3

c 13

c 12

c 11

c 10

c 9

c 8

c 7

c 6

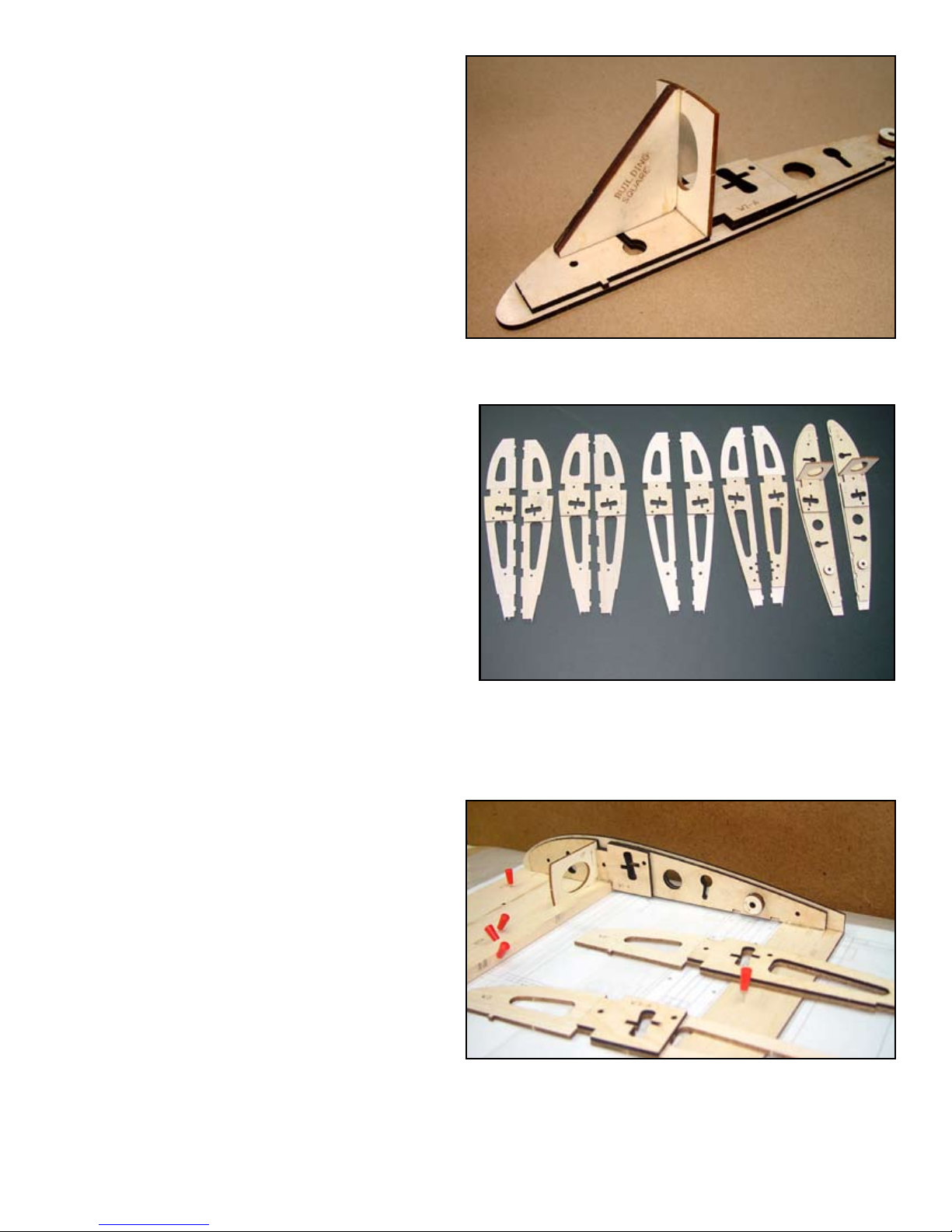

c 4The dihedral angle will be set by W1-B so it

is important that W1-B be accurately tted in

position, Glue W1-B to the W1 assembly en-

gaging the notch in W1-A. W1-B must be per-

fectly at against the W1 assembly. Use the

building square to insure that W1-B is at 90°

to the W1 assembly.

c 5Again, using the registration pins in the holes

provided, glue W2-A to W2. Note that W2-A

should be on the Tip Side of W2.

Glue W3-A to the Tip Side of W3.

Glue W4-A to the Root Side of W4.

Glue W5-A to the Tip Side of W5.

Carefully align the leading edge plate (LEP-

A) with the plans and pin in place. You may

notice a discrepancy between the parts and

the plans as far as position is concerned. This

is normal as the paper the plans are printed

on can change size with changes in tempera-

ture and humidity. Align the slot in TEP with

the W2 on the plans and use the plans only to

align the parts. The parts are correct.

W1-B will determine the correct dihedral angle for your wing so it

must be assembled accurately. Make sure it is fully engaged in the

tab of W1-A and at against the W1 assembly.

The rib subassemblies should look like this. It is best to assembly

them all at the same time to avoid errors. When installing them into

the wing, observe the correct direction they face, Root Side or Tip

Side as they will vary.

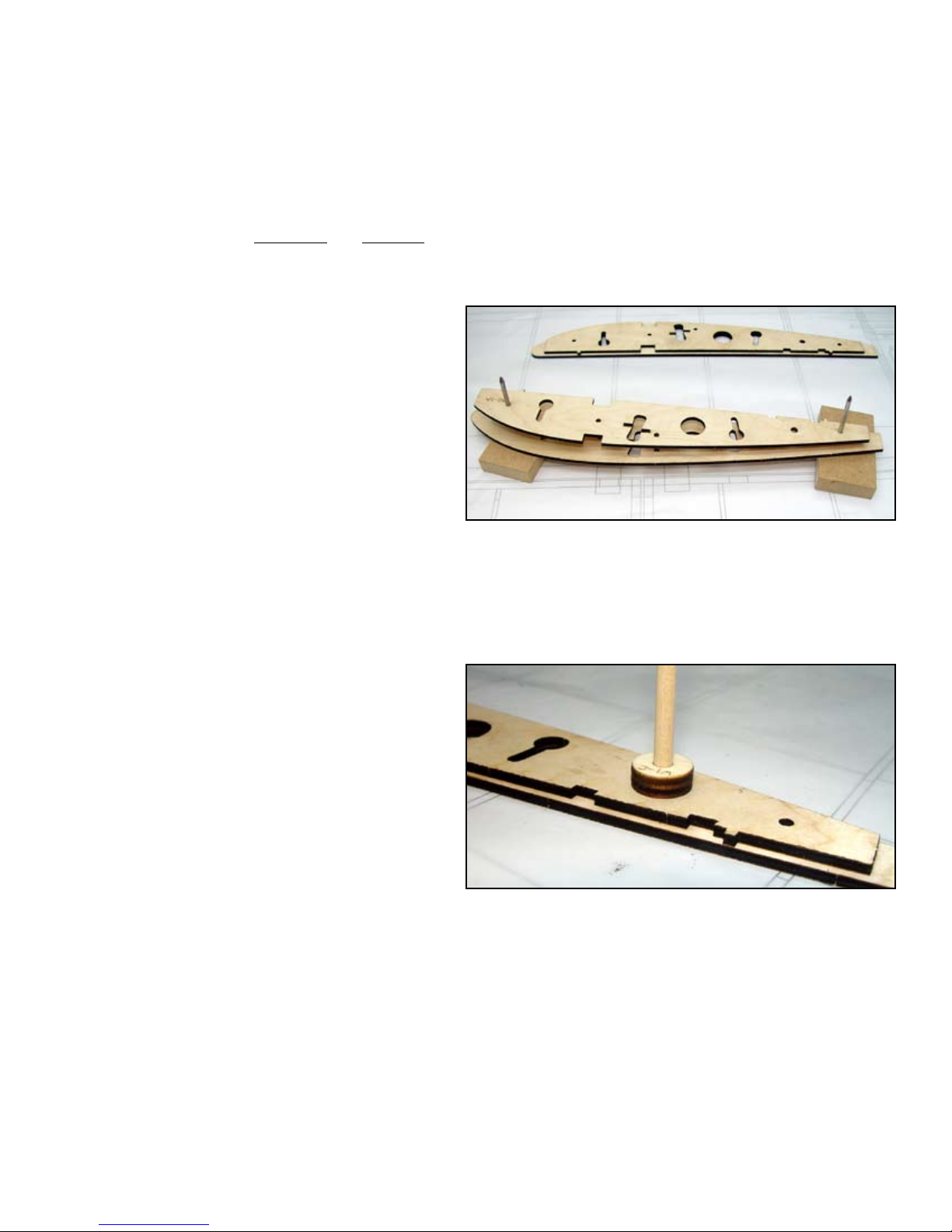

Temporarily place ribs W2 and W13 in there

respective notches in LEP, place a 3/8” x 1/2”

X 48” balsa spar in the bottom notches in each

rib to align it and then pin it at W2 and W13.

Place (TEP) into position with the notches for

Ribs W2 and W13 fully engaged. Make sure

ribs W2 and W13 are perfectly parallel with

the ribs on the plans and then pin TEP and

the bottom spar in place then remove W2 and

W13.

W1W5 W4 W3 W2

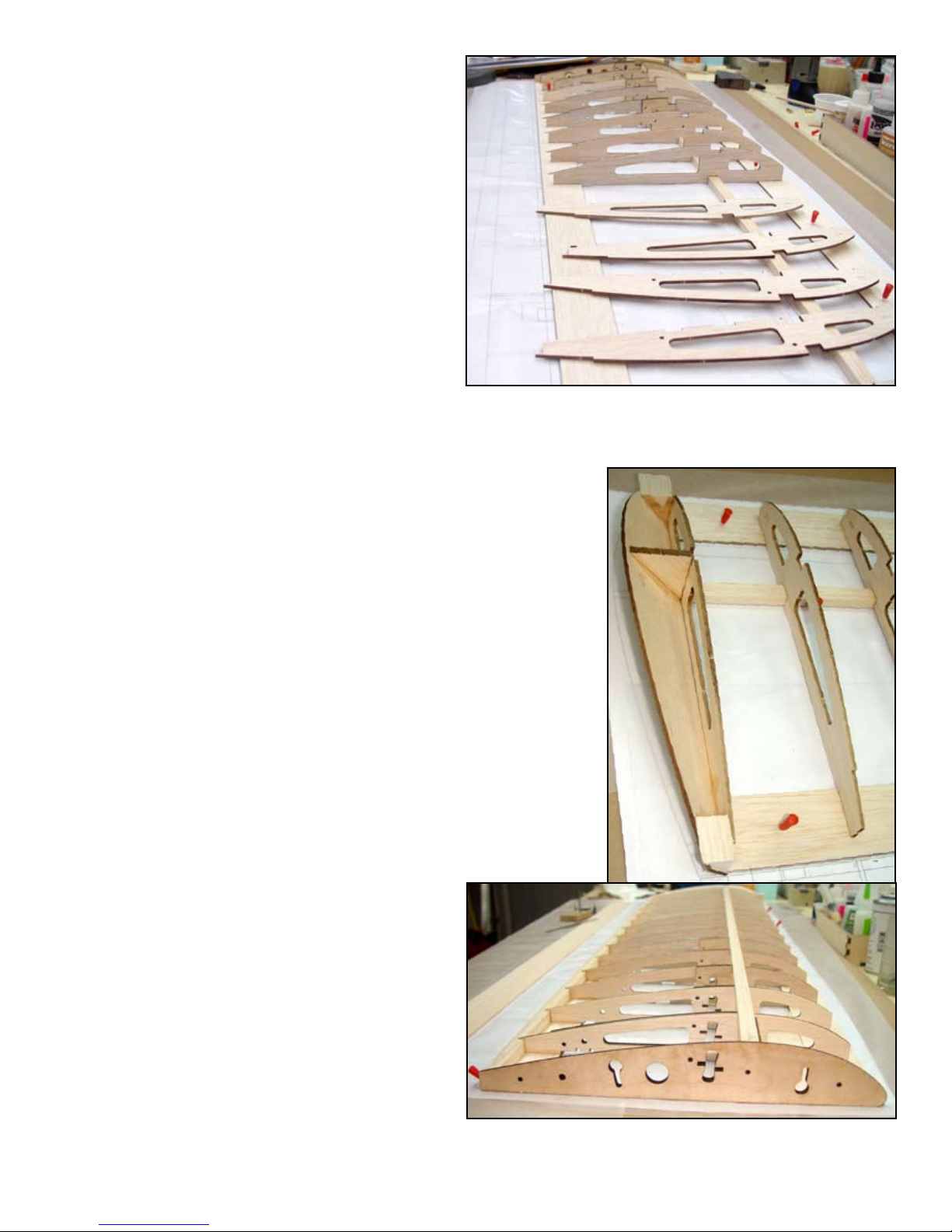

Carefully align the bottom sheeting part A

(BSA) to LEP and glue it to LEP.

Use Epoxy to glue the W1 assembly to the

wing assembly, LEP, TEP, BSA and the bot-

tom spar. Make sure the bottom spar is fully

engaged in the notch provided in the W1 as-

sembly and that W1-B is glued to the bottom

spar. W1-B will set the correct dihedral so it

must be at against BSA when installed.

LEP and TEP have been positioned. BSA has been installed and

now the W1 assembly is being Epoxyed to the wing assembly.