2

ated "GND" terminals (12 terminals total).

A total of 9 continuously variable, VDC and/or PWM con-

trolled, EC motors may be wired (in any combination) to the

VDC and/or PWM output terminals. For heating applications, a

maximum of 90 mA is available to operate the SCRs.

The 890-Series sequencer can be used for local, remote or both

local and remote operation. Remote operation can be implemented,

at any time, by using a Modbus RTU master computer to send the

appropriate register data, listed in Table 1, on pages 14 & 15, to the

890-DSQ Series sequencer's internal data registers The sequencer

communicates via a 3 wire Modbus RTU connection to the Modbus

RTU master computer. All of the 890-DSQ Sequencer's options,

parameters and numerical values can be read and set remotely

using the Modbus RTU connection. During remote operation, the

Modbus master reads and writes to the 890-DSQ Sequencer's 76

internal data registers, using Modbus RTU commands 3, 6 and 16

(hexadecimal 10).

The 890-DSQ Sequencers come with a pre-programmed series

of relay output stage setpoint (turn on & off) values. Each one of

the relay's turn on and turn off values may be individually adjusted,

either locally or remotely to suit a particular installation.

When a unique application requires the selection of different

setpoints, other than the pre-programmed setpoints, the new

setpoint values can be automatically calculated by the sequencer's

microcontroller, using equal spacing between stages. Any or all of

the pre-programmed setpoint values can also be updated, manually.

The selection of EC motors depends upon the end use of the EC

motor. When the EC motors will be used as variable stage modu-

lating motors they must be continuously variable EC motors that

accept a 1) 0 - 10 Vdc, or 2) 10 - 0 Vdc or 3) 17.5 volt, 80 Hz

PWM control signal. These continuously variable EC motors do not

need to have the same horsepower and maximum rpm as the fixed

rpm, staged PSC and EC motors. The ratio of max performance

can be set in the controller. However, installing continuously vari-

able EC motors that have the same size, line voltage, horsepower

and maximum rpm as the fixed rpm, staged PSC motors, they are

replacing, makes the installation simpler.

When the EC motors will be used as staging motors they should

provide the same performance (size, line voltage, horsepower and

maximum rpm) as the other staged motors.

When updating a bank of 4 or 6 PSC condenser fan motors to

obtain continuous airflow across the condenser, two of the PSC mo-

tors should be replaced with two continuously variable EC motors,

to supply enough modulating airflow, to achieve continuously

smooth air-flow thru the condenser coils over the sequencer's full

operating range.

When installing the 890-DSQ Sequencer in a heating system, and

the continuous vernier capability will be implemented, size the VS

(variable stage's) SCR with twice the KW capacity as a single fixed

staged heater to ensure continuously smooth heating functionality.

Pre-Installation Information/

Instruction

The 890 sequencer's operation is organized into two sections:

local and remote, with each section containing the same selectable

modes, menus, submenus, settings and numerical values.

The 890-DSQ Sequencer controls its operation by using the

information stored within its microcontroller's 76 internal data

registers. These data registers are numbered from 0 to 75, with each

register's data contents representing a unique sequencer function or

numerical value.

Each 890-DSQ sequencer's microcontroller is programmed, at

the factory, with the internal register data needed for that sequenc-

er's anticipated application. However, the pre-programmed data

can be changed, during or after installation, by manually and/or

remotely updating the microcontroller's internal register data.

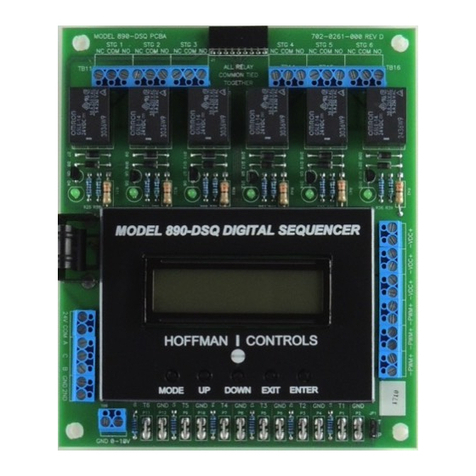

Manually updating the internal register data is accomplished by

viewing and then responding to the LCD screen's information and

appropriately pressing one or more of the sequencer's five push

buttons.

Manual operation starts with the LCD's Home Screen (Figure 1,

page 3). The Home Screen displays the number of fixed relay stages

turned on (Stages On: ), along with the selected input type (Tm p ,

PSI or VDC) and that input's present value (Tmp: 53.1).

When selected, the LCD's Home Screen also displays the variable

stage's percent of operation (VS: 75) along with a number repre-

senting the total of all of the fixed relay stages and effective variable

stages that are turned on (2.5). Refer to Mode 1.2, on page 4, for a

description of effective variable stage operation.

The sequencer's MODE button is used to sequentially cycle thru

the LCD screen's 5 available modes. Pressing the MODE but-

ton once advances the LCD's screen to the Change Output Stage

Settings screen (Mode 1). Slowly pressing the MODE button

repeatedly, cycles the sequencer thru its 5 available modes and then

back to the Home Screen.

Remotely updating the 890-DSQ Sequencer's internal register

data requires connecting the sequencer to a Modbus RTU master

computer that can send new register data to, and/or read current

register data from, the 890 microcontroller's internal memory.

NOTE: Since the 890-DSQ's operation is controlled by the data

stored within its internal registers, the sequencer provides the same

identical operation whether the register data is changed locally

(manually) or remotely.

In both local and remote operation the 890-DSQ Sequencer can

be setup to select 1) traditional or continuous VS (variable stage)

operation 2) the number and type of outputs used, 3) the number

and type of inputs used, 4) the primary, and/or secondary setpoint

values used and 5) the Modbus communication parameters.

Operating Methods

IMPORTANT:

When using replacement EC motors, review the system's

current protection device's capability to ensure the protection

devices can handle the much larger in-rush current experienced

during EC motor power up.