HL-190 D25 4WD/P/N / HL-220 D25 4WD/P/N

B-165DL25 4WD/P/N / B-195DL25 4WD/P/N

Rev. A

5/2/18 Page 3

Contents Page

1 General information ................................................................................................................................ 5

1.1 Use of this instruction manual ..................................................................................................................5

1.1.1 Objective ..................................................................................................................................................5

1.1.2 Symbols used in this instruction manual ..................................................................................................5

1.2 Standard equipment.................................................................................................................................5

1.3 Additional documentation.........................................................................................................................5

1.4 Optional extras .........................................................................................................................................5

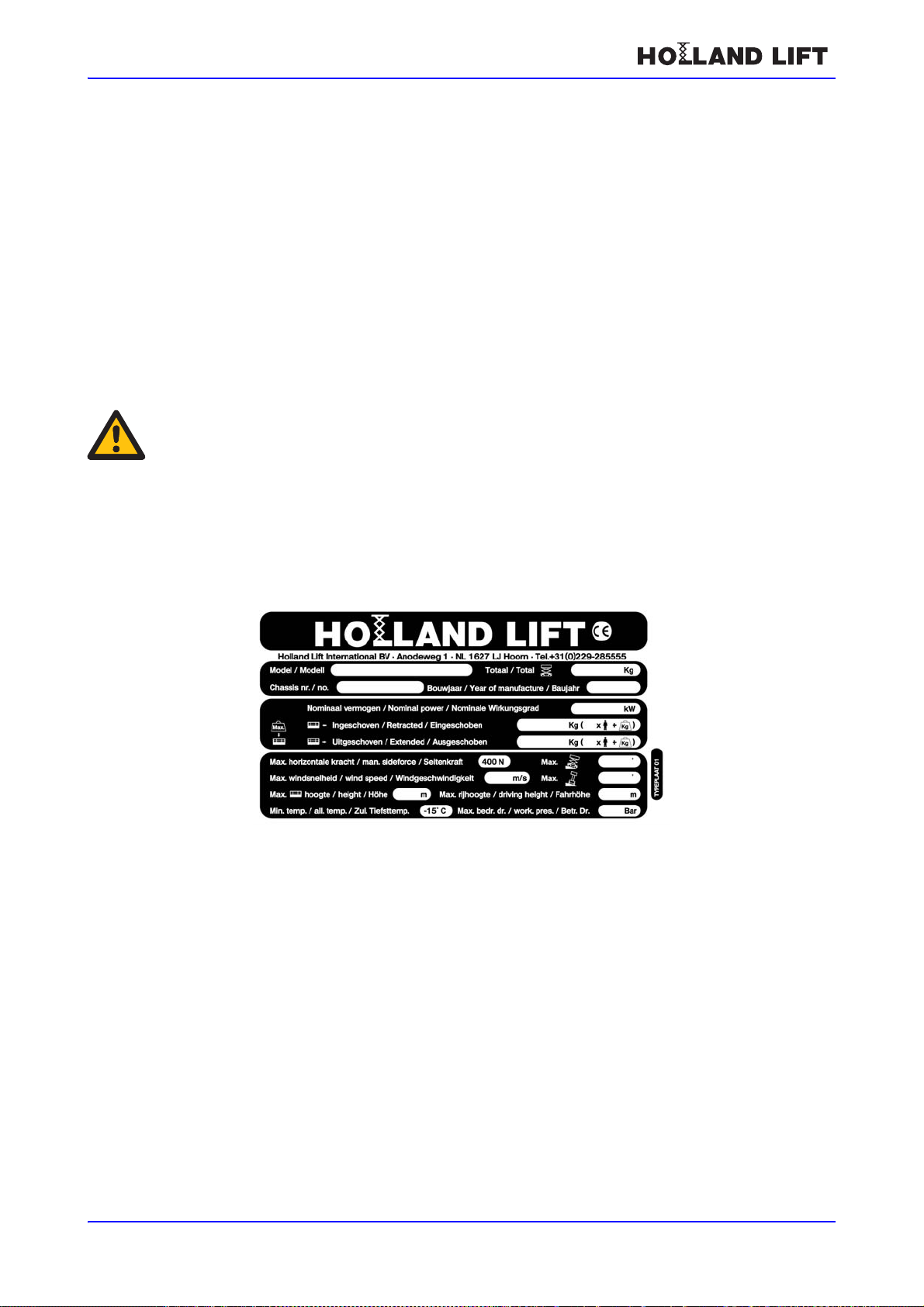

1.5 CE marking...............................................................................................................................................6

1.6 Scissor lift identification (type plate).........................................................................................................6

1.6.1 Location of the type plate.........................................................................................................................6

1.7 Delivery conditions and warranty .............................................................................................................7

1.7.1 Delivery conditions...................................................................................................................................7

1.7.2 Warranty...................................................................................................................................................7

1.8 Intended use and modifications................................................................................................................7

1.8.1 Intended use.............................................................................................................................................7

1.8.2 Modifications ............................................................................................................................................7

1.9 Service and technical support ..................................................................................................................8

2 Safety...................................................................................................................................................... 9

2.1 Emergency procedures............................................................................................................................9

2.1.1 Emergency stop .......................................................................................................................................9

2.1.2 Contact with electrical (high voltage) cables............................................................................................9

2.2 Safety instructions....................................................................................................................................9

2.2.1 General information..................................................................................................................................9

2.2.2 Safety instructions during normal use ....................................................................................................10

2.2.3 Safety regulations during maintenance..................................................................................................11

2.2.4 Safety regulations when working on the electrical system.....................................................................11

2.2.5 Safety regulations when working on the hydraulic system.....................................................................11

2.3 Liability ...................................................................................................................................................11

2.4 Users......................................................................................................................................................11

2.5 Intended use...........................................................................................................................................12

2.6 Stickers on the scissor lift.......................................................................................................................13

2.6.1 Stickers on the front of the scissor lift.....................................................................................................13

2.6.2 Stickers on the left-hand side of the scissor lift ......................................................................................14

2.6.3 Stickers on the right-hand side of the scissor lift....................................................................................15

2.6.4 Stickers on the platform..........................................................................................................................16

2.6.5 Stickers in the valve/electrical compartment. .........................................................................................17

2.6.6 Sticker on the engine..............................................................................................................................18

2.6.7 Sticker on the control box.......................................................................................................................18

2.7 Location of the safety devices on the scissor lift ....................................................................................19

2.7.1 Emergency stop button ..........................................................................................................................20

2.7.2 Safety bracket ........................................................................................................................................20

2.7.3 Protective scissor skirt............................................................................................................................20

2.7.4 Driving alarm - visual..............................................................................................................................20

2.7.5 Emergency descent device....................................................................................................................21

2.7.6 Driving alarm – acoustic.........................................................................................................................22

2.7.7 Speed limiter ..........................................................................................................................................22

2.7.8 Tilt indicator............................................................................................................................................22

2.7.9 Overload safety device...........................................................................................................................23

2.7.10 Lifting cylinder safety device ..................................................................................................................23

2.7.11 Pipe/hose break safety device ...............................................................................................................24