INSTALLATION STEPS

fig 2 fig 3

5. CENTRALISE THE PADS OVER THE DISC

=

=

pad

pad

rotor

This step is very important and mustn’t be ignored.

Gently pump the lever in order to bring the pads closer to the disc. One pad might

enter in contact with the disc before the other. If this happens, hold the disc against

the pad that is already in contact with the disc to allow the other one to move.

For an optimised lever feel, both pads must enter in contact with the disc at the

same time and allow the same clearance (see arrows) when retracted. The disc

should not be flexing at any time.

1. CONNECTING THE MASTER CYLINDER TO THE CALIPERS

2. ATTACHING THE LEVER TO THE BARS

3. ATTACHING THE CALIPER TO THE FORK OR FRAME

3.1 MOUNTING THE CALIPER ON POSTMOUNT TYPE MOUNTS

=

=

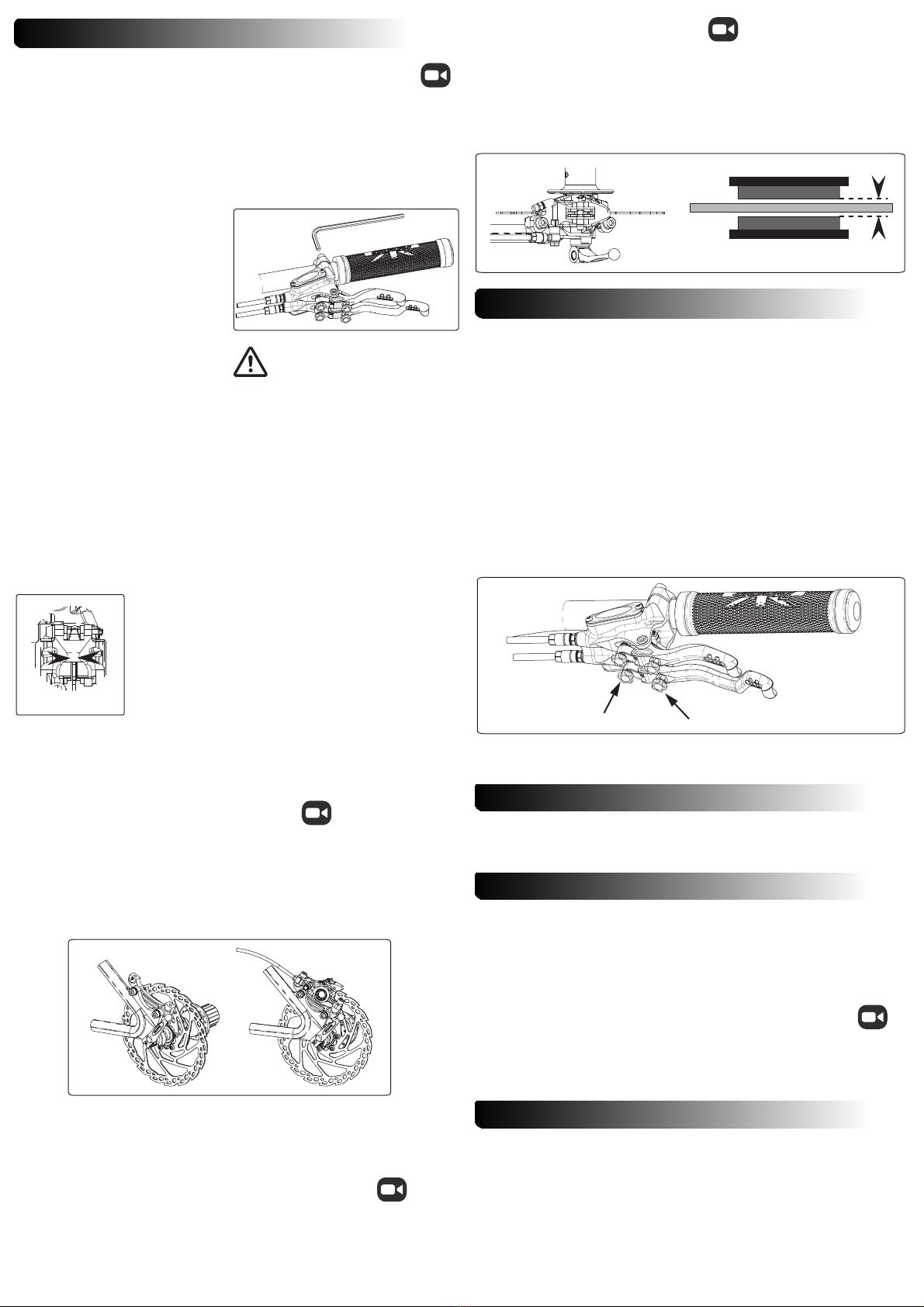

fig 1

Note : We do not recommend pumping the lever to push pads out to align caliper

at this point. See section 4 regarding the alignment of pistons.

To ensure that the caliper is properly aligned and to help avoid squealing or bad lever

feel - prior to fitting the brake, it is important that the tabs of your fork or frame are

clear of any paint or burrs.

Only follow these steps if the calipers have been purchased separately and not

already installed on the bike.

The HOPE calipers are postmount type. You will therefore need to use an

adaptor bracket to fit it on IS brake mounts or using a different size rotor.

a) Attach the master cylinder assembly

to the handlebars. When you are happy

with the orientation of the lever, tighten

alternately the M5 clamp bolts using a

4mm Allen key. Recommended tighten-

ing torque : 4-5 N.m.

b) If not already in place, route the hose

and caliper down to the fork brake mount

or along the frame to the rear brake

mount.

3.2 MOUNTING THE CALIPER ON IS TYPE MOUNTS

On IS mount you will have to use an adaptor bracket to be able to fit the brake

caliper.

a) According to the rotor size and type of mounts, attach the suitable adaptor

bracket onto the brake tabs and tighten the two M6 bolts using a 5mm Allen key.

Recommended tightening torque 8-9 N.m. Illustration fig 2.

b) Follow the same instructions as fitting the brake onto a postmount (see

previous section). Illustration fig 3.

Avoid situations that could

damage the brake hose and/or

your bike frame and components

Please refer to the website videos and technical documents if you

require more information about setting up this brake system, servicing

and maintenance. www.hopetech.com / Tech support section

Tech3 Duo/09.19/ISS1

WARRANTY

All Hope Technology disc brake systems are covered for 2 years from original date

of purchase against manufacturer defects in material and workmanship. Proof of

purchase is required. Products must be returned to the original place of purchase or to

Hope Technology to process any warranty claim.

This warranty does not cover any damage caused through mis-use or failing to

comply by the recommendations given in this manual.

This warranty does not affect your statutory rights.

NOTE ON GEAR SHIFTERS DIRECT MOUNTS

For Shimano shifter users : there is no direct shiter mount available

For SRAM shifter users : you can purchase as an option our SRAM shifter direct

mount for TECH3 Duo master cylinder, part number HBSP384.

BREAK IN PERIOD AND MAINTENANCE

Before riding and before every ride, check the correct action of the brake and that

braking effort is applied as the lever is pulled.

To achieve the maximum braking performance, the new pads will need bedding in.

Please note that sintered pads take longer to bed in than organic pads.

To bed in the pads, ride a short distance whilst alternatively gently applying the

brake on and off without attempting to stop. This procedure will achieve good

braking performance but will reach its full potential after a few rides.

About maintenance tips refers to our “how to” videos on the website.

To optimise the performance of the brake it is important to keep the caliper pistons

lubricated using silicon lubricant only. We advice doing this at least at every pad

replacement.

For brake bleeds use only dot 5.1 or dot 4 brake fluid from a clean container.

First connect each caliper to the master cylinder using Hope hydraulic hose and

connectors.

The rear caliper must be routed to the lower cylinder controlled by the longer lever.

For cleaner hose routing you may swap a straight connector and use the 90° connec-

tor provided.

4. BLEED THE BRAKE SYSTEM

Use only DOT4 or 5.1 brake fluid and wear adequate protective equipment such as

nitrile gloves and safety glasses.

To bleed the system proceed as bleeding a Tech3 brake system.

Refer to the How to video in the technical section of our website.

Using Hope Technology Easy Bleed kit would facilitate the task but is not compul-

sory.

Proceed individually with each caliper making sure the reservoir lid is level before

opening it. Typically, you’ll need to spin the master cylinder 180° to bleed the rear

brake.

a) Before attaching the caliper ensure that the brake pads are

fully retracted in the caliper. If not, gently push the piston back

using a plastic tyre lever or something similar. Beware

not to damage the pads. Take them off if necessary. Push

on the left hand side pad backplate to push the right hand

side piston and vice versa.

b) Mount the wheel fitted with the rotor, ensuring

correct fitment in dropouts.

c) Position the caliper on the mount and slightly tighten the

two M6 bolts.

d) At both front and rear of the caliper, adjust its position

so it is central over the rotor (see arrows on fig 1) then tighten

the two M6 bolts using a 5mm Allen key. Recommended

tightening torque 8-9 N.m.

a)

free stroke.

b)

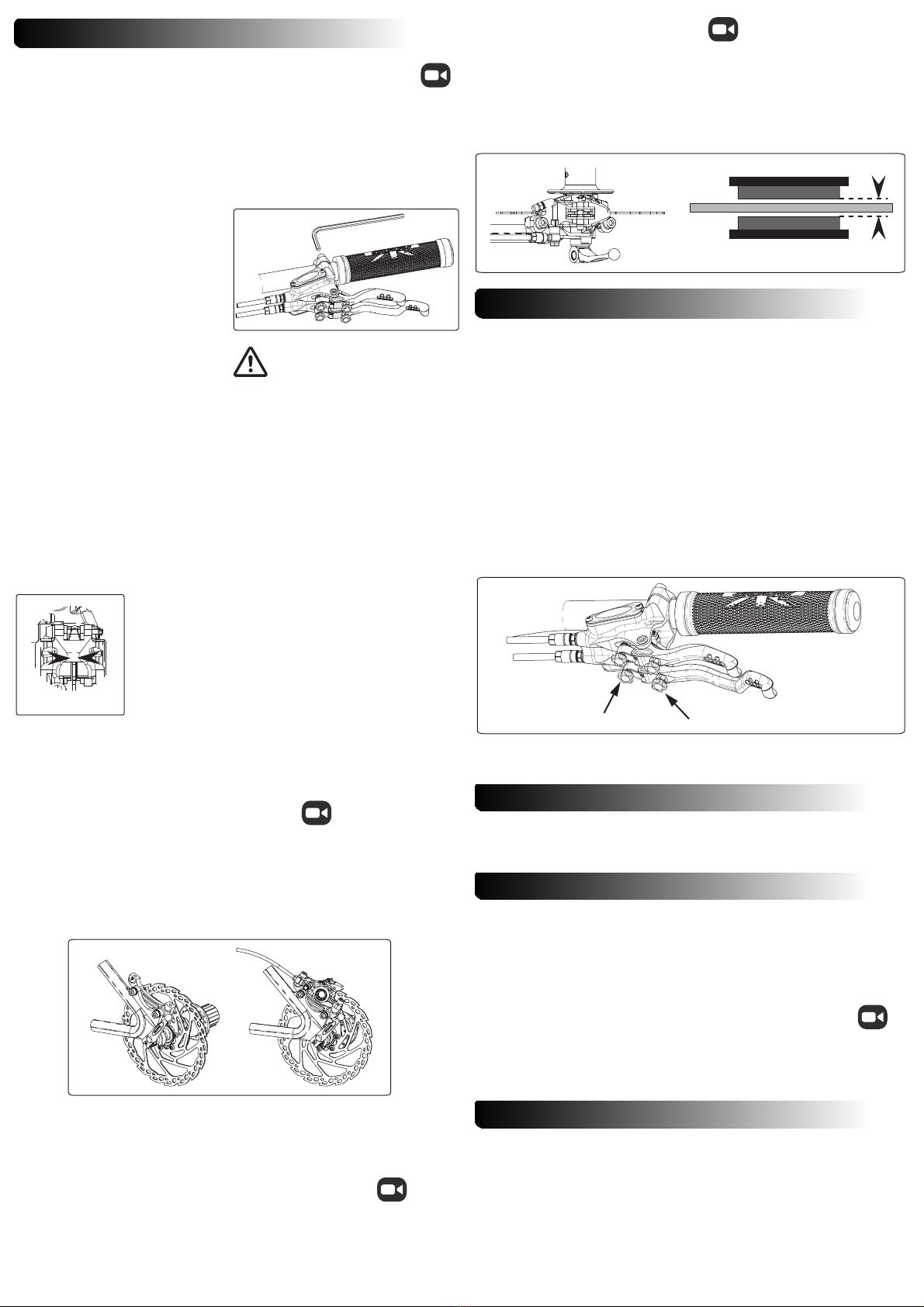

PERSONAL SETTINGS

The TECH3 lever allows two types of personal adjustment to fit all preferences.

The Bite Point adjustment : This will modify the free stroke of the lever blade

before the pads enter in contact with the disc. With your fingers, turn the bite point

adjuster knob clockwise to reduce the free stroke and anti-clockwise to increase the

Finger reach adjustment : This refers to the position of the lever blade relative

to the bars. After adjusting the bite point, you will need to set or re-set your lever

reach as it will change when adjusting the BPC.

With your fingers, turn the adjuster screw clockwise to increase the reach and anti-

clockwise to reduce it.

Bite point adjuster knob Reach adjuster knob

The Tech3 Duo levers are easy to set if you note the following steps:

1- first adjust the bite point on the long lever

2- adjust the reach on the long lever

3- adjust the bite point on the short lever with the same setting as the long lever

4- adjust the reach of the short lever with the same setting as the long lever then

add 3 click clockwise

Note : you made need to reproduce each step several times before reaching your

optimum setting.