HM Electronics HM3000CDM User manual

HM3000CDM Operating Instructions

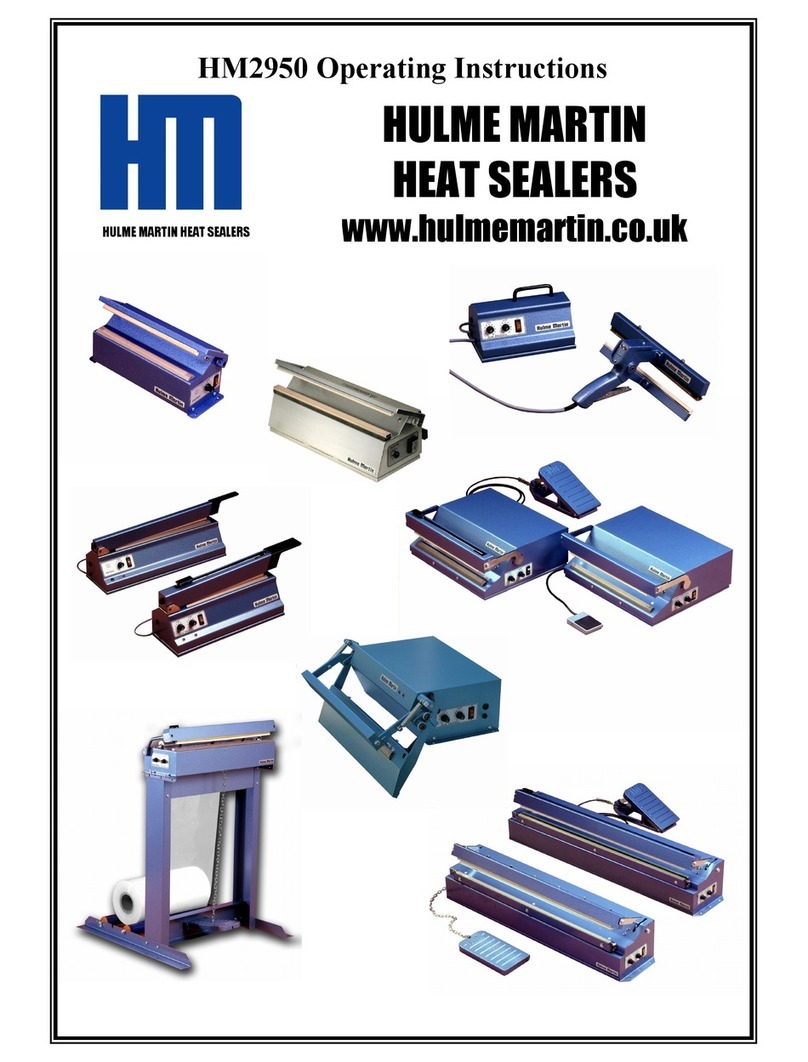

HULME MARTIN HEAT SEALERS

HULME MARTIN

HEAT SEALERS

www.hulmemartin.co.uk

SAFETY INSTRUCTIONS – HEAT SEALING EQUIPMENT

A. Protection against hazards arising from the electrical equipment

1. Safety warnings and instructions in the operators instruction sheets and

attached to the machine should be followed with care.

2. The equipment has an earthed power cable with integral 5 amp plug to

BS 1363/A fitted with a 5 amp fuse. The panel mounted fuse holder on

the machine is fitted with a 3.15A antisurge fuse for additional

protection. If either fuse fails the reason should be investigated and the

machine inspected and tested to ensure that there are no causative

faults. Higher value fuses must not be used, as they do not provide the

required level of protection.

3. Ensure that the power is switched off and the cable plug is removed

from the supply outlet before any servicing is undertaken on the

product.

4. Increased user safety can be achieved if a residual current device

(RCD) is used in the supply circuit to the heat sealer. This applies

particularly in damp conditions but the equipment must not be allowed

to get wet, either from sealing liquids, cleaning or inclement weather.

Only specially designed water resistant sealers should be used in

these circumstances. Electrical components and internal wiring, unlike

the element assembly, are not all protected by the low voltage safety

transformer, which powers the element.

5. Switch off the power supply when the machine is not attended.

6. The equipment should be regularly serviced and subjected to Portable

Appliance Test procedures in accordance with the Health and Safety

Electricity At Work regulations 1989.

7. It is essential that only approved spares be used for servicing this

equipment. Incorrect element wire can result in excessive electrical

load on internal components, which can lead, to malfunction and

failure.

Note

Hulme Martin Heat Sealing equipment satisfies the Health and Safety

requirements of the Electrical Equipment (Safety) Regulations 1994, CE Low

Voltage Directive 2006/95/EC

B. Protection against non electrical hazards

1. The equipment is designed to be operated on a flat, level surface to

ensure machine stability. In the case of chain operated machines, the

equipment should be securely screwed or clamped to the workbench

using the flanges provided, to avoid dislodging the machine when the

pedal is depressed.

2. Heat sealing machines must not be used for packing flammable or

explosive materials unless specifically modified to do so.

3. When sealing PVC and some other plastic films, which may produce

potentially harmful fumes, adequate airflow ventilation or extraction

may be required.

4. The heating element and jaws can become hot during sealing and

adequate cooling time must be allowed before touching these parts of

the machine.

5. Care should be taken on machines fitted with cutting knives that the

blade is moved to a safe position before attempting to reach between

the jaws. On hand operated machines, which are pivoted at one end of

the pressure bar the knife will slide towards the pivot point when the

pressure bar is lifted. For safety ensure that the blade is positioned at

the pivot end before lifting the pressure bar.

6. The heating cycle on impulse sealers is controlled by a timer allowing a

maximum heating time of 4 seconds. If the timer indicator light does

not go out at the selected time and heating continues, switch off the

power immediately and investigate the fault after removal or

disconnection of the element.

7. Repeated operation of the machine without sufficient cooling time

between cycles can cause accumulative heat build up in the element

resulting in poor seals, damaged elements and excessive temperatures

8. Ensure that hands and fingers are clear of the pressure bar before

actuating the foot pedal. The element will not operate until the

pressure bar is fully closed but some discomfort will result from the

pressure applied manually or by solenoid operated units.

IMPULSE SEALING EQUIPMENT

To ensure that satisfactory sealing performance is achieved and that

service life of consumable spares (such as element wire, Teflon and

rubber pressure pads) are maximised, it is necessary to understand the

operating principles of this type of equipment.

1. To adjust the heat setting for a particular thickness of material, the

power output is not varied, and varying the length of time that the

current passed through the element resistance wire effects adjustment.

The timer control allows infinitely variable time adjustment up to a

maximum of around 4 seconds.

2. When the red heating indicator light goes out the temperature has

reached its maximum and the polythene is molten to effect the weld. It

is important that before allowing the jaws to open for removal of the

polythene a short cooling time is allowed to enable the polythene to

solidify and to regain its original strength. On machines fitted with a

dual timer control, the cooling time can be pre set but on standard

machines with simple heating time control, the operator should allow

sufficient time for cooling before releasing the jaws. Depending on

material thickness a cooling time of 1 to 7 seconds is usually sufficient.

3. To complete the seal in the minimum possible time considerable power

is applied to the element for the short duration of the welding cycle.

The instantaneous temperature reached during the brief cycle is very

high, but close contact of the rubber pressure pad removes excess

temperature and prevents deterioration of the thin Teflon barrier tape.

4. It follows that if the pressure bar is released before the temperature

reduces to a level that the Teflon can withstand, it will deteriorate

rapidly and require premature replacement.

5. For this reason adequate cooling allowance is critical to the service life

of the Teflon. Although capable of withstanding up to 20,000 seals

before replacement, insufficient cooling time can cause burning within a

very short period.

6. If the Teflon is not replaced when showing signs of wear, the polythene

will stick and seal quality will deteriorate. Also the rubber pressure pad

will start to wear and if this is allowed to continue to the stage where

the surface of the pad is burnt and uneven, the resulting ‘air gap’

between the pad and element will reduce heat transfer and cause

further rapid deterioration of the Teflon. Excessive burning will

eventually result also in the element wire requiring replacement.

7. To avoid this ‘ vicious circle’ always operate the machine at the

minimum heat setting consistent with satisfactory seal quality. Allow

sufficient cooling time between each successive seal. When sealing

repetitively at high frequency reduce the heating time from its original

setting to compensate for residual heat build up in the element.

8. The micro switch is set to avoid application of power to the element

until the rubber pad is fully aligned and pressed closely to the Teflon to

allow the necessary heat transfer. The rubber pressure pad is

sufficiently pliable to accommodate several thickness’ of polythene, but

accidental closure onto thicker objects or attempting to seal bubble

pack material and heavy paper laminate gusseted materials will cause

deterioration of the Teflon for the reasons explained previously.

9. The rubber pressure pad, and element wire strip are easily replaceable,

but care in operating and maintenance of the Teflon barrier tape can

extend the service interval before element reconditioning becomes

necessary.

10. If the machine fails to seal, but the on off switch and indicator lights

show that the power and timer circuits are operating correctly, unplug

the element and check the condition of the resistance wire and Teflon.

Simple replacement of these low cost consumable spares will normally

restore the full performance of the equipment.

HM3000CDM POLYTHENE HEAT SEALER

OPERATING INSTRUCTIONS

General

Before connecting the machine to the electricity supply, check the operating

voltage on the name plate attached to the base of the machine.

The wires in the mains lead are coloured in accordance with the following

code:

Green & Yellow Earth

Blue Neutral

Brown Live

Ensure that the machine is correctly earthed and connected to the mains

supply with a 5 amp fused plug.

The heating element operates at a reduced safety voltage and the machine

has its own 3.15 amp internal fuse, accessible at the rear of the body.

Installati n

For transportation purposes the black handle has been fitted to the upper arm

in the reverse position. Before operating the machine this handle should be

fitted to the correct position.

Operating Instructi ns

Switch on the machine using the amber on/off switch on the side of the

machine. Check that the switch lights up to indicate that the machine is

powered.

The HM3000CDM impulse sealer is fitted with a dual electronic timer

controlling the heating and cooling cycles. When sufficient pressure is applied

to the pressure bar, the audible ‘click’ of the microswitch and the illumination

of the red LED indicator lights will confirm that the machine is correctly

adjusted and that power is being applied to heat up the element.

The heating time is variable between 0 and 3.5 seconds using the external

control knob. The cooling cycle is also adjustable to allow a sufficient cooling

time before the pressure bar is released.

Once the pressure bar has been depressed, the magnet will hold the bar

down until both neon lights go out. This should prevent the possibility of

insufficient cooling which can result in premature wear of the teflon barrier

tape and other consumable spares.

To extend the service life of the consumable items, always operate at the

minimum setting consistent with good seals and allow adequate cooling time

before removal of the bag.

Setting the Heating Time

Switch on the machine and set the timer control to position No. 2. Place the

polythene bag between the jaws and depress the upper jaw to the preset stop

point. The timer light will illuminate for a period of approximately one second.

Allow a further two seconds to cool before releasing the pressure from the

sealed bag. Examine the seal and progressively increase the heating and

cooling time until satisfactory seal strength is achieved.

Maintenance

The complete element assembly can be unplugged (without tools) from the

machine body so that it can be replaced with a new or reconditioned unit.

Removal of the Teflon barrier tape from the displaced element enables the

wire to be inspected and replaced if kinked or damaged. When rewiring the

element, ensure that the wire passes over the pins, down through the hole at

each end of the bar and up through the contact pin hole. Secure one end with

the nut and washer and tension the wire strip before tightening the remaining

nut. This ensures that any excess wire is on the top of the element. It is

important that this excess is removed to avoid any risk of a short circuit to the

metal body that can result in damage to the timer circuit.

To replace the pressure pad, fit approximately 30mm at each end of the

pressure bar and work the pad into the gap working towards the centre.

SPARES

The following consumable spares will enable the machine to be serviced as

required.

300211 Element Assembly complete each

300203 Teflon Barrier Tape pkt 5

300205 Rubber Pressure Pad each

300204 Underwire Insulating tape pkt 5

300206 Resistance wire strips pkt 5

490 Cutter blades pkt 10

445 Safety cutter Assembly each

When ordering spares please quote the serial number of the machine as

printed on the plate on the base of the machine. If special modifications such

as wide seal elements have been fitted to the machine ensure that the spares

department are informed when ordering these parts.

Spares Items F r 3000

Element Bar Assy 300211

Teflon Barrier Tape

300203

Element Wire Strip

300206

Insulation Tape 300204

Soft Rubber Pad 300205

Black Neoprene Pad

300265

Safety Cutter Assy

445

Cutter Blades 490

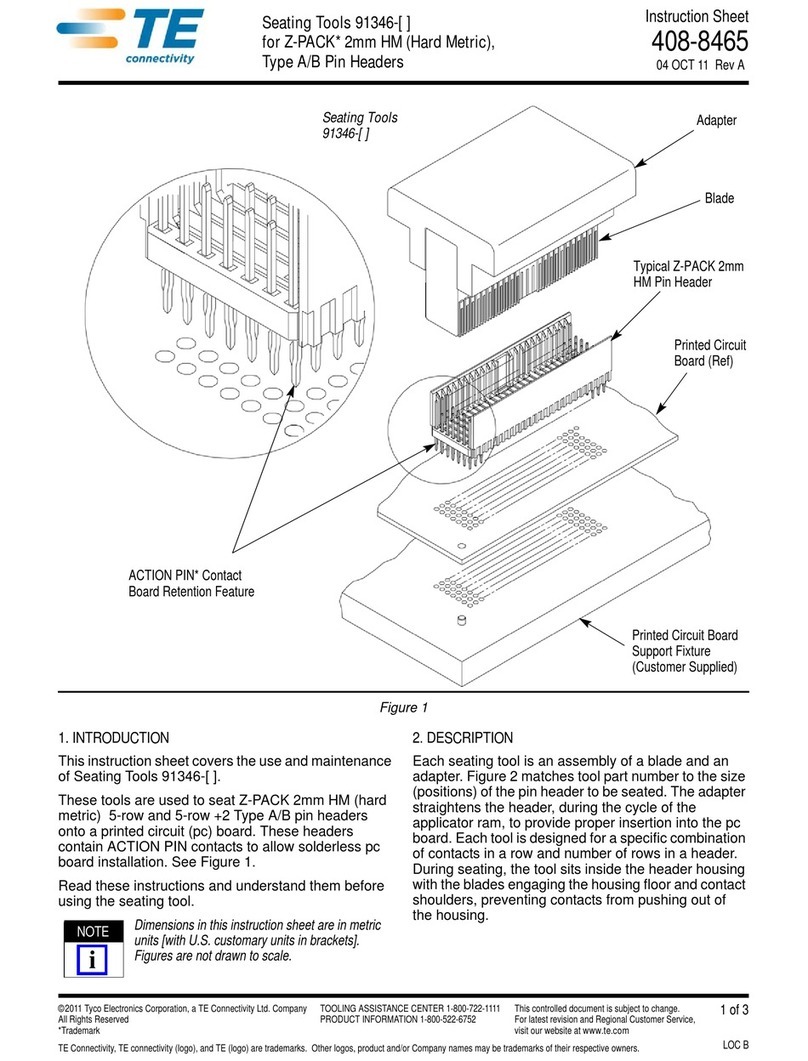

Using the 445 Safety cutter assembly

Safety Tab

For transportation and additional safety, the manual cutting device is fitted with a locking

‘safety tab’, which must be removed before the cutter can be used. To remove the safety tab

hold it firmly and pull it horizontally, with a small rocking motion, away from the blade carrier

marked ‘caution cutter’ the tab will simply pull out of its locked position, it is held via two

prongs. To lock the blade in a safe position simply replace the ‘safety tab by pushing the

prongs back in to the blade carrier.

Operation

Even with the ‘safety tab’ removed the blade is fully withdrawn and not exposed, ensuring the

operators safety at all times. As with any sharp objects extreme caution should always be

used.

To trim off the excess material above the seal or manufacture bags from layflat tubing simply

close the sealing jaws on your heat sealer. The LED indicators will illuminate, then fully press

the yellow blade carrier marked ‘caution cutter’ down level with the black carrier and slide the

cutter assembly along the pressure bar housing. The depth of the cut is pre set at the factory

and no adjustment should be necessary. If during the course of time the cutter needs

adjustment the slider bar (carrying the cutting assembly) can be adjusted via the hexagon

head screws on the outside of the pressure bar housing.

Changing the blade

Please read all of the following instructions before changing the cutter blade

Eventually it will be necessary to replace the cutting blade. Please always use extreme

cauti n when handling these blades, as even when they no longer cut the material they can

be extremely sharp.

Remove the aluminium cutter stop fitted on the machines pressure bar housing. This is

located at one end and secured with two M3 countersunk screws to stop the cutting assembly

coming out during use, as illustrated below.

Remove 2 x M3 counter sunk screws from the end of the pressure bar housing. Lift out the

aluminium cutter stop. Slide the cutter assembly to this exit point on the pressure bar housing

and lift out the assembly to remove.

Safety Tab

Activating spring part No. 446

Blade carrier marked

‘Caution cutter’

Black carrier handle

Retaining button

Cutter Blade part No.490

Safety Cutter Assembly part

No.44

CHANGING THE BLADE

Always use cauti n when changing the blade

Hulme Martin Heat Sealers Duty f Care

Directive 2002/95/EC on the restriction of the use of certain hazardous

substances in Electrical and Electronic Equipment(RoHS)

The RoHS Directive stands for "the restriction of the use of certain hazardous substances in electrical and electronic

equipment". This Directive bans the placing on the EU market of new electrical and electronic equipment containing

more than agreed levels of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and

polybrominated diphenyl ether (PBDE) flame retardants.

All machines manufactured from 1

st

April 2006 comply with the above

directive.

Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

The WEEE Directive aims to reduce the quantity of waste from electrical and

electronic equipment and increase its re use, recovery and recycling.

From 1

st

March 2007 Hulme Martin machines are marked with the ‘crossed out wheeled bin

symbol’ to ensure they are dealt with separately from general waste. We can arrange to

collect machines that are no longer required and ensure they are either recycled or disposed

safely. We will record details of all collected and recycled machines.

WEEE REG N WEE/DB1381SS

Packaging Directive

Directive 2004/12/EC (94/62/EC). Whilst we are not required to register under this directive

we use minimal packaging to ensure your purchase reaches you in a first class condition.

Packaging used has been recycled wherever possible and can be reused or recycled by the

receiver.

EC Declaration of Conformity

Machinery Directive 2006/42/EC

The Low Voltage Directive 2006/95/EC

Electromagnetic compatibility directive 2004/108/EC.

Our machines comply with the above directives. All new machines are built to

a high standard and subjected to visual and electrical tests at several stages

during their manufacture. Once assembled we produce test seals to ensure

quality standards are met. Finally every machine is Portable Appliance Tested

to ensure electrical safety requirements are met.

ISO 9000 Quality Management

Hulme Martin Heat Sealers Ltd operates from documented quality management systems to ensure we meet our

customers’ requirements. We conform to the required directives as listed above, and our equipment meets CE

requirements. Customers are welcome to visit our factory to inspect our documentation and manuals.

ISO 14000 Environmental Management

Hulme Martin Heat Sealers ensures its activities causes minimal effects on the

environment. We continually monitor our practices to achieve the best possible

improvement on our environmental performance.

Warranty

In the unlikely event that it becomes necessary to return the machine for

repair or maintenance, please ensure that it is adequately packed to avoid

accidental damage and include your advice note detailing the date of

purchase and invoice reference number. Defects occurring from faulty

materials or manufacture will be repaired free of charge within the 12 month

warranty period provided that the machine has not been misused; is correctly

maintained, and has not been subject to unauthorised repair. Consumable

spares items such as the heating element assembly, resistance wire strips,

Teflon barrier tapes, rubber pressure pads and transportation costs are

excluded from the warranty.

HULME MARTIN HEAT SEALERS LTD

Unit 5B, C untry Business Centre,

White C ttage Farm,

Lucas Green R ad,

West End,

W king,

Surrey

GU24 9LZ

Teleph ne 01483 476767 Fax. 01483 486343

www.hulmemartin.c .uk

Table of contents

Other HM Electronics Food Saver manuals