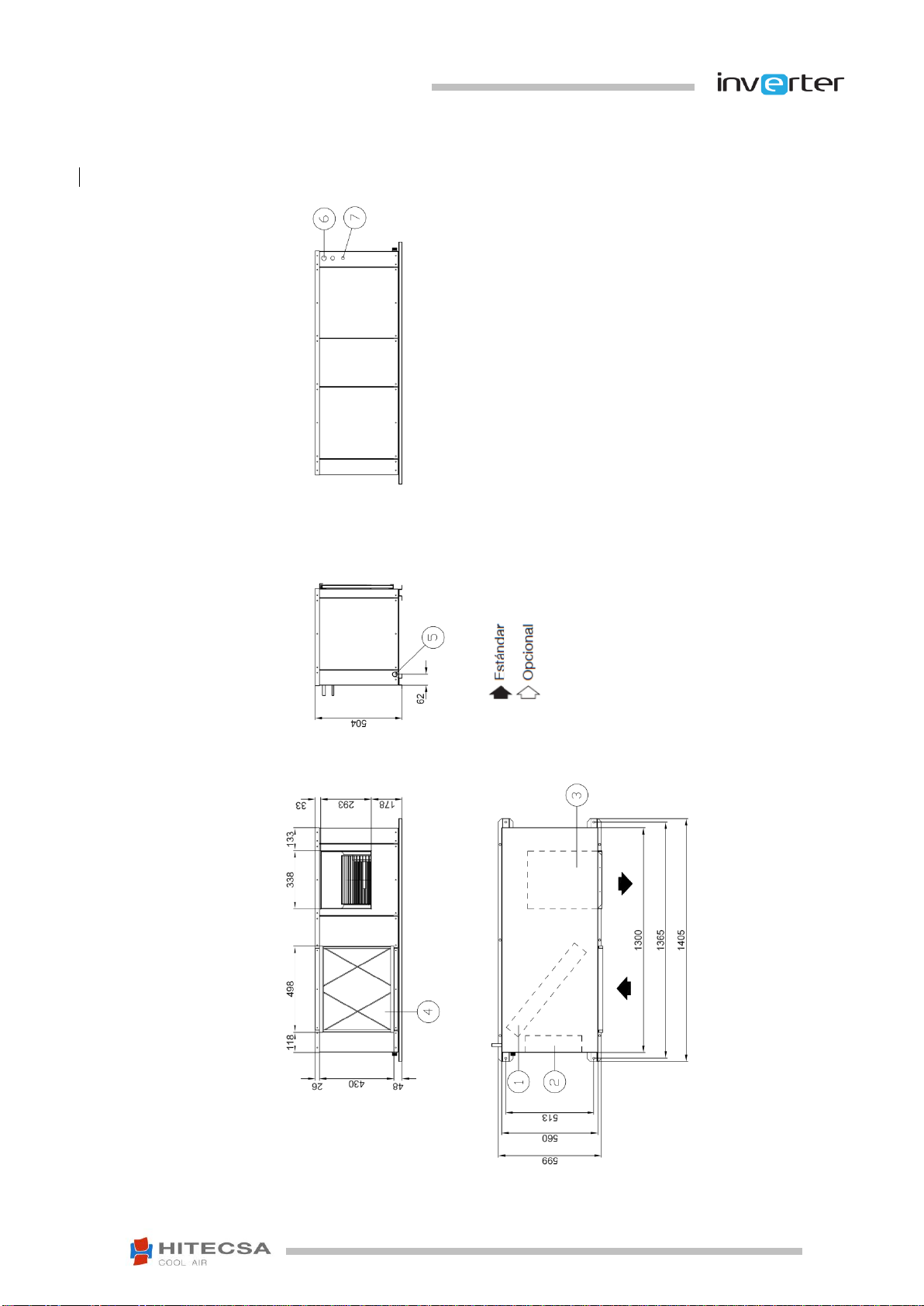

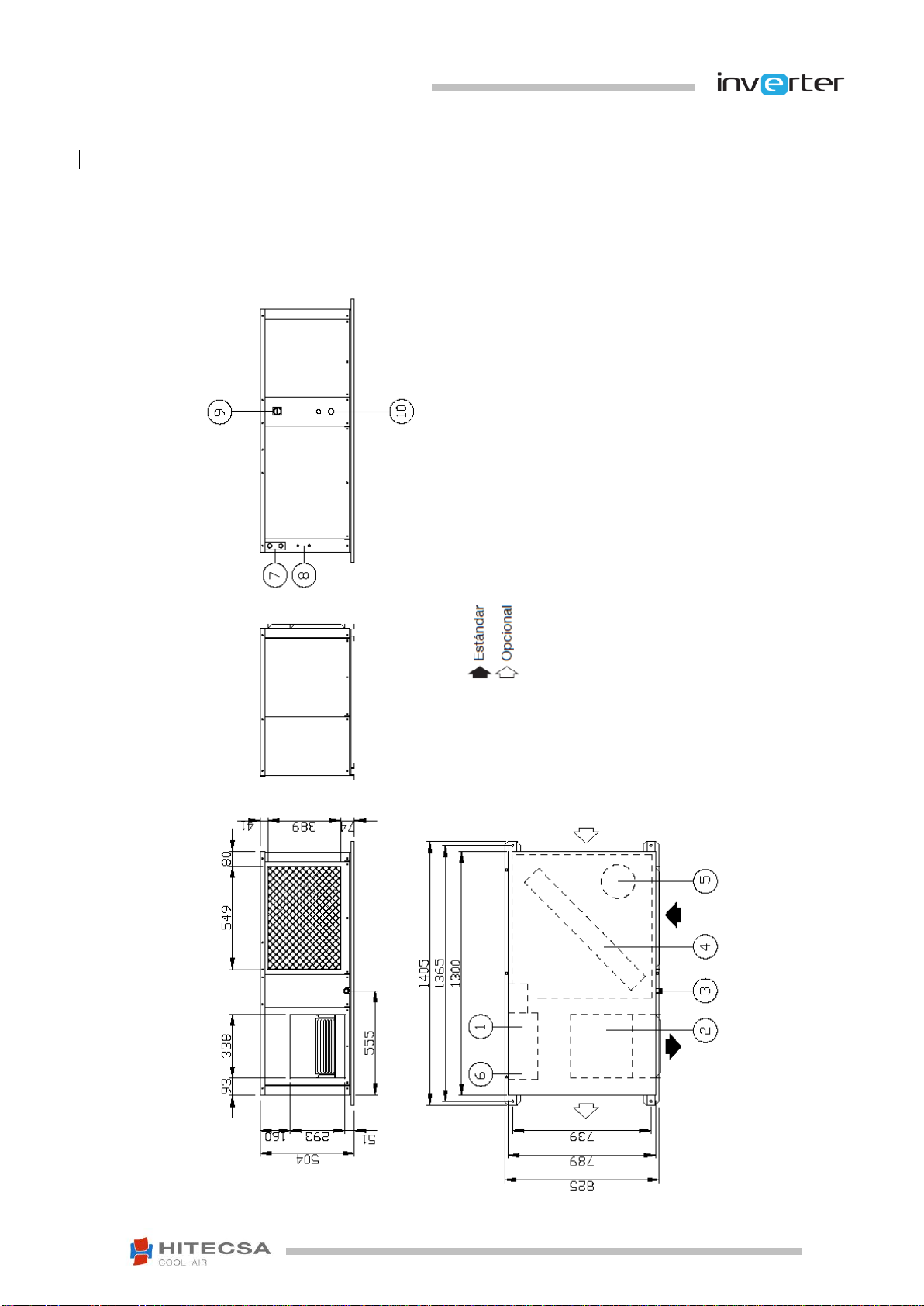

DIMENSIONS

ACHIA-ACHIBA 301

CONSTRUCTION DETAILS:

1. Compressor

2. Outdoor heat exchanger

3. Indoor heat exchanger

4. Electric box

5. Indoor Turbine

6. Outdoor turbine

7. Air filter

8. Main power switch

9. Drainage

10.Input power supply

11.Pressure plugs

15

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

ECHIA-ECHIBA 301

CONSTRUCTION DETAILS:

1. Heat exchanger

2. Electrical box

3. Turbine

4. Air filter

5. Drainage ¾”

6. Input power supply

7. Cooling connections

16

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

CCHIA-CCHIBA 301

CONSTRUCTION DETAILS:

1. Electrical box

2. TTurbine

3. Interior drainge¾”

4. Heat exchanger

5. Compresor

6. Comressor inverter

7. Cooling connections

8. Pressure plugs

9. Inin switch

10. Power supply

17

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

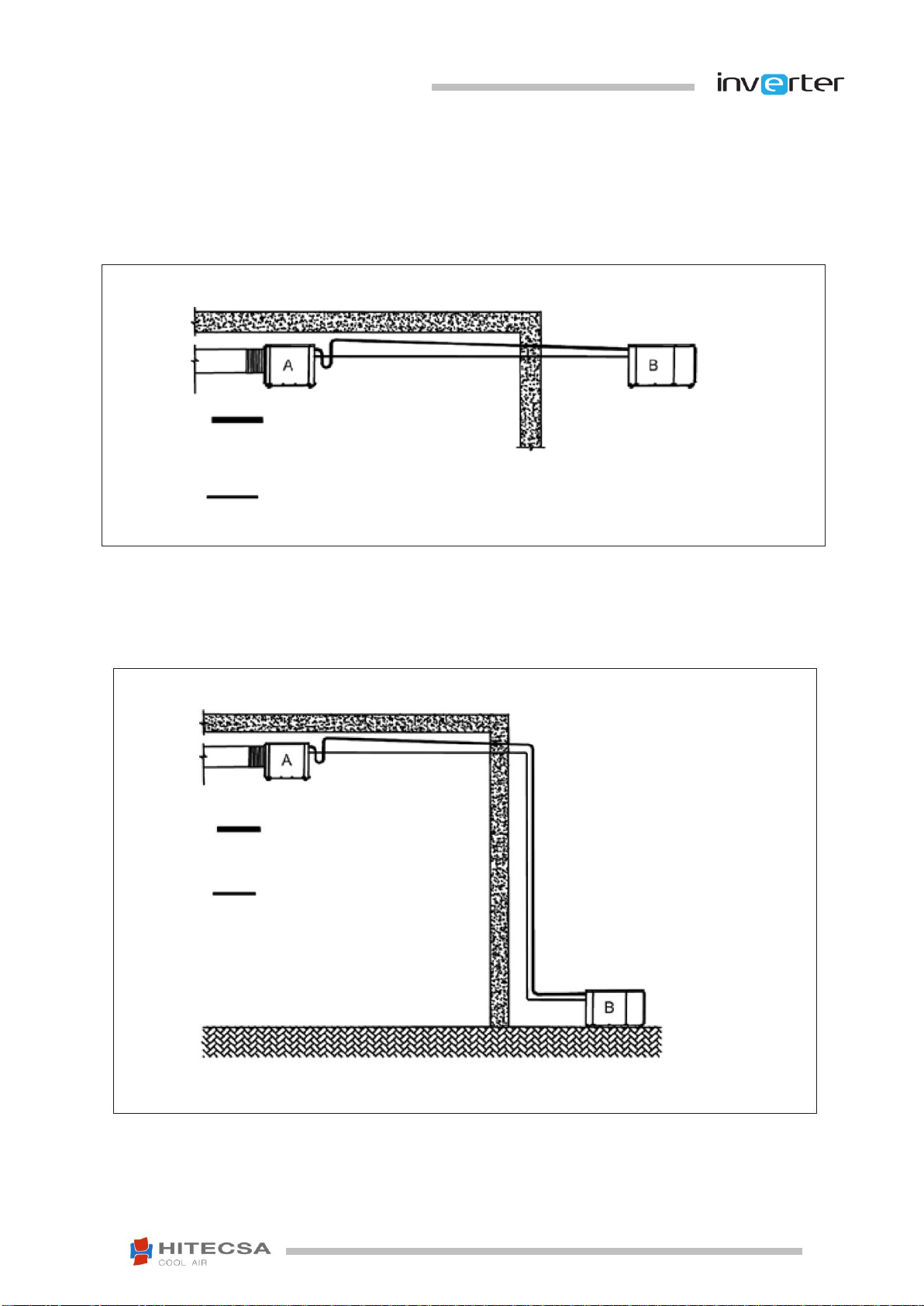

Split systems demand a correct disposition of refrigerant piping and a correct connection between both indoor and

outdoor units.

Pressure drop of the line

Circulation speed of the refrigerant

Refrigerant mass

In heat pump operation, the gas line works as discharge line.

1. When indoor unit is at a lower level than outdoor unit:

It is not essential to install traps in the vertical line. However, it could be convenient to install some every 6 to 9 meters in

order to help oil return.

A –INDOOR UNIT

B –OUTDOOR UNIT

GAS LINE

LIQUID LINE

B

A

LINES POSITION

DISCHARGE LINES

COOLING CIRCUIT

REFRIGERANT LINES

When working with the machines in operation,

discharge line temperature is very HIGH and could result in burns.

18

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

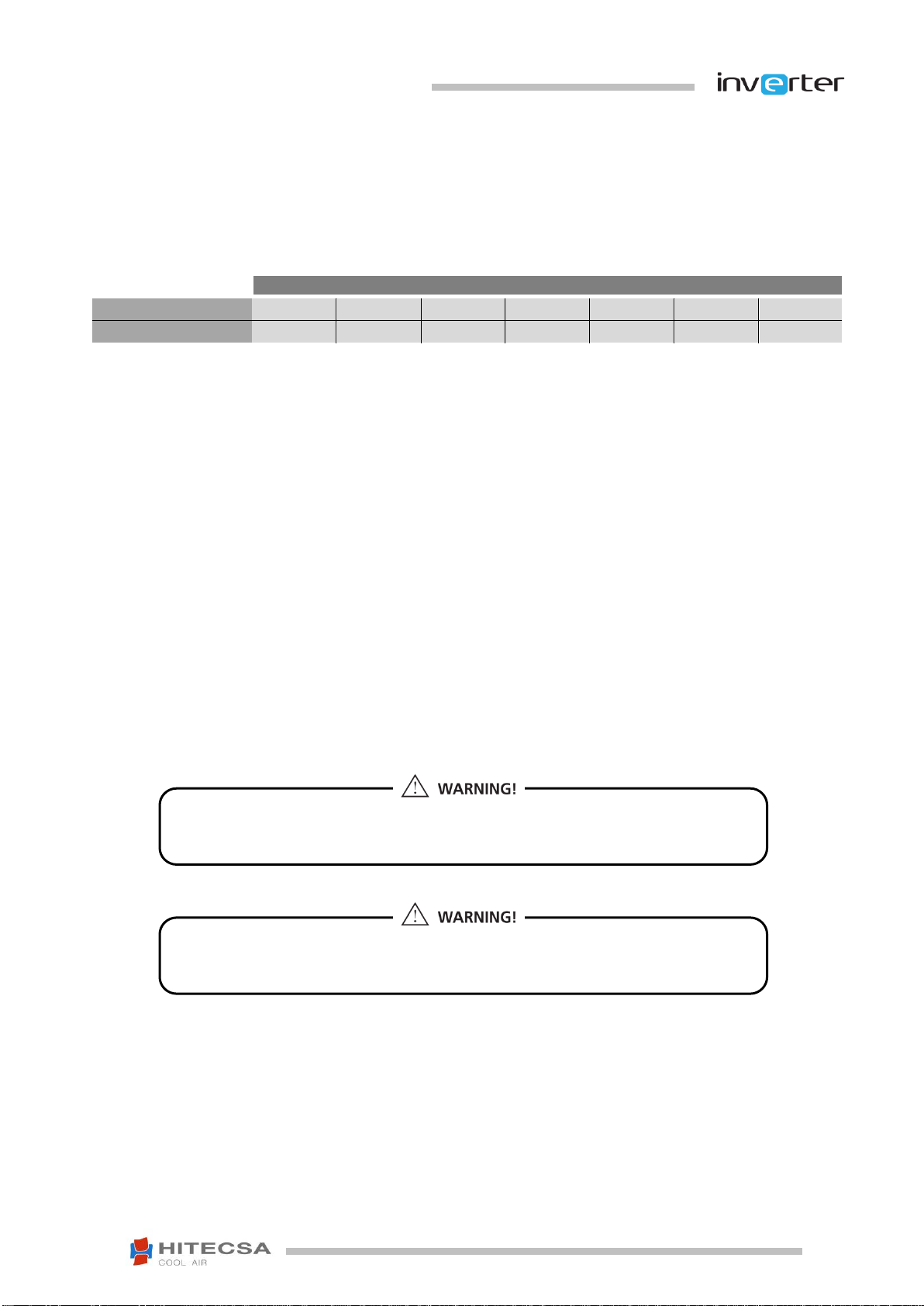

2. When indoor unit is at the same level as outdoor unit:

Rise the suction line to a higher level than the exchanger in order to avoid refrigerant return into the compressor.

3. When indoor unit is at a higher level than outdoor unit.

A–INDOOR UNIT

B–OUTDOOR UNIT

GAS LINE

LIQUID LINE

A–INDOOR UNIT

B–OUTDOOR UNIT

GAS LINE

LIQUID LINE

19

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

NOTAS:

Refrigerant lines should be as short and straight as possible.

Use recommended diameters to reduce quantity of refrigerant in the system.

R410A

Liquid line

Ø

3/8”

1/2”

5/8”

3/4”

7/8”

1 1/8”

1 3/8”

Gas quantity

gr/m

52

100

166

244

341

538

867

Fasten the tubes to fixed elements by means of braces to avoid vibration.

Carry out welding works in dry nitrogen atmosphere inside the line to be welded -USE A BOTTLE WITH PRESSURE

REGULATOR- to avoid the appearance of oxide and to expel rest of polluting material or humidity. Use rods with a

minimum 15% of silver alloy.

Insulate suction line in order to avoid condensation. Liquid line will be insulated only when exposed to high

temperatures (solar radiation, etc.)

Horizontal segment of suction line: 4% pitch towards the compressor.

In addition to refrigerant, sometimes it’s necessary to add oil. For more than 25 meters, add 30 grams.

When height difference is more than 30 meters, it may be necessary to install an oil separator on discharge line.

If liquid line is descendant and there is a considerable height difference, you have to compensate the excess

pressure before the expansion.

If liquid line is ascendant and there is a considerable height difference, the formation of gas refrigerant before the

expansion must be avoided.

If you should not find the chosen pipe diameter, you can use the immediately lower diameter. The system will

function normally only with a slight reduction of performance.

• Units ACHIA-ACHIBA / ECHIA-ECHIBA / CCHIA-CCHIBA are supplied with nitrogen charge. Before proceeding to any

welding work, it’s necessary to remove this charge out of the interconnection lines. Once you have finished, make the

vacuum and charge with the right amount of refrigerant.

It is forbidden by law to expel refrigerant into the atmosphere; therefore, it is

necessary to recover all the refrigerant and to avoid leaks.

Units without valves come loaded with nitrogen pressure leak test. Drain with caution

previously the realization of unions.

20

AIR-TO-AIR UNITS –COMPACT HORITZONTAL INVERTER

ACHIA / ACHIBA

11.16 207464 Rev.106

• Should it be necessary to add or recover refrigerant, do it always in LIQUID phase, never in gas or vapour phase since

this would cause wrong mixing conditions.

• Due to its high pressure and quick evaporation, refrigerant R410A cannot be kept in liquid phase inside charge cylinder

because bubbles would form, making reading difficult.

21

• Repair immediately any refrigerant leak.

• Never overcharge the system.

• Never use compressor as a vacuum pump.

• If symptoms of refrigerant loss appear during operation, it’s necessary to carry out a leak test. Leak detectors usually

employed with CFC and HCFC cannot be used with R410a, due to chlorine in its composition. A leak detector for R134A

may be used but the sensibility will be lower (when sensibility is 1 for R134A, it falls to 0,6 for R410A).

• To find small leaks, you will need a detector for HCF. Sensibility for R410A is approx. 23 grams per year.

• If a gas leak is found, it will be necessary to remove and completely recover the refrigerant charge. Pressurize the

system with dry nitrogen. If no leakage is detected, then do the vacuum and charge again with refrigerant.

REFRIGERANT CHARGE

Never use oxygen to carry out leak tests. Oxygen reacts violently when in

contact with oil and could cause an explosion resulting in damage, personal

injuries or even death.

If it’s necessary to make welding operations, you must fill the circuit with dry

nitrogen. Combustion of R410A refrigerant generates toxic gases.

This manual suits for next models

6

Table of contents

Other Hitecsa Air Conditioner manuals

Hitecsa

Hitecsa ACHIA 601 Installation and operating instructions

Hitecsa

Hitecsa ECV-SP 1001 User manual

Hitecsa

Hitecsa EKWXA 1001.1 Instruction manual

Hitecsa

Hitecsa ECVBZ Series Manual

Hitecsa

Hitecsa ACVA STD 401 Manual

Hitecsa

Hitecsa FPW 20 Owner's manual

Hitecsa

Hitecsa KUBIC RMXRBA HE Series User manual

Hitecsa

Hitecsa Verne WPHA HE Series User manual

Hitecsa

Hitecsa DXCZ 171 Manual

Hitecsa

Hitecsa VERNE WPHBA Series User manual