Before starting, use the

Contents list to take an

inventory and make sure it is

complete. If any parts are

missing or are not of

acceptable quality, contact

Hobby Express Support at

1-615-373-1444 .

This manual assumes the

builder possess intermediate

assembly skills. Seek help

from another pilot or an

experienced modeler if you

are unsure how to complete any steps in this manual.

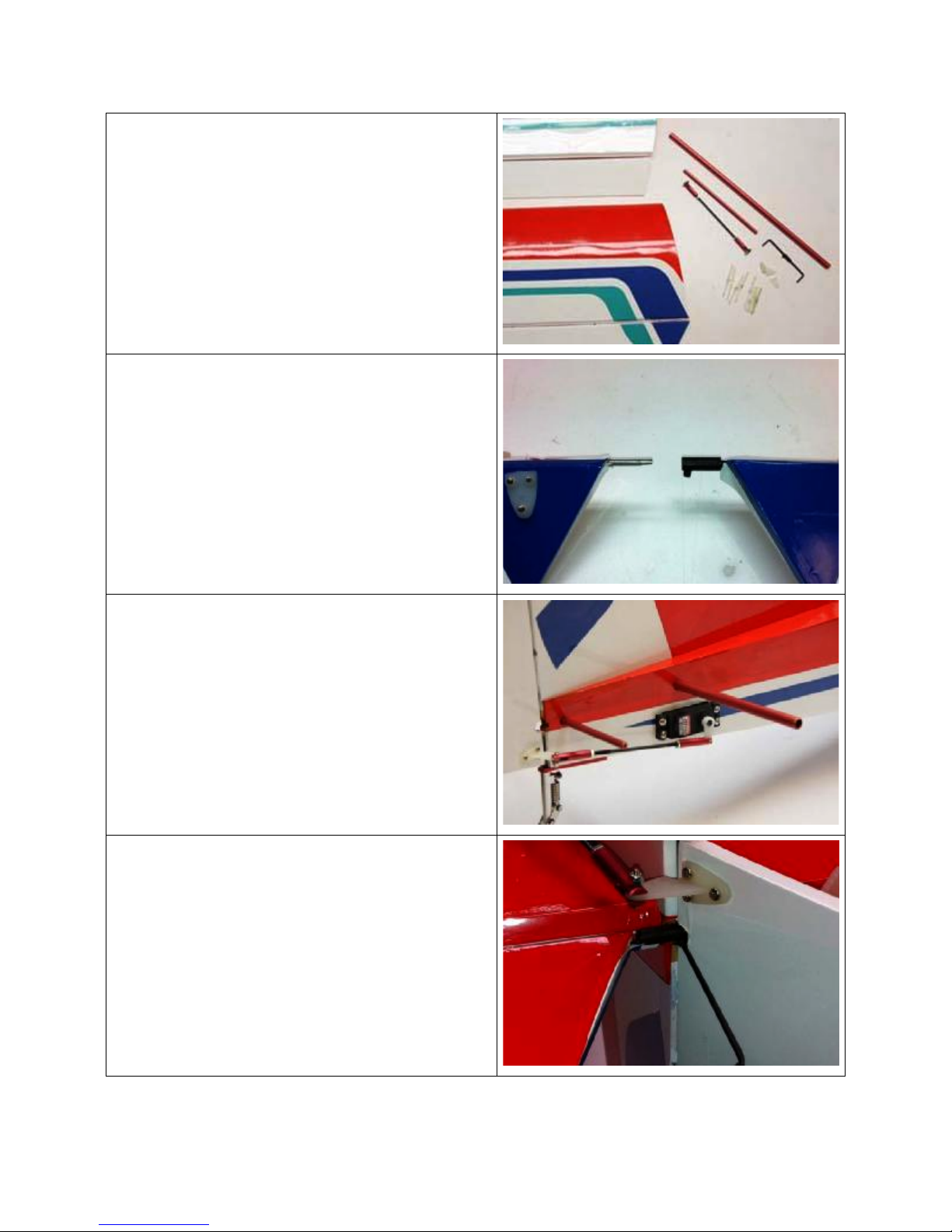

Contents List

!Fuselage

!2 Wing Panels

!2 Horizontal Stabilizers

!Vertical Stabilizer and Rudder

!Aluminum Wing Joiner Tubes

!Aluminum Stab Joiner Tubes

!2 Aluminum Wing Struts

!Wire Landing Gear

!Main Wheels and Steerable Tail Wheel

!Wooden Motor Mount

!Pushrods, Control Horns, Pin Hinges and assorted fasteners

Additional Items Required

!6-channel Aircraft Radio w/ Receiver (minimum)

!5000mah, 5-cell, 18.5v Lipo battery

!(6) Standard sized servos

!(4) 24” Servo extensions

!(2) 12” Servo extensions

!(3) 6” Servo extensions

!(1) Servo Y-harness

!70-80 amp Brushless ESC

!AXI 4120/18 Brushless Motor and radial mount set

!APC 14x10 “E” Propeller

!Glues, solder, connectors

2