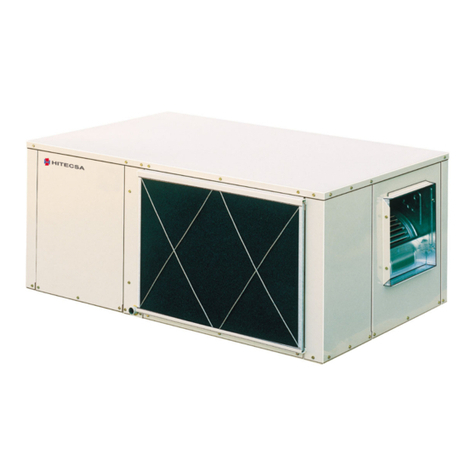

Hitecsa ECV-SP 1001 User manual

Models 1001 │1502 │1602 │2003 │2303

Installation, Operation and Maintenance Manual

01.18 207691 Rev101

ECV-SP

EVAPORATOR UNITS –TAILOR-MADE SOLUTIONS FOR VRF OUTDOOR UNITS

SOLO FRIO

Thank you for trusting in Hitecsa Products. Our company has been offering the market an extended range of

specialized units for air conditioning and cooling installations for over 35 years. Our approach is based on efficiency,

adaptability, usability and practical solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to contribute solutions,almost tailored to each project’s specifications, in search

of a solution to every problem that arises in design and implementation of air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

3

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INDEX

INTRODUCTION................................................................................................................................................5

CONTENTS...................................................................................................................................................5

REGULATIONS AND CERTIFICATIONS .........................................................................................................6

SAFETY PRECAUTIONS ..................................................................................................................................7

TECHNICAL SPECIFICATIONS........................................................................................................................8

OPTIONAL EC MOTOR ................................................................................................................................9

TRANSPORT & RECEPTION..........................................................................................................................10

INSPECTION AT RECEPTION ...................................................................................................................10

RIGGING.....................................................................................................................................................10

STORAGE...................................................................................................................................................10

INSTALLATION ...............................................................................................................................................11

INSTALLATION LOCATION........................................................................................................................11

UNIT SETTLEMENT....................................................................................................................................11

SERVICE AREA ..........................................................................................................................................11

WATER DRAIN............................................................................................................................................11

AIR DUCTS..................................................................................................................................................12

DIMENSIONS..............................................................................................................................................13

Centrifugal fan...................................................................................................................................13

Radial fan ..........................................................................................................................................15

REFRIGERATION CONNECTIONS ...........................................................................................................17

Guide for a proper installation of the refrigeration connections ...............................................17

OPERATION ....................................................................................................................................................18

BEFORE START UP ...................................................................................................................................18

START UP...................................................................................................................................................18

INDOOR FAN TRANSMISSION ADJUSTMENT.........................................................................................19

OPERATING LIMITS........................................................................................................................................20

MAINTENANCE ...............................................................................................................................................20

CONSERVATION AND CLEANING............................................................................................................20

FAILURES...................................................................................................................................................20

FAN DOES NOT START...................................................................................................................20

LUBRICANT ................................................................................................................................................21

REFRIGERANT CHARGE...........................................................................................................................21

ECV-SP

4

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

FAN WITH EC MOTOR (OPTIONAL)..............................................................................................................22

SAFETY INSTRUCTIONS...........................................................................................................................22

Intended use......................................................................................................................................22

Improper use .....................................................................................................................................22

Explanations of symbols ...................................................................................................................23

Product safety ...................................................................................................................................23

Requirements placed on the personnel / due diligence....................................................................23

Working on device.............................................................................................................................23

Modifications / interventions in the device ........................................................................................25

DIAGNOSIS /FAULTS ................................................................................................................................26

Trouble shooting................................................................................................................................26

Status Out with flash code ................................................................................................................27

Rotation caused by an air flow in false direction...............................................................................28

MAINTENANCE AND REPAIRS .................................................................................................................28

CLEANING ..................................................................................................................................................29

APPENDIX: SAFETY DATA R-410A ..............................................................................................................30

ECV-SP

5

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INTRODUCTION

CONTENTS

Purpose of this Manual

This manual and any other instructive document attached as refrigeration lines design, electrical diagrams,

etc. have been written to allow a correct installation, commissioning and maintenance of theunit. Therefore

it is essential to read the instructions with due attention.

Verify that all the necessary information for the correct installation of the system is included in the manuals

supplied with this unit and/or the rest of the indoor units, accessories, etc. Otherwise, the manufacturer

declines any responsibility for any damage to persons, animals or things, as a result of improper use of the

unit and/or failure to observe these instructions.

Preservation Manual

This manual and the electric diagram of the unit must be retained and remain available to the operator for any further

consultation.

Updating the Data

The continuous improvement in design and performance to which we are committed gives us the right to modify the

specifications of our products without prior notice.

Electrical Network

Check that the electrical network features are in accordance to data shown in the data nameplate of the

unit.

Local Safety Regulations

Observe and analyze all possible causesof accidents that may arise in the place orplaces of installation of the units, check

means and tools to use, etc. It is not possible to anticipate each and every one of the potential circumstances of danger in

this manual. Respect the valid local security standards during installation.

Principles of Security on Installation

The unit is designed and built in a way that does not pose a risk to the health and safety of people. Appropriate solutions

for the project have been adopted to eliminate the possible causes of risk in the installation.

Packaging and Replacement of Equipment

The material of the package (plastic bags, insulating materials, nails, etc.) is a potential source of danger.

Consequently, it should be kept out of the reach of children and properly recycled according to the valid

local safety regulations.

This product should not be mixed with household waste at the end of its life. Due to the refrigerant, oil and

other components contained in this product, it must be dismantled by professional installers in accordance

with current regulations.

Utilization

The unit will be used only for the reason it has been conceived. Any other use does not imply any kind of compromise or

link for the manufacturer.

Incorrect Operation

In case of breakdowns or operation faults, turn off unit.

6

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INTRODUCTION

CONTENTS

Periodic Inspections and Maintenance

Carry out periodic inspections to detect possible damaged or broken pieces. If they are not repaired it could

cause damage to people or stuff. Before executing any maintenance operation, cut off the unit power

supply.

All operations should be carried out in accordance with local safety regulations.

Repairs

The reparations should be always and exclusively realized for trained personal authorized by the

manufacturer using original spares. The safeties of the unit could be affected due to the failure to comply

with these warnings.

Modifications

The manufacturer will not respond to the warranty and to the possible damages of the unit in case of electrical and/or

mechanical modifications. The unauthorized manipulation, reparation or modification of the unit will automatically invalidate

the warranty.

Refrigerant

This product is hermetically sealed and contains R-410A which is a HFC fluorinated greenhouse gas.

REGULATIONS AND CERTIFICATIONS

ISO 9001:2008 CERTIFICATION: HIPLUS AIRE ACONDICIONADO S.L., trying always to find the maximum satisfaction

of costumers, has obtained the ISO 9001:2008 Quality System referred to its production activity. This will result in a

continuous determination to improve quality and reliability of all our products; commercial activities, design, raw materials,

production and after-sales service, are the means to reach our goal.

CE MARKING: Our machines have got the CE mark, in conformity with the essential requirements of the applicable EC

directives and their last modifications as well as with the national legislation of each country.

EUROVENT CERTIFICATION: HITECSA participates in the EUROVENT Certification program. Check certified products

on the web.

7

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

SAFETY PRECAUTIONS

DANGER

• In case of folding electrical panels, before folding them up in order to access to the interior of the machine, it is

MANDATORY to disconnect the power supply hose from the electrical voltage, IT MUST ALWAYS BE FREE OF

VOLTAGE for this operation.

• Do not touch or adjust the safety elements inside of any unit of the system. Use only original spare parts in

repairs and install them in the same position where old parts were placed.

• The installation and maintenance of the air conditioning equipment could be dangerous because the system is

under pressure, some of its elements have high temperatures and include electrical components.

• Do not install the unit in the explosive atmosphere.

ATTENTION!

• Only qualified and trained service staff (technical service) must make the installation, commissioning and carry out

maintenance works. Unqualified staff can only make basic tasks such as cleaning and replacement of filters, etc.

• Prevent access to children so they cannot play with the appliances.

• In every visit, all precautions must be taken into account: those recommended in the installation, operation and

maintenance instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any other safety

precautions. .

• DO NOT introduce objects into the air inlets or outlets that can be drawn into the fan, people, etc.

• Use safety glasses, work gloves and any other safety accessory necessary.

• For brazing operations use a quenching cloth and take precautions to have at close distance a fire extinguisher.

• This product contains fluorinated greenhouse gases, its leakage can cause displacement of air and cause insufficient

oxygen to breath.

• All safety recommendations must be followed.

Before starting installation, service or maintenance, turn off the main power switch in order

to avoid electrical shock that may cause personal damages.

WARNING!

In case if the existance of water tanks with ELECTRIC HEATERS.

Before starting the equipment, make sure that the water tank is completely full and that the installation is

perfectly drained of air.

WARNING!

8

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

TECHNICAL SPECIFICATIONS

MODEL

1001

1502

1602

2003

2303

POWER SUPPLY

Voltage

V / f / Hz

400 / III / 50

HEAT EXCHANGER COIL

Type

Aluminium fins and copper tubing

Number of cooling circuits

1

1

2

2

2

3

3

Refrigerant (1)

R-410 (50% HFC32 + 50% HFC125)

GWP (2)

2088

Installed Expansion Kit (3)

EXV-8.0 E1

EXV-10.0 E1

2 x EXV-8.0

E1

EXV-8.0 E1 +

EXV-10.0 E1

2 x EXV-10.0

E1

3x EXV-8.0

E1

3 x EXV-10.0 E1

Cooling capacity

kW

20

26

40

46

50

60

73

Heat capacity

kW

23

28

45

50

52

65

81

Volume

l

3,48

4,63

3,23

3,46

4,62

4,28

3,15

4,03

Volume min

l

2,92

3,89

2,89

2,92

3,89

3,89

2,92

3,89

Volume max

l

3,89

4,76

3,89

3,89

4,76

4,76

3,89

4,76

FAN

Type

Centrifugal, double suction

Model

12/9 G2L

12/9 G2L

12/12 G2L

12/12 G2L

12/12 G2L

15/11G2L

15/11G2L

Rated air flow

m3/h

6200

6300

9000

9000

11200

12000

13000

Available static pressure

Pa

150

150

200

200

200

200

200

Motor power

KW

1,1

1,1

2,2

2,2

3,0

3,0

4,0

Speed

r.p.m.

789

809

914

930

996

740

765

ELECTRICAL DATA (for a fan)

Rated motor power

kW

1,1

1,1

2,2

2,2

3,0

3,0

3,0

Maximum current (at 400V)

A

2,4

2,4

4,6

4,6

6,2

6,2

6,2

Total absorved power

kW

0,6

0,7

1,3

1,4

2,1

1,9

2,2

Total sound power (Lw)

dBA

81

81,5

84,5

84,5

88

83,5

85

DIMENSIONS & WEIGHT

Length

mm

1700

1700

2000

2000

2000

2600

2600

Width

mm

870

870

939

939

939

980

980

Height

mm

650

650

747

747

747

752

752

Weight

Kg

211

211

272

272

272

333

333

1. Mixture of greenhouse gases for which the machine has been designed. The load will depend on the external unit / units with

which it is connected.

2. GWP: Global Warming Potential (GWP) of kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year

warming potential.

3. This Expansion Kit, as well as all other technical features, is optimized for HITACHI VRF units. The other Manufacturers, may require the

installation of its own Expansion kits, as well as other volumes of Coils, Air Speeds, etc.

Consult with HITECSA

9

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

TECHNICAL SPECIFICATIONS

OPTIONAL EC MOTOR

MODEL

1001

1502

1602

2003

2303

Type

RADIAL with EC motor (Type Plug-Fan)

Number / Size

- / mm

2 / 400

2 / 400

2 / 450

2 / 450

2 / 450

2 / 450

2 / 450

Coil width

mm

65

87

87

108

65

87

108

ELECTRICAL DATA (for a fan)

Power supply

V / ~ / Hz

400V / 3 Phases / 50Hz

Rated motor power (1 Fan)

kW

2,4

2,4

2,0

2,0

2,0

2,0

3,6

Maximum current (1 fan at 400V)

A

3,7

3,7

3,2

3,2

3,2

3,2

5,6

RATED OPERATING CONDITIONS

Nominal air flow

m3/h

6200

6300

9000

9000

11200

12000

13000

Available static pressure

Pa

75

75

75

75

100

100

100

Total absorved power

kW

0,40

0,42

0,68

0,69

1,22

1,20

1,52

Speed

rpm

1063

1088

1074

1078

1327

1354

1435

Potencia sonora Total (Lw)

dBA

72

72

76

76

81

83

86

VALORES LÍMITES DE FUNCIONAMIENTO

Maximum available pressure

Pa

1150

1150

850

850

710

700

1075

Maximum air flow

m3/h

16000

15800

17350

17300

17250

17900

22340

Maximum speed

r.p.m.

2400

2400

1880

1880

1880

1880

2260

Maximum sound power

dBA

92

92

86

86

86

87

93

Sound power at 400Pa

dBA

77

77

81

81

83

84

87

10

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

TRANSPORT & RECEPTION

INSPECTION AT RECEPTION

It is advisable to examine the equipment carefully at the time of its reception.

Check that the equipment has not been damaged during transport and has been supplied complete with all parts

specified in the order and/or with the optional specified in the order. If this is not the case contact the transport

company immediately. (First 48h)

Verify the correct voltage of the nameplate and make sure it is in accordance with local power supply.

In case of any flaw or anomaly detected, please contact HITECSA.

RIGGING

Before moving the unit, make sure that all panels are well fixed.

Raise and set down the equipment carefully.

Do not tilt the unit more than 15 degrees during transportation. (Fig. 1) (Fig. 2)

Always transport the unit in its original packaging to the place of installation.

All units come with a particular rigging diagram of that model, similar to the one shown below. Be sure to hoist

the machine through the points indicated in the diagram.

Make sure that the unit is balanced, stable and without any deformations when it is lifted.

STORAGE

If the equipment is going to be stored before the installation, please follow the instructions below in order to avoid damages,

corrosion or deterioration:

Move it carefully.

Do not place the machine in places exposed to ambient temperature above 50ºC and preferably keep the unit away

from direct sunlight.

Avoid placing the unit with plastic wrapping protection under the sun, as the pressure of the circuits could assume

values that could lead to the intervention of the safety valves.

In addition, when cooling, water condensation occurs inside the machine and the plastic wrap.

Avoid placing other objects on top of the unit (unless it is done within the limits of the overlap planes indicated on the

packaging, etc. Follow these indications).

Avoid prolonged storage, before installation, water inlet, dust and objects in general due to invasion or biological,

meteorological and/or human inclemencies.

Minimum storage temperature: -10ºC

Maximum relative humidity: 90%.

Fig. 1

Fig. 2

11

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

INSTALLATION LOCATION

- Consult and respect the rules and local regulations which regulate the installation of air conditioning systems.

- Choose a site without dust and debris.

- Respect the appropriate service area for the equipment which will be installed.

- Verify that the ground or structure on which the unit will be installed is able to support its weight in operation.

- Fit shock absorbers throughout the installation to prevent the transmission of noise and vibration.

- Check that the direction of the sound level is not going to disturb anyone.

UNIT SETTLEMENT

Be sure unit is correctly leveled.

The bed frame should have sufficient strength to support unit weight.

Be sure that after settlement the unit drain is working properly.

SERVICE AREA

Make sure to respect the following measurements for the correct operation of the unit.

WATER DRAIN

The indoor drain unit (of condensate water) has 3/4” MPT connection.

Condensate drain pipe diameter should be equal or larger than the unit connection depending on the line length

and general building configuration.

The drainage line should be inclined a minimum 2% for proper water evacuation.

When drain line is exposed to air temperatures below 0 degrees, it is necessary to cover with thermal insulation or

electrical heating wire to avoid water freezing and tube damage.

It is convenient to install the drain trap with proper dimensions (see diagram).

Recommended drain trap

measures

Área de Servicio

12

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

AIR DUCTS

Air duct dimensions will be determined according to the airflow and available pressure of the unit.

Ducts must be designed by qualified technical people.

Use ducts made of non-inflammable materials in order to avoid any risk of fire as a consequence of the deflagration

of gases. It is advisable to use metal sheet duct with insulation.

Use flexible ducts to connect air ducts into the unit and thus avoid vibration and noise transmission.

In case of units destined to human confort, it is MANDATORY to provide an outdoor air renewal

superir to 0% and lower than 10%.

ATTENTION!

13

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

DIMENSIONS

Centrifugal fan

Model 1001

HORITZONTAL DISCHARGE

LEGEND

1. Gas connection

2. Liquid connection

3. Electrical supply input

4. Air filter

5. Fan

6. Centrifugal turbine motor

7. Heat exchanger

8. Drainage 3/4’’

14

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

DIMENSIONS

Centrifugal fan

Models 1502 - 1602

Models 2003 - 2303

LEGEND

1. Liquid connection

2. Gas connection

3. Air filter

4. Electrical supply input

5. Fan

6. Drainage 3/4’’

7. Heat exchanger

HORITZONTAL DISCHARGE

HORITZONTAL DISCHARGE

LEGEND

1. Gas connection

2. Liquid connection

3. Electrical supply input

4. Air filter

5. Fan

6. Centrifugal turbine motor

7. Heat exchanger

8. Drainage Ø 3/4’’

15

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

DIMENSIONS

Radial fan

Model 1001

Models 1502 - 1602

LEGEND

1. Air filter

2. Electrical supply input

3. Drainage Ø 3/4”

16

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

DIMENSIONS

Radial fan

Models 2003 - 2303

LEGEND

1. Liquid connection

2. Gas connection

3. Air filter

4. Electrical supply input

5. Radial fan

6. Coil

7. Drainage Ø 3/4”

HORITZONTAL DISCHARGE OPTIONAL

17

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

REFRIGERATION CONNECTIONS

Damages caused by an improper installation of the refrigeration connections between the

indoor and the oudoor units will not be covered by the warranty.

As a result of an improper installation, the following sources of problems can be derived:

- Entrance of air, water or any type of object or animal small enough.

- Pipes too thick or thin.

- Strangled or poorly welded tubes.

- Unfulfillment of the current local laws, for a bad layout, aesthetics of facades, etc.

In turn, the above aspects may have an impact on:

- Speed of the refrigerant inside the pipe too high or too low.

- Migration and no return of compressor oil.

- Noises.

- Explosive breaks of the pipes.

- Contamination due to refrigerant losses, that it is a greenhouse gas.

- Break of the solenoid valves or expansion valves.

- Rise of the electrical consumption and loss of performance and capacity.

- Reduction of operating limits, even to total inoperability.

- Breakage of the compressor or shortening of its operational life.

Guide for a proper installation of the refrigeration connections

1. Having determined a place and proper settlement of the units and the equivalent length of the route of the

refrigeration lines that connect them.

2. Calculate the pipes (diameters, lengths) and necessary couplings for the installation.

Use as a reference the document nº207682, REFRIGERATION LINES DESIGN (R410a).

3. Before beginning the installation check that the tubes have a clean and protected interior against the entry of

moisture. Use preferably long radius curves, do not produce throttles when handling the tube.

4. Installation of the pipes.

- Cut the tube with a cutter and then remove the burr and recalibrate the

diameter that has been reduced. Recalibrate with interior gauge or

expansion tong. Do not use file, knife, orany other tool non-specific tool that

could leave particles inside the tube.

- Reduce the number of welds that should always be strong type. In compliance with local laws, the welder must be

an approved employee. A bad weld can cause dirt inside the pipe, more or less explosive blowouts that can cause

third-party damage, pipe obstruction, refrigerant losses, etc. Remember that tubes to be welded must be clean of

oil and refrigerant. Through its inside must circulate dry nitrogen without pressurizing and have a good penetration

of the weld, heat the male pipe mainly.

5. The connection of the pipes to the machines can be threaded or welded. Check the tightness after the connections.

6. The most common threaded connections in small pipes are Flare type (flared). A bad flare will cause leaks and/or

blowouts. When doing the flare, it is essential to clean the burr of the tube well to avoid cracks, and do not leave

the pipe wall very thin and without consistency by tightening too much.

Correct

Too big

Very small

Inclined

Cracked

Very thin or

uneven wall

Internal

scratches

18

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

INSTALLATION

7. Make the vacuum to the installation and the units that are not charged with refrigerant. Once the vacuum pump

stops, check that the vacuum remains during 20 min., a proper vacuum will be at an absolute pressure of 2hPa

(2mbar) or less.

Humidity or water in the installation may cause irreversible damages to the compressor and other devices of the

circuit. Liquid water cools and boils when the vacuum reaches its vapor pressure and does not allow it to do so

correctly until it freezes, once the water is frozen it does not boil but it is much more difficult to remove and detect.

To avoid the freezing of the water, it is advisable to make a soft and prolonged vacuumand not make a fast vacuum

with very powerful pumps.

8. Open all the keys and load with the refrigerant indicated on the nameplate. If it is not included in the machine, add

the additional load due to the length and thickness of the pipes. Follow current legislation regarding who and how

can handle the refrigerant.

9. Check for leaks during the first operating hours and schedule maintenance after the first month.

OPERATION

BEFORE START UP

Start-up has to be performed by a qualified service personnel in air conditioning.

Make sure that panels are firmly secured with screws.

Check that there is no leakage of oil or refrigerant.

Ensure that the unit is evenly leveled.

Check if there is enough space for operation and maintenance.

Before opening the electrical panel and having access to the inside of the machine it is MANDATORY to

disconnect the power supply cable of the machine which MUST BE FREE OF VOLTAGE for this

operation.

Check that the drainage is not blocked.

Always use the electrical diagram of the unit to make the connections.

Make sure that all electrical connections are properly tight.

The power supply of the unit must be as indicated on the serial plate. Damage caused by the start-up of the unit

in an incorrect voltage line is not covered by Hitecsa’s warranty.

The unit must not be supplied with any other voltage than that indicated on the serial plate. The power supply to

the unit must be within 10% of the voltage indicated on the serial plate.

Check the correct rotation direction of the fans.

The installer must place line protection elements in accordance with current legislation.

Wiring of electrical connections must be protected by a tube or other cable conduits.

Make sure if the crankcase heater of each compressor has been operating during 24 hours prior the Start Up.

Check that he air filters are clean and correctly fitted.

Check the condition and placement of grilles, diffusers, air ducts, tarpaulins, etc.

START UP

It is necessary to take notes of the air inlet and outlet temperatures to the internal coil, the volts and amps of the

compressor and motor fan, as well as the suction and discharge pressure of each compressor.

It should be remembered that it is necessary to clean the air filters after the first 4 hours of operation.

Observe, at least, 3 cooling cycle operations.

Due to the unit has frequency converters, it is essential that the protection be at least 300mA to prevent power

cuts caused by the activation of the circuit breaker.

19

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

OPERATION

INDOOR FAN TRANSMISSION ADJUSTMENT

Adjust transmission in such a way that the indoor motor consumption comes to its normal value.

If consumption is below nominal value it means that unit air flow is too low.

-To change fan speed:

1. Remove the belt. Move the motor along its track (or loosen the tensor set screw) in order to release it.

2. Loose the set screws of the motor pulley and turn the movable flange. Open or close depending on the needs

(Open: speed decreases).

3. Tighten set screws.

4. Place the belt in the pulley channel. The closure or opening of the pulley could void the size of the prior belt. In

this case, replace it for other belt of the same profile and with the appropriate length.

5. Tighten the belt by using tensor screw or sliding the motor, depending on the case.

-Align fan and motor pulleys:

1. Loose fan pulley set screws.

2. Slide fan pulley along the shaft and align it with motor by using a ruler in order to ensure that is parallel to the

belt.

3. Tighten fan pulley set screws.

- Adjust belt tension:

1. Loose motor mounting plate bolt and slide it.

2. Belt flexion millimeters is estimated by dividing S by 40.

1. Motor

2. Motor pulley

3. Transmission belt

4. Fan pulley

5. Tensor set screw

6. Set screw

7. Fixed flange

8. Movable flange

20

01.18 207691 Rev101

ECV-SP

AUTONOMOUS UNITS FOR OUTDOOR UNITS

AIR-AIR

OPERATING LIMITS

This unit is ready to operate properly with VRF (Variable Refrigerant Flow) or VRV (Variable Refrigerant Volume) outdoor

units. The operating limits will depend on the external units to which the unit is connected, and its Safety Systems.

MAINTENANCE

It is advisable to do maintenance works every 1.000 hours as well as at the beginning of each cooling season.

In case of leakage, any manipulation and/or recovery of refrigerant must be carried out by qualified and accredited

personnel in the current legislation. Add the quantity of oil that has been lost.

CONSERVATION AND CLEANING

Electrical circuit: Make sure that all electrical connections –wires, contactors and terminals- are properly tight. Record

the readings for volts and amperes of each compressor and fan motor. Verify the starting current. Check the good operation

of all relays, pressure switches and phase sequence relay of Scroll compressor.

Refrigeration circuit: Check for oil or refrigerant leaks, noises or system’s vibration. Take measurements of temperatures

and pressures of components and record them on the maintenance form.

Coils: At least once a year, clean condenser coils with water and detergent, then dry with air at low pressure. Never clean

with a wire brush, water and/or air at high pressure.

Fans: Check the direction of rotation of the fans, verify their carriers. Check the transmission elements and the operating

status.Before handling the fan, make sure that it is disconnected from the mains, even if it is already stopped and no one

can start during the intervention.

It is necessary a regular inspection of the unit. Its frequency must be in function of the working conditions to avoid dirt

accumulation in propellers, turbines, motors and grids that could entail risks and significantly shorten its life.

- In cleaning operations be very careful not to unbalance the propeller or the turbine.

- In all maintenance and repairing works, must take into account the current safety rules in each country.

Motors and fans do not need additional lubrication.

Drainage system: Verify condition and good operation of the drainage tray and drain trap.

Air filters: Clean filters after the first operating hours to collect possible light materials such as papers, porexpan pieces,

etc. excess of the installation and that have been dragged through air circulation. Clean again every 3 months (or more

often depending on how it works). The filter can be cleaned with soapy water, then rinse with clean water and let dry. If it

is necessary, replace the filters before they are in poor conditions (see current legislation, EN 779, UNE-EN 13053…).

FAILURES

FAN DOES NOT START

1. Check for loose or broken cables, in this case, replace or retighten them.

2. Check that the appliance is effectively in demand for cold, heat or ventilation only, otherwise check the outdoor unit.

3. Check the condition of the fuses or the power supply. Check the electrical wiring of the fan.

4. The mains voltage is too weak, in this case verify with the company.

Before performing any service or maintenance of the unit, it is mandatory to disconnect and lock

the system main switch to prevent anyone other than the technician from connecting the unit and

causing personal injury.

WARNING!

This manual suits for next models

4

Table of contents

Other Hitecsa Air Conditioner manuals

Hitecsa

Hitecsa ACHIA User manual

Hitecsa

Hitecsa FPW 20 Owner's manual

Hitecsa

Hitecsa WCVZ Series Owner's manual

Hitecsa

Hitecsa Verne WPHA HE Series User manual

Hitecsa

Hitecsa ECVBZ Series Manual

Hitecsa

Hitecsa ACVA STD 401 Manual

Hitecsa

Hitecsa CCHBA/CCHA 201 Instruction manual

Hitecsa

Hitecsa DXCZ 171 Manual

Hitecsa

Hitecsa WCHZ 201 User manual

Hitecsa

Hitecsa EKWXA 1001.1 Instruction manual