Hitecsa WPVBZ HE Instruction manual

1

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

WPVBZ HE WPVZ HE

Heat pump Cooling only

PACKAGED COMPACT VERTICAL WATER-AIR UNITS

INSTALLATION, OPERATION & MAINTENANCE MANUAL

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_ES

Models: 401 - 1201 - 4002

2

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

Thank you for trusting the Hitecsa Products. Our company has been offering the market an extended range of specialized units for air

conditioning and cooling installations for over 35 years. Our approach is based on efficiency, flexibility and on practical solutions. This has

been the hallmark of our product catalogue.

The versatility of our factory allows us to deliver solutions that can meet any requirement and we endeavour solving any problem that may

arise in designing and implementing air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

3

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INDEX

INTRODUCTION ............................................................................................................................4

REGULATIONS AND CERTIFICATIONS.......................................................................................5

SAFETY PRECAUTIONS...............................................................................................................6

TECHNICAL SPECIFICATIONS ....................................................................................................8

TRANSPORT ...............................................................................................................................10

INSPECTION AT RECEPTION .......................................................................................................................................... 10

RIGGING ........................................................................................................................................................................ 10

STORAGE ....................................................................................................................................................................... 10

INSTALLATION............................................................................................................................11

SERVICE AREA (MM)........................................................................................................................................................ 11

WEIGHT DISTRIBUTION (KG)........................................................................................................................................... 11

DIMENSIONS.................................................................................................................................................................. 12

INSTALLATION SITE ........................................................................................................................................................ 14

UNIT SETTLEMENT ......................................................................................................................................................... 14

DRAIN ............................................................................................................................................................................ 14

ELECTRICAL INSTALLATION ............................................................................................................................................ 14

WATER INSTALLATION ................................................................................................................................................... 15

Water filling................................................................................................................................................................ 15

Purging ....................................................................................................................................................................... 15

Risk of frost................................................................................................................................................................. 15

Glycol additions .......................................................................................................................................................... 15

HYDRAULIC CIRCUIT AND ITS COMPONENTS................................................................................................................. 16

Regulating devices...................................................................................................................................................... 17

Condenser water regulating valve.............................................................................................................................. 17

HYDRAULIC DIAGRAM ................................................................................................................................................... 18

HYDRAULIC CONNECTIONS WITH WATER PRESSURE REGULATING VALVE (OPTION) ................................................... 19

ELECTRICAL CONNECTIONS ........................................................................................................................................... 20

Connection of thermostats ......................................................................................................................................... 20

Electrical connection of the hydraulic devices with TH-TUNE and µPC ...................................................................... 21

OPERATION ................................................................................................................................22

BEFORE START-UP.......................................................................................................................................................... 22

START UP ....................................................................................................................................................................... 22

OPERATION LIMITS ........................................................................................................................................................ 23

EC MOTOR FAN .............................................................................................................................................................. 24

Safety instructions ...................................................................................................................................................... 24

Working on the device................................................................................................................................................ 25

Modifications / interventions in the device ................................................................................................................ 26

TH TUNE CONTROLLER................................................................................................................................................... 27

Start / Stop ................................................................................................................................................................. 27

Setpoint Temperature Adjustment ............................................................................................................................. 27

Operation modes ........................................................................................................................................................ 27

Indoor Fan: ................................................................................................................................................................. 27

WARNINGS ....................................................................................................................................................................... 27

Description of the warding codes ............................................................................................................................... 27

Alarms ........................................................................................................................................................................ 27

DESCRIPTION OF THE ALARM CODES............................................................................................................................. 28

MAINTENANCE ...........................................................................................................................29

EC MOTOR FANS ............................................................................................................................................................ 30

Rotation caused by an air flow in false direction........................................................................................................ 30

Diagnosis / Faults ....................................................................................................................................................... 31

Status Out with flash code.......................................................................................................................................... 32

REFRIGERANT CHARGE .................................................................................................................................................. 34

4

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INTRODUCTION

Purpose of this Manual

This manual and any other instructive document attached as refrigeration lines design, electrical

diagrams, etc. have been written to allow a correct installation, commissioning and maintenance of

the unit. Therefore it is essential to read the instructions with due attention.

Verify that all the necessary information for the correct installation of the system is included in the

manuals supplied with this unit and/or the rest of the indoor units, accessories, etc. Otherwise, the

manufacturer declines any responsibility for any damage to persons, animals or things, as a result of

improper use of the unit and/or failure to observe these instructions.

In case of different interpretations and/or errors the documentary priority will be: 1. Characteristics

plate of the unit, 2. IOM (this document), 3. EDM, technical catalogue, 4. UM user manuals.

Conservation of the Manual

This manual and the electric diagram of the unit must be retained and remain available to the operator for any further

consultation.

Updating the Data

The continuous improvement in design and performance to which we are committed gives us the right to modify the

specifications of our products without prior notice.

Electrical Supply

Check that the electrical network features are in accordance to data shown in the data nameplate of the

unit.

Local Safety Regulations

Observe and analyse all possible causes of accidents that may arise in the place or places of installation of the units, check

means and tools to use, etc. It is not possible to anticipate each and every one of the potential circumstances of danger in

this manual. Respect the valid local security standards during installation.

Principles of Security on Installation

The unit is designed and built in a way that does not pose a risk to the health and safety of people. Appropriate solutions

for the project have been adopted to eliminate the possible causes of risk in the installation.

Packaging and Replacement of Equipment

The material of the package (plastic bags, insulating materials, nails, etc.) is a potential source of danger.

Consequently, it should be kept out of the reach of children and properly recycled according to the valid

local safety regulations.

This product should not be mixed with household waste at the end of its life. Due to the refrigerant, oil and

other components contained in this product, it must be dismantled by professional installers, all waste

should be sent, according to its nature to recycling, composting or treatment plants, or to an authorized

waste management agency in accordance with the current local legislations.

Utilization

The unit will only be used for the purpose it has been designed. Any other use does not imply any kind of liability or

responsibility from the manufacturer.

Incorrect Operation

In case of breakdown or operation faults, turn the unit off.

5

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INTRODUCTION

Periodic Inspections and Maintenance

Carry out periodic inspections to detect possible damaged or broken parts. If these parts are not repaired

it could cause damage to people or material. Before executing any maintenance operation, switch the unit

power supply off.

Make sure to keep the maintenance areas open. If these areas have to be invaded by the construction of

air supply and/or lateral return ducts, verify that the design of the ducts allows the access to the fans and

the replacement of the filters.

All operations shall be carried out in accordance with the local safety regulations.

Repairing Operations

The reparations shall always and exclusively be completed by trained personal authorized by the

manufacturer using original spares. The safety devices of the unit could be affected due to the failure to

comply with these warnings.

Modifications

The manufacturer will not respond to the warranty and to the possible damages of the unit in case of electrical and/or

mechanical modifications. The unauthorized manipulation, reparation or modification of the unit will automatically invalidate

the warranty.

Refrigerant

This product is hermetically sealed and contains R-407C which is a HFC fluorinated greenhouse gas.

REGULATIONS AND CERTIFICATIONS

ISO 9001 CERTIFICATION: HIPLUS AIRE ACONDICIONADO S.L., by endeavouring to always gain the maximum

satisfaction from their customers, obtained the ISO 9001: Quality System for its design and production activities. That result

shows our continuous determination to improve quality and the reliability of all our products. Our commercial activities,

design, raw materials, production processes and after-sales service represent the means to reach our goal.

CE MARKING: Our products are CE marked according to the essential requirements of the applicable EC directives and

their last modifications and comply with the national legislation of each country.

6

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

SAFETY PRECAUTIONS

Before starting any installation, service or maintenance operation, turn off the main power switch in

order to avoid electrical shock that may cause personal damages.

In case of folding electrical panels, before folding them up in order to access to the interior of the machine, it is

MANDATORY to disconnect the power supply hose from the electrical voltage, THE LINE MUST ALWAYS BE

FREE OF VOLTAGE for this operation.

It is absolutely prohibited to realize any operation on parts that are electrically powered on. The protection class

of the opened equipment is IP00!

The absence of voltage must be confirmed by a minimum two poles voltage tester.

DANGER

Do not touch or adjust the safety devices inside any unit of the system. For repairs use only original spare parts

and mount them properly in the same position where old parts were placed.

The installation and maintenance of air conditioning equipment may be dangerous because the system is under

pressure, some of its elements have high temperatures and include electrical components.

Do not install the unit in an explosive atmosphere.

The units equipped with water-air, water-water, or refrigerant-water heat exchangers shall be protected

properly against damage caused by frost. A proper protection is obtained by adding the necessary anti-

frost liquid so that the freezing temperature becomes minimum -2°C (6% when using Ethylene Glycol).

Moreover when the ambient temperature in any part of the installation may reach values lower than 5°C

it is COMPULSORY to protect the unit and the whole installation with additional measures such as

heating tubes, draining the unit and the whole installation for water (when the unit is not under

operation) or adding more anti-frost liquid so that the freezing point always will be lower than the

minimum temperature that the ambient air may reach.

Even after disconnecting the main voltage, life-threatening charges may appear between the protective ground

“PE” and the main connection.

When the motor runs independently due to air flowing through or if it continues to run down after being turned off,

dangerous voltages of over 50 V can arise on the internal connections of the motor through operation of the

generator.

When there are EC motors or motors with variable speed control, the protective earth is conducting high discharge

currents (depending on the switching frequency, current source voltage and motor capacity). Grounding in

compliance with EN specifications shall therefore be observe even for testing and trial conditions (EN 50 178, Art.

5.2.11). Without grounding, dangerous voltages can be present on the motor housing.

Because of the use of capacitors, danger of death exists even after switching off the device in case of direct

contact with conductive parts or with parts that carry voltage due to fault condition. It is only allowed remove or

open the housing of the controller when the power supply cable is disconnected and after a waiting time of 3

minutes.

The warranty of the unit will not respond to the damages caused by frozen water.

WARNING!

7

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

SAFETY PRECAUTIONS

Only qualified and trained service staff (technical service) must make the installation, commissioning and carry

out maintenance works. Unqualified personnel can only make basic tasks such as cleaning and replacement of

filters, etc.

Prevent access to children so they cannot play with the appliances.

In every visit, all precautions must be taken into account: those recommended in the installation, operation and

maintenance instructions, as well as the ones indicated in labels of the unit. Do not forget to strictly follow any

other safety precautions.

DO NOT introduce objects into the air inlets or outlets that can be drawn into the fan, people, etc.

Use safety glasses, work gloves and any other safety accessory necessary.

The fan / motor may switch on and off automatically for functional reasons.

After power failure or main disconnection automatic restart of the fan may occur when power supplyis back!

Wait for the fan to come to a complete standstill before approaching it!

In the AC external rotor motor the external rotor turns during operation!

For brazing operations use a quenching cloth and take precautions to have at close distance a fire extinguisher.

This product contains fluorinated greenhouse gases, leakage can cause displacement of air and entail insufficient

oxygen to breath.

The decomposition of fluorinated gases when being burned due to e.g. brazing operations, may cause the

existence of highly toxic and corrosive gases.

Must follow all safety recommendations.

ATTENTION!

The responsibility of all personal and material damages caused by an unplanned or inappropriate use will be given

to the person or operating company of the unit, and not to the manufacturer.

WARNING!

8

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

TECHNICAL SPECIFICATIONS

WPVZ HE / WPVBZ HE

401

1201

4002

REFRIGERANT

Type

-

R407c

GWP (1)

-

1774

Refrigerant charge WPVZ

kg

1.05

3.7

5.8 + 5.8

Refrigerant charge WPVBZ

kg

2

7

9 + 9

COOLING CAPACITIES

Cooling capacity (2)

kW

13.2

41.0

129.3

Total absorbed power (2)

kW

4.33

13.68

44.28

EER coefficient (2)

kW / kW

3.05

3.00

2.92

ηs,c (2)

%

106.8

108.0

103.7

Water flow

mᶟ/h

2.97

9.27

29.4

WPVBZ HE (Heat pump units)

HEATING CAPACITIES

Nominal heating capacity (3)

kW

15.8

49.6

155

Heating capacity (4)

kW

12.7

39.92

124.99

Total absorbed power (4)

kW

3.75

11.67

37.88

COP coefficient (4)

kW / kW

3.39

3.42

3.3

ηs,h (4)

%

109.6

110.7

106.5

Water flow

mᶟ/h

2.6

8.19

25.27

1) GWP: Global Warming Potential (climatic) of 1 kg of greenhouse gas relative to 1 kg of CO2, calculated in terms of 100-year warming

potential.

2) Cooling tower conditions: Room temperature 27/19ºC. Condenser water: inlet 30 ºC / outlet 35ºC.

3) Dry air temperature 20°C. Humid temperature, room air 14°C. Inlet water temperature 16°C.

4) Ground water conditions: Room temperature 20ºC. Evaporator water: inlet 10ºC, Unit’s water flow 100 % inlet 7ºC.

9

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

TECHNICAL SPECIFICATIONS

WPVZ HE / WPVBZ HE

401

1201

4002

COMPRESSOR

Type

-

Scroll

Quantity

-

1

2

Power supply

V / ~ / Hz

400V / 3 ~ / 50 Hz

Oil type

-

FV68S

160PZ

160SZ

Oil quantity - compressor

L

1.7

3.9

2 x 6.8

INDOOR FAN

Type

-

Radial with EC motor (Plug-Fan type)

Quantity

-

1

2

2

Size

mm

310

400

500

Nominal air flow

mᶟ/h

2400

8200

21500

Nominal available pressure

Pa

50

75

150

Maximum available pressure

Pa

900

940

440

Nominal power - motor

kW

1.4

2.4

3.5

Maximum speed

rpm

2920

2400

1860

Power supply

V / ~ / Hz

230V / 1 ~ / 50 Hz

400V / 3 ~ / 50 Hz

INDOOR EXCHANGER

Type

-

Coil of finned copper tubes

Front surface

m²

0.31

0.84

2.1

Number of stages

-

4

4

4

OUTDOOR EXCHANGER

Type

-

Welded plates

Quantity

-

1

1

2

Water connections (MTP)

ø (")

1

1 1/2

2

Number of plates

-

20

40

70

ELECTRICAL GENERAL SPECIFICATIONS

Power supply

V / ~ / Hz

400V/ 3 ~+ N /50 Hz

Maximum operation current

A

8.7

26.2

87.3

Start-up current

A

54

146

215

DIMENSIONS AND WEIGHT

Length

mm

780

1790

2404

Width

mm

650

870

1157

Height

mm

1380

1630

2122

Duct

mm x mm

297 x 338

373 x 1003

481 x 1407

Weight

kg

165

515

1060

SOUND LEVEL

Total sound power

dB (A)

69

81

91

10

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

TRANSPORT

INSPECTION AT RECEPTION

It is advisable to check the equipment carefully upon reception.

Check that the equipment has not been damaged during transport and has been supplied complete with all parts

specified in the order and/or with the optional specified in the order. If this is not the case contact the transport

company immediately (within 48h)

Verify the correct voltage of the nameplate and make sure it is in accordance with the local power supply.

In case of any flaw or anomaly detected, please contact HITECSA.

RIGGING

Before moving the unit make sure that all the panels are fixed correctly.

Raise and set down the equipment carefully.

Do not tilt the unit more than 15 degrees during transportation, (Pict. 2).

Always transport the unit in its original packaging to the place of installation.

All units come with a particular rigging diagram of that model similar to the one shown below. Be sure to hoist the

machine through the points indicated in the diagram.

Make sure that the unit is balanced, stable and without any deformations when it is lifted.

STORAGE

If the equipment is going to be stored before the installation, please follow the instructions below in order to avoid damages,

corrosion or deterioration:

Move it carefully.

Do not place the machine in places exposed to ambient temperatures above 50ºC and preferably keep the unit away

from direct sunlight.

Avoid placing the unit with plastic wrapping protection under the sun as the pressure of the circuits could assume

values that could lead to the intervention of the safety valves.

In addition, when cooling, water condensation occurs inside the machine and the plastic wrap.

Avoid placing other objects on top of the unit (unless it is done within the limits of the overlap planes indicated on the

packaging, etc. Follow these indications).

Avoid prolonged storage before installation, water penetration, dust and objects in general due to invasion or

biological, meteorological and/or human impacts.

Minimum storage temperature: 5ºC.

Maximum relative humidity: 90%.

The warranty will not cover any damage caused by frozen water.

WARNING

Fig. 1

Fig. 2

11

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

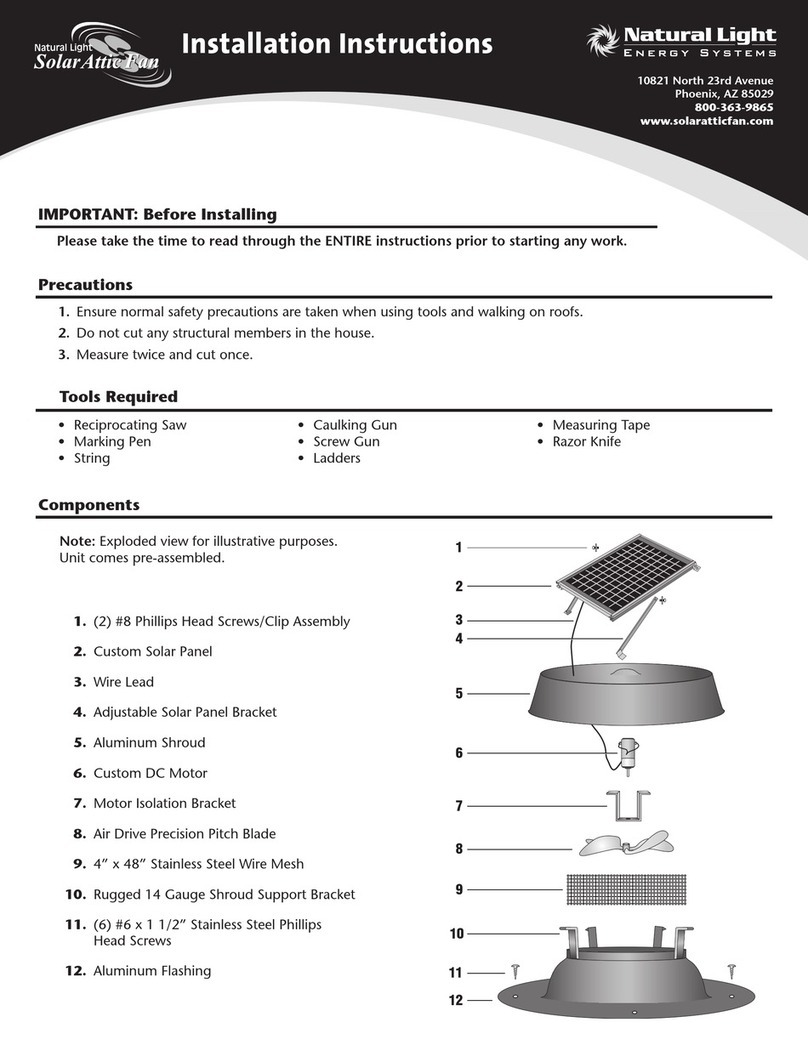

SERVICE AREA (mm)

Make sure you respect the following measurements for the correct operation of the unit.

WEIGHT DISTRIBUTION (kg)

MODEL

1

2

3

4

Total

401

41

41

41

42

165

1201

128

128

129

130

515

4002

262

262

268

268

1060

(3 –4): Electrical box side

12

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

DIMENSIONS

Model 401

Model 1201

Legend:

1. Water outlet

2. Water inlet

3. 3/4” MPT drain

4. Electrical connections

5.

Connection for pressure operated water valve

Legend:

1. Water outlet

2. Water inlet

3. 3/4” MPT drain

4. Electrical connections

5. Connection for pressure operated water valve

6. Main switch

13

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

DIMENSIONS

Model 4002

Legend:

1. Water outlet

2. Water inlet

3. 3/4” MPT drain

4. Electrical connections

5. Pressure operated water valve connection

6. Main switch

14

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

INSTALLATION SITE

Consult and respect the rules and local regulations which regulate the installation of air conditioning systems.

Choose a site without dust and debris.

Respect the appropriate service area for the equipment that is to be installed.

Verify that the ground or structure on which the unit will be installed is able to support its weight in operation.

Fit shock absorbers throughout the installation to prevent the transmission of noise and vibration.

Check that the direction of the sound level is not going to disturb anyone.

UNIT SETTLEMENT

Make sure that the equipment is levelled correctly.

The bed frame shall be strong enough to support the unit weight.

Verify that the drains are working properly.

Use shock-absorbers for installation.

The manufacturer’s warranty will not cover any refrigerant leakage caused by deterioration due to vibrations if the

shock-absorbers have not been installed correctly between the floor/base stand and the unit.

DRAIN

All the drains are provided with a 3/4” male gas connection (MPT).

The diameter of the condensate drain pipe shall be equal or larger than the unit connection depending on the line

length and the building configuration.

The drainage line shall have a slope of not less than 2% to guarantee thecorrect evacuation of the condensate water.

When the drain line is exposed to air temperatures below 0 degrees, thermal insulation or electrical heating wires

shall be used to prevent the water from freezing and avoid the possible following tube damages.

Install a siphon with the appropriate dimensions (refer to drawing).

ELECTRICAL INSTALLATION

The unit power supply shall be within the 10% of voltage value indicated on the unit nameplate. The Hitecsa warranty

will not cover any damage caused by the start-up of the unit with an incorrect voltage.

Always refer to the unit wiring diagram when completing electrical connections.

The electrical wiring connections and the line protection devices must be installed by the installer according to the

current local laws.

The interconnecting wires shall be protected by a tube or an electrical cable conduit, cable tray, etc.

Turn the main power switch off before starting any type of operation.

WARNING!

Recommended dimensions

15

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

WATER INSTALLATION

The selection and installation of the components of the installation must be carried out by a qualified installer, respecting

the current legislation at the place of work and rules of good practice.

Make sure that you are aware of all the local rules and regulations for hydraulic installations and that you comply with

them.

The design and calculation of pipes shall be carried out in such a way that the pressure drop of the installation never

exceeds that which can overcome the pump built into the unit. In addition, a poor design of the pressure drop of the

branch pipes that go to the indoor units can cause the malfunction of some of them.

Proceed to the installation of a water filter that is provided with an inner net to retain the particles with a maximum

diameter of 0.5 mm.

A proper maintenance of the filter and the flow switch at an appropriate periodicity shall be completed to avoid deposits

that could block them.

Comply with the stated indications regarding the water inlet and outlet of the unit and install a by-pass valve if necessary.

Water filling

Use water at around 20ºC to fill the hydraulic circuit. After the system has been drained, the pressure level must be as

stated in the installation projector according to the pressure level of the main installation. In case when the water installation

of the unit is going to be added to an existing water installation, the main installation probably will comprise a filling system

already.

Attention: An expansion tank with a bigger capacity will be required according to the filled water volume.

Purging

Verify that all the high points of the installation are provided with a bleed valve.

Operate the pump during one minute and stop it. Wait for one minute more and repeat the same process until there is no

more air in the system. 5 to 10 operations may be necessary.

Remember to drain any other components that include tubes where there might be air pockets (example: differential

switch). They will not work properly with air.

Air in the circuit will produce noises, will entail a lower water flow and a bad performance of the exchanger, etc…

Risk of frost

If the unit or the water installation are exposed to temperatures below 5°C it is necessary to take the appropriate measures

against the risk of frost (Please refer to the Safety Precautions section).

For example:

Mix the water of the installation with glycol.

Protect the pipes with heating cables placed under the insulation lining.

Empty the installation and control at the same time that there are no:

- Closed valves that may retain water even after draining the installation.

- Low spots where water may stagnate even after draining; if necessary proceed to blowing the installation.

Glycol additions

Keep in mind that the use of glycol solutions increases the pressure drop.

Make sure that the type of glycol you will use is compatible with hydraulic circuit components (pumps, filters, etc.) and that

it is a non-corrosive product.

GLYCOL ADDITION to WATER (%)

TARGET FREEZING TEMPERATURE

0ºC

-2ºC

-5ºC

-10ºC

-15ºC

-20ºC

-25ºC

-30ºC

ETHYLENE GLYCOL

0%

6%

14%

24%

31%

36%

41%

45%

PROPYLENE GLYCOL

0%

7%

15%

25%

33%

39%

44%

48%

Make sure that the freezing temperature is lower than the minimum temperature that the water may reach keeping a

security margin even when the unit is Off.

16

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

HYDRAULIC CIRCUIT AND ITS COMPONENTS

The most delicatecomponent of the hydraulic circuit isthe plate exchanger. Therefore itis important thatthe units equipped

with plate exchangers operate in an open hydraulic circuit or a thermal loop within the control values as stated in the below

chart. If the Langelier rate is exceeded (lower or higher), the water may become corrosive or incrusting which would

jeopardise the equipment and thus cancel the warranty. In that case it is necessary to use a special exchanger specially

designed for the available water quality.

The units that are equipped with a plate exchanger can operate in an open hydraulic circuit or in a thermal loop provided

that the water quality matches the control values of the following chart.

Contents in water

Concentration mg/l

If higher values

If lower values

Suspended solids

Variable

Possible erosion of the material

No detection of effects

Conductivity

≤ 500 µs/cm

No detection of effects

-

> 500 µs/cm

-

Not recommended

NH3

between 2 and 20

Not recommended

No detection of effects

Chlorides

≤ 300

-

No detection of effects

> 300

Corrosion

-

Iron

≤ 10

No detection of effects

-

> 10

-

Corrosion

Carbonic acids

between 20 and 50

Corrosion

Not recommended

PH

between 6 and 9

Incrusting

No detection of effects

Sulphates

between 70 and 300

Corrosion

No detection of effects

Langelier

between -0,5 and +0,5

Water with a tendency to creating incrustation

Agua that tends to be corrosive

Shut-off valves

Installed at the inlet and the outlet of each component, they allow to carry out the maintenance operations without having

to empty the installation.

Thermometers and pressure gauges

Installed at the inlet and the outlet of the main elements. They make maintenance and control operations easier.

Air release valves

Installed at the highest points of the installation. They enable air drainage of the circuit.

Drainage valves

Install them at all the low points to empty the circuit.

Supports

The weight of the pipes must not be supported by the connections of the unit. Therefore supporting brides shall be used.

Expansion vessel

The expansion vessels maintains the correct pressure in the installation. We recommend you to fill at 2.15 bar when the

water temperature varies from cold to heat and the other way round. The expansion vessel has to be dimensioned

according to the water volume in the installation.

Be careful that it might be necessary to install a bigger expansion vessel or additional expansion vessels even if the unit

already is equipped with one.

Security devices

The installation of the following safety devices is MANDATORY when they ARE NOT included as standard features.

Likewise it is mandatory to control that they work correctly and to maintain them. Not complying with this condition will

entail the LOSS OF WARRANTY.

Water filter

Fitted at the water inlet of the unit to protect the heat exchanger or other critical components from obstructions and/or

clogging.

Flow switch

This device protects the plate heat exchanger from breaking in case of insufficient water flow. This situation would

make the equipment inoperative.

17

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

HYDRAULIC CIRCUIT AND ITS COMPONENTS

Differential pressure switch

We will use it along with the flow switch and both devices will be redundant. Their function is similar: they protect the plate

exchanger from breakage. Air pockets may be generated after filling the circuit with water. We will have to make sure that

there is no air to guarantee that this component works properly: we will proceed to purging by loosening the nuts of the

tubes (please see below, 1.).

Any damage to the plate exchange caused by accumulated air in the pressure switch that prevented it from working

correctly will not be covered by the warranty.

Regulating devices

Condenser water regulating valve

The regulating valve controls the condensation pressure mechanically by preventing that it decreases when the water

temperature is too cold. For that it closes the water flow proportionally.

The regulating valves shall be adjusted if that was not made from factory. For that use the valve stem or the control stick

depending on the model.

The inlet water temperature shall be below 26°C to adjust the regulating valve. We will adjust it so that the condensation

pressure is at 23 bars.

1. Loosen until water comes out and

tighten the nuts again.

18

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

HYDRAULIC DIAGRAM

It is compulsory to mount the flow switch at the water outlet of the unit. The water flow shall be laminar to make sure that

the flow switch works properly: Install the flow switch on a straight section of the tube where there is no section change. The

distance to the switch shall be minimum 6 times the diameter (D) of the tube and at the outlet there shall be a distance of

minimum 3 times the diameter of the tube. Do not install any other component or accessory on that tube. If you use a flow

switch from another supplier (not delivered by Hitecsa), refer to the instructions of the producer and respect the dimensions

as previously stated.

Mesh filter

Flap

3

4

7

8

11

12

Condensate water

drain

Dry tower

Automatic purging

Manometer

Circulation pump

15

Flow switch

1

2

5

6

9

10

Unit

Air duct

Shut-off valve

Water line

Thermometer

13

14

Drain

Buffer tank

WARNING!

19

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

HYDRAULIC CONNECTIONS WITH WATER PRESSURE REGULATING VALVE

(OPTION)

Mount the by-pass solenoid valve with the optional water pressure regulating valve on Heat pump units.

1. Anti-vibration flexible connection

2. Shut-off valve

3. Water pressure

regulating valve

4. ON/OFF solenoid valve (Bypass)

5. Flow switch

6. Mesh filter

7. Condensate water drain / Evacuation

8. ON/OFF solenoid valve with the

compressor

9. Manometer

10. Evacuation valve

NOTE: Connect the water pressure regulating valve tothe high pressureintake ofthe unit. The drawingshows the heat pump connections.

Do not install the solenoid valve on cooling only units. When installing a water pressure regulating valve it is mandatory to set a

timer for the flow switch at the compressor start-up during 1 minute to let that valve operate.

20

IOM_WPVBZ HE-WPVZ HE_401-1201-4002_208110_200901_EN

PACKAGED COMPACT VERTICAL –WATER / AIR

WPVBZ HE / WPVZ HE

INSTALLATION

ELECTRICAL CONNECTIONS

1. Main power supply :

* 091- 251 Single phase (phase +

Neutral)

** 351-1201 Three-phase + Neutral

2. Ground

3. Time delay fuses or Curve D thermal

circuit breaker.

4. Main switch

5. Th TUNE controller

Connection of thermostats

Th-TUNE CONNECTION:

- Two 230 VAC (L+N) power cables

- One twisted and shielded pair AWG 20/22 with a

drain wire to GND.

- If the “Cn” message does not disappear from the

TH-Tune display, it means that communication

between the thermostat and the control board has

failed (possible reasons: wrong connection to the

terminals, the “Rx/Tx+” and the “Rx/Tx-“ cables

have been swapped; the connection has been

made through the wrong connector; etc…).

Proceed to verifying the cable connection and

make sure that they are connected to the right

terminals.

pGD CONNECTION (Option):

- Connection to pGD with 6-wire telephone cable, for

lines longer than 50m intercalate with TCONN (4

wires twisted and shielded, see diagram).

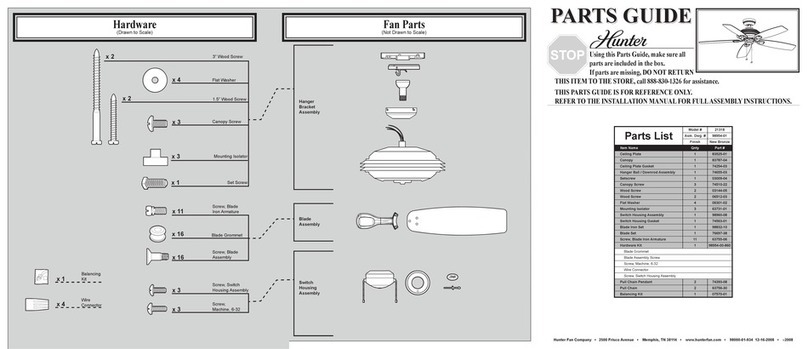

This manual suits for next models

4

Table of contents

Other Hitecsa Fan manuals

Popular Fan manuals by other brands

Maxim

Maxim 60002SN Installation and safety instructions

aldes

aldes EasyHOME Auto Compact CLASSIC Series Installation and maintenance instructions

Hunter

Hunter F-7508 owner's guide

Hunter

Hunter Captiva 21318 Parts guide

Ebmpapst

Ebmpapst D3G160-LV13-30 operating instructions

Prem-I-Air

Prem-I-Air EH1698 user manual