| 2

PART 1 . Section 1

MANUAL CONTROL OR COMPUTER CONTROL?

One of the ongoing debates when discussing rebreather safety is whether manually controlled

or electronically controlled rebreathers are safer. From the day in 1995 when PRISM Topaz class

#1 was held in Hermosa Beach, CA, students were taught to “fly” their rebreathers manually by

watching their secondary analog displays and manually injecting oxygen and diluent as needed.

From day one, PRISM students were taught that the primary control system was always the divers

brain. It wasn’t until the last dive of the last day of class that students were told, “OK, you can turn

on your electronics and experience a computer controlled dive”.

Diving with the computer monitoring the oxygen and the user keeping an eye on everything with

(at that time) a Heads Up Display primary and a wrist-mounted analog secondary sure kept us

busy, but we quickly realized that the computer was a LOT better at closely maintaining a set

point! We also realized that our instructor had trained us to be manually controlled rebreather

divers with the safety of “computer over-watch”.

Why two independent monitoring systems in one rebreather? Simply put, electronics, batteries

and wiring combined with salt water (or even fresh water) do not get along well together. While

we can seal circuit boards and wiring interfaces against water intrusion, rebreathers should have

a diver accessible compartment to change batteries, and because of this need for accessibility,

flooding can occur.

This is the Achilles heel of rebreathers with on-board electronics. Any time an O-ring sealed

Compartment is unsealed, the potential for debris to get on the O-ring and cause the

compartment to flood during the next dive is increased.

So, with two separate systems onboard with separate battery compartments, if one battery

compartment floods and destroys the battery, we simply switch to the other monitoring system to

safely end the dive. When our dive is over, we dispose of the wiring harness and battery, clean the

compartment and put in a fresh battery and new O-ring(s).

// DESIGN PHILOSOPHY

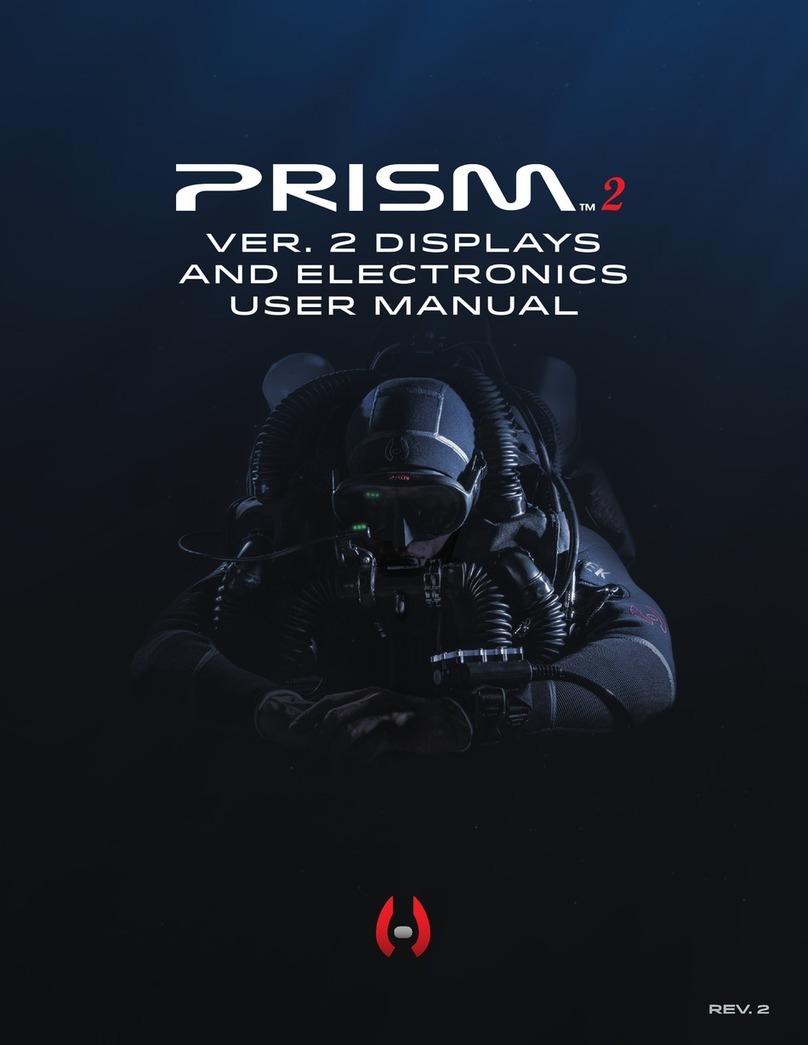

The PRISM family of rebreathers has a long and illustrious history, and it is

considered one of the foundation platforms of the modern day electronically

controlled “sport” rebreather.

The PRISM 2, like its forerunner the PRISM Topaz, is a digitally controlled

electronic closed circuit rebreather with split front-mounted over the shoulder

counterlungs (OTS-CL). It incorporates a radial design scrubber for the best

possible duration and work-of-breathing. All gas delivery systems on the PRISM 2

have both automatic and manual function.