PS1202C, PS2402C REPLACEMENT POWER SUPPLY KITS FOR ELECTRONIC AIR CLEANERS

69-1137EF—05 2

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to fol-

low them could damage the product or cause a

hazardous condition such as electrical shock.

2. Check the ratings given in the instructions and

on the product to make sure the product is suit-

able for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electric Shock Hazard.

Safety Hazard.

Can cause electrical shock or equipment

damage.

Disconnect power before removing old power

supply board and installing replacement power

supply board. When servicing the F57 or F90,

stand on a stable work platform or ladder.

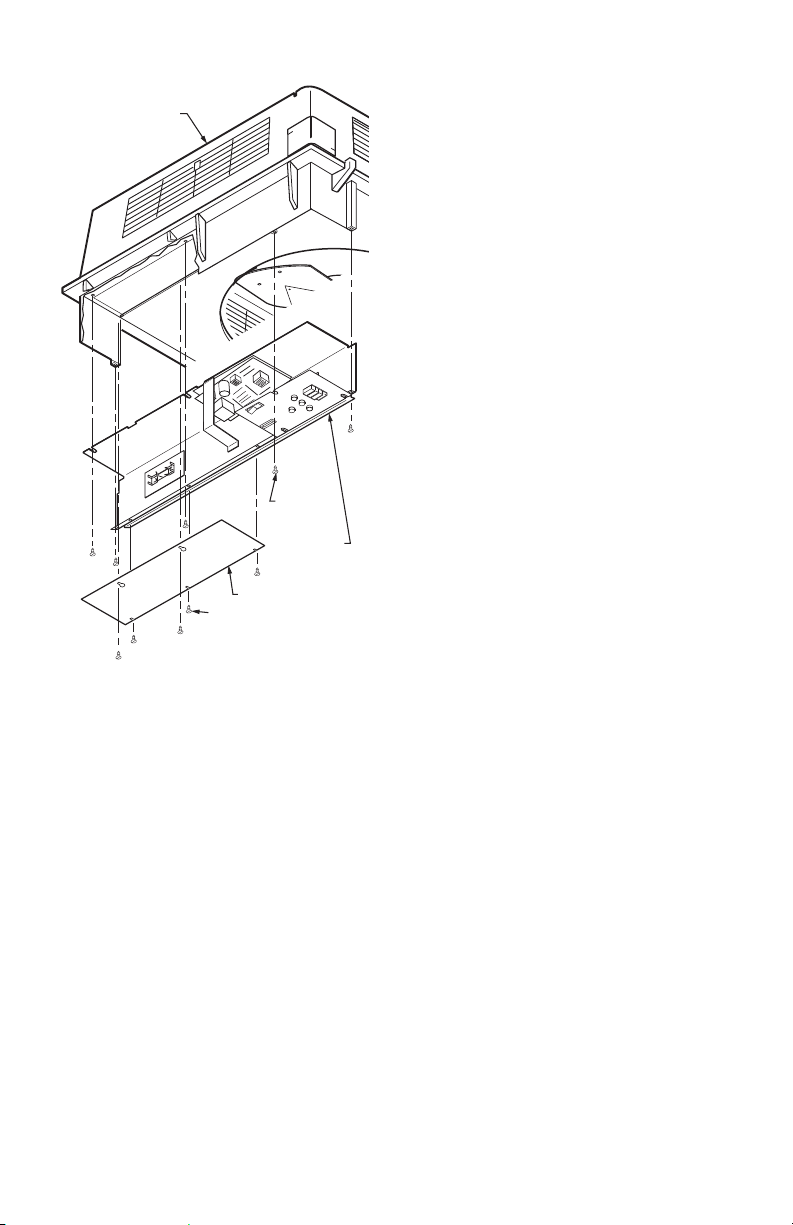

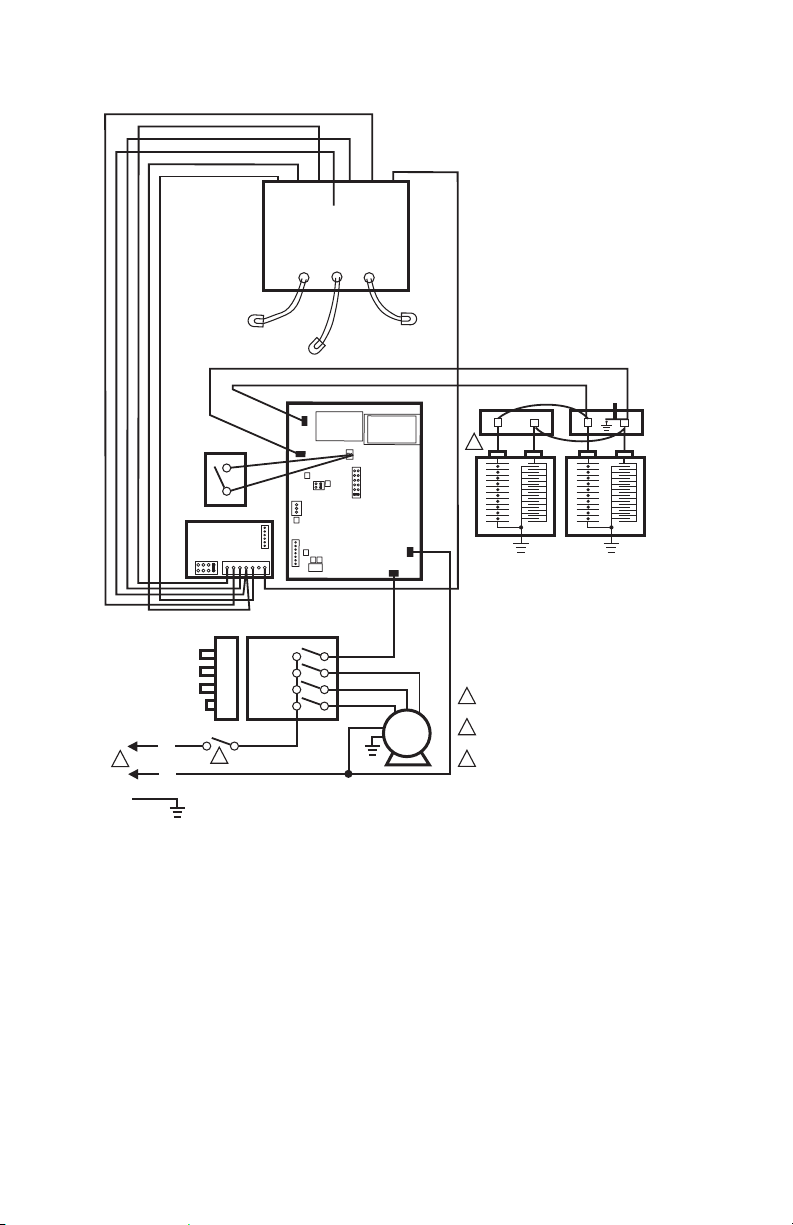

Fig. 1. Power supply location on F50E Two-Cell Air

Cleaners.

To Remove Old Power Supply

Board And Performance

Indicator Board

NOTE: It is advisable to observe the location of lead-

wires on the power supply to be replaced. Tag-

ging the lead-wires as they are removed will

help to correctly reconnect them.

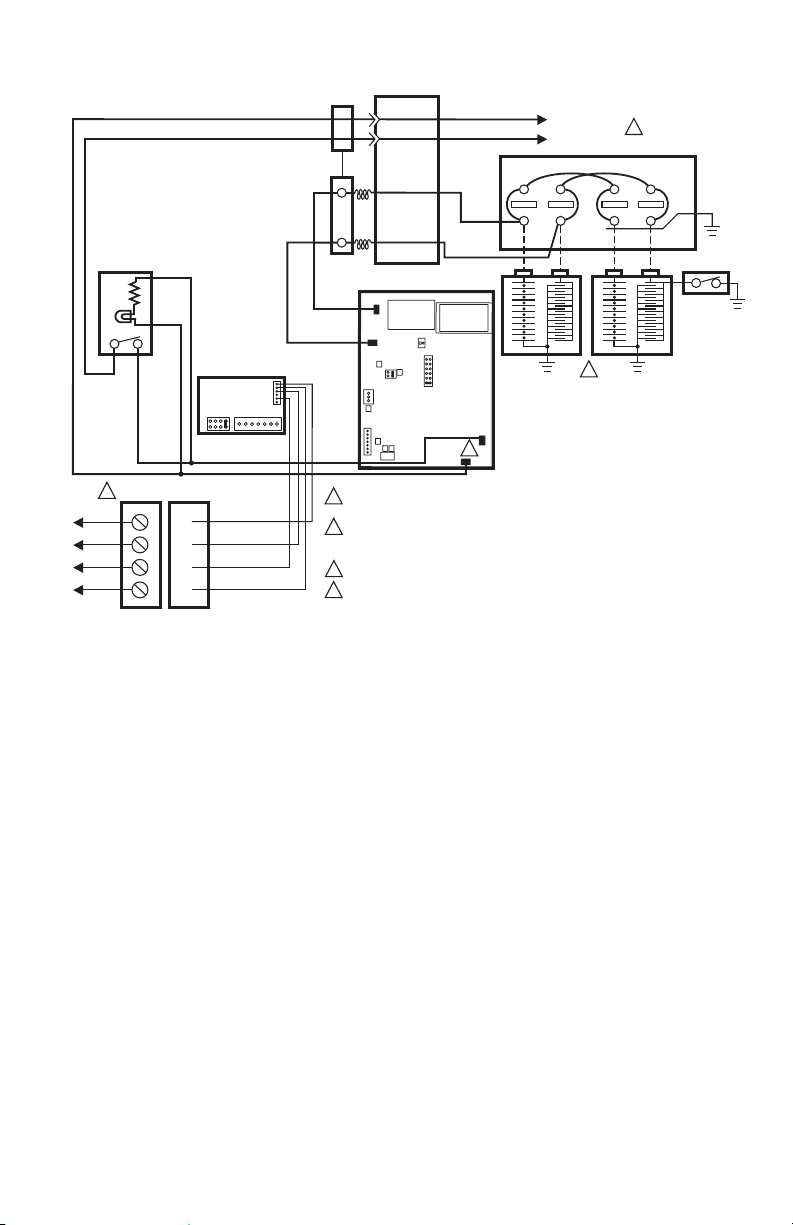

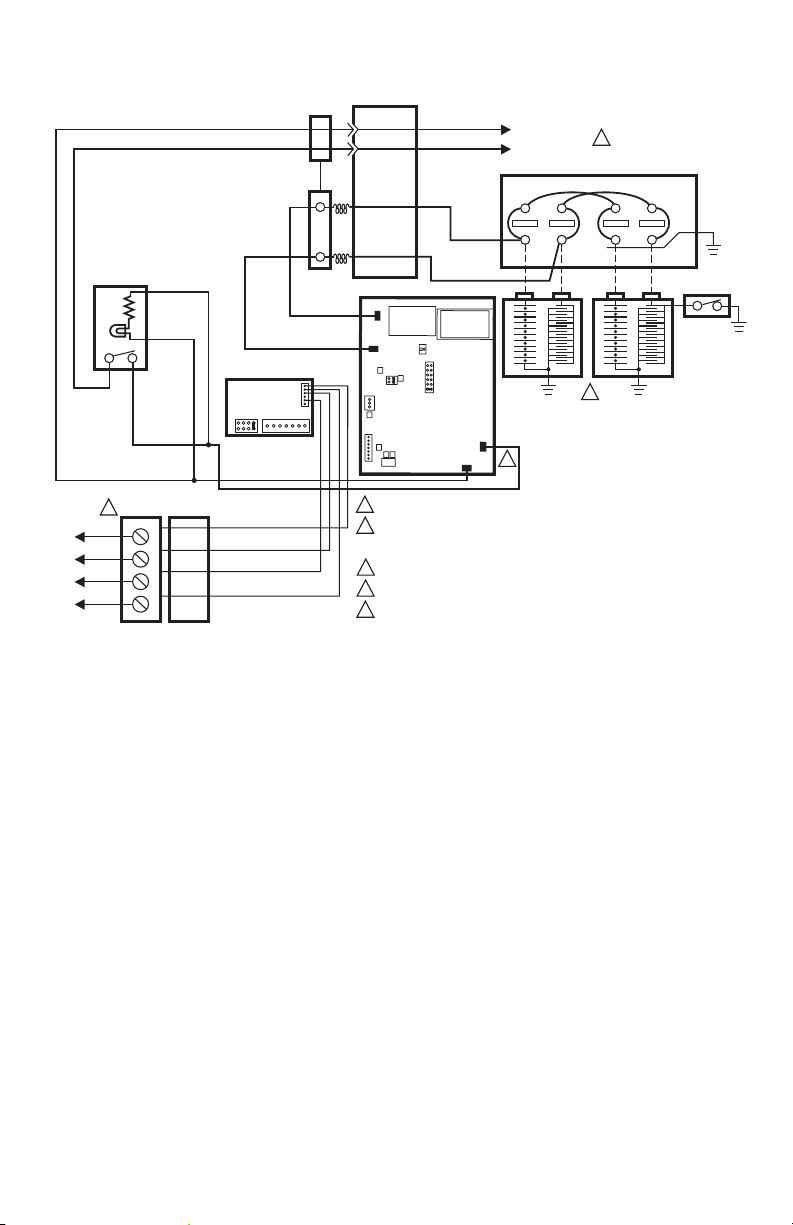

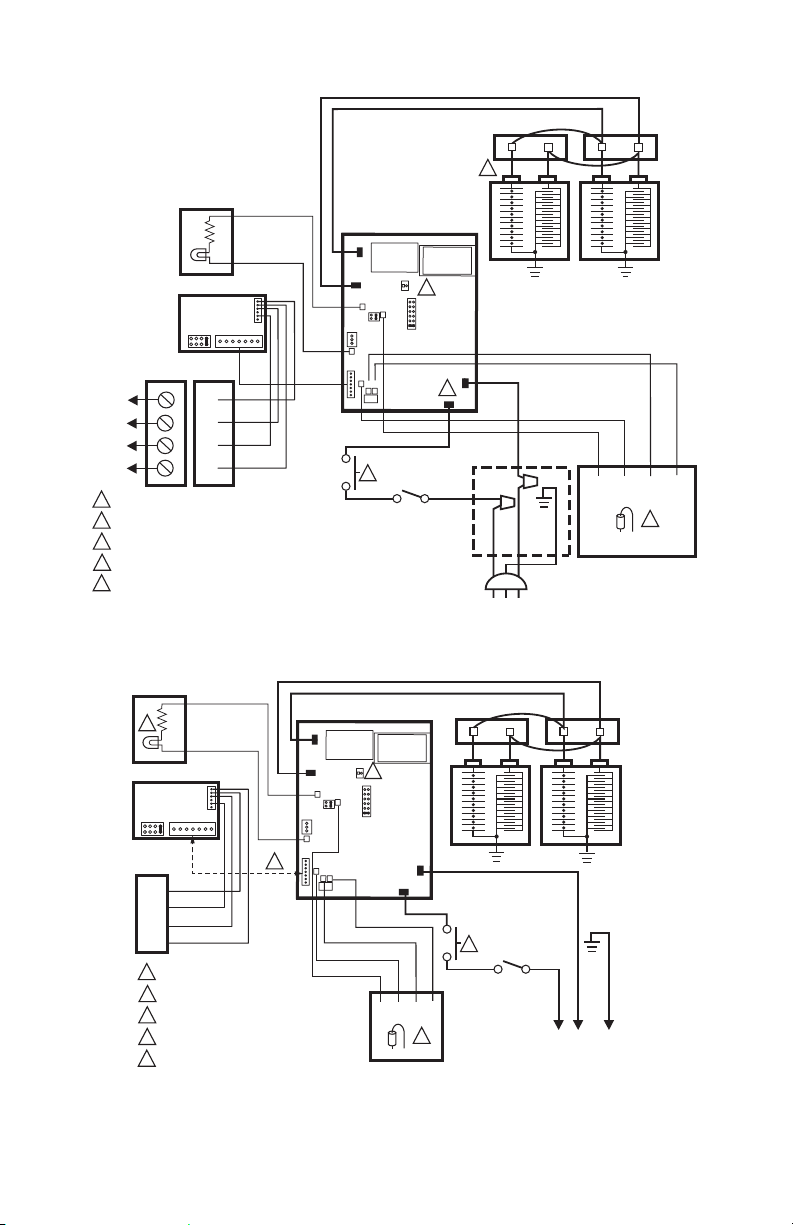

Open access door or grille. See Fig. 1 through 5.

Open power box.

Remove W8600E terminal block and wiring. Save

screws for future use.

On the F90, remove the power supply assembly as

follows:

— Open the cover by pulling the two latches

located on the front of the cover and swinging

the cover down until it hangs (see Fig. 5).

— Remove the two prefilters and the two cells

from the channel guides.

— Loosen the screws holding the power supply

assembly cover plate and remove the cover

plate. See Fig. 6.

— Loosen the two screws on the inner wall of the

power supply assembly and three screws on

the top of the assembly. Slide the power supply

assembly toward the center of the air cleaner

and disconnect the two Molex connectors and

the one quick connect connector. See Fig. 6.

— Remove the power supply assembly to a table

or work bench to replace the power supply.

Disconnect the red ionizer and black collector leads

at the board quick connects.

Disconnect remaining input leads at the quick

connects.

Remove and set aside the sheet metal screws

holding the power supply board in place. Remove

the performance indicator board by clipping the

four plastic standoffs with diagonal cutters, or

squeezing the ends of the standoffs to release the

board. Remove and discard the board.