Drive User Guide

2

Contexts

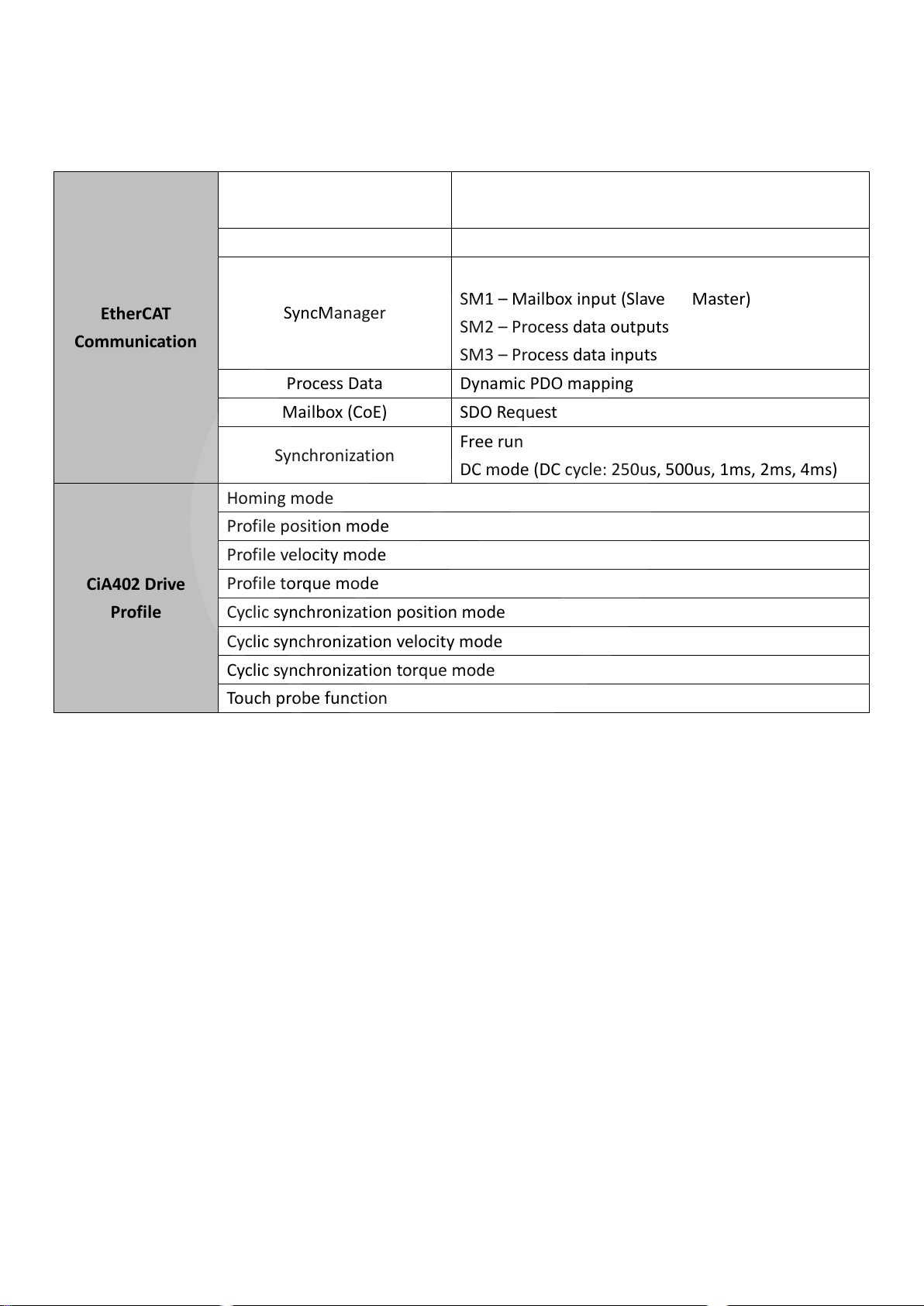

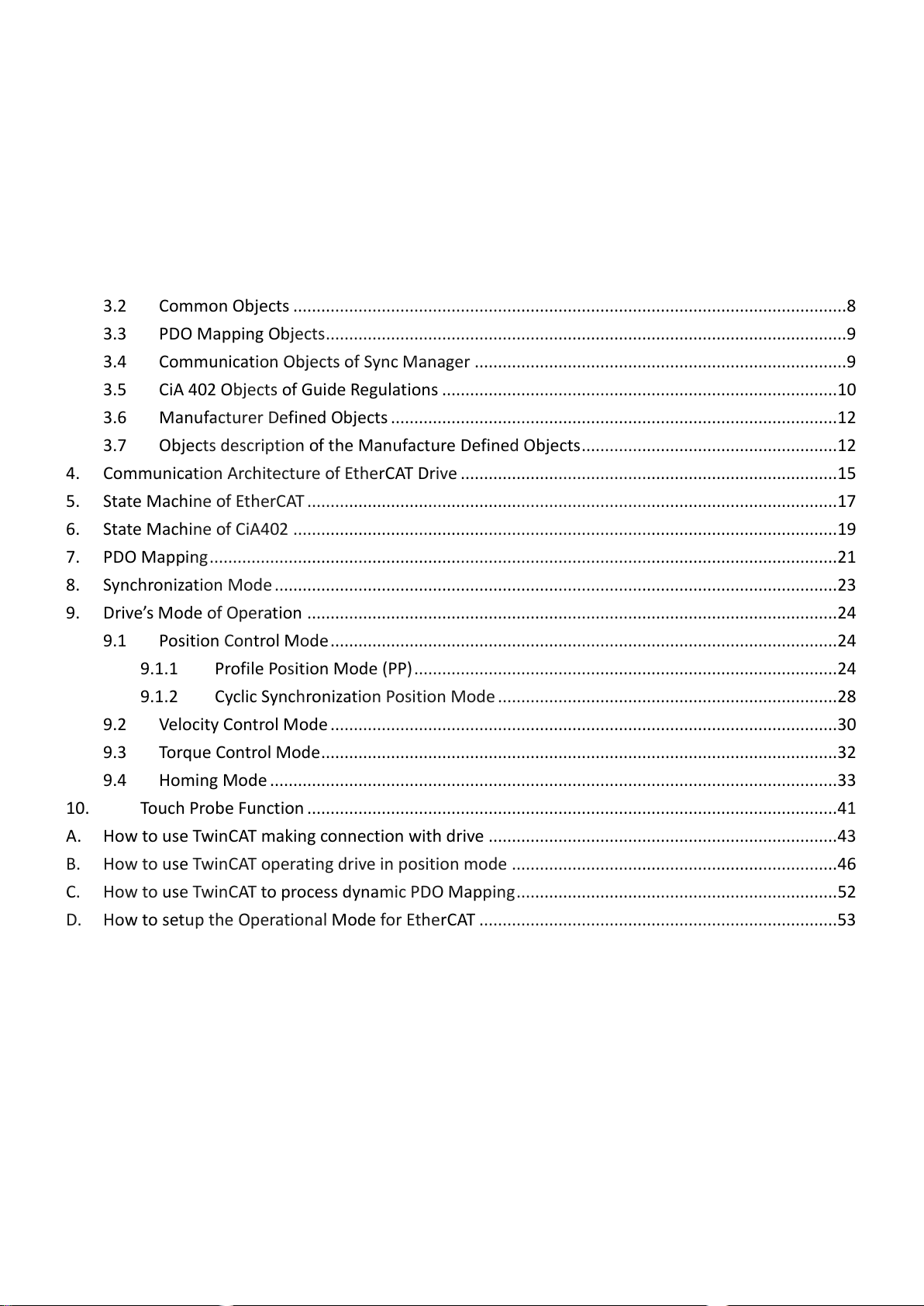

1. Communication Specification of EtherCAT ............................................................................................4

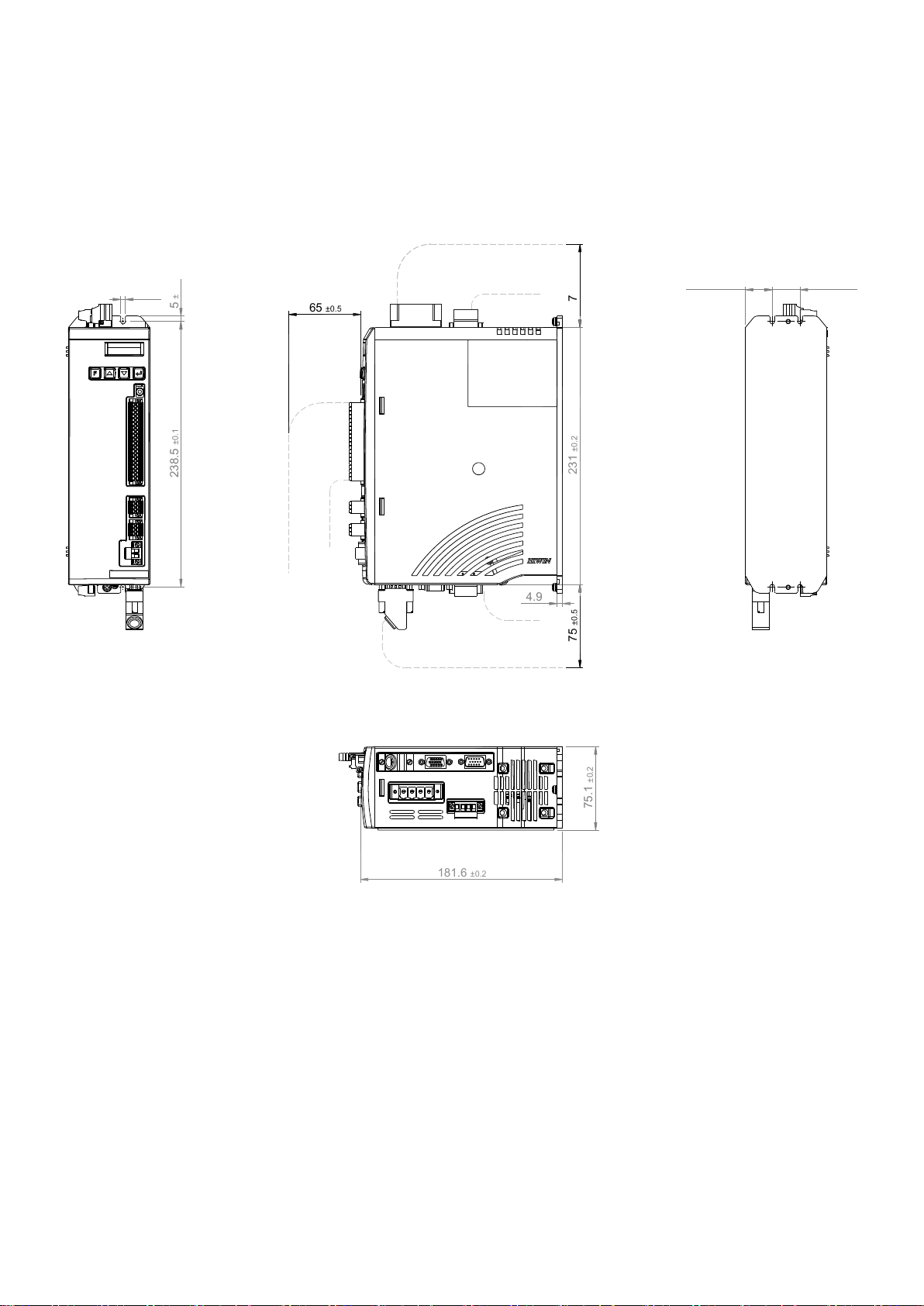

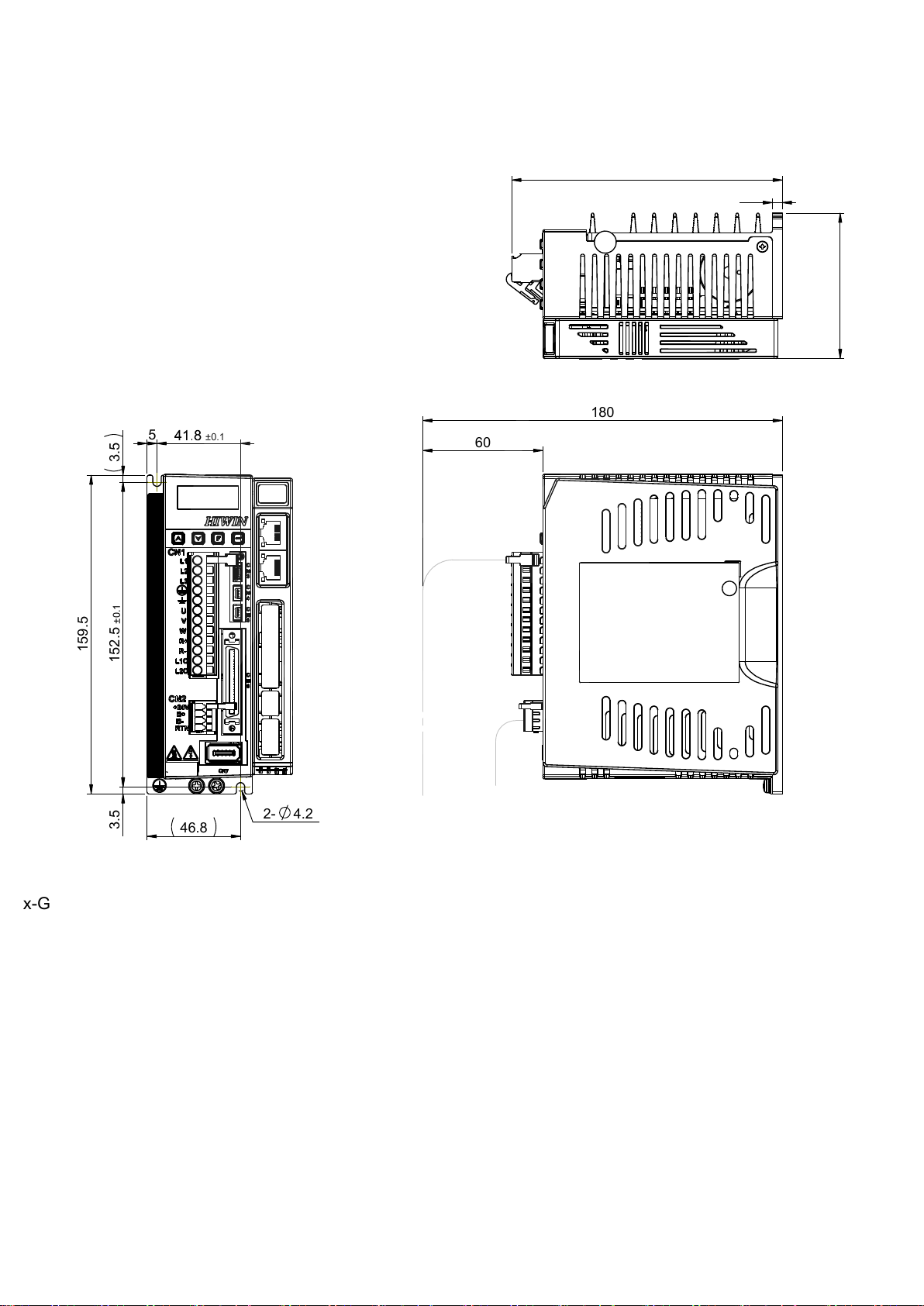

2. Physical Dimensions...............................................................................................................................5

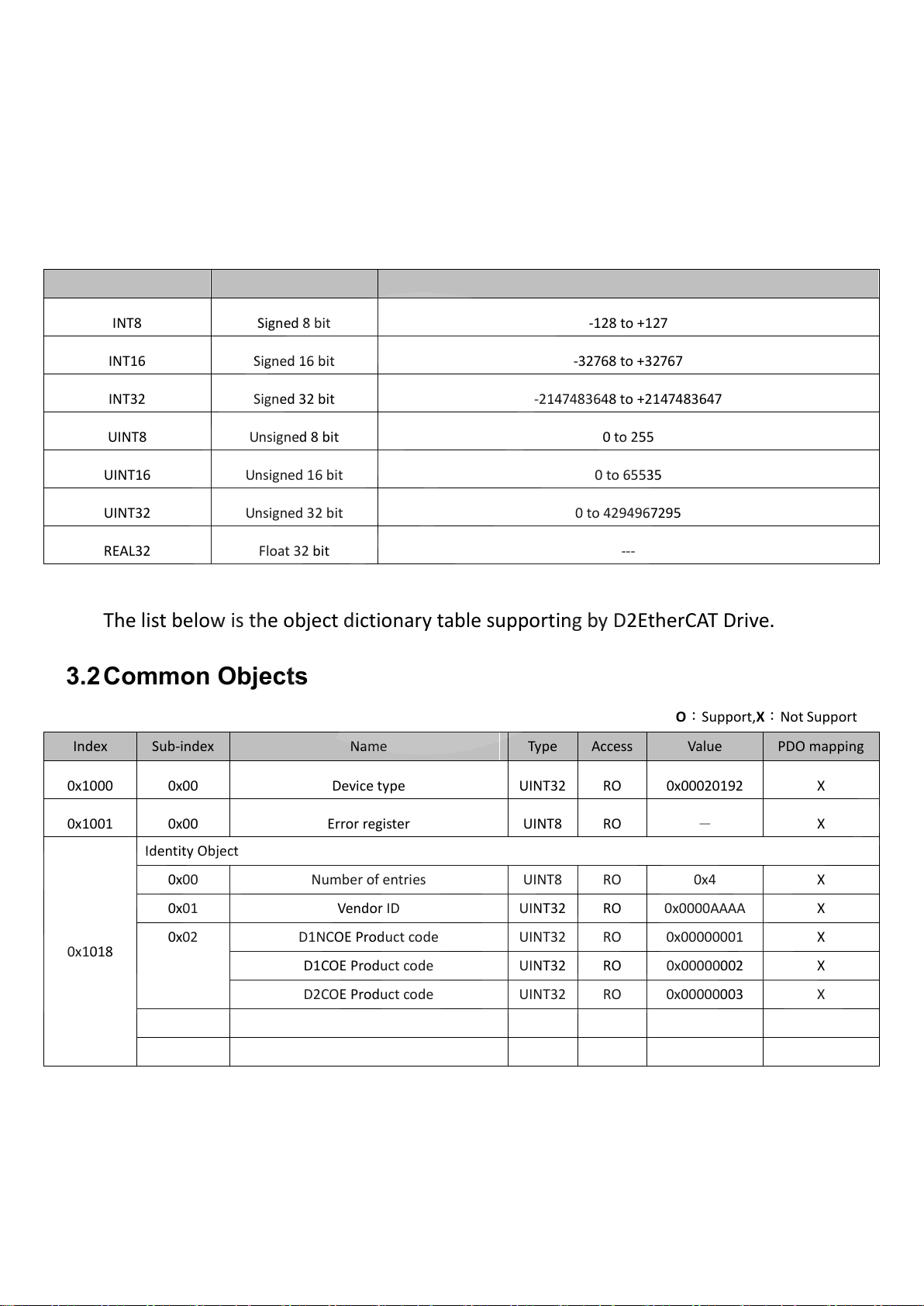

3. Object Dictionary Table..........................................................................................................................8

3.1 Data Type ...................................................................................................................................8

3.2 Common Objects .......................................................................................................................8

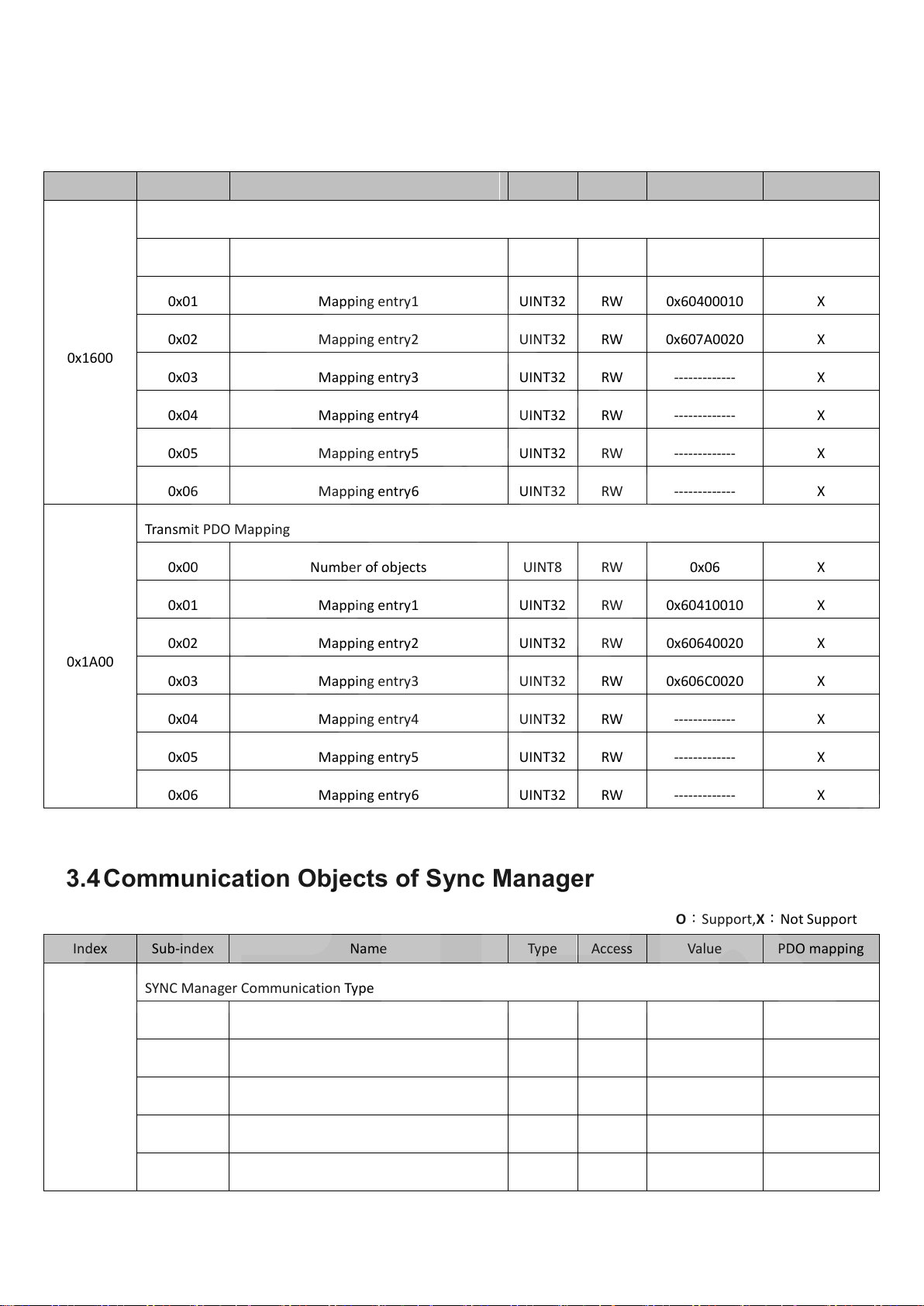

3.3 PDO Mapping Objects................................................................................................................9

3.4 Communication Objects of Sync Manager ................................................................................9

3.5 CiA 402 Objects of Guide Regulations .....................................................................................10

3.6 Manufacturer Defined Objects ................................................................................................12

3.7 Objects description of the Manufacture Defined Objects.......................................................12

4. Communication Architecture of EtherCAT Drive .................................................................................15

5. State Machine of EtherCAT ..................................................................................................................17

6. State Machine of CiA402 .....................................................................................................................19

7. PDO Mapping.......................................................................................................................................21

8. Synchronization Mode.........................................................................................................................23

9. Drive’s Mode of Operation ..................................................................................................................24

9.1 Position Control Mode.............................................................................................................24

9.1.1 Profile Position Mode (PP)...........................................................................................24

9.1.2 Cyclic Synchronization Position Mode .........................................................................28

9.2 Velocity Control Mode .............................................................................................................30

9.3 Torque Control Mode...............................................................................................................32

9.4 Homing Mode ..........................................................................................................................33

10. Touch Probe Function ..................................................................................................................41

A. How to use TwinCAT making connection with drive ...........................................................................43

B. How to use TwinCAT operating drive in position mode ......................................................................46

C. How to use TwinCAT to process dynamic PDO Mapping.....................................................................52

D. How to setup the Operational Mode for EtherCAT .............................................................................53

www.servosystem.ru +7(495) 407-01-02