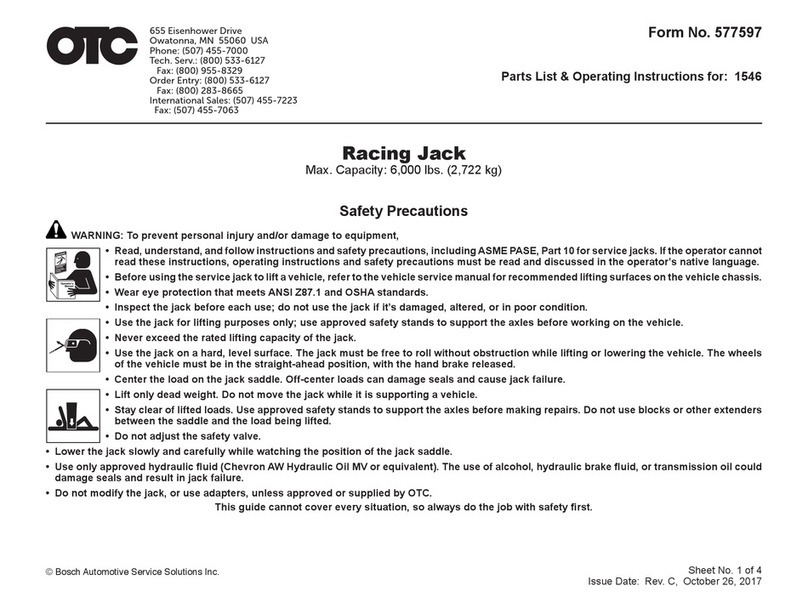

Safety Precautions

WARNING: To help prevent personal injury and/or equipment damage,

• Study, understand, and follow all safety precautions and operating instructions

before using this transmission jack. If the operator cannot read these instructions,

operating instructions and safety precautions must be read and discussed in the

operator’s native language.

• Wear eye protection that meets ANSI Z87.1, CE EN166, AS/NZS 1337, and OSHA

standards.

•

Only qualied operators may install, operate, adjust, maintain, clean, inspect, or

transport this transmission jack.

• A load must never exceed the rated lifting capacity of the jack.

• Do not lift or support the vehicle with this jack. Place support stands under the

vehicle before starting repairs.

• Only use the jack on a hard, level surface.

• Center the load on the jack saddle. Off center loads can damage the seals in the

hydraulic cylinder and cause jack failure.

• Never move the jack with a load any higher off the ground than necessary. Slowly

and carefully move the jack around corners because the load could tip. Stay clear

of a lifted load.

• Lower the jack slowly and carefully while watching the position of the load.

• Do not use this transmission jack for anything other than its intended purpose.

• No alteration shall be made to this product.

• Inspect the condition of the transmission jack before each use. Do not use if damaged, altered, or

in poor condition.

• Do not use adapters with this jack unless supplied by OTC.

• Use only anti-wear hydraulic jack oil with a 215 SUS viscosity rating at 37.78° C (100° F). The use of

alcohol, hydraulic brake uid, or transmission oil could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety rst.

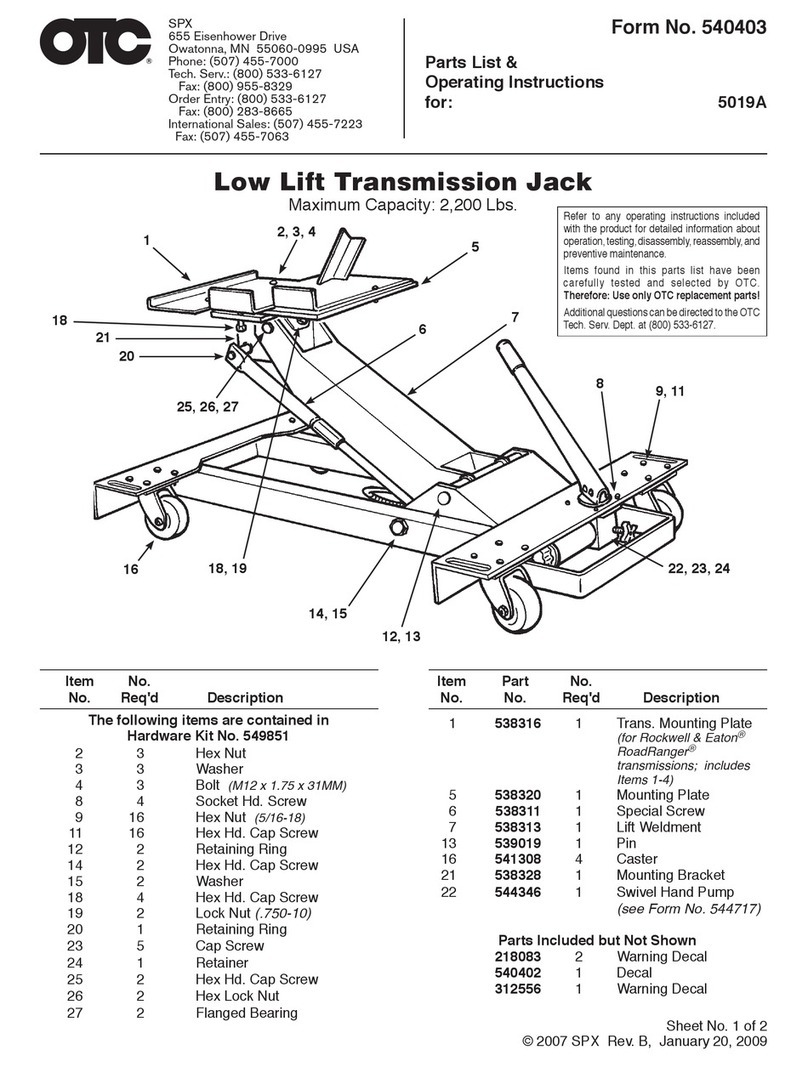

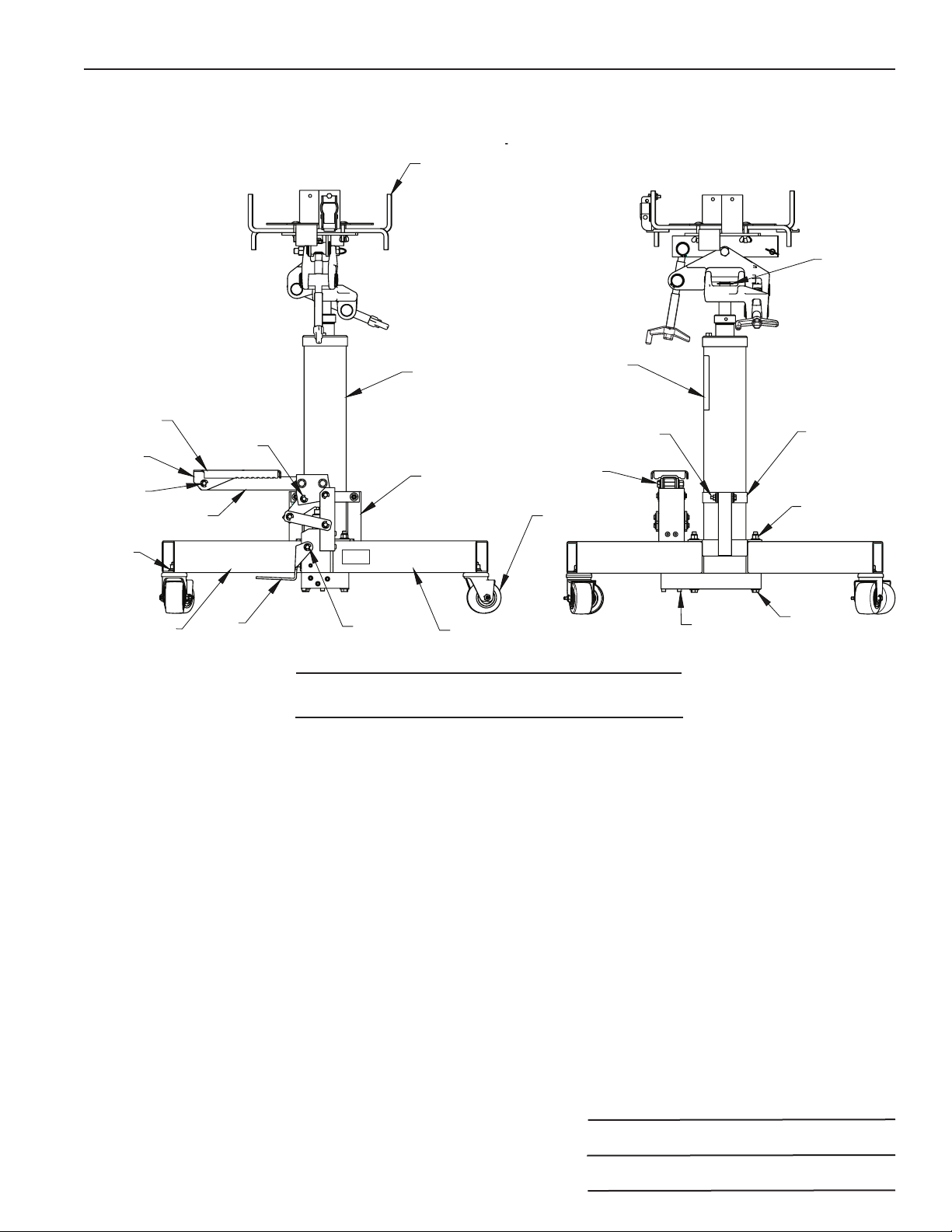

Setup Instructions

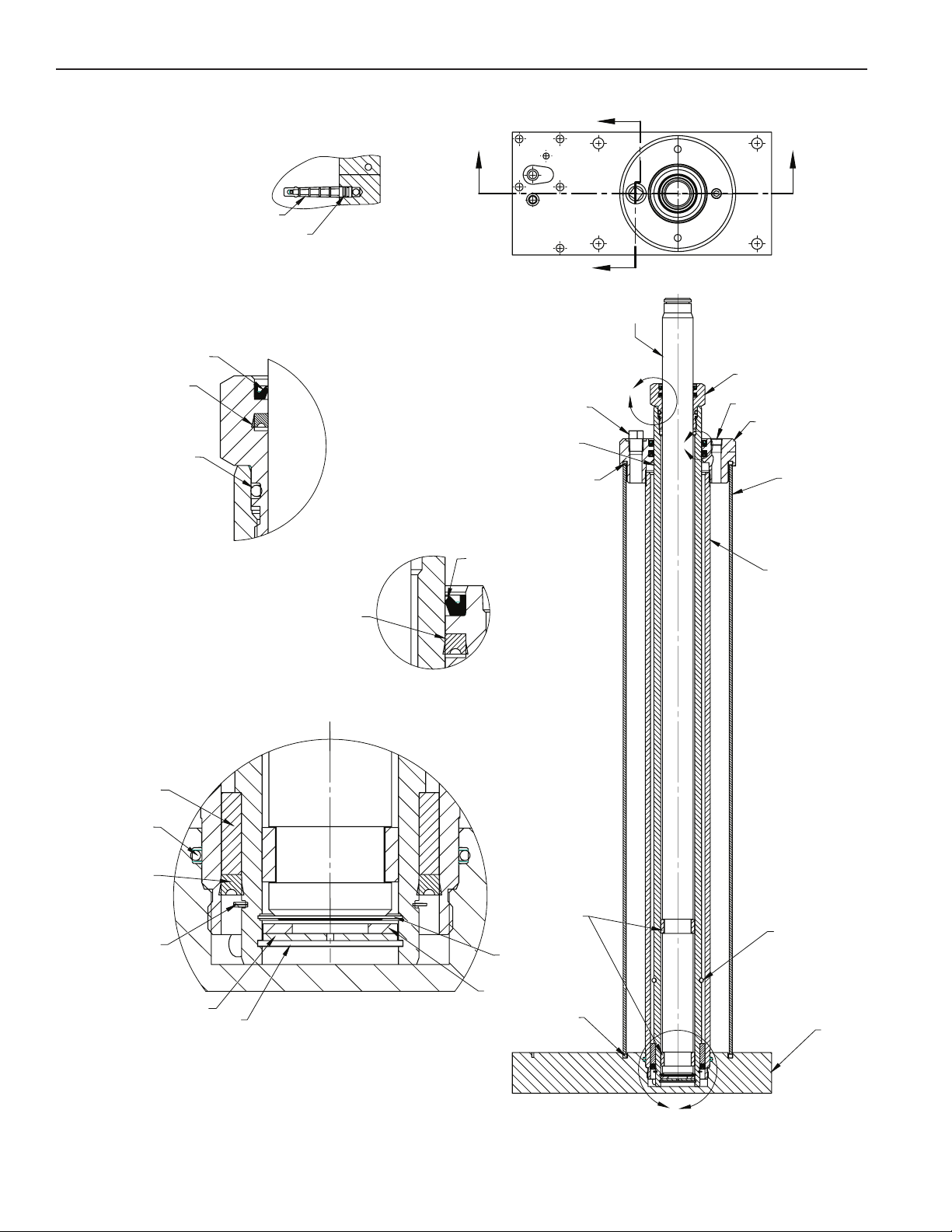

1. Remove the transmission jack from the pallet, and attach the casters using the hex nuts provided.

2. Remove the hex nuts holding the head assembly plate, and replace them with the wing nuts provided.

3. Remove the shipping oil plug, and replace it with the vented oil plug provided.

4. The transmission jack is shipped with hydraulic oil in the cylinder reservoir. Before using the jack for the

rst time, press the release pedal to open the release valve, and operate the foot pump eight full strokes

to distribute the oil.

Operating Instructions

1. Follow the vehicle's recommended service procedure for removal of the component.

2. Position the jack under the vehicle.

3. Raise the jack by operating the foot pump until the saddle touches the component.

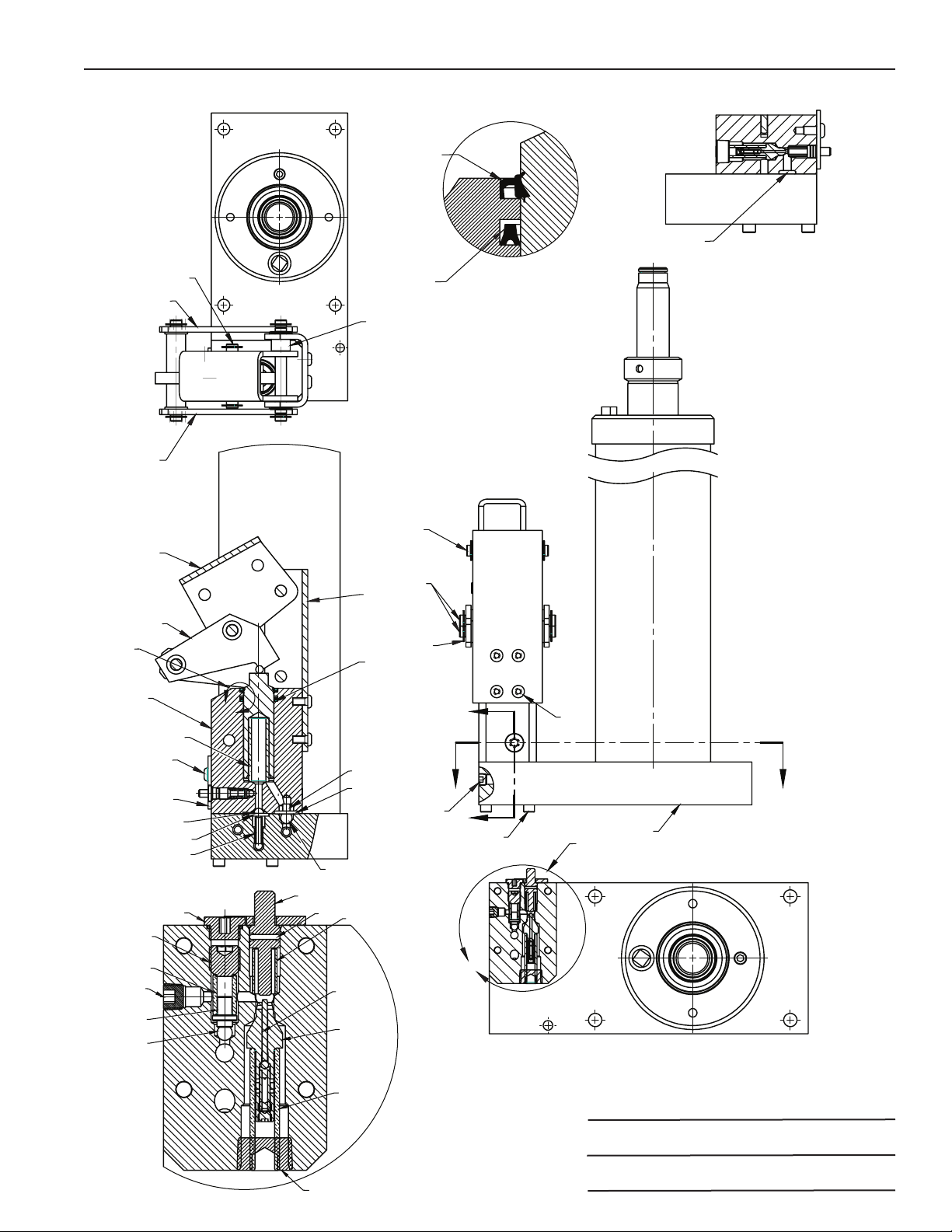

4. Adjust the support brackets to t the component.

5. Use the tilt crank to align the saddle with the component.

6. Finish raising the jack to the component. Secure the strap assembly around the component.

Parts List & Operating Instructions Form No. 560935, Sheet 1 of 6, Back