PROCESSES

Stick (SMAW)

Welding

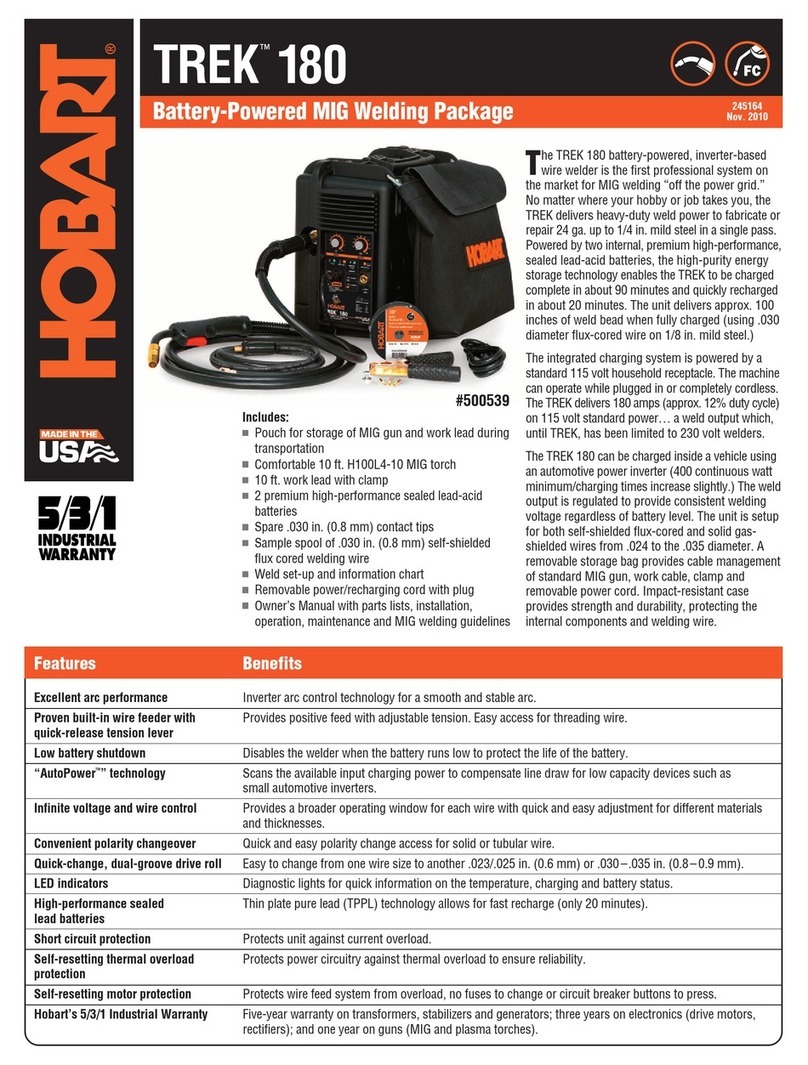

Champion 10,000

All-in-One 10,000-Watt AC Generator and DC Welder 211801

June 2008

Combining a 10,000-watt generator with a 230-amp

constant-current DC welder, the Champion 10,000

is ideal for farm, general construction, and emergency

power applications. This unit is designed for Stick

welding with quick and easy arc starts. It also performs

general scratch start DC TIG. The Champion 10,000

offers a “no-nonsense” warranty. The engine is

warranted separately by the engine manufacturer.

Rated output decreases approximately 3.5% per 1000 ft (305 m) above sea level. The rated output of any engine-driven welder/generator decreases as temperatures rise. The ratings for the

Champion 10,000 were taken at high temperatures, only after the machine reached operating temperature. Even in hot weather the Champion 10,000 has the vigor to let you finish the job.

FEATURES BENEFITS

You get a generator

and

welder for about what you would pay for just a generator!

Smooth arc starts with minimal “sticking”. Extraordinary motor starting characteristics. Strong continuous

rating to run compressors, pumps, lights, hand tools and other equipment.

Provides stamina and long dependable service. Enclosed design, large battery, rugged electrical

connections and wiring, and circuit-breaker protection.

Just over 3 ft long and weighs 10 – 20% less than competitive units.

Modern engines from Robin or Kohler, with 10-gallon fuel tank and low oil pressure shutdown as standard

features. Dependable engines conserve fuel and provide long operation before refueling.

Help maintain scheduled routine oil servicing (every 100 hours) and other preventative maintenance.

Easy to set up and start welding.

Primarily designed for the Stick process, the Champion 10,000 also provides a smooth arc for scratch start

DC TIG welding.

All-in-one 10,000-watt generator

and 230-amp welder

Innovative Hobart technology

Heavy-duty construction

Lightweight and compact design

Choice of OHV engines

A “no tools” oil change and

standard hour meter

Quick-set current control

Smooth DC weld output

210 amps at 25 V,

60% duty cycle

Rated Output

230 amps at 25 V,

30% duty cycle

Amperage Range

50–230 amps

Max. Open-Circuit Voltage

73 VDC

Dimensions

H: 33 in (838 mm)

W: 18-3/4 in (476 mm)

D: 37-1/2 in (953 mm)

Auxiliary Power

10,000 watts peak; 120/240 VAC, 60Hz,

9,500 watts continuous while not welding

Net Weight

Kohler:440 lb (200 kg)

Robin: 445 lb (202 kg)

SPECIFICATIONS

(SUBJECT TO CHANGE WITHOUT NOTICE.)

INDUSTRIAL

Engine Brand

Kohler

#500 434

Subaru/Robin

#500 433

Type

Twin-cylinder, 4-cycle, overhead-valve,

industrial, air-cooled, gasoline engine

Twin-cylinder, 4-cycle, overhead-valve,

industrial, air-cooled, gasoline engine

Horsepower (HP)

23 HP at 3600 RPM

(3-year mfg. warranty)

22 HP at 3600 RPM

(3-year mfg. warranty)

Fuel Capacity

10 gallons

10 gallons

Weld Speed

3750 RPM

3750 RPM

Idle Speed

2200 RPM

2200 RPM

Oil Capacity/Change

1.75 qt (1.7 L) every 100 hours;

2 qt (1.9 L) w/filter every 200 hours

1.6 qt (1.55 L) every 100 hours;

1.8 qt (1.75 L) w/filter every 200 hours

ENGINE SPECIFICATIONS

(SUBJECT TO CHANGE WITHOUT NOTICE.)

Comes complete with 15 ft Work Cable and Clamp,

and 20 ft Welding Lead and Electrode Holder!

Hobart Welders An Illinois Tool Works Company

U.S. Distributor Sales Phone 920-735-4576 FAX 800-637-2315

Hobart Retail Sales Phone 800-332-3281 FAX 937-332-4161

Canadian Sales Phone 888-489-9353 FAX 519-421-0480

International Sales Phone 920-735-4509 FAX 920-735-4125

Web Site HobartWelders.com