Hoffmann Propeller

Manual No. E 0107.72A

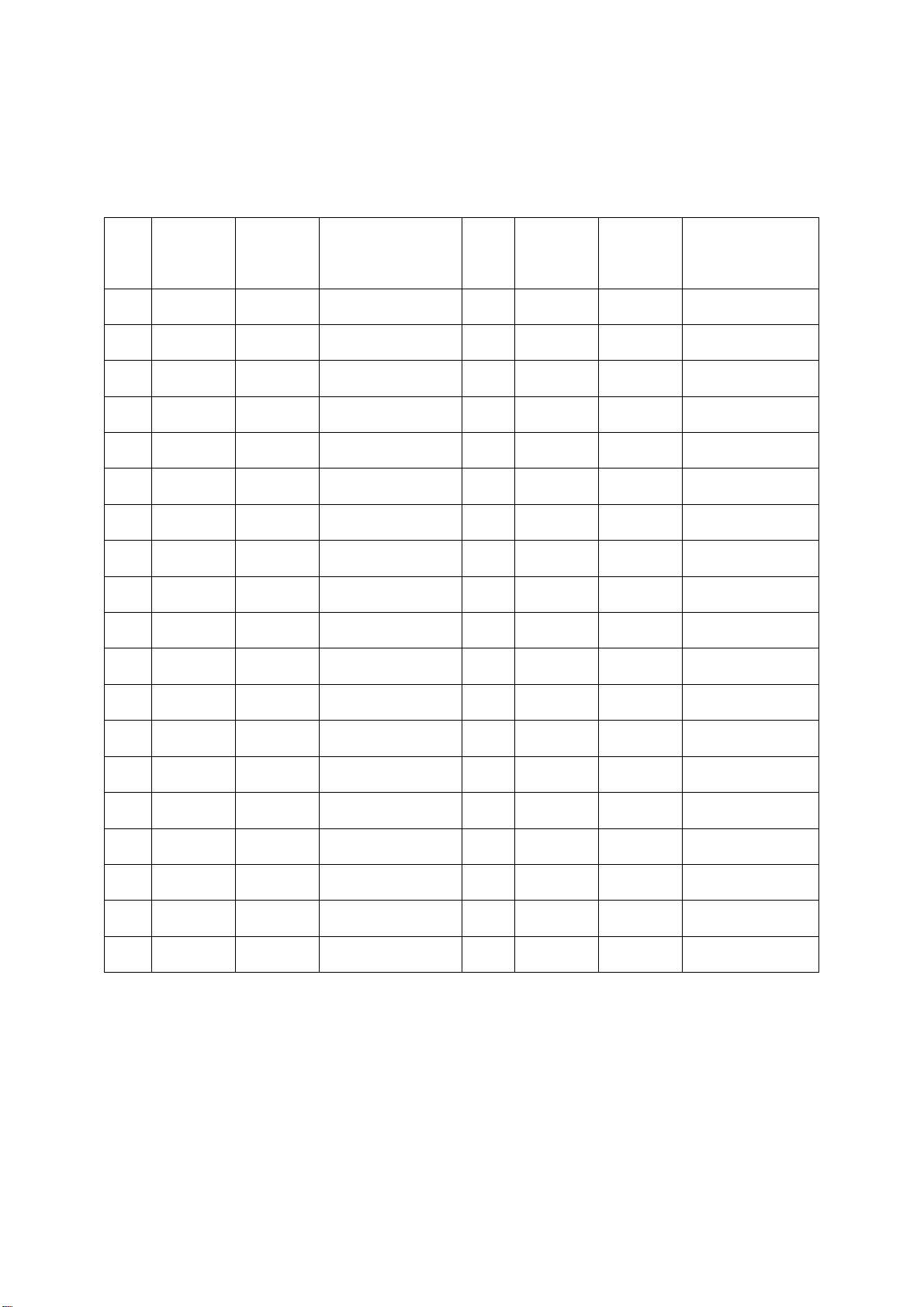

Content

1- GENERAL........................................................................................................ 1-1

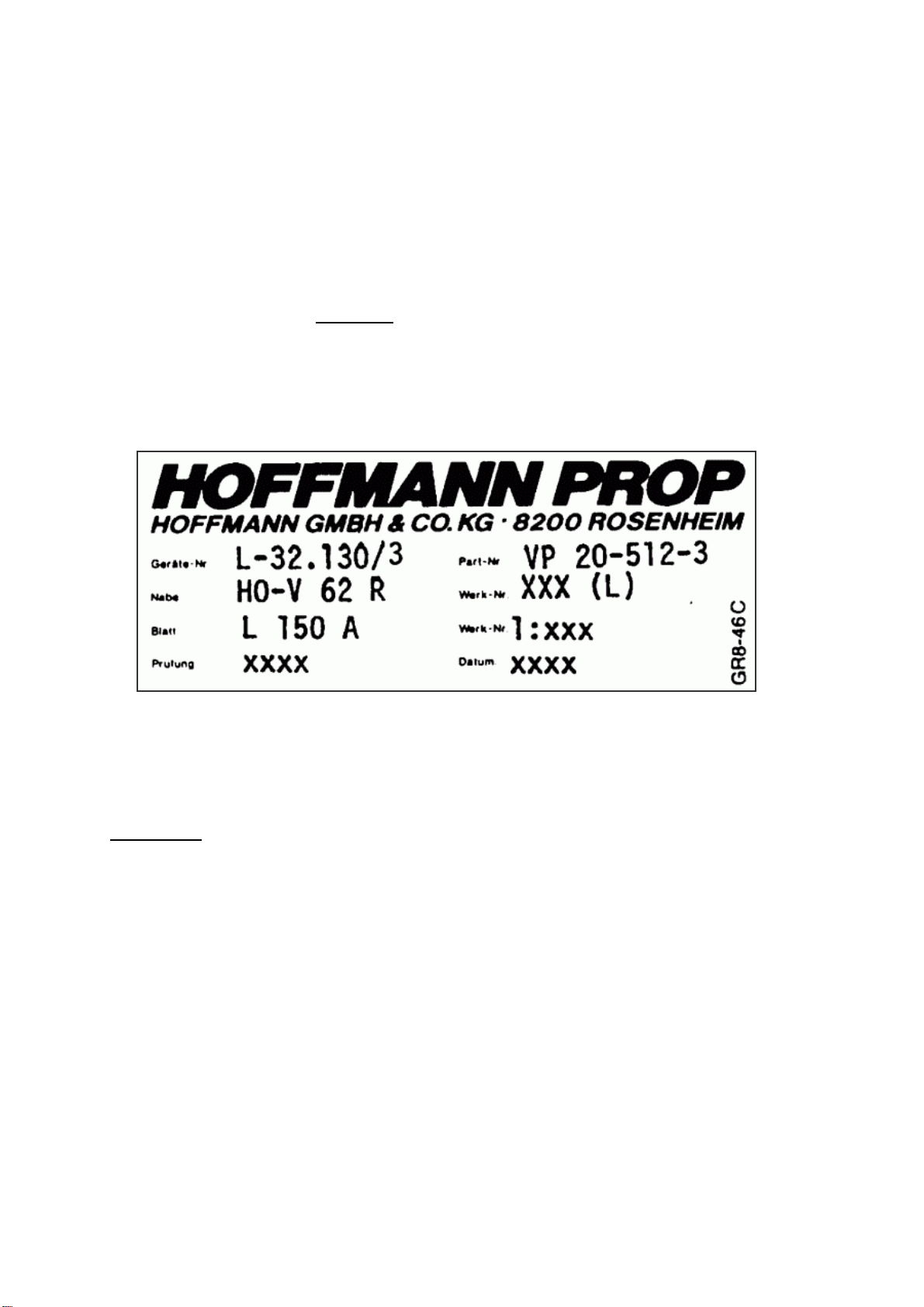

2- DESIGNATION ................................................................................................ 2-1

2-1. Designation of the Hub .............................................................................................2-1

2-2. Designation of the Blade...........................................................................................2-2

3- DESIGN DATA................................................................................................. 3-1

4- CONSTRUCTION............................................................................................. 4-1

4-1. Hub Assembly............................................................................................................4-1

4-2. Pitch Change Mechanism.........................................................................................4-1

4-2.1. HO – V62R..........................................................................................................4-1

4-2.2. HO – V62 ............................................................................................................4-5

4-3. Blade Assembly..........................................................................................................4-5

4-4. Blade Bearing.............................................................................................................4-6

4-5. Spinner Assembly......................................................................................................4-6

4-6. Counterweights..........................................................................................................4-6

5- OPERATION.................................................................................................... 5-1

5-1. Propeller Model HO – V62R....................................................................................5-2

6- INSTALLATION............................................................................................... 6-1

7- INSPECTION ................................................................................................... 7-1

7-1. Daily Inspection.........................................................................................................7-1

7-2. 100h Inspection..........................................................................................................7-2

7-3. Inspection of the blades.............................................................................................7-3

7-4. Damaged fibre glass cover........................................................................................7-6

7-5. Additional periodic inspections................................................................................7-6

61-10-01 ii

7-6. Overhaul.....................................................................................................................7-6

New Edition August 2003