Table of contents

1 Introduction and standards.........................................................................1

2 Installation and Electrical connection........................................................2

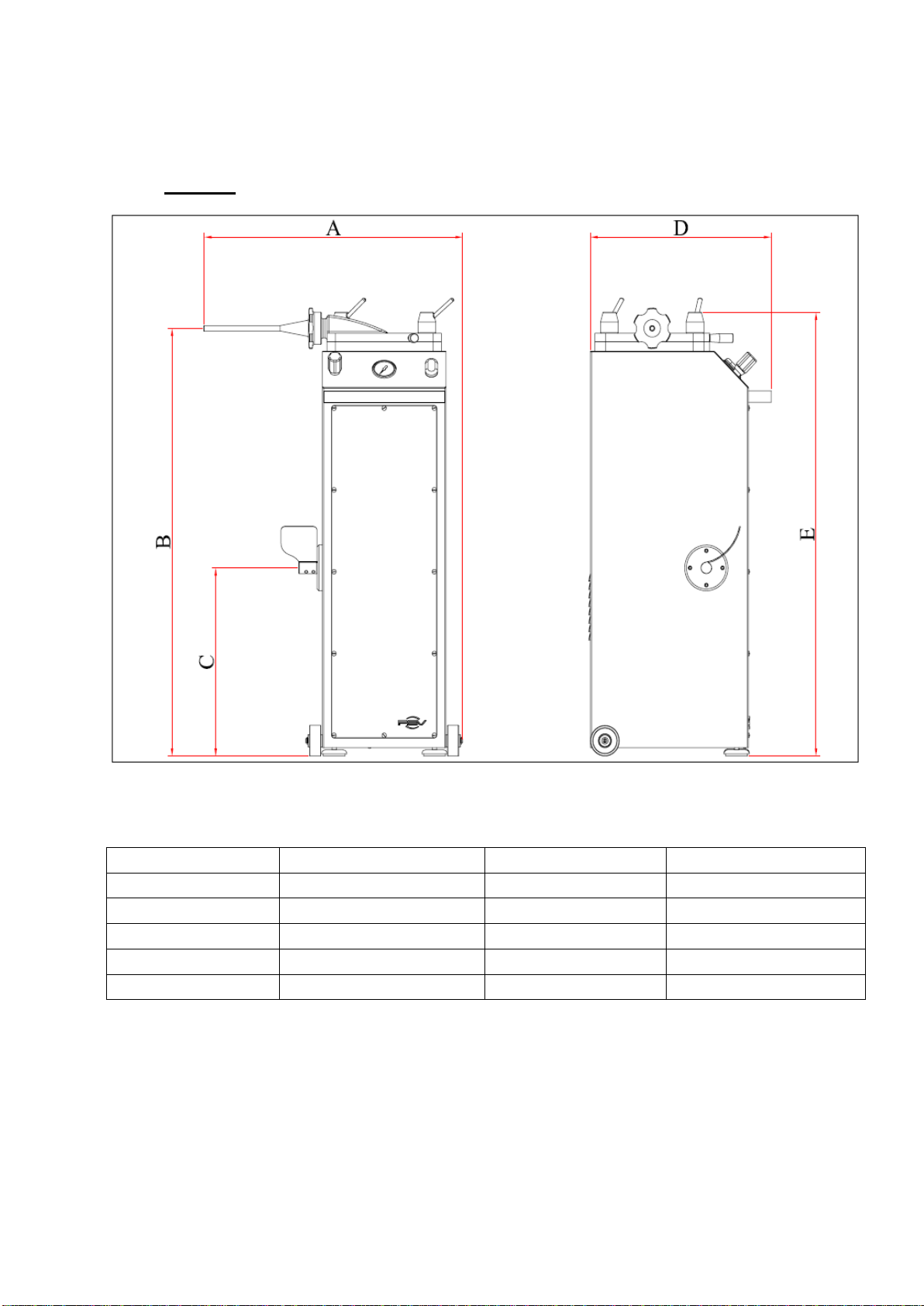

3 Features and specifications ........................................................................3

4 Getting started ..............................................................................................4

5 Good using....................................................................................................4

6 Cleaning.........................................................................................................6

7 Maintenance..................................................................................................7

8 Accessories...................................................................................................7

9 Warranty........................................................................................................8

10 Electrical schemes Tri phases ..................................................................9

11 Electrical schemes single phase ............................................................10

12 Exploded scheme.....................................................................................11

Detail (A) :......................................................................................................12

Detail (B) :......................................................................................................13

13 Nomenclature............................................................................................14