3

Introduction � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

California Proposition 65 . . . . . . . . . . . . . . . . . . .5

General Information � � � � � � � � � � � � � � � � � � � � 5

Serial Number Location � � � � � � � � � � � � � � � � � 5

Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . .6

Accident Prevention . . . . . . . . . . . . . . . . . . . . . . .7

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Training . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operation Safety. . . . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . .9

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Hydraulic Safety . . . . . . . . . . . . . . . . . . . . . . . . .10

Safe Work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

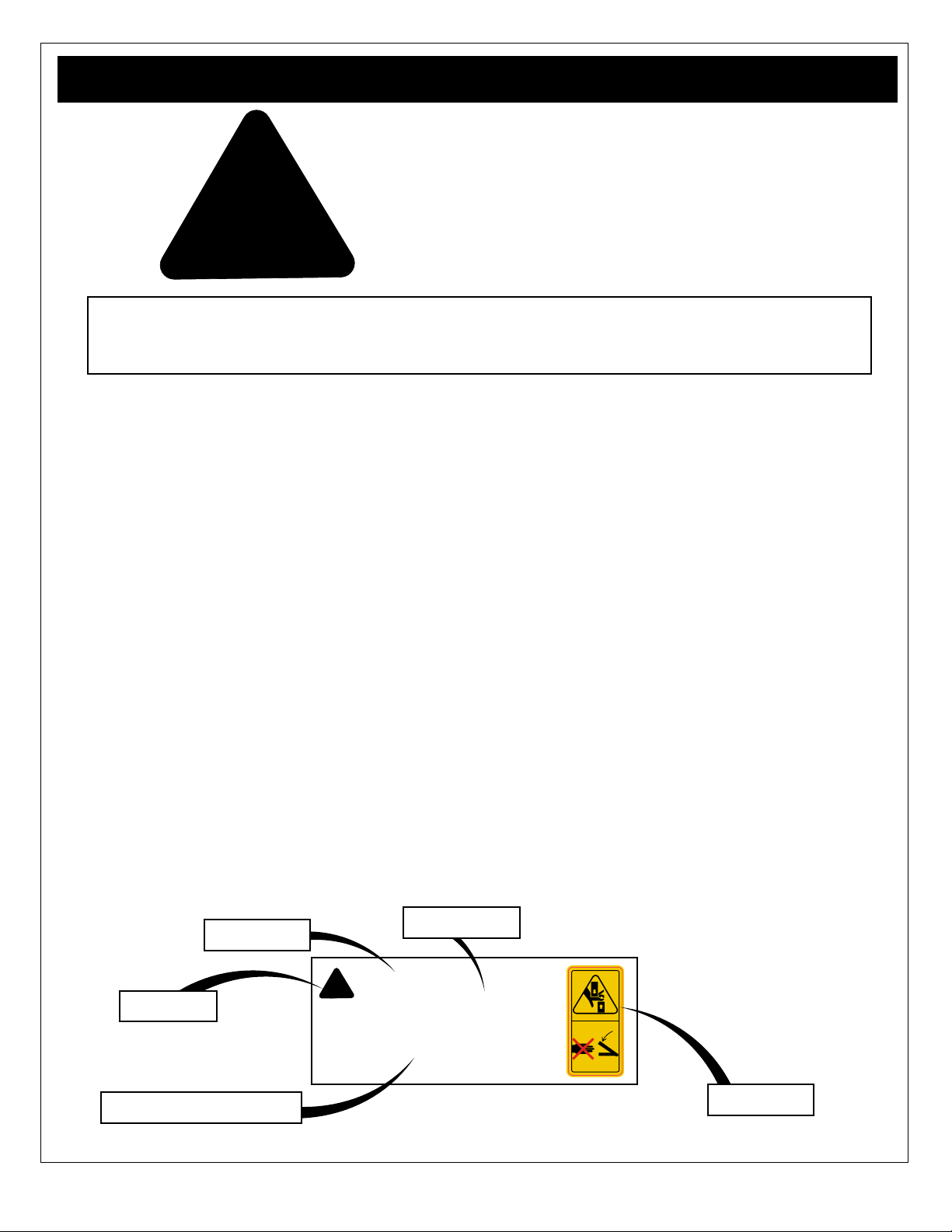

Safety Labels � � � � � � � � � � � � � � � � � � � � � � � � � 11

Safety Label Descriptions. . . . . . . . . . . . . . . . . . 11

If labels need to be replaced: . . . . . . . . . . . . . . . 11

Safety Label Layout . . . . . . . . . . . . . . . . . . . . . .12

� � � � � � � � � � 13

. . . . . . . . . . . . . . . . . . . . . . . . . . .13

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Inspection� � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

Components and Features � � � � � � � � � � � � � 15

BK Series Bale Knife Components. . . . . . . . . . .15

Product Features . . . . . . . . . . . . . . . . . . . . . . . .16

Bumper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wrap Undresser . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wrap Grabber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Kverneland Tines . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardened Cutting Knives . . . . . . . . . . . . . . . . . . . . 17

Initial Setup � � � � � � � � � � � � � � � � � � � � � � � � � � 18

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Mount the Bale Knife . . . . . . . . . . . . . . . . . . . . .19

Remove Shipping Clamps . . . . . . . . . . . . . . . . . . . 19

Adjust the Bumper (BK60 & 72 only) . . . . . . . . .19

Adjust the Undresser . . . . . . . . . . . . . . . . . . . . .20

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Field Operation � � � � � � � � � � � � � � � � � � � � � � 21

Operation Safety Checklist . . . . . . . . . . . . . . . . .21

Prepare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Mount the Blade Knife . . . . . . . . . . . . . . . . . . . .22

Quick Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Bale Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Feeding the Bale . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Storage Safety Checklist . . . . . . . . . . . . . . . . . .24

Placing in Storage: . . . . . . . . . . . . . . . . . . . . . . .24

Service & Maintenance � � � � � � � � � � � � � � � � 25

Maintenance Safety Checklist . . . . . . . . . . . . . .25

General Maintenance . . . . . . . . . . . . . . . . . . . . .25

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Lubrication: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Grease: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cutting Knives: . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sharpening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Kverneland Tines: . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bolt Torque Table . . . . . . . . . . . . . . . . . . . . . . . .28

Trouble Shooting � � � � � � � � � � � � � � � � � � � � � 29

Accessories � � � � � � � � � � � � � � � � � � � � � � � � � 30

Index � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 31