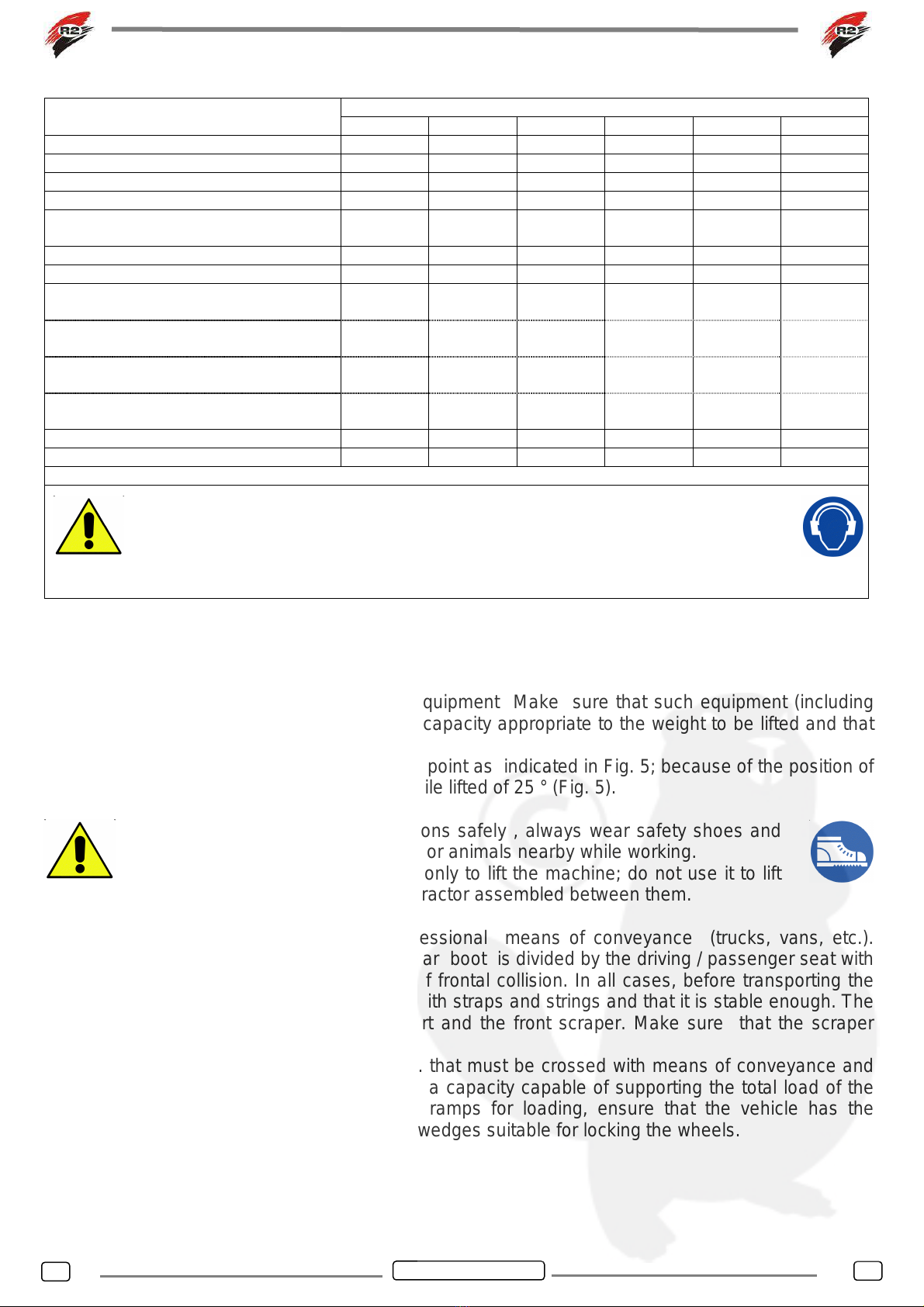

3 – Technical specifications and dimensions

(*note 2 mod. hi) ModelMTL 50 MTL 75 MTL 100 MT 60 MT 90 MT 125

Milling width (Fig. 3a – Ref. A) 50 cm 75 cm 100 cm 60 cm 90 cm 122 cm

Levelling width (Fig. 3a – Ref. A) 50 cm 75 cm 100 cm 60 cm 90 cm 122 cm

Compactness width (Fig. 3a – Ref. B) 60 cm 85 cm 110 cm 70 cm 100 cm 132 cm

Depth (Fig. 3a – Ref. C) 75 cm 75 cm 75 cm 75 cm 75 cm 75 cm

Maximum height from the ground (Fig.

3b – Ref. A) 42 cm 42 cm 42 cm 42 cm 42 cm 42 cm

Walking tractor/tractor HP 8-10 HP 12-14 HP 14-18 HP 12-14 HP 14-18 HP 16-18 HP

Maximum working depth 14 cm 14 cm 14 cm 14 cm 14 cm 16 cm

Minimum working depth: (with new

hoes)

●With flank extensions low position

(Fig. 4 – Ref. a) 6 cm 6 cm 6 cm 6 cm 6 cm 6 cm

●With flank extensions medium position

(Fig. 4 – Ref. b) 8 cm 8 cm 8 cm 8 cm 8 cm 8 cm

●With flank extensions high position

(Fig. 4 – Ref. c) 10 cm 10 cm 10 cm 10 cm 10 cm 10 cm

Number of hoes 6 10 14 6 10 14

Weight 70 Kg 95 Kg 115 Kg 90 Kg 110 Kg 130 Kg

Lubricant: ROLOIL LITEX - EP/0

Note: Emission of airborne noise. The noise produced by the machine varies according to the soil

features at work. Exposure also depends strictly on the noise produced by the working equipment

(walking tractor or tractor). Considering the data in the literature relating to similar equipment, it can

be considered an approximate value of exposure to the noise (determined by the machine and the

walking tractor or tractor) between 90 dB (A) and 95 dB (A).

Verify the level of exposure to the noise with the proper instruments each time any work is performed. Follow the legislative

references of your country to identify the personal protective necessary equipment.

4 Handling and transportation of the machine.

(*note 3 mod. hi)

- The machine must be handled with lifting equipment Make sure that such equipment (including

the straps and the strings ) have a carrying capacity appropriate to the weight to be lifted and that

they are in good maintenance conditions.

The machine can be anchored in the coupling point as indicated in Fig. 5; b

ecause of the position of

the center of gravity, the machine will lean while lifted of 25 ° (Fig. 5).

In order to make handling operations safely , always wear safety shoes and

make sure that there are no people or animals nearby while working.

The anchorage ring must be used only to lift the machine; do not use it to lift

the machine group and two-wheel tractor assembled between them.

- The machine must be transported by professional means of conveyance (trucks, vans, etc.).

Transportation by car is permitted only if the car boot is divided by the driving / passenger seat with

a barrier that can hold the machine in case of frontal collision. In all cases, before transporting the

machine , make sure that it is well anchored with straps and strings and that it is stable enough. The

anchor points can be the roller group support and the front scraper. Make sure that the scraper

adjustment screws are properly tightened.

Always check that any walkways, ramps, etc. that must be crossed with means of conveyance and

lifting equipment are well anchored and have a capacity capable of supporting the total load of the

vehicle + machine + operator. When using ramps for loading, ensure that the vehicle has the

handbrake on and have been positioned the wedges suitable for locking the wheels.