HONGDA HOLDING WATER TECHNOLOGY CO.,LTD

Service

hotline: Tel

: +86-577-27885553

Http://www.sparklingwater.in o E

-mail: Stanle

[email protected] o

Introduction

Thank you for purchasing this separated air water dispenser. It is an ad anced drinking water equipment for household

and office use, especially for water pro ision on the islands and ships. By making use of the most ad anced technology, this

water dispenser integrates the air water condensing system, water filtering and disinfecting system, and water heating and

cooling system, which has greatly impro ed the water intaking by air and satisfying the water needs in pulic places and other

en ironments.

This dispenser uses the excellent components as key ones to ensure the operation reliability of the entire machine.

The filtering system adopts the integrated module design, thus making change of the filter element more con enient.

Operating Principle

This Dispenser mainly makes the water from the humidity in the air. In other words, it totally relies on the water apour in

the air to make water. The best water making can only be achie ed under the ideal en ironment where the humidity is around

70

%

--80

%

. Water can also be made in places with low humidity, but the speed is slow. This is also the same case for places

with high humidity and low temperature. So it is better to test the humidity of e ery position in a room before the dispenser is

placed. In a li ing house, positions near the kitchen or window, or spacious places, will see high humidity.

If the air water dispenser wants to reach the best operating state, the temperature of ambient en ironment is ery

important, with the ideal temperature of 24

℃

--29

℃

. Howe er, this does not mean that the dispenser will fail to work in places

where the temperature is higher or lower. More drinking water will be produced at faster speed under ideal temperature. So it

is necessary to measure the indoor temperature before placing the dispenser.

As water is made by con erting the water apour in the air, the diespenser will become a ery powerful humidity intaker.

Therefore, for the sake of health, please use this dispenser only in rooms where the humidity is ensured, or when the window

is opened and the indoor and outdoor air exchange is a ailable.

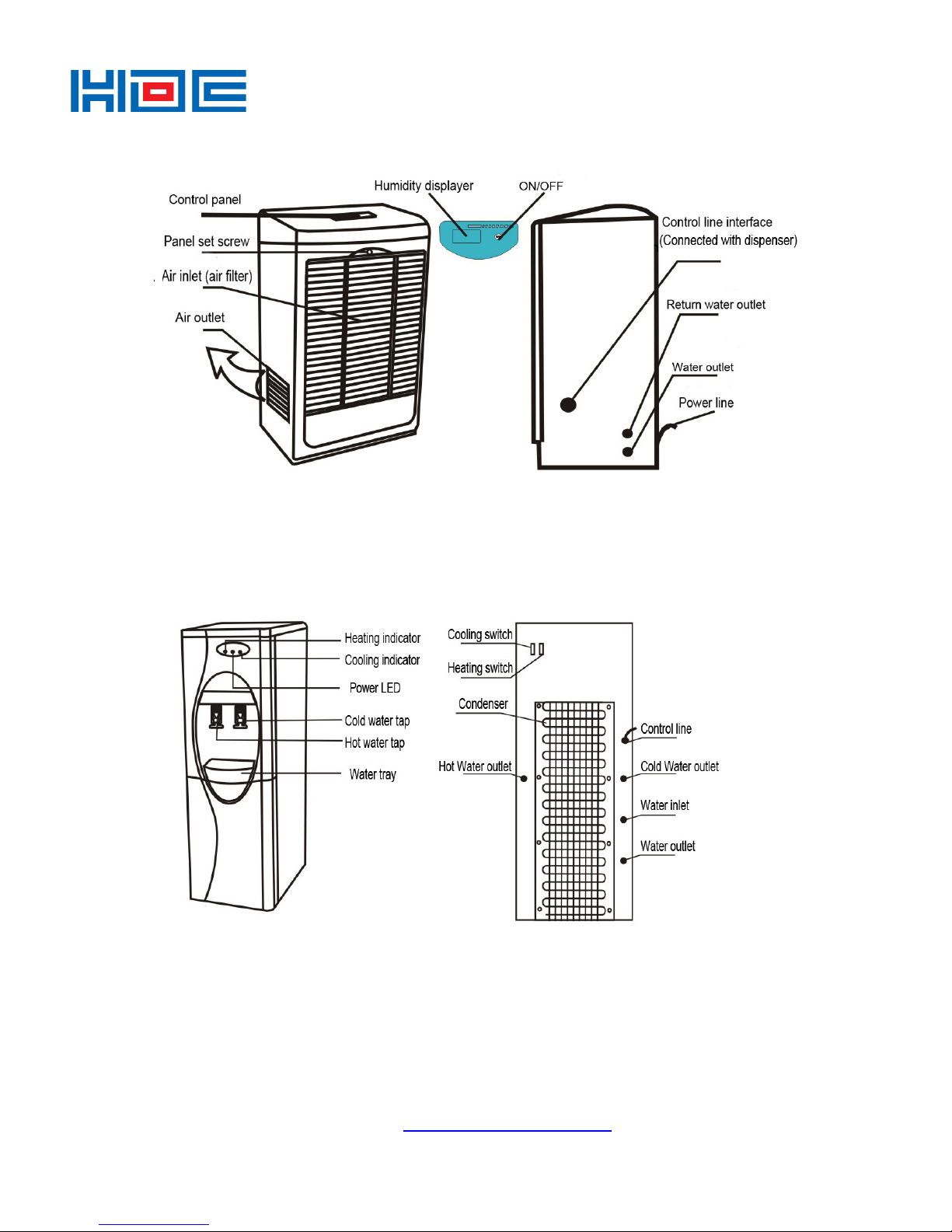

Maintenance for Machine

1. Cleaning of air filter: The air filter shall be cleaned on a regular basis according to the pollution of specific locations. The

air permeability of filter is closely related with the water making efficiency. It is recommended that the air filter be cleaned

e ery half month.

Cleaning steps: Loosen the panel set screw in the front of air water intaker, and take out the front panel and pull out the

air filte. Clean the dust and air floatation on the filter surface, and finally install the filter and panel back.

2. Cleaning of water tank: Dismantle the front panel and clean the inside of water tank with towel. Drain the water in the

tank and flush the tank with clean water. It is recommended that the air filter be cleaned e ery half month.

3. Change of filter element:

PPF and acti ated carbon filter element: Take out the filter element from the bracket and the connector from the filter

element with wrench, replace with new filter, and install the connector. Connect with water pipe and put back to the bracket. It

is recommended that the PPF filter element be changed e ery 6-8 months and the carbon filter element changed e ery 12-15

months.

Change of RO/ UF film: Take out the RO film from the bracket and the connecting pipe at the top of film shell. Turn down

the film shell end counter-clockwise, pull out the film and put the new filter element to the film shell, install the film shell end

clockwise, and connect the water pipe. It is recommended that the film be changed e ery 24-26 months.

Note:

①:

For new installed water dispenser, if the RO film has not been installed in the RO film shell before ex-factory, it

shall be installed during the machine assembly.

②:

Disconnect power supply in case the abo e operations are conducted.

③:

The changes of filter element and sol ing to machine breakdowns shall be conducted by professionals.

Component Introduction