DESCRIPTION................................................................................................... 3

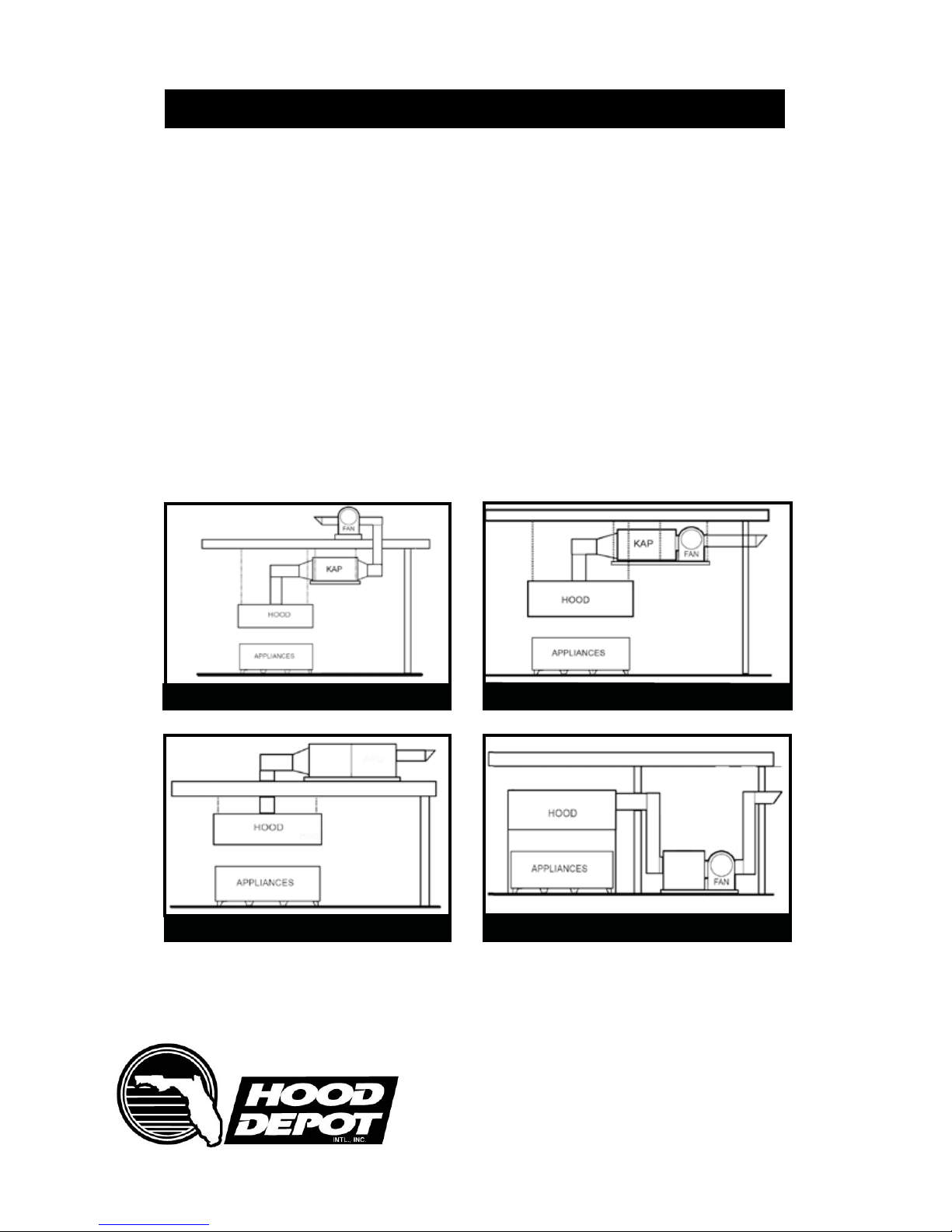

Common Installation Formats........................................................................ 4

INSTALLATION................................................................................................... 4

Preparation.................................................................................................... 4

Duct Work & Minimum Sizes......................................................................... 5

Grease/Water Drains..................................................................................... 6

Roof Installation / Floor Installation............................................................... 6

Ceiling Mount Installation.............................................................................. 7

Air Pressure Switch...................................................................................... 8

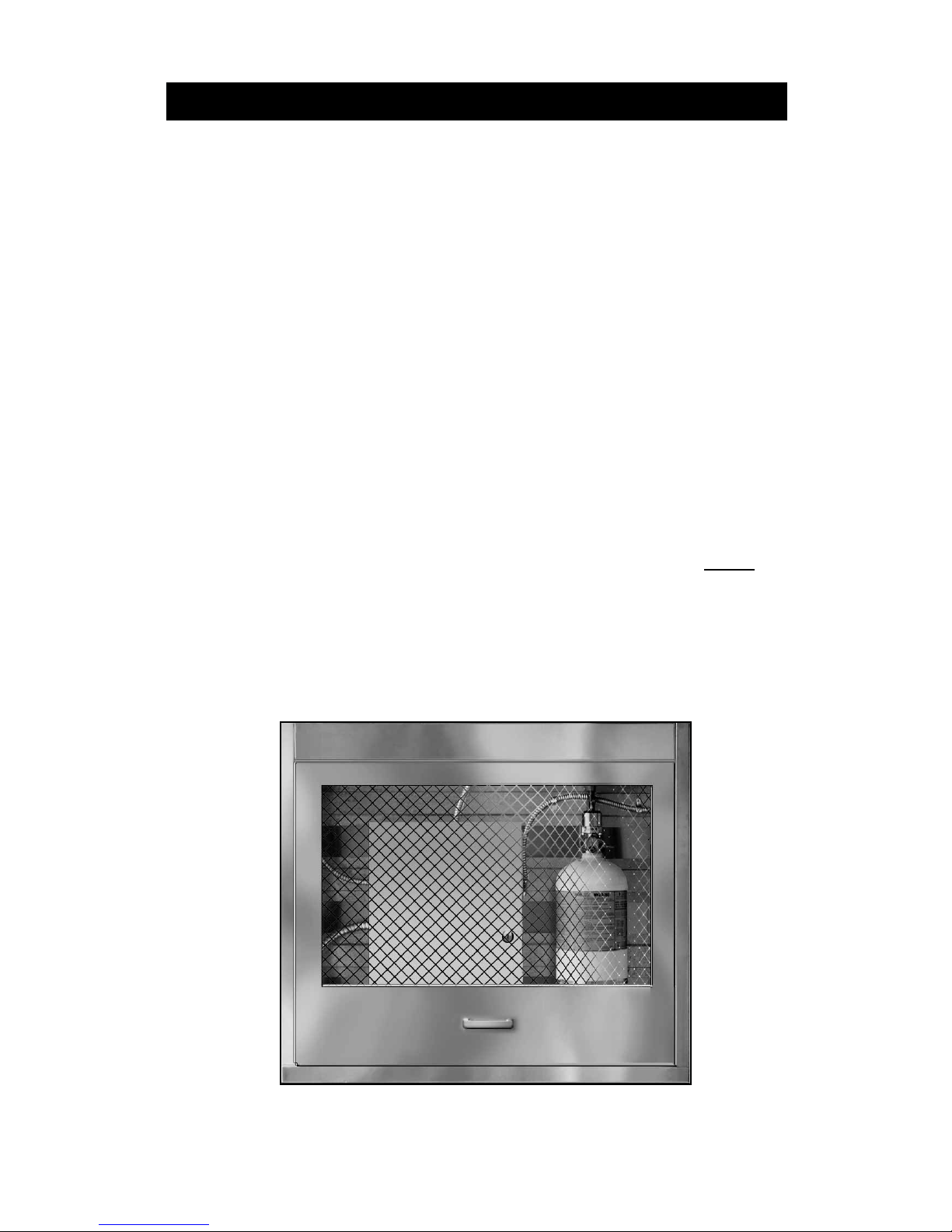

Fire System.................................................................................................... 9

OPERATION......................................................................................................10

Tools Required..............................................................................................10

Start-Up Check List.......................................................................................10

Start-Up Procedure.......................................................................................10

Troubleshooting.............................................................................................11

General Maintenance....................................................................................12

Filter Chart....................................................................................................13

Gasket Chart.................................................................................................13

Maintenance Intervals...................................................................................14

DOCUMENTATION........................................................................................... 15

Job & Site Information..................................................................................15

Name Plate/APU Information........................................................................15

Maintenance Record.................................................................................. 16

Listings..........................................................................................................17

Warranty........................................................................................................17

HD Service Dept...........................................................................................17

Commercial Kitchen Ventilation Products

710 S. Powerline Road, Deereld Beach, FL 33442 • 954 570-4083 • 800 322-8730 • www.hooddepot.net

CONTENTS