児ҥ

These instructions are for your safety. Read them thoroughly & carefully.

This Safety Alert Symbol indicates important messages in this manual. When you

see this symbol, carefully read the message that follows and be alert to the

possibility of personal injury.

Remember: The operator is responsible for

a oiding dangers or accidents.

Always make sure long hair is not left down when

ser icing and/or operating the machine. Make sure hair

is out of the way of any mo ing parts or pinch points.

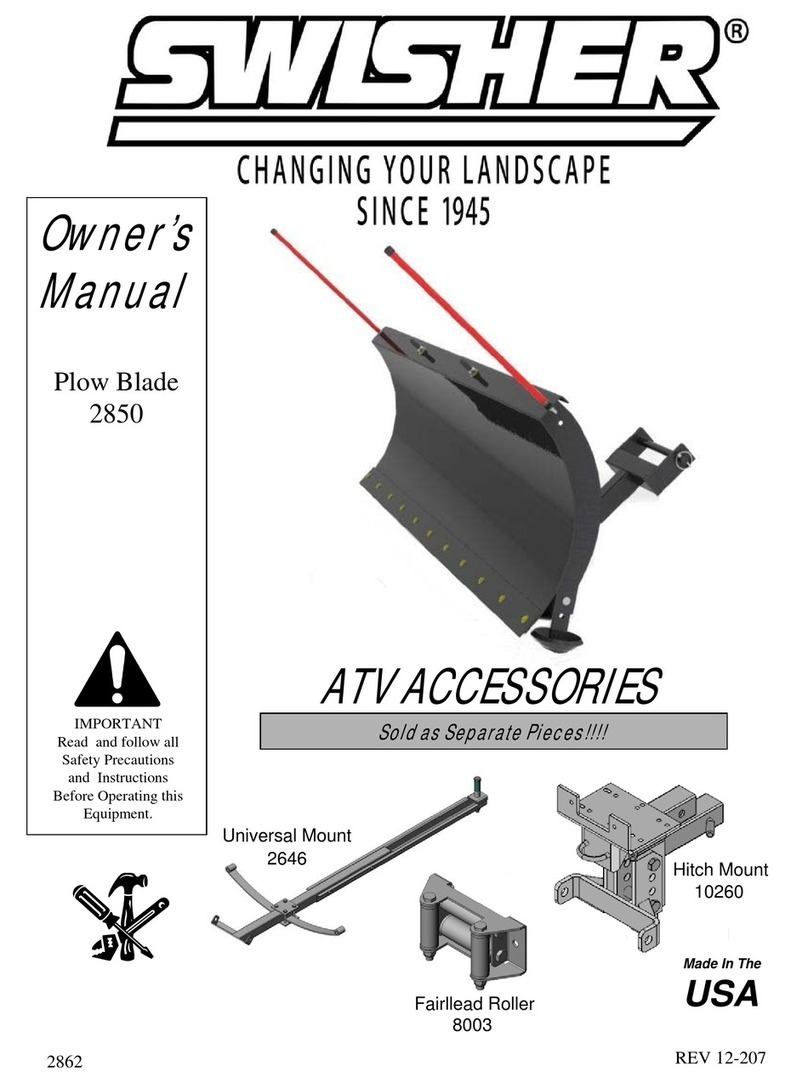

Inspect the attachment and tractor before each use.

Make sure all hardware is in place and tightened

properly.

Make sure this attachment is in good operating

condition and properly connected and secured.

Ne er use the machine when barefoot. Always wear

protecti e shoes or boots.

Always wear protecti e glasses or full isor and hearing

protection when assembling or operating.

Ne er wear loose clothing that can get caught in

mo ing parts.

Check that any safety or informational decals are in

place and legible. Replace any damaged decals.

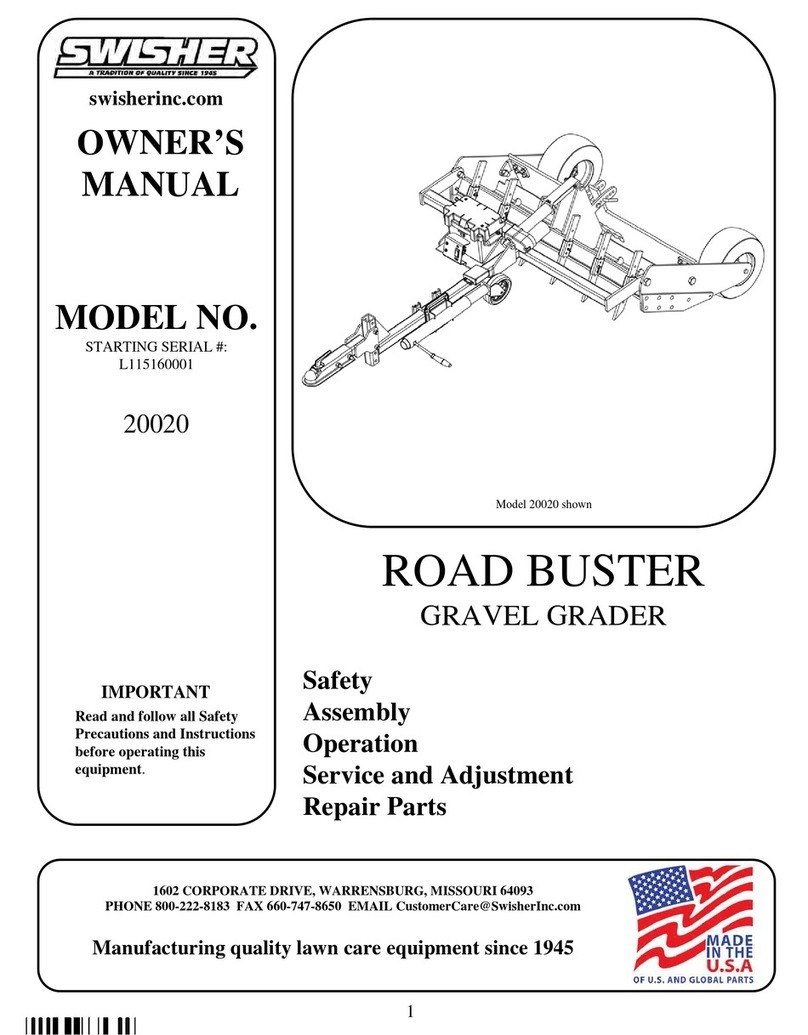

Slope Operation:

Inspect the area and remo e obstacles such as stones,

tree branches, etc.

With walk behind machines, operate across slopes, not

up and down.

Ne er dri e the machine on terrain that slopes more

than 15 degrees.

A oid starting or stopping on a slope. If the tires begin

to slip, dri e slowly straight down the slope.

Always dri e e enly and slowly on slopes.

Do not make sudden changes in speed or direction.

A oid unnecessary turns on slopes. If it becomes

necessary, turn slowly and gradually downward if

possible.

Watch for holes, ruts or bumps. On une en terrain, the

machine can tip more easily. Deep snow or other debris

can hide obstacles.

Dri e slowly and use small mo ements of the steering

controls.

Do not plow snow or ice co ered slopes. It is slippery,

and the tires can lose their traction, allowing the

machine to slide down the slope.

Safety instructions continue on next page….

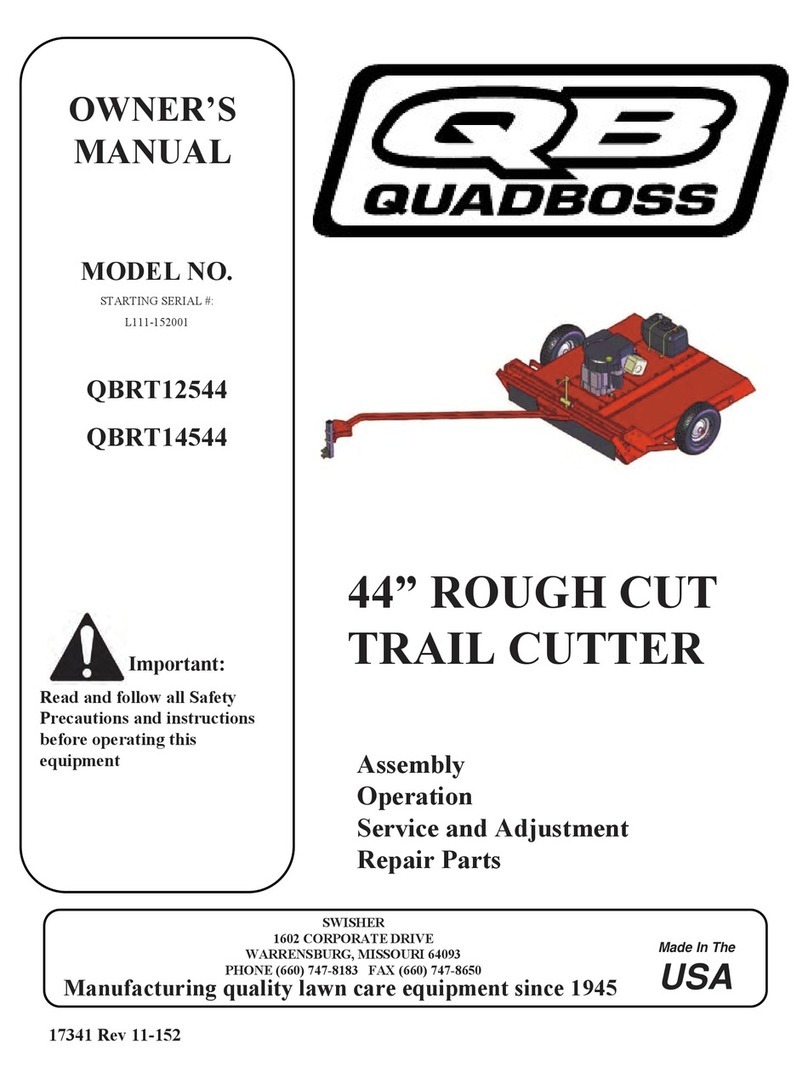

General Use:

Read all instructions in this operator’s manual and on

the machine before starting it. Ensure that you

understand them and then abide by them. Be prepared

to stop the engine quickly in an emergency.

Learn how to use the machine, operate its controls

safely, how to stop quickly and recognize safety decals.

Only allow the machine to be used by adults who are

familiar with its use and operation. If there are any

questions about safety do not operate or allow others

to operate this machine.

Make sure nobody else is in the area of the machine

when you start the engine, engage the dri e or operate

the machine.

Stop the machine if someone enters the work area.

Clear the area of any objects such as stones, toys, etc.

that may be struck by the plow.

DO NOT use this machine without the Guards or Belt

Co ers in place.

Stop the engine and disconnect the spark plug before

performing maintenance checks.

Ne er attempt to inspect the PTO shaft with the engine

running and always remo e the ignition key and spark

plug wires before clearing debris.

Ne er take passengers. The machine is only intended

for use by one person.

Always look around before and during re ersing

maneu ers.

Slow down before turning.

Be careful when rounding fixed obstacles.

Keep the machine a safe distance from holes or other

irregularities in the ground.

Ne er use the machine if you are tired, if you ha e

consumed alcohol or if you are taking other drugs or

medications that can affect your ision, judgment or

coordination.

Beware of traffic and pedestrians when working near or

crossing roads, walkways, or parking lots.

Ne er lea e the machine unsuper ised with the engine

running.

Always disengage the blades, engage the parking

brake, stop the engine and remo e the ignition key

before lea ing the machine.

Ne er allow children or other persons not trained in the

use of the machine to use or ser ice it. Local laws may

regulate the age of the user.

SAFETY PRECAUTIO S

4