4

3. Safety Instructions

Study these instructions carefully before operating this

equipment.

* Never use a Core™ Technology product with a Twin-line hose product.

* Use this equipment only for jobs for which it is designed. If in doubt or not clear, be sure to

consult your dealer.

* Always wear personal protection equipment such as safety goggles, helmet, gloves, protective

clothing and safety shoes.

* Keep spectators at sufficient distance.

* Stand on stable ground and use both hands to hold and/or operate the equipment.

* Hold the equipment only at the appropriate places, i.e. at the deadman's handle and the carrying

handle.

* Stabilize the objects the tool will be used on.

* Never cut parts under hydraulic and/or pneumatic pressure, at live voltage or mechanical stress.

* Stop immediately if the blades are bent open during cutting.

* The equipment is not designed for lifting or raising loads.

* In the event of oil leakage, stop immediately and consult the troubleshooting list.

* In the event of unfamiliar noise, vibration or other unusual behavior, stop immediately and

consult your dealer.

* For Twin-line tools, never disconnect the quick-action couplings when the pump is in operation

and when the pressure relief valve of the pump is in the "Operation" position.

* Store the unit with the blades slightly crossed.

* The safety valves between the couplers must never be adjusted. In the event a problem develops

with the safety valve, contact your dealer.

* The equipment must only be operated with non-toxic mineral base hydraulic oil distributed by

Holmatro.

* Use only Holmatro accessories and parts.

* Observe the maintenance instructions.

* Only trained service technicians, certified by Holmatro, are allowed to repair this equipment.

* Replace safety symbols / pictograms and / or information labels if worn.

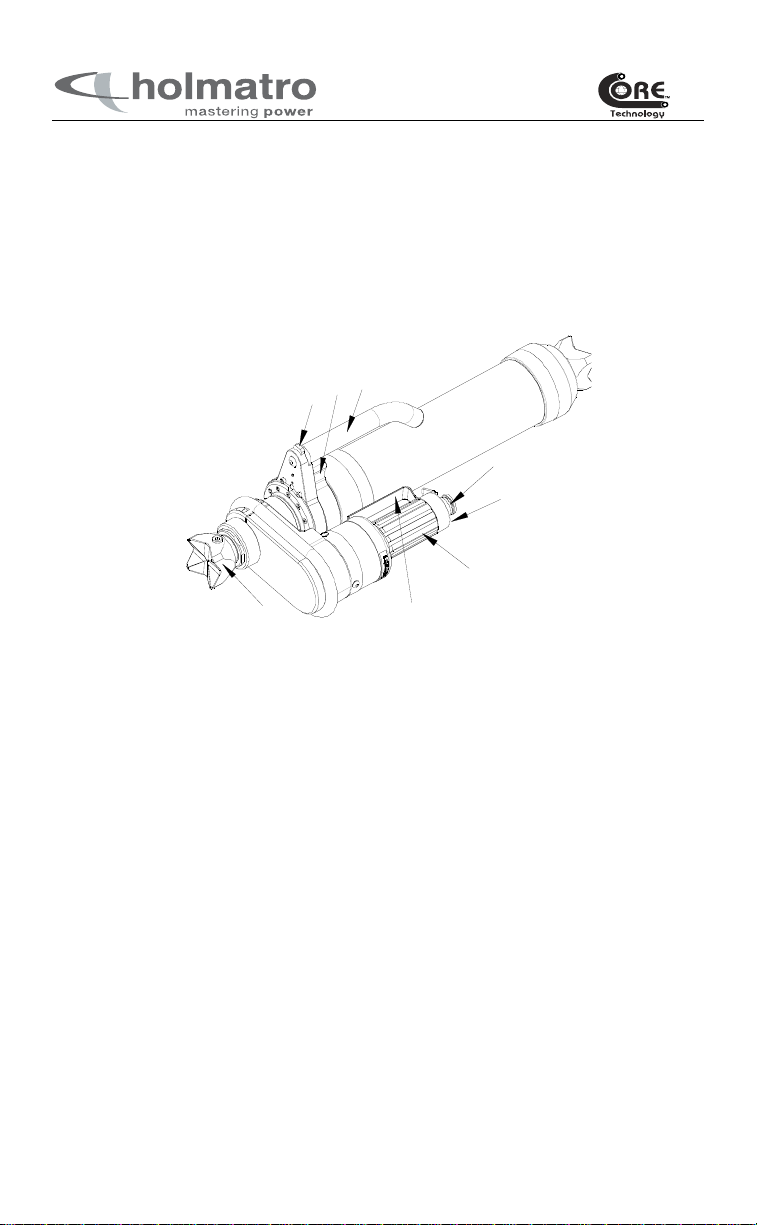

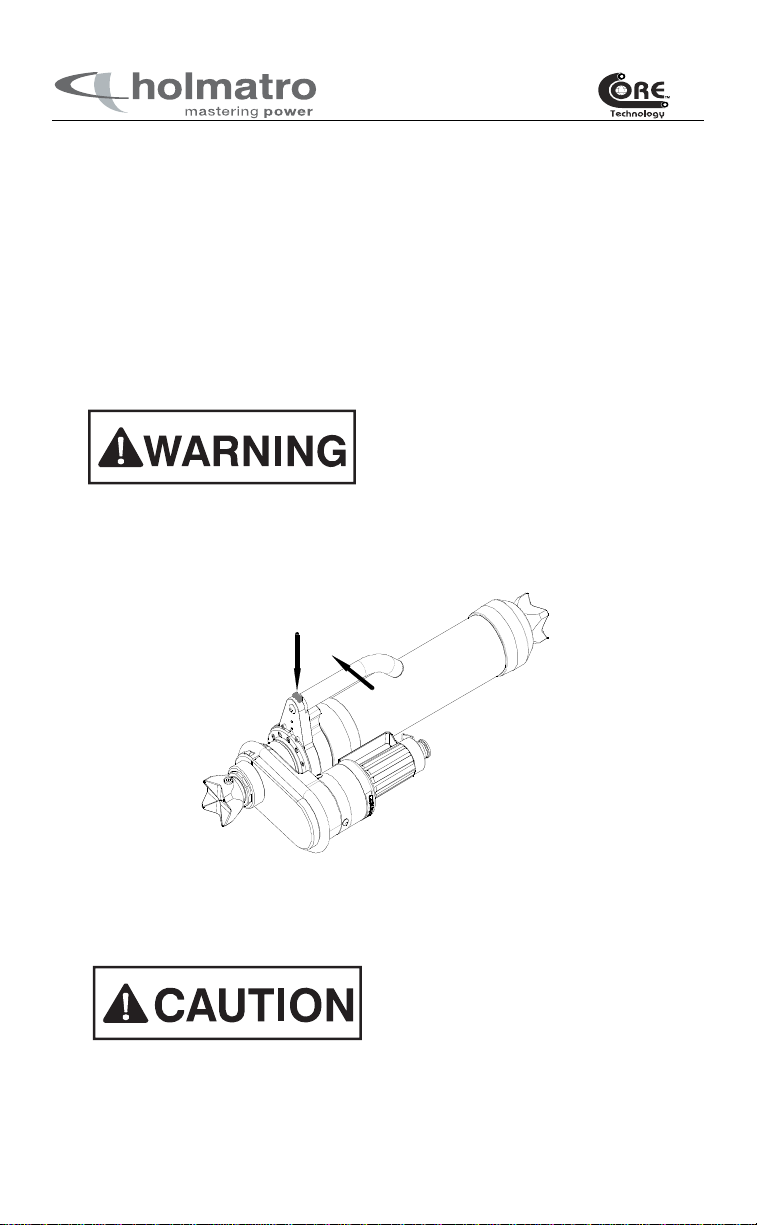

4 The tool is equipped with the following

labels/stickers:

1. Wear personal protection equipment

2. Dead-man's handle operating direction

3. Warning to prevent parts of the body being pinched/cut off

4. Product identification: model, serial number, year of construction, etc.

5. Grease and lubrication label.

6. Safety / warning Label.