INDEX

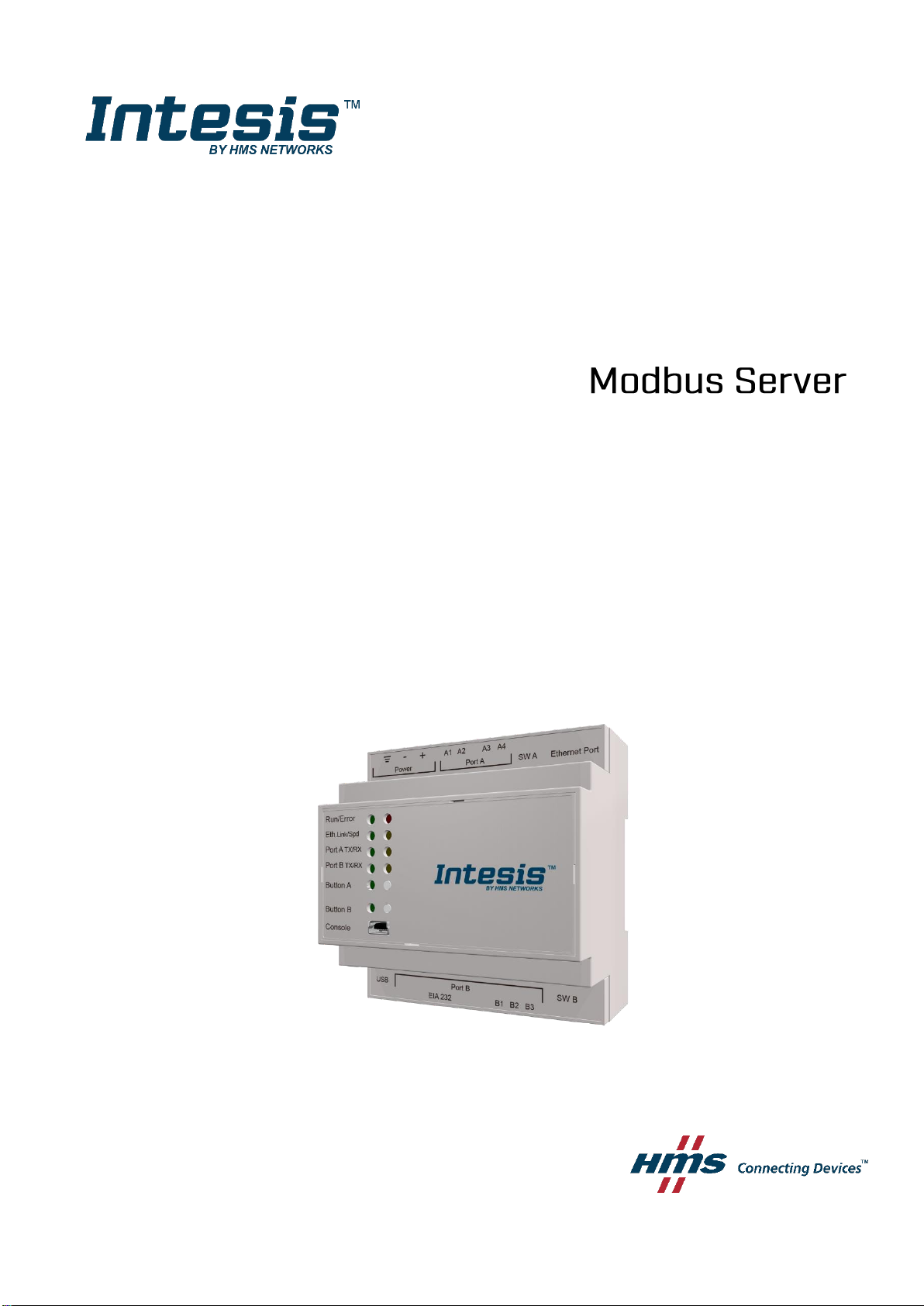

1Description ............................................................................................................................................................5

Introduction.............................................................................................................................................................5

Functionality............................................................................................................................................................6

Gateway’s capacity.................................................................................................................................................6

2Modbus interface...................................................................................................................................................7

Functions supported...............................................................................................................................................7

Modbus RTU...........................................................................................................................................................7

Modbus TCP...........................................................................................................................................................7

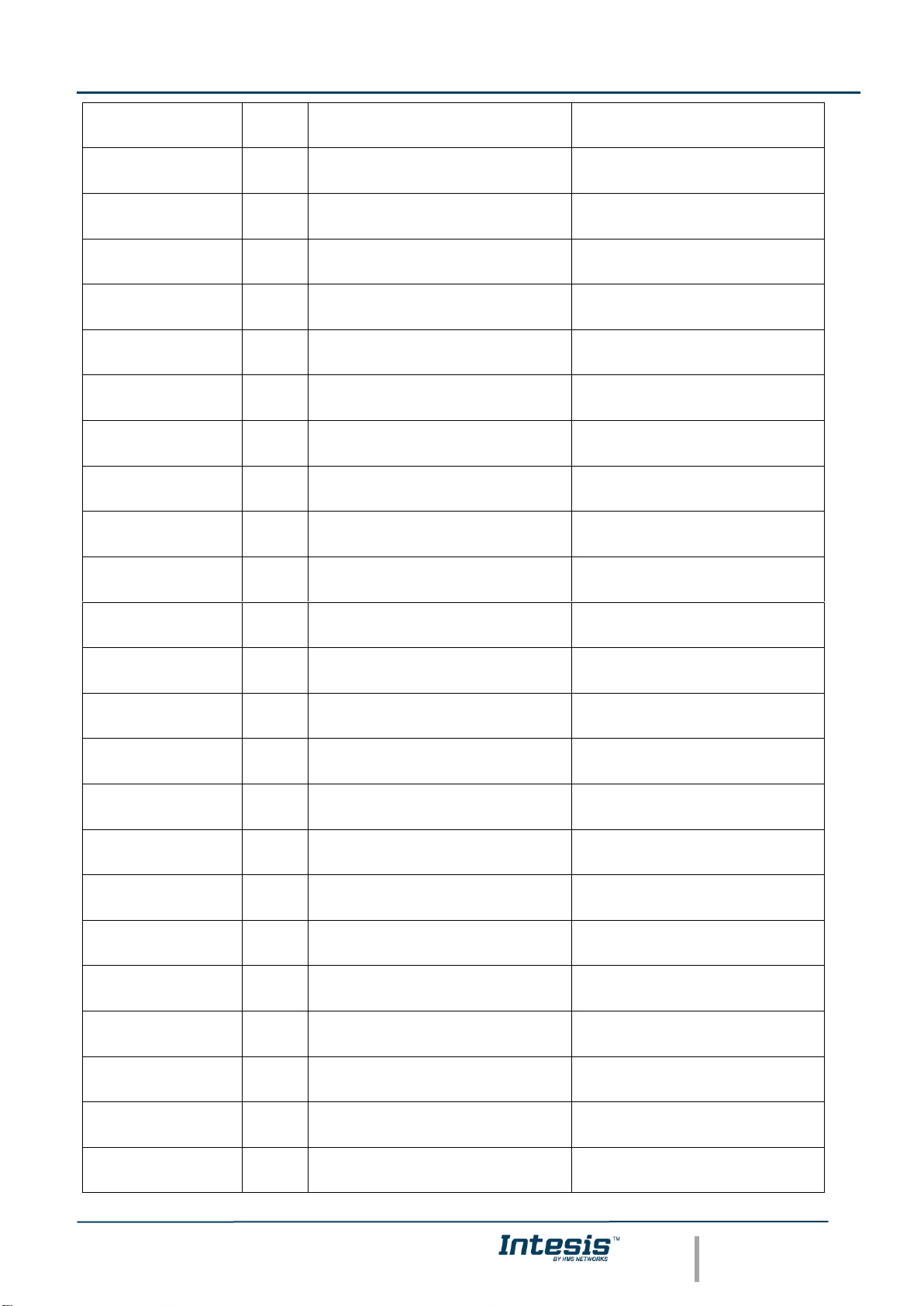

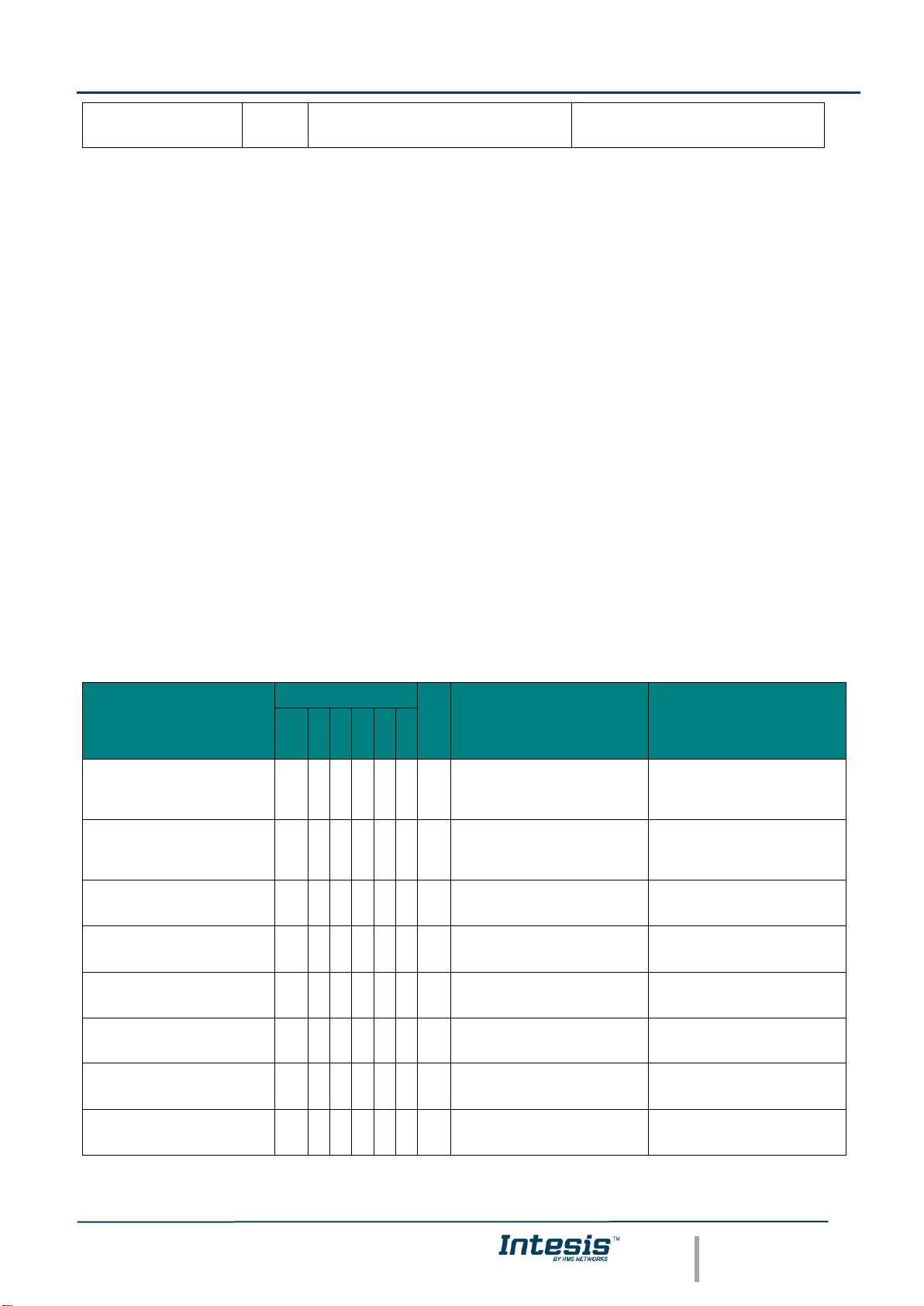

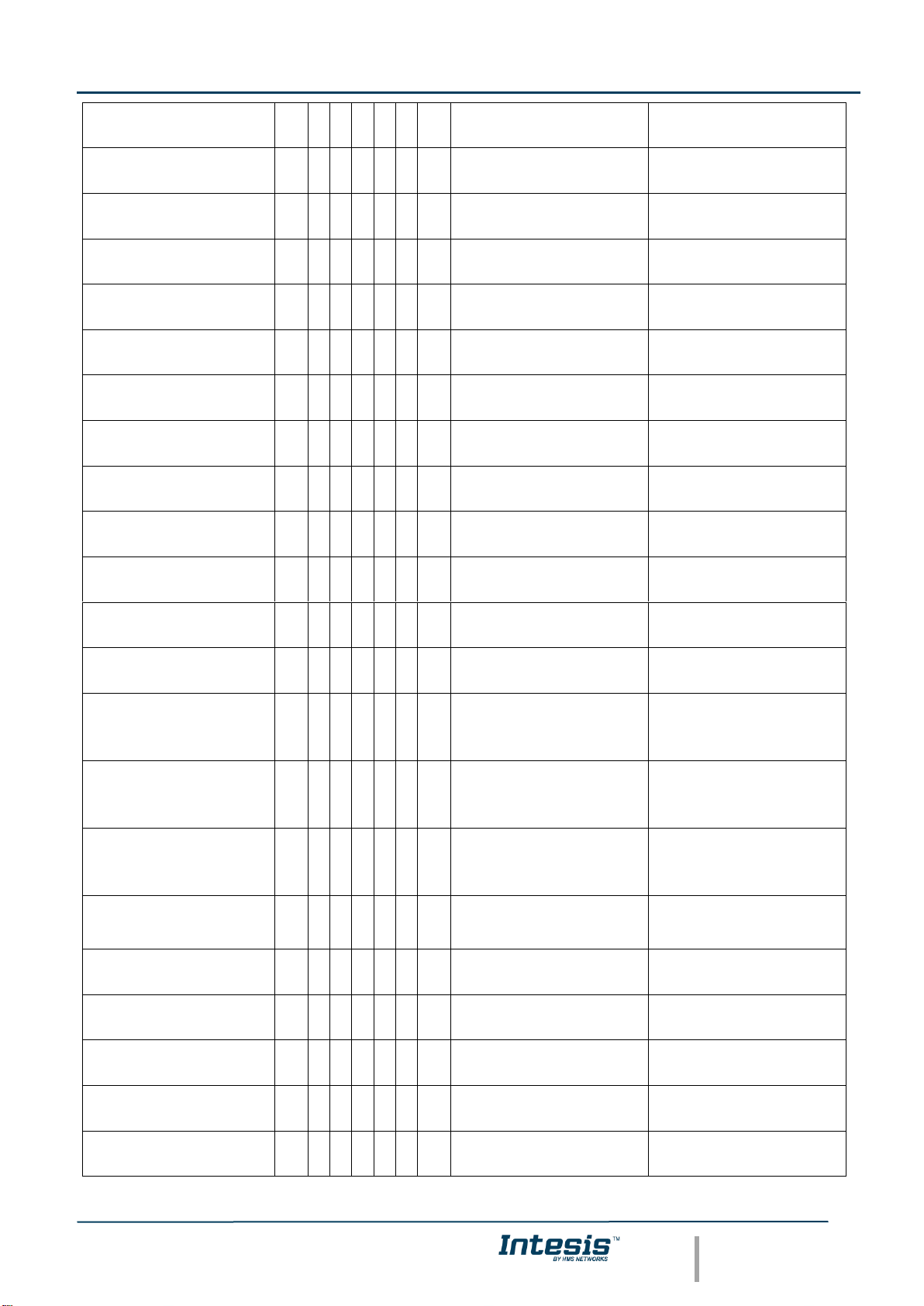

Modbus Address Map.............................................................................................................................................7

2.1.1 Centralized Controller signals................................................................................................................7

2.1.2 City Multi Group signals.........................................................................................................................9

3Connections ........................................................................................................................................................12

Power device........................................................................................................................................................13

Connect to Mitsubishi’s Centralized Controller(s). ...............................................................................................13

Connection to Modbus..........................................................................................................................................13

3.1.1 Modbus TCP........................................................................................................................................13

3.1.2 Modbus RTU........................................................................................................................................13

Connect to PC (Configuration tool).......................................................................................................................13

4Set-up process and troubleshooting ...................................................................................................................14

Pre-requisites........................................................................................................................................................14

Intesis MAPS. Configuration & monitoring tool for Intesis....................................................................................14

4.1.1 Introduction..........................................................................................................................................14

4.1.2 Connection...........................................................................................................................................14

4.1.3 Configuration tab .................................................................................................................................15

4.1.3.1 Mitsubishi Electric Configuration..................................................................................................15

4.1.4 Signals.................................................................................................................................................20

4.1.5 Sending the configuration to Intesis ....................................................................................................20

4.1.6 Diagnostic............................................................................................................................................21

Set-up procedure..................................................................................................................................................23

5Electrical & Mechanical Features........................................................................................................................24

6Dimensions .........................................................................................................................................................25