IN 1830 Charles Portway built a stove to heat his ironmongery shop at Halstead in Essex. It was so good that his neighbours

started asking for them. Mr Portway had done something completely new designed his stoves right from the start to give out

the maximum heat from the minimum fuel, so that he is known as "The Founding Father of Energy Efficiency". The stoves

that bear his name are still made in Britain by the direct successors of the company he established.

Building regulations are available at www.soliftec.com

INST LLING a stove is a 'controlled service', the law expects that it is

either supervised by a qualified installer or that the building inspector is

informed. Check with your local authority.

SBESTOS: Your stove does not contain asbestos, but take care to

avoid disturbing asbestos in an old installation.

WEIGHT: Your stove is heavy - take great care when moving it and

ensure that the intended fireplace can support the weight- consider

fitting a load distributing plate.

YOUR CHIMNEY, by becoming warm, makes the gas inside it rise,

pulling fresh air into the stove to make it work. It must:

●Generate a draught in use of at least 12Pa (0.05ins wg)

●Be capable of withstanding the temperatures generated.

●Be absolutely incapable of leaking fumes into the dwelling

This may commonly be achieved by it:

●Being at least 5m high.

●Terminating at least 1m above any roof ridge.

●Having an internal cross-section equivalent to not less than

150mm diameter, and never more than 0.14m² (eg 375 x 375mm)

●Being free from even the slightest crack or source of leakage.

●Having no bends sharper than 45º.

●Being swept and entirely free of obstructions

●Being connected only to this one appliance.

●Being of thick masonry or otherwise adequately insulated.

●Conforming to local building regulations.

Special rules apply where the flue passes through timber, thatch or

other vulnerable materials- take specialist advice.

Although it is possible to access the chimney through the fire with the

baffle removed, fit hatches to provide access if needed.

YOUR FIREPL CE: Stoves become VERY hot, the setting must be

made entirely of durable fireproof materials. Thin (<50mm) stone slabs

risk cracking unless cut into sections to allow for expansion and

backed with a heat resistant concrete. Even beyond the safety

clearance items can still become very hot - take great care in siting

wax, paper etc. Inset convector stoves deliver very hot air into the

room, so that the 350mm clearance above to combustible materials

must be strictly observed.

FRONT HE RTH: To guard against fallen embers and protect against

fire we recommend a solid non-combustible hearth, which may simply

be an area of solid flooring, extending at least 300mm in front of the

appliance, no matter at what height the stove is fitted.

IR SUPPLY: Your stove needs air to breathe - there must be a

permanent fresh air supply to the stove, provided either by:

(1) AIR SUPPLY FROM OUTSIDE THE BUILDING:

Remove the rear air port and fit connector and 75mm flexi air supply

tube direct to outside. Make sure the inlet can't be blocked by snow,

rodents, etc.

(2) AIR SUPPLY IN THE ROOM:

Remove the front air port. There should be an air supply from outside

the building into the room in which the stove is installed equal to about

550mm² for each kW of output. This can often be provided by air

leaking around door frames etc. (it is commonly accepted that this

alone may suffice for appliances <c.5kW) but in any case of doubt, fit a

purpose-made air vent. An extractor fan, or another fuel-using

appliance in the same building, can remove this air.

FITTING

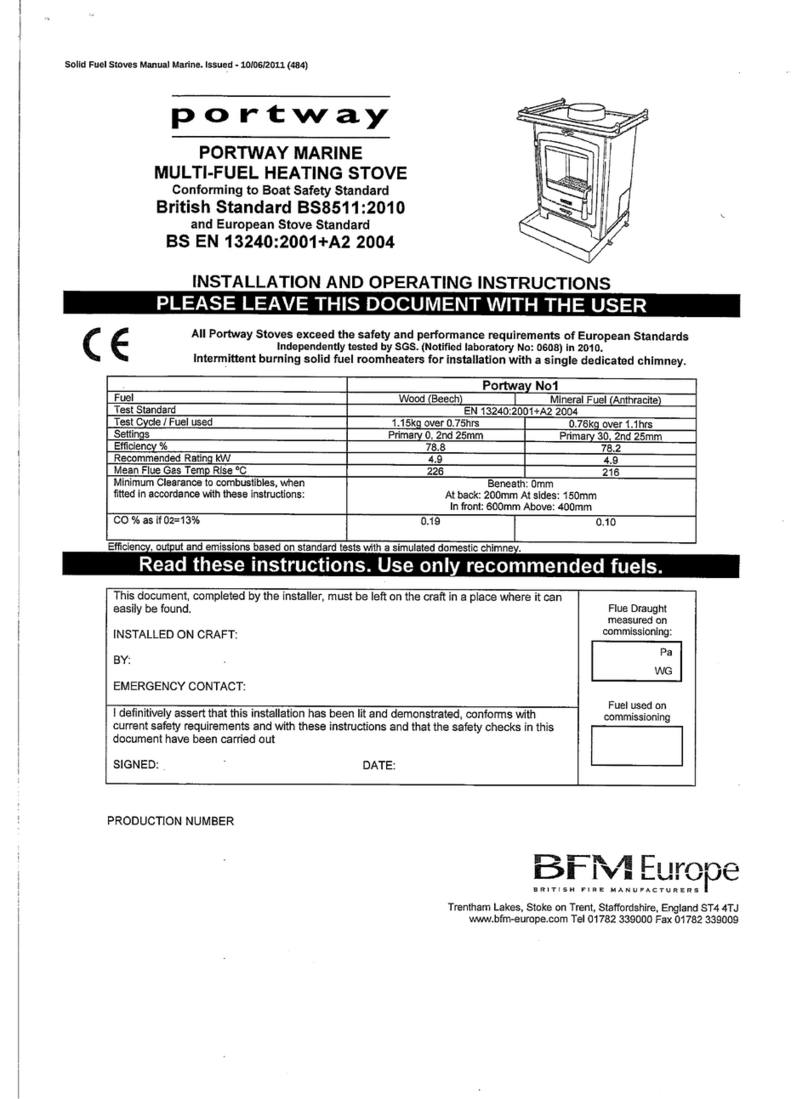

The stove must be fixed down to the solid hearth through the two points under the base insulation panels. It may be connected to the chimney

flue in many different ways, three of which are shown here. If required, the lower frame bar ('LFB') may be removed.

◄ 'FREE INSET' or 'CASSETTE'

METHOD (3):

The stove is fitted inside a hollow chimney

breast which is ventilated to the room at

high and low levels, creating extra hot air

circulation. The stove flue is connected to

the chimney using up to 1.5m of

uninsulated flue pipe.

CONVECTION

This Portway stove is not just a

'firefront' or a simple 'inset stove',

but a genuine hot-air convector

fire. It has a very precisely

shaped, sealed chamber,

behind, above and underneath

the fire to collect heat and

naturally force a stream of

extremely hot air into the room,

to evenly heat every corner.

'FIREPLACE SEAL' METHOD (4): ►

Fix the stove and, through the flue outlet,

fill any gap behind with vermiculite

granules topped with mortar. Carefully

check that the fire has an absolutely

airtight seal against the fireplace.

'CHIMNEY SEAL' METHOD (5): ►

Remove the round connector. Fit the flue

pipe, or flexible liner with a 150mm

adaptor, into the chimney and seal its

loose end to the round connector with fire

cement. Fix the stove. Bolt the connector

and pipe back in place from inside. Check

that the pipe forms a clear route from stove

to chimney terminal with no leaks into the

masonry space.

Whichever method is used it is imperative that: (1) The route for gases from the stove to the chimney terminal is completely air-tight; even the

tiniest gap or crack can spoil the updraught. Seal all joins with fireproof cement and/or heatproof rope. (2) It is possible to sweep the entire

length- access doors may be required. (3) The entire construction is of durable fireproof materials. (4) Fit a CO alarm!

2

present. The installer is required to EX CTLY follow

local, national and international standards.