OM-194 0 4 Page

;$ :-<-7!

-

Do not install or place unit on, over, or near

combustible surfaces.

-

Do not install unit near flammables.

-

Do not overload building wiring -- be sure power supply system

is properly sized, rated, and protected to handle this unit.

$$ - -3 836!

-

Use lifting eye to lift unit only, NOT running

gear, gas cylinders, or any other accessories.

-

Use equipment of adequate capacity to lift and

support unit.

-

If using lift forks to move unit,be sure forks are

longenough toextend beyondopposite sideof

unit.

0 - -3 0'

-

Allow cooling period; follow rated duty cycle.

-

Reduce current or reduce duty cycle before

starting to weld again.

-

Do not block or filter airflow to unit.

-

Put on grounded wrist strap BEFORE

handling boards or parts.

-

Use proper static-proof bags and boxes to

store, move, or ship PC boards.

0 - -3 836!

-

Keep away from moving parts.

-

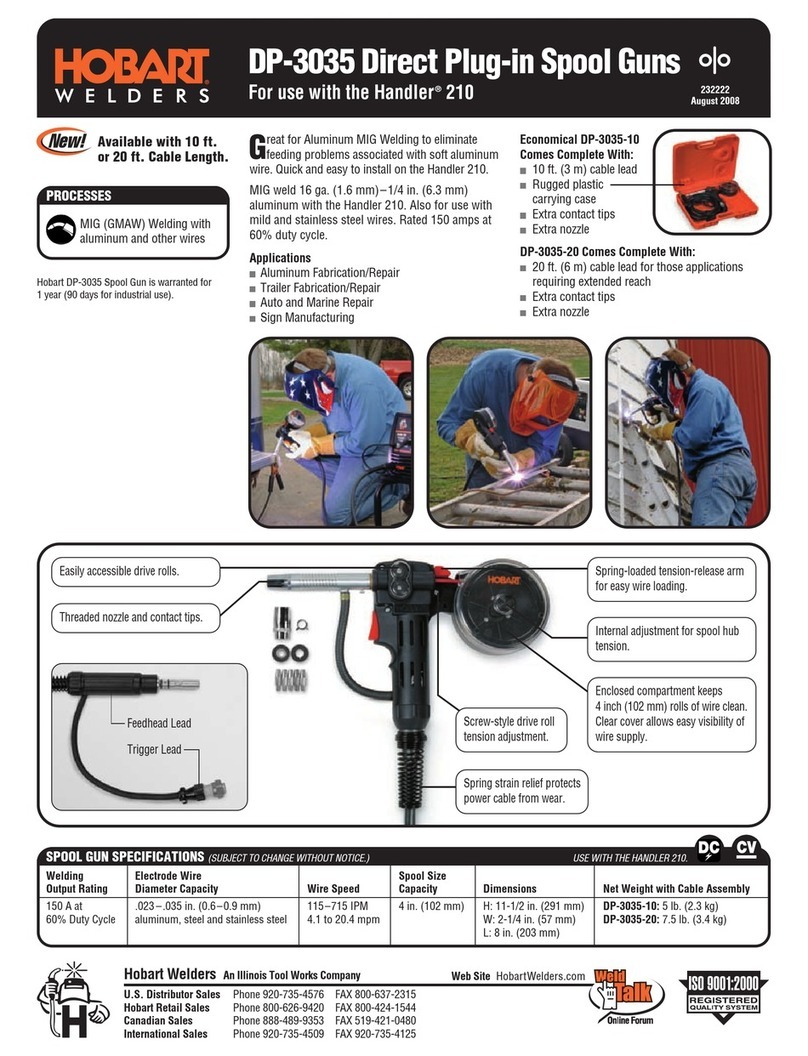

Keep away from pinch points such as drive

rolls.

)$ ) - -3 836!

-

Do not press gun trigger until instructed to do

so.

-

Do not point gun toward any part of the body,

other people, or any metal when threading

welding wire.

0 - -3 836!

-

Keep away from moving parts such as fans.

-

Keep all doors, panels, covers, and guards

closed and securely in place.

H.F. RADIATION can cause interference.

-

High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

-

Have only qualified persons familiar with

electronic equipment perform this installation.

-

The user is responsible for having a qualified electrician

promptly correct any interference problem resulting from the

installation.

-

If notified by the FCC about interference, stop using the

equipment at once.

-

Have the installation regularly checked and maintained.

-

Keep high-frequency source doors and panels tightly shut,

keep spark gaps at correct setting, and use grounding and

shielding to minimize the possibility of interference.

ARC WELDING can cause interference.

-

Electromagnetic energy can interfere with

sensitive electronic equipment such as

computers and computer-driven equipment

such as robots.

-

Be sure all equipment in the welding area is

electromagnetically compatible.

-

To reduce possible interference, keep weld cables as short as

possible, close together, and down low, such as on the floor.

-

Locate welding operation 100 meters from any sensitive elec-

tronic equipment.

-

Be sure this welding machine is installed and grounded

according to this manual.

-

If interference still occurs, the user must take extra measures

such as moving the welding machine, using shielded cables,

using line filters, or shielding the work area.

! " #

6DIHW\ LQ :HOGLQJ DQG &XWWLQJ

, ANSI Standard Z49.1, from American

Welding Society, 550 N.W. LeJeune Rd, Miami FL 126

6DIHW\ DQG +HDOWK 6WDQGDUGV

, OSHA 29 CFR 1910, from Superinten-

dent of Documents, U.S. Government Printing Office, Washington,

D.C. 20402.

5HFRPPHQGHG 6DIH 3UDFWLFHV IRU WKH 3UHSDUDWLRQ IRU :HOGLQJ DQG

&XWWLQJ RI &RQWDLQHUV 7KDW +D H +HOG +D]DUGRXV 6XEVWDQFHV

,

American Welding Society Standard AWS F4.1, from American

Welding Society, 550 N.W. LeJeune Rd, Miami, FL 126

1DWLRQDO (OHFWULFDO &RGH

, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

6DIH +DQGOLQJ RI &RPSUHVVHG *DVHV LQ &\OLQGHUV

, CGA Pamphlet

P-1, from Compressed Gas Association, 12 5 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202.

&RGH IRU 6DIHW\ LQ :HOGLQJ DQG &XWWLQJ

, CSA Standard W117.2, from

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R .

S

DIH 3UDFWLFHV )RU 2FFXSDWLRQ $QG (GXFDWLRQDO (\H $QG )DFH

3URWHFWLRQ

, ANSI Standard Z87.1, from American National Standards

Institute, 14 0 Broadway, New York, NY 10018.

&XWWLQJ $QG :HOGLQJ 3URFHVVHV

, NFPA Standard 51B, from National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.