- 10 -

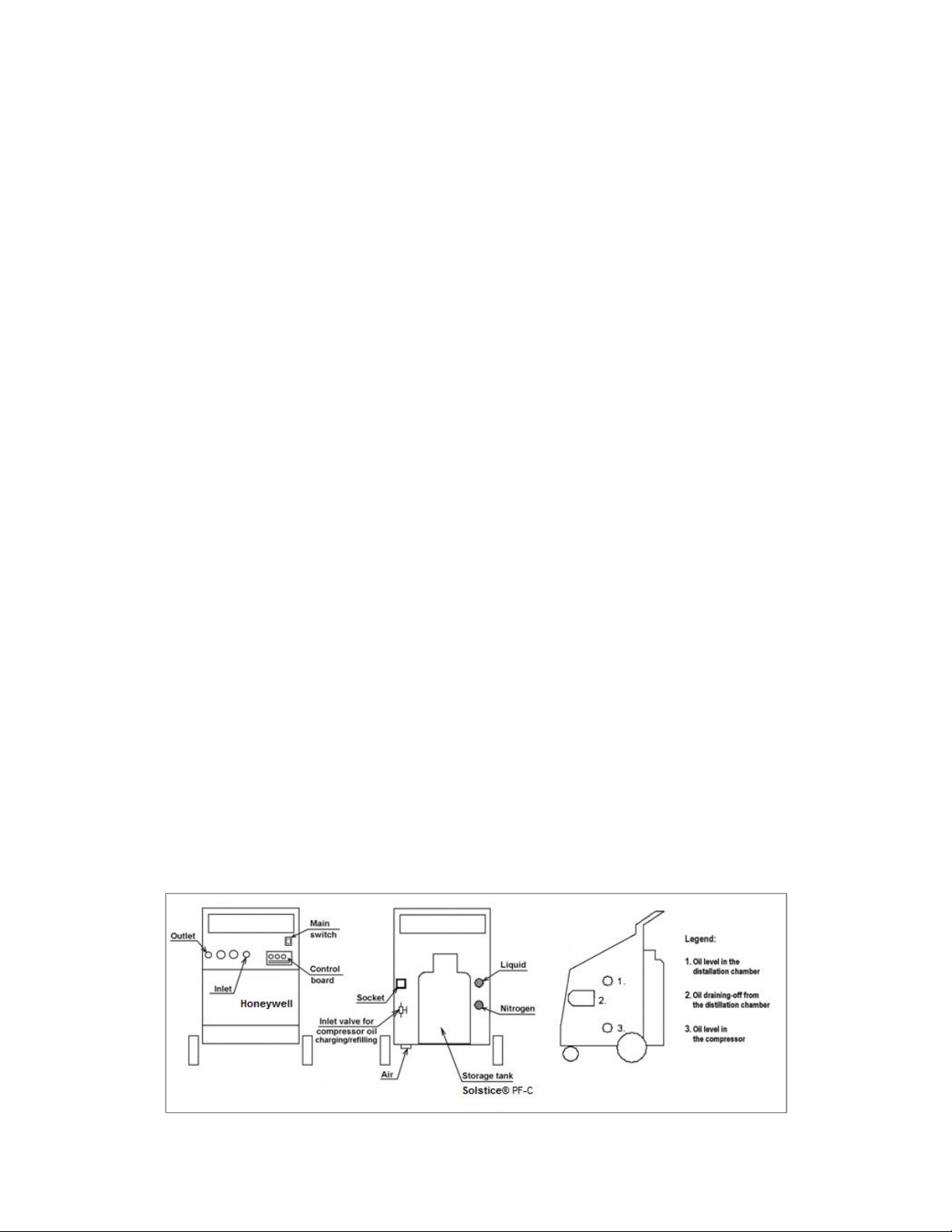

8. Unit controlling – work flow

G = green

Y = yellow

PB = button

LED = diode-signal light

DISPLAY or LEDS

8.1. Turn on the main switch. The display shows the number of remaining

flushing procedures three times. –see 10

8.1.1.

Initial status. On display “1” and LED 1, LED 6

8.1.2.

Select the number of flushing cycles (1 to 9), PB

2 increases, PB 3 decreases.

It is possible to change the number of cycles at any

time. With min. cycle count at „1“, just one

processing cycle will be completed.

On display “X” and LED 1, LED 6

“

X” = number of selected flushing procedures

8.1.3.

Option to discharge the oil and sludge from

distillation chamber. – see 8.4.

On display “X” and LED 1,

LED 6 blinks.

8.2. Press PB 1 – start

8.2.1.

Sucking-off (90 sec.) On display “X” and LED 2

8.2.2.

Flushing (after filling the distillation chamber, 7min.

sucking-off)

Next cycle of flushing.

On display “X” and LED 3

LED7 lights up when the distillation chamber is

full.

On display X-1 and LED 3

At any time during flushing, the number of flushing cycles PB 2 or PB 3 can be changed.

processing cycle will be completed.

8.2.3.

Sucking-off the liquid phase of SOLSTICE

®

PF-C

through nitrogen purge.

5 cycles made of 20 sec

On display “0” and LED 4

during the pause intervals: LED 4 blinks

8.2.4.

Sucking-off the vapor phase of SOLSTICE

®

PF-C -

after the discharge of liquid is completed.

It is possible to blow-out the solvent with nitrogen

(20 sec) during this period – pressing PB 4

After 180 sec. 3 beeps will follow.

After this acoustic signal and at a pressure higher

than 0 bar on LP manometer, pressing PB 4 the

blow-out with nitrogen can be repeated up to 5

times.

On display “-” and LED 5,

LED 6

By pressing PB 4, LED 6 blinks

On display “-” and LED 5

blinks, LED 6

8.2.5 Within 15 min. from the acoustic signal, the

compressor turns off, the display goes blank.

Before PB 5 -“END” is pushed, nitrogen blow-out

LED 6, LED 5 blinks, on display “-”

NOTE:

During the flushing (8.2.2) the dist. chamber is filled and/or emptied with solvent and LED 7 blinking or

simply on.

When the procedure of par. 8.2.4 is in progress, the nitrogen purging process can be activated

pushing PB 4 (LED 6 blinks).

If the pressure on the low-pressure manometer is higher than 0 bar after the acoustic signal, repeat nitrogen

purging 5 times by pushing 1x PB 4.

Picture 7 - K572 Switchboard