SPECIAL INSTRUCTIONS

1. Read and follow operator’s manual thoroughly.

2. DO NOT touch rotating cutter or parts.

3. Always stop machine completely and unplug from power source before changing cutters, clearing swarf,

refilling lubrication or performing adjustments.

4. Never wear loose clothing or gloves when working near cutting area or machine arbor.

5. Always wear eye protection. Any tool can shatter.

6. Always use safety chain or strap provided with machine.

7. Always use proper tooling. Keep cutters securely fastened.

8. DO NOT use dull or broken cutters.

9. Beware of ejected slugs at end of cut. They become HOT during the cut.

10. Keep all safety features functioning and working properly.

11. Keep bottom of magnet burr free and clear of chips and debris.

12. To reduce the risk of electrical shock, DO NOT remove or alter electrical panels or use machine in damp

areas.

13. Use only authorized service centers for repairs.

Remove all contents from packaging and inspect to ensure no damage was incurred during shipping.

Your Holemaker package should include the following:

QTYDESCRIPTION

METAL CARRY CASE

HOLEMAKER SM4X4 MACHINE 1

1

SAFETY CHAIN WITH CLIP

HEX WRENCH 4MM

1

1

OPERATORS MANUAL

#3 MT ARBOR ASSEMBLY 1

COOLANT BOTTLE ASSEMBLY 1

DRILL DRIFT 1

FRONT HANDLE

3

SPOKE HANDLE WITH KNOBS

WHAT YOU SHOULD KNOW BEFORE YOU DRILL

1. Type of material to be drilled, Brinnell or Rockwell hardness, material thickness and position should all be

determined to ensure proper selection of cutting tools.

2. Remove any excessive mill scale or rust from surface to be drilled.

3. When drilling thin materials, it is recommended that you placea steel plate under the work piece and Holemaker

magnet area to increase magnetic holding force.

4. Material that has been flame cut may become heat treated and therefore difficult to drill.Avoid drilling near such

areas whenever possible.

5. Special cutter lubricant is available for using the Holemaker and annular cutters in the horizontal

position. Consult you distributor for more information.

Caution: Do not drill on material where welding is also simultaneously being performed. Drilling machine will

be damaged.

Caution: Powering drilling machine from generator without proper surge protection device between

generator and drilling machine may cause damage to the Printed Circuit Board in machine.

The Holemaker SM2X2 is not designed for use on steel thinner than 3/8” or 10mm, as the magnet’s adhesive

power would be significantly reduced which can cause machines failure or individuals injury.

The machines built in “Smart Magnet Technology” will detect insufficient magnetic adhesion, and will

cause the machines motor on/off button to not engage. Although it is not recommended, this feature can

be bypassed by following the attached “Smart Magnet Technology Bypass” instruction leaflet.

7

1

SAFETY GUARD 1

1

1

HEX WRENCH 2.5MM

HEX WRENCH 6MM 1

SPANNER 8MM 1

1

HEX WRENCH 5MM

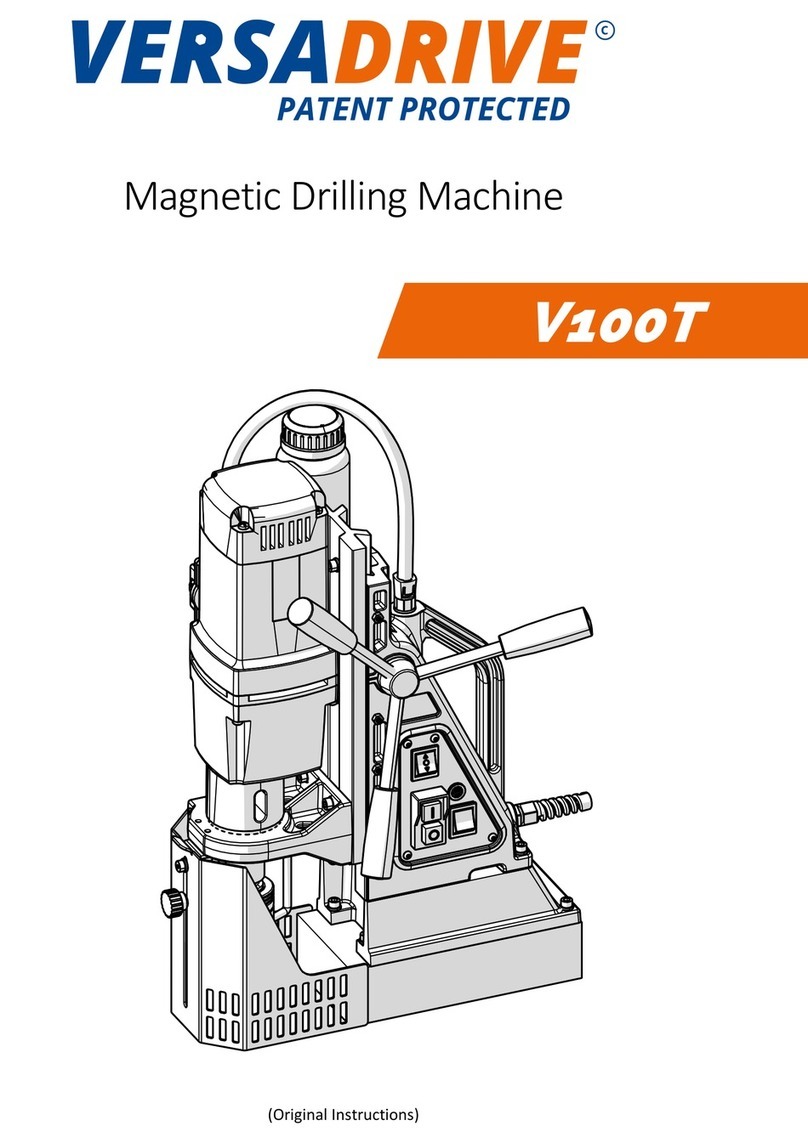

Assemble three spoke handles to feed hub. NOTE: Feed hub assembly

is mounted on right side of machine frame – if necessary, it can be reversed

for left hand operation by simply removing the fastener and hub from frame.

Remove hub pinion shaft from right side of frame and insert it into left side of

frame. Replace hub and fastener into frame and tighten securely. Install the

arbor into the drill motor by inserting the arbor body into the spindle. By turning

the arbor while inserting, the arbor tang will properly line up in the spindle.

Turn the arbor until it bottoms out in the spindle and then tap lightly with a

plastic hammer to secure.